Frank I was just looking back over this thread and re read one of your early posts. where you said....

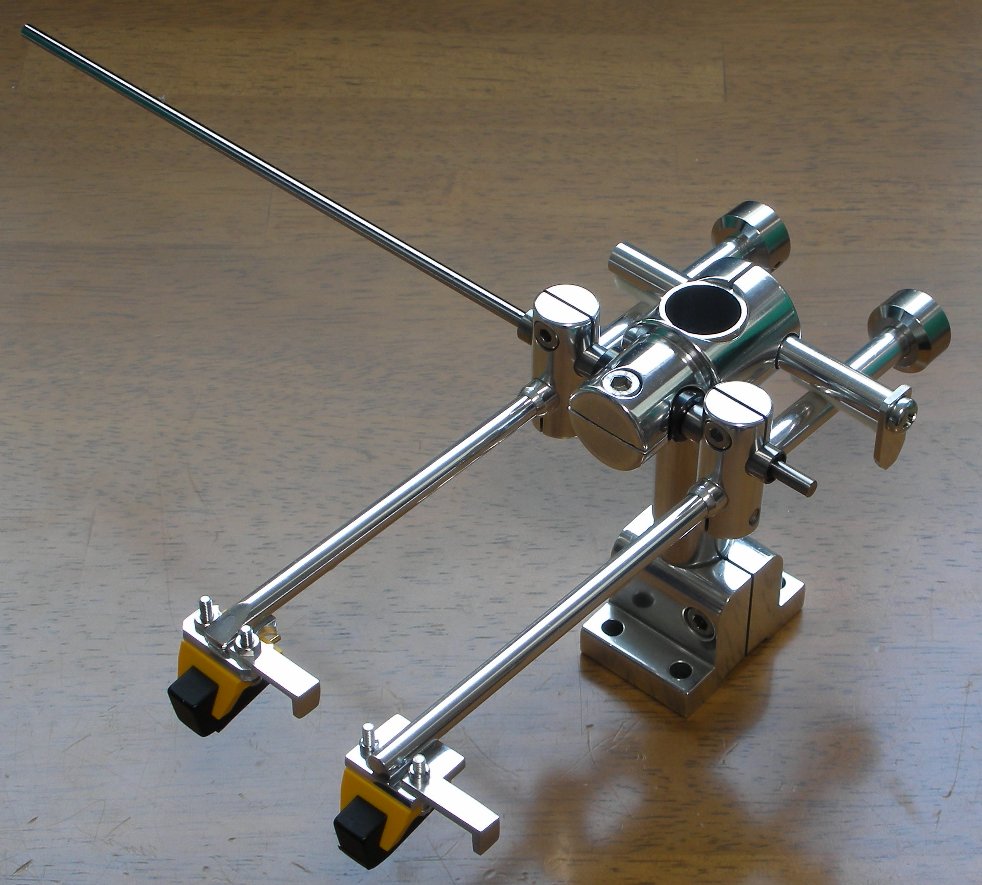

"If you absolutely must use mechanical bearings than a three point design, one point making firm contact, the other two damped, provides better energy evacuation than a four point carriage but that's a fine-tune in case someone gets the thing to work properly in the first place.

For this to work it probably needs to hang off the rails, not sit on top of it, much like the Goldmund T3 design and it will still be a nightmare as the lateral forces will even try and succeed, to skew the carriage sideways."

Can you comment on the means of damping for the two bearings? Do you have any pictures of the T3 which clearly show the workings? I also like the three point carriage assembly and also pondered over the issue of steering as it traverses the length of the tube. Thanks.

"If you absolutely must use mechanical bearings than a three point design, one point making firm contact, the other two damped, provides better energy evacuation than a four point carriage but that's a fine-tune in case someone gets the thing to work properly in the first place.

For this to work it probably needs to hang off the rails, not sit on top of it, much like the Goldmund T3 design and it will still be a nightmare as the lateral forces will even try and succeed, to skew the carriage sideways."

Can you comment on the means of damping for the two bearings? Do you have any pictures of the T3 which clearly show the workings? I also like the three point carriage assembly and also pondered over the issue of steering as it traverses the length of the tube. Thanks.

BL: I think that the Japanese design will work well and I agree that it could be built to have a reasonable moving mass. Fluid damping could be applied at the cartridge end or at the main bearing end (probably more user friendly). I remember the "Ivor" days and that the earth was flat. Max Townshend is a good guy and makes solid products.

Can you elaborate on the comment you made about lowering friction by lowering the inner part of the slider rod a degree or two. I am not understanding this. Thanks.

Yes,the phrase was elliptic.

I mean that the rod can be mounted with an angle of the degrees required (if),

to the mounting post, and will be lower lateraly towards the center of the platter in relation to the edge. Like a single dimensional servo ,thus "helping"

the cartridge to track without too much friction .

B.L.

Linear motion bearings

I actually do NOT own a Souther arm. I am only good at finding pictures on the net.

I do own a Rabco SL-8 arm and a Yamaha PX-2 turntable, but I don't own any mechanical linear tracker. However, I am fascinated by the issues of tangential tracking.

______________________________________________

Here's the Japanese website again for linear bearing arm.

kiirojbl.exblog.jp/i109

It uses the THK linear bushing LM4. Here are some quotes:

_________________________________________

I think these are suitable for the project, too.

This can travel horizontally and vertically.

IKO Miniature Stroke Rotary Bushing | Products | IKO NIPPON THOMPSON

This can travel horizontally only.

IKO Stroke Ball Spline G LS | Products | IKO NIPPON THOMPSON

I think this place, Maryland Metric, sells IKO linear motion bearings.

MARYLAND METRICS 'HOME PAGE'

http://mdmetric.com/prod/iko/ikostain.pdf

.

moray james: "Yes directdriver pointed the Japanese site out some time back. Direct driver has a Souther arm and has posted pictures perhaps he might take some additional pictures of the mechanism."

I actually do NOT own a Souther arm. I am only good at finding pictures on the net.

I do own a Rabco SL-8 arm and a Yamaha PX-2 turntable, but I don't own any mechanical linear tracker. However, I am fascinated by the issues of tangential tracking.

______________________________________________

Here's the Japanese website again for linear bearing arm.

kiirojbl.exblog.jp/i109

It uses the THK linear bushing LM4. Here are some quotes:

The bearing of my linear tracking tonearm is a linear bushing of THK.

The followings are THK website and their linear bushing’s page.

THK Global Top

https://tech.thk.com/en/products/thk_cat_main.php?id=322

"The linear bushing has balls its inside. Please see an explanation and a structure drawing of a following page."

https://tech.thk.com/en/products/pdf/en_a5_002.pdf#1

"The linear bushing of my tonearm is LM4L from THK."

(bore:4mm, length:23mm, weight:4g, price: about 10 US dollar)

"It is important to use a linear shaft, too."

https://tech.thk.com/en/products/pdf/en_b5_043.pdf#2

"The linear tracking arm is not perfect. I had to polish the linear shaft until the linear shaft’s surface become like a mirror. Further, it is necessary to keep clean the surface before vinyl playing."

_________________________________________

I think these are suitable for the project, too.

This can travel horizontally and vertically.

IKO Miniature Stroke Rotary Bushing | Products | IKO NIPPON THOMPSON

An externally hosted image should be here but it was not working when we last tested it.

This can travel horizontally only.

IKO Stroke Ball Spline G LS | Products | IKO NIPPON THOMPSON

An externally hosted image should be here but it was not working when we last tested it.

I think this place, Maryland Metric, sells IKO linear motion bearings.

MARYLAND METRICS 'HOME PAGE'

http://mdmetric.com/prod/iko/ikostain.pdf

.

Hi,

That post dates from when exactly? 2000 or even before?

What do you want me to to do?

Show you how your design choices are flawed and explain why?

I think I've done that already. Deja vu.

Cheers,

Frank I was just looking back over this thread and re read one of your early posts. where you said....

"If you absolutely must use mechanical bearings than a three point design, one point making firm contact, the other two damped, provides better energy evacuation than a four point carriage but that's a fine-tune in case someone gets the thing to work properly in the first place.

For this to work it probably needs to hang off the rails, not sit on top of it, much like the Goldmund T3 design and it will still be a nightmare as the lateral forces will even try and succeed, to skew the carriage sideways."

Can you comment on the means of damping for the two bearings? Do you have any pictures of the T3 which clearly show the workings? I also like the three point carriage assembly and also pondered over the issue of steering as it traverses the length of the tube. Thanks.

That post dates from when exactly? 2000 or even before?

What do you want me to to do?

Show you how your design choices are flawed and explain why?

I think I've done that already. Deja vu.

Cheers,

T3

Am I missing something here? The Goldmund tonearm is a servo motorized arm like the Rabco and it's really a different technology and different approach to vibration control than the mechanical linear tracker like the Cantus and Souther. Essentially Goldmund, Rabco, Yamaha PX2, are really pivot arms that pivot horizontally and vertically with a motorized mounting base. Put a conventional pivot arm on a sliding base add a sensor and a motor and that's a Goldmund for you. I wonder why people haven't come up with a sensor detected motorized sliding armboard for conventional pivot arms. Most quality pivot arms certainly are better build in their bearings than many of these servo arms. Disassemble a Rabco or a Japanese servo arm and you will see mechanically they are utter junk. Never own a Goldmund so I can't tell but T3 and its siblings don't look very impressive build wise.

.

Am I missing something here? The Goldmund tonearm is a servo motorized arm like the Rabco and it's really a different technology and different approach to vibration control than the mechanical linear tracker like the Cantus and Souther. Essentially Goldmund, Rabco, Yamaha PX2, are really pivot arms that pivot horizontally and vertically with a motorized mounting base. Put a conventional pivot arm on a sliding base add a sensor and a motor and that's a Goldmund for you. I wonder why people haven't come up with a sensor detected motorized sliding armboard for conventional pivot arms. Most quality pivot arms certainly are better build in their bearings than many of these servo arms. Disassemble a Rabco or a Japanese servo arm and you will see mechanically they are utter junk. Never own a Goldmund so I can't tell but T3 and its siblings don't look very impressive build wise.

.

3 point carriage

.

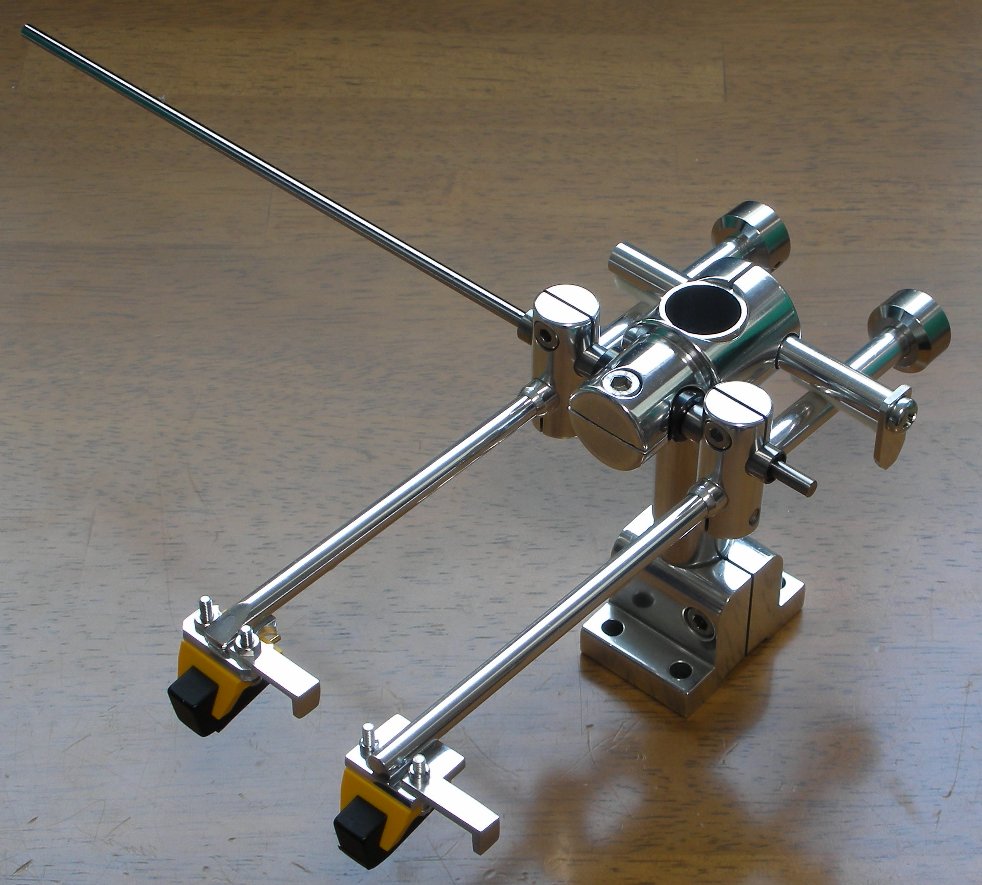

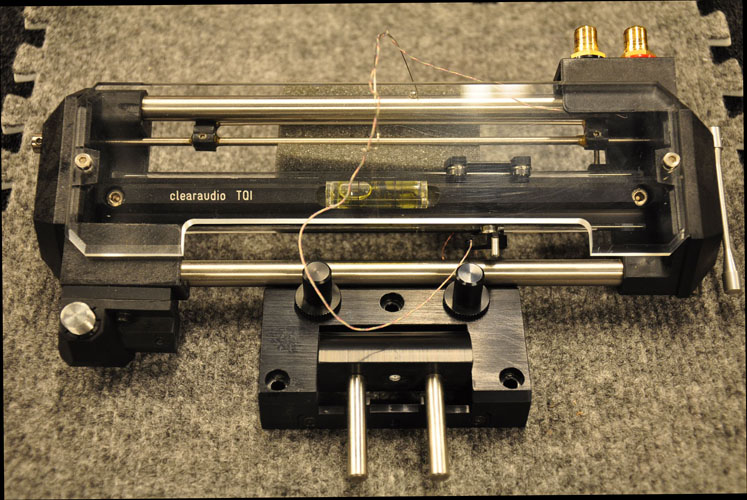

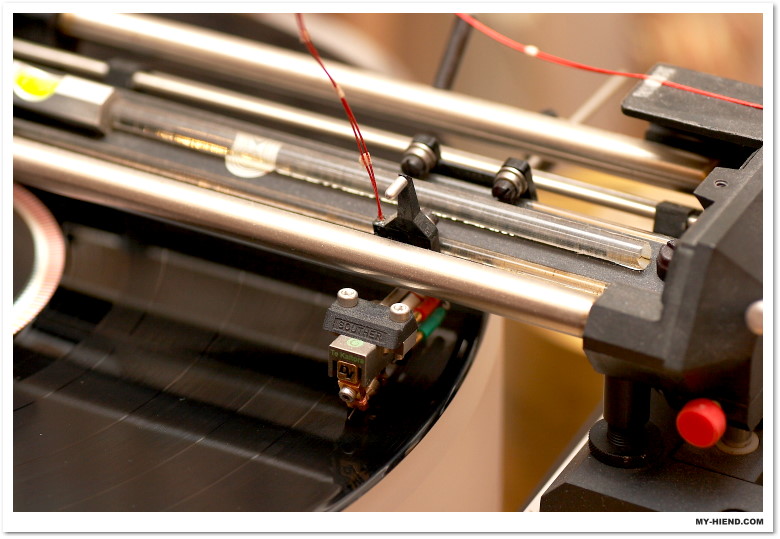

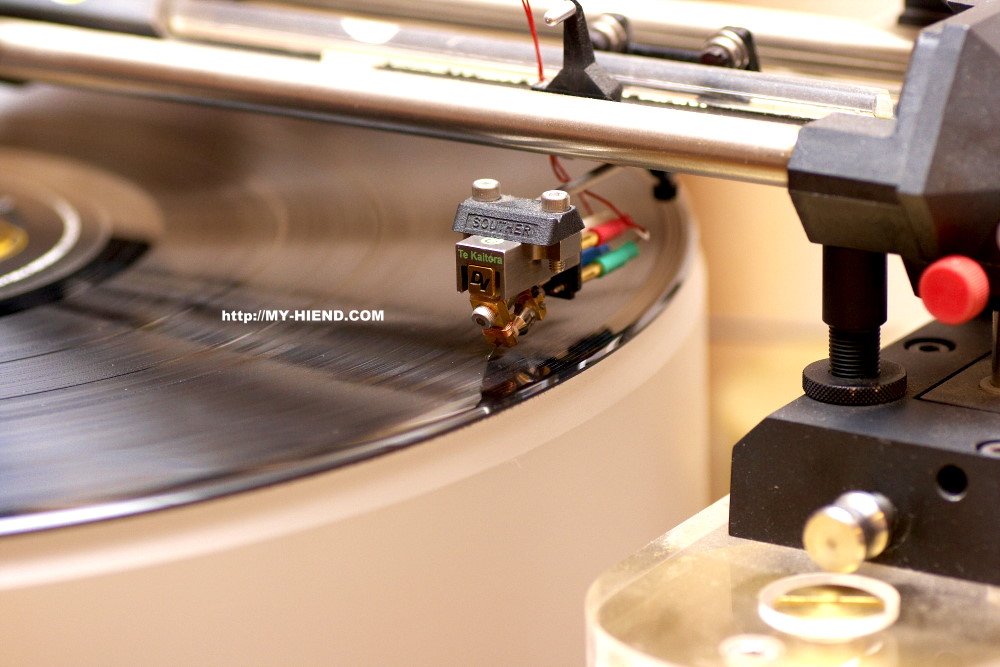

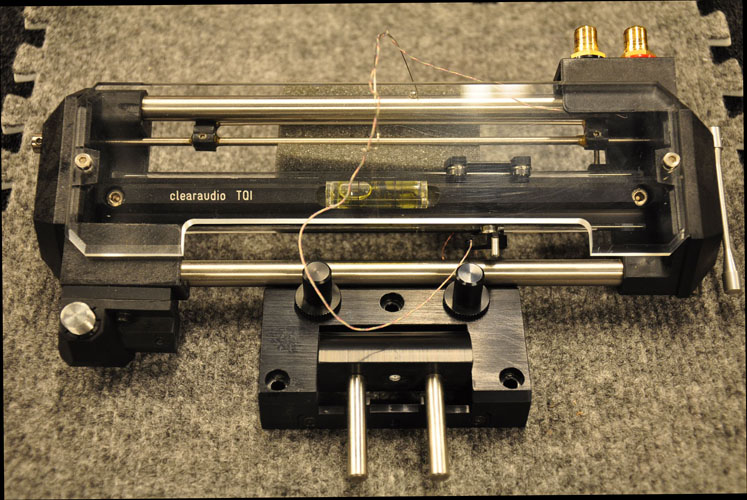

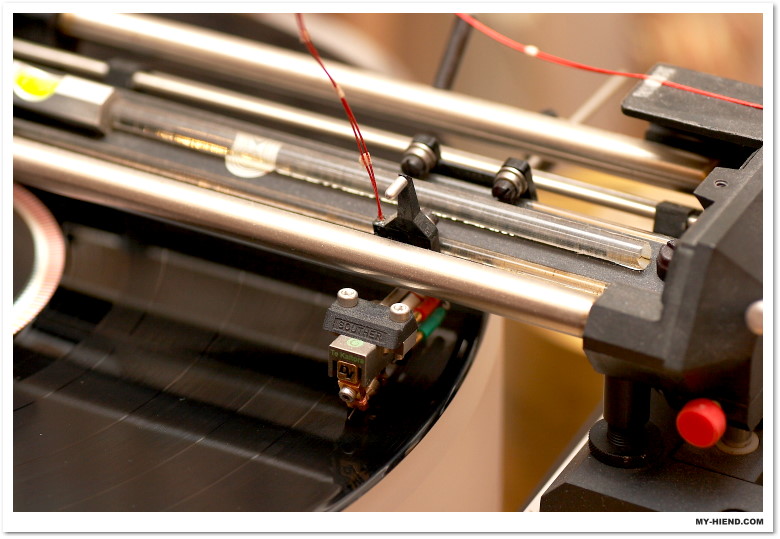

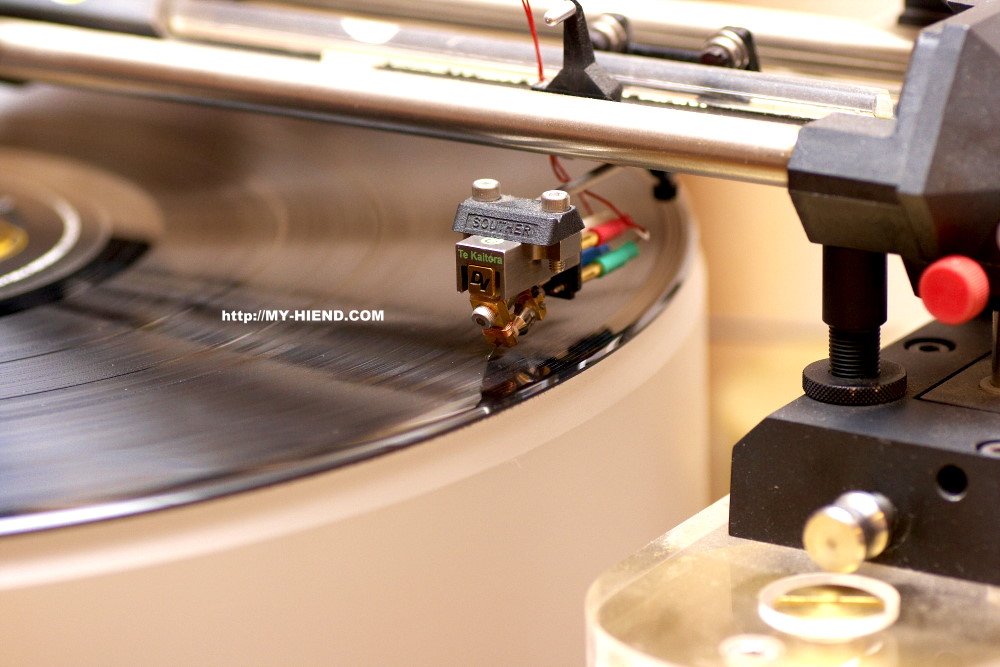

Since people talked about 3 point carriage so here's more pictures of bearing mechanism of Souther and early Clearaudio when they still use 3 roller carriage assembly before the recent conversion to Cantus style. The triagular carriage has two rollers in the back and one in the front.

vinylengine.com/phpBB2/album_showpage.php?pic_id=13527&user_id=97278

vinylengine.com/phpBB2/album_showpage.php?pic_id=12185&user_id=97278

___________________________________

The curious thing about the Clearaudio arm is that their flagship model TT1 has the arm above the rollers and whereas TT2 and TT3 have the arm hanging below the rollers.

Blinded by really obnoxious gold plating! Yuck!

.

.

Since people talked about 3 point carriage so here's more pictures of bearing mechanism of Souther and early Clearaudio when they still use 3 roller carriage assembly before the recent conversion to Cantus style. The triagular carriage has two rollers in the back and one in the front.

vinylengine.com/phpBB2/album_showpage.php?pic_id=13527&user_id=97278

vinylengine.com/phpBB2/album_showpage.php?pic_id=12185&user_id=97278

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

___________________________________

The curious thing about the Clearaudio arm is that their flagship model TT1 has the arm above the rollers and whereas TT2 and TT3 have the arm hanging below the rollers.

An externally hosted image should be here but it was not working when we last tested it.

Blinded by really obnoxious gold plating! Yuck!

An externally hosted image should be here but it was not working when we last tested it.

.

fluid damping

.

I wonder if fluid damping can be implemented like this short air bearing arm on the Cantus.

vinylengine.com/phpBB2/album_showpage.php?pic_id=8686

vinylengine.com/phpBB2/album_showpage.php?pic_id=8687

vinylengine.com/phpBB2/album_showpage.php?pic_id=8688

vinylengine.com/phpBB2/album_showpage.php?pic_id=8684

vinylengine.com/phpBB2/album_showpage.php?pic_id=8685

http://www.youtube.com/watch?v=ldg3gez0Bys -- Youtube video

.

.

I wonder if fluid damping can be implemented like this short air bearing arm on the Cantus.

vinylengine.com/phpBB2/album_showpage.php?pic_id=8686

vinylengine.com/phpBB2/album_showpage.php?pic_id=8687

vinylengine.com/phpBB2/album_showpage.php?pic_id=8688

vinylengine.com/phpBB2/album_showpage.php?pic_id=8684

vinylengine.com/phpBB2/album_showpage.php?pic_id=8685

http://www.youtube.com/watch?v=ldg3gez0Bys -- Youtube video

.

Last edited:

Hi,

What's missing is the proper context.

Once aware of the context you'll also be able to understand what I say in the quote above.

The impressive part starts when you learn how to properly set up such arms , after that you'll likely also understand how to avoid the design flaws that crept into these arms.

Cheers,

Am I missing something here? The Goldmund tonearm is a servo motorized arm like the Rabco and it's really a different technology and different approach to vibration control than the mechanical linear tracker like the Cantus and Souther. Essentially Goldmund, Rabco, Yamaha PX2, are really pivot arms that pivot horizontally and vertically with a motorized mounting base. Put a conventional pivot arm on a sliding base add a sensor and a motor and that's a Goldmund for you. I wonder why people haven't come up with a sensor detected motorized sliding armboard for conventional pivot arms. Most quality pivot arms certainly are better build in their bearings than many of these servo arms. Disassemble a Rabco or a Japanese servo arm and you will see mechanically they are utter junk. Never own a Goldmund so I can't tell but T3 and its siblings don't look very impressive build wise.

.

What's missing is the proper context.

Once aware of the context you'll also be able to understand what I say in the quote above.

The impressive part starts when you learn how to properly set up such arms , after that you'll likely also understand how to avoid the design flaws that crept into these arms.

Cheers,

Frank that sounds like a line from $10.00 swami at a seance. Look deep deep into my eyes and you will be able to understand what I say. If you don't say how am I supposed to know what you didn't say? Oh I forgot about the part where I look deep deep into your eyes while I give you a ten spot.

I think we need a few more prototypes built here.

The thing that's stopping me is ..... time. I just don't seem to have enough of it lately. i suppose the other thing that's holding me back is that there has been a good bit of talk here about this arm only suiting high (or was it low) compliance carts - that means that there's no point in building it if you don't have the right cart to match.

I wonder could someone spec a range (or does Cantus - I looked on the site but couldn't find it) of compliance that this arm suits? For example, my Benz L2 has dynamic compliance of 15 µm/mN. This figure kinda means nothing to me - would this arm work OK with this cart?

Fran

The thing that's stopping me is ..... time. I just don't seem to have enough of it lately. i suppose the other thing that's holding me back is that there has been a good bit of talk here about this arm only suiting high (or was it low) compliance carts - that means that there's no point in building it if you don't have the right cart to match.

I wonder could someone spec a range (or does Cantus - I looked on the site but couldn't find it) of compliance that this arm suits? For example, my Benz L2 has dynamic compliance of 15 µm/mN. This figure kinda means nothing to me - would this arm work OK with this cart?

Fran

Hi,

I'd put my bets on high compliance carts.

Low compliance cartrides need a longer arm to cope with warps.

Keep in mind: anything that's allowed to move loses energy, energy contains information.

Cheers,

I think we need a few more prototypes built here.

The thing that's stopping me is ..... time. I just don't seem to have enough of it lately. i suppose the other thing that's holding me back is that there has been a good bit of talk here about this arm only suiting high (or was it low) compliance carts - that means that there's no point in building it if you don't have the right cart to match.

I wonder could someone spec a range (or does Cantus - I looked on the site but couldn't find it) of compliance that this arm suits? For example, my Benz L2 has dynamic compliance of 15 µm/mN. This figure kinda means nothing to me - would this arm work OK with this cart?

I'd put my bets on high compliance carts.

Low compliance cartrides need a longer arm to cope with warps.

Keep in mind: anything that's allowed to move loses energy, energy contains information.

Cheers,

The Cantus will run a wide range of cartridges. I have seen Decca's Ortofon MM and MC and The Music Maker (The Cartridge Man). I am sure that Bo can provide you with a wide range of possible cartridges. Doug here was running an old Shure MM. I would expect that any cartridge you see running on an air bearing or Clear Audio would work on a Cantus. I am getting an older Ortofon 540 Mk2 which works very well and is an excellent tracking arm. Try what you have and see how it sounds.

You can also take a look here Opus Cantus parallel tracker (page 3) - Tonearms - Lenco Heaven Turntable Forum

You can also take a look here Opus Cantus parallel tracker (page 3) - Tonearms - Lenco Heaven Turntable Forum

Moray's right about the cartridge in my Cantus clone - it's an old M105E at 15cm/dyne, which makes it high compliance, I think.. It does the job and makes good music, but it doesn't particularly like warps. It keeps playing but gets buried in the cartridge, probably because of the short arm so I think Frank is probably right about low compliance carts. I don't have any. With one exception, all of my carts are thrift store, which means they're good, cheap, expendable lab rats.

Again, I strongly suggest to anyone who has an idea they like, build it! My experience is that the basic form of these parallel trackers is just that - basic. Build it, then start tinkering. I would love to see more of these ideas become some kind of real. Once we have a proto-type zoo going, we can begin to talk about what works best for dealing with whatever comes up.

Again, I strongly suggest to anyone who has an idea they like, build it! My experience is that the basic form of these parallel trackers is just that - basic. Build it, then start tinkering. I would love to see more of these ideas become some kind of real. Once we have a proto-type zoo going, we can begin to talk about what works best for dealing with whatever comes up.

I was thinking about building a head shell which would act as an energy sink. The jist of the idea is to have an open rectangular metal frame with a horizontal cross member about 3/16-1/4 inch wide (front) and the other 1/8 inch wide at the back, the side pieces would be about 1/8 of an inch wide. So the centre section is hollow (for the moment). The two cartridge fixing holes would be in the front section. The mounting points would have a washer hard fixed to this frame one at each hole and a third in the centre on the rear cross section so the cartridge makes contact at three points when screwed down. Now comes the interesting part. The open central section would be fitted with five flat prongs about 1/16 of an inch wide and spaced apart, three attached to the front cross piece and two attached to the rear cross piece. These three prongs hard mount to the front cross piece and extend back toward the rear cross piece but stop short and do not touch the rear cross piece. The other two similar prongs attach to the back cross piece and extend toward the front cross piece but again do not make contact at the front. So we have five rectangular prongs three from the front and two from the back all parallel to each other. Then the space between the prongs is filled with a damping compound.

The idea is that energy from the cartridge makes the prongs vibrate and the damping compound eats the vibration up. There may even be a little out of phase cancellation between the front mounted prongs and the rear mounted prongs but I can't be sure about that.

Any comments or suggestions would be most welcome. I hope that I have described this well enough for readers to understand so please ask questions if you are not clear on the design. I look forward to any and all comments. Regards Moray James.

The idea is that energy from the cartridge makes the prongs vibrate and the damping compound eats the vibration up. There may even be a little out of phase cancellation between the front mounted prongs and the rear mounted prongs but I can't be sure about that.

Any comments or suggestions would be most welcome. I hope that I have described this well enough for readers to understand so please ask questions if you are not clear on the design. I look forward to any and all comments. Regards Moray James.

I was at IKEA today and found this glass looking pole with hook made of "polystyrene-acrylic plastic" and cost only $5 USD. It's about 3/4" diameter and 37" long. And that's enough to make about 4 tubes for the Cantus experiment. Since it's not glass so it shouldn't be too hard to cut. And when I finger flick it, there's no ringing, pretty inert. Good sign. I might to try to slice it with a Dremel kit.

.

.

.

.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Opus 3 Cantus parallel tracking arm