That is quite the labor of love and it came out really nicely. I enjoyed reading your write up as well. Making that for only $720 is very impressive. As you noticed the price for transformers jumped recently thanks to supply chain woes.This amp is a crazy idea I had for long time that finally got built. It is a 17 watt stereo EL84 amp (basically a Dynaco ST35) built in the style of a classic McIntosh. It took forever, but turned out surprisingly well. I expect some double-takes from McIntosh experts who would know that an "MC217" never existed

Here also is a link with more details on the build saga:

https://lensprojects.com/2022/03/03/a-tube-stereo-amp-built-in-the-style-of-classic-mcintosh/

I use a Dynakitparts ST35 at least once a week, great little unit.

I had them laser cut 😉Jeeezz, how did you manage to get those square holes into the chassis?

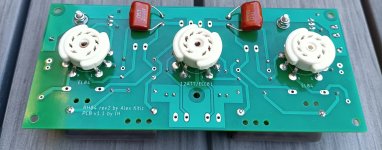

My latest RH84 build. Bamboo box bought from Action = General store with good prices. Feet=broomstick also bought from Action. Output transformers are by TBT Trafobau. Who for some reason don't have a website anymore.

Attachments

-

IMG20220228111728.jpg202.8 KB · Views: 287

IMG20220228111728.jpg202.8 KB · Views: 287 -

IMG20220228111704.jpg663.5 KB · Views: 247

IMG20220228111704.jpg663.5 KB · Views: 247 -

IMG20220226173352_BURST001.jpg257.2 KB · Views: 259

IMG20220226173352_BURST001.jpg257.2 KB · Views: 259 -

IMG20210702210700_2.jpg428.9 KB · Views: 250

IMG20210702210700_2.jpg428.9 KB · Views: 250 -

IMG20210702210243_2.jpg242.5 KB · Views: 251

IMG20210702210243_2.jpg242.5 KB · Views: 251 -

IMG20220228111713.jpg286.4 KB · Views: 290

IMG20220228111713.jpg286.4 KB · Views: 290 -

IMG20220226174036.jpg644.9 KB · Views: 289

IMG20220226174036.jpg644.9 KB · Views: 289

Last edited:

Bass Horneman,

Very nice looking construction!

I am sure it sounds very nice.

You are probably using a capacitor input filter on the B+.

Choke input filtered B+ might have some hum coupling from the filter choke to the one output transformer, the coils are in equal orientation (zero degrees).

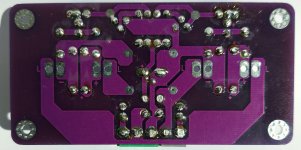

I use point to point wiring, but some people like you almost convince me to change to PCB construction.

Very nice looking construction!

I am sure it sounds very nice.

You are probably using a capacitor input filter on the B+.

Choke input filtered B+ might have some hum coupling from the filter choke to the one output transformer, the coils are in equal orientation (zero degrees).

I use point to point wiring, but some people like you almost convince me to change to PCB construction.

Indeed. There are a few small caps now after the rectifier...not that I had hum. But b+ was on the lowish side.You are probably using a capacitor input filter on the B+.

Very nice layout & execution!My last project, completed, PP with KT88 EH, with timing mode, anodic voltage, and bluetooth, Toroidy output transformers, Alps potentiometer, Kendeil electrolytic capacitors, Nipon chemikon. The laser-cut housing, painted in an electrostatic field, still has meters to connect. On and off, with smart socket mode with Tuya application and local push button.

I noticed you're using MH-M18 bluetooth module. Do you have it configured so that incoming BT connection overrides the signal? Is that what the relay is for? If so, did you use the 'mute' output to control the relay? Also, does BT signal get through metal chassis OK?

Thanks,

Jim

Thanks, the anodic voltage delay relay is set to 40 seconds. The bluetooth module does not have enough attack voltage and I will replace it with a more efficient one. I also have to add the wumeter circuits. I will add a small antenna outside connected to the new bluetooth module from picture.

Regards

Alex mm

Regards

Alex mm

Attachments

Excellent set up and mixing vintage with some modern, very beautiful functioning room, well done.

I love it.

Sent you a pm through the forum.lovely work Bas:

Where is the circuit board from. I would like to get one.

Good morning,

completed a few days ago the last project of a SE KT88 amplifier (based on Abdellah / Gendrano).

It is driven by a single 12AT7WC with anode CCS and the usual led + resistor cathode bias. I tried also ECC85 and 6N1P but I at the end I opted for the above mentioned. The power tubes are in a triode configuration, with a slight S.f. (500k) and an estimated output power of 5W per channel.

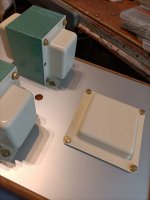

The amplifier chassis was made, as in the previous one, by a carpenter friend. This time, oak wood was used instead of chestnut. However color is quite similar.

Regarding how it plays, well in my opinion it's fine: compared to the EL34 it seems with a more full-body sound, tighter bass, but if it can be said so, perhaps less "elegant" than the younger sisters...

completed a few days ago the last project of a SE KT88 amplifier (based on Abdellah / Gendrano).

It is driven by a single 12AT7WC with anode CCS and the usual led + resistor cathode bias. I tried also ECC85 and 6N1P but I at the end I opted for the above mentioned. The power tubes are in a triode configuration, with a slight S.f. (500k) and an estimated output power of 5W per channel.

The amplifier chassis was made, as in the previous one, by a carpenter friend. This time, oak wood was used instead of chestnut. However color is quite similar.

Regarding how it plays, well in my opinion it's fine: compared to the EL34 it seems with a more full-body sound, tighter bass, but if it can be said so, perhaps less "elegant" than the younger sisters...

Attachments

Laser cutting is extremely cheap, some places have been mentioned here already. I'm done buying material myself and dealing with chassis punches and measuring. Send off a cad file and a week later I have the exact part in my hands.

How about water jetting? Have costs come down for these services? I want some lettering cut through 1/4" thick stainless steel. It should look good. No other way to neatly cut the stuff that I know of.

How about water jetting? Have costs come down for these services? I want some lettering cut through 1/4" thick stainless steel. It should look good. No other way to neatly cut the stuff that I know of.

Can't speak of water jet prices but this is the company I've used and it looks like they will do stainless up to 1/2" thick. https://sendcutsend.com/stainless-steel/

My local source is water jet- I've used them to cut everything from AL sheet up to 1/2" stainless steel. They quoted $68 for 20ga 304 stainless (non ferrous) of the file below. Water jets will exhibit some taper to the shape, which is more pronounced as the mat'l gets thicker. I'd think laser cutters would not have this phenomenon. Shop I use allows for the 'Q' of the cut (speed) to be specified (more $$) to minimize taper and maximize accuracy of shape.How about water jetting? Have costs come down for these services? I want some lettering cut through 1/4" thick stainless steel. It should look good. No other way to neatly cut the stuff that I know of.

Jim

Attachments

My local source is water jet- I've used them to cut everything from AL sheet up to 1/2" stainless steel. They quoted $68 for 20ga 304 stainless (non ferrous) of the file below. Water jets will exhibit some taper to the shape, which is more pronounced as the mat'l gets thicker. I'd think laser cutters would not have this phenomenon. Shop I use allows for the 'Q' of the cut (speed) to be specified (more $$) to minimize taper and maximize accuracy of shape.

Jim

It happens to be 304 stainless, its the hardest steel I ever cut with a hand grinder. It does a nice clean cut with some patience. I think there is no other way of cutting letters in the stuff other than what you quoted.

Bob Danielak EL509. With One-Electron UBT-1. My first DC coupled amp. As you can see the patient needed emergency surgery. Something fell on it. Also damaging the hammerite...but sorta patched that up.

Attachments

A couple more pics

Attachments

-

IMG20210604105745.jpg77.4 KB · Views: 125

IMG20210604105745.jpg77.4 KB · Views: 125 -

IMG20220322173138.jpg757.2 KB · Views: 121

IMG20220322173138.jpg757.2 KB · Views: 121 -

IMG20210604105701.jpg141.9 KB · Views: 123

IMG20210604105701.jpg141.9 KB · Views: 123 -

IMG20210604105510.jpg60 KB · Views: 133

IMG20210604105510.jpg60 KB · Views: 133 -

IMG20210525172028.jpg119.6 KB · Views: 140

IMG20210525172028.jpg119.6 KB · Views: 140 -

IMG20210527114550.jpg158.8 KB · Views: 139

IMG20210527114550.jpg158.8 KB · Views: 139 -

IMG20220322163321_2.jpg161.9 KB · Views: 125

IMG20220322163321_2.jpg161.9 KB · Views: 125

- Home

- Amplifiers

- Tubes / Valves

- Photo Gallery