The sub reminds me of the older Martin Logan Descent, though a LOT better looking.

Tough to sell subs though.. parts cost is high and price-range is comparatively low. I probably wouldn't market them except to those also purchasing your loudspeakers (or those who have purchased them) - a way to increase exclusivity (and as a result appeal).

Tough to sell subs though.. parts cost is high and price-range is comparatively low. I probably wouldn't market them except to those also purchasing your loudspeakers (or those who have purchased them) - a way to increase exclusivity (and as a result appeal).

Last edited:

The sub reminds me of the older Martin Logan Descent, though a LOT better looking.

Thanks Scott. Its a challenge to make a sub box look interesting and right from the start I knew I wanted to get multiple smaller drivers in there so as to keep the overall footprint manageable yet still afford some real output without resorting to a great big cube you often see housing a 15 or 18" driver. Four 10" have an larger Sd than an 18" although the compromise has been made to reduce size and because of this EQ is used along with a large amount of power - 2kw (into 4ohm).

Tough to sell subs though.. parts cost is high and price-range is comparatively low. I probably wouldn't market them except to those also purchasing your loudspeakers (or those who have purchased them) - a way to increase exclusivity (and as a result appeal).

I didn't want folks to feel they absolutely needed a sub so the loudspeakers themselves are all quite capable when it comes to music, particularly those featuring larger side firing woofers. Home theater is really what the sub is targeted at or for people who absolutely must have appreciable response into the high teens. I'd say for most music this isn't necessary but certainly some genres benefit.

A design like this is practically begging for Sulfur Hexafluoride, but you'd need a really good seal/coupling for the drivers and probably a thin "painted" coating of silicone caulk to make the diaphragm/dustcap/surround impermeable (..to keep the gas from escaping).

Yeah, not practical (much like Audax's little gas-charged gold-foil piezo tweeter).. but the results would be astonishing (as long as the gas was properly contained).

Yeah, not practical (much like Audax's little gas-charged gold-foil piezo tweeter).. but the results would be astonishing (as long as the gas was properly contained).

Last edited:

Hey folks,

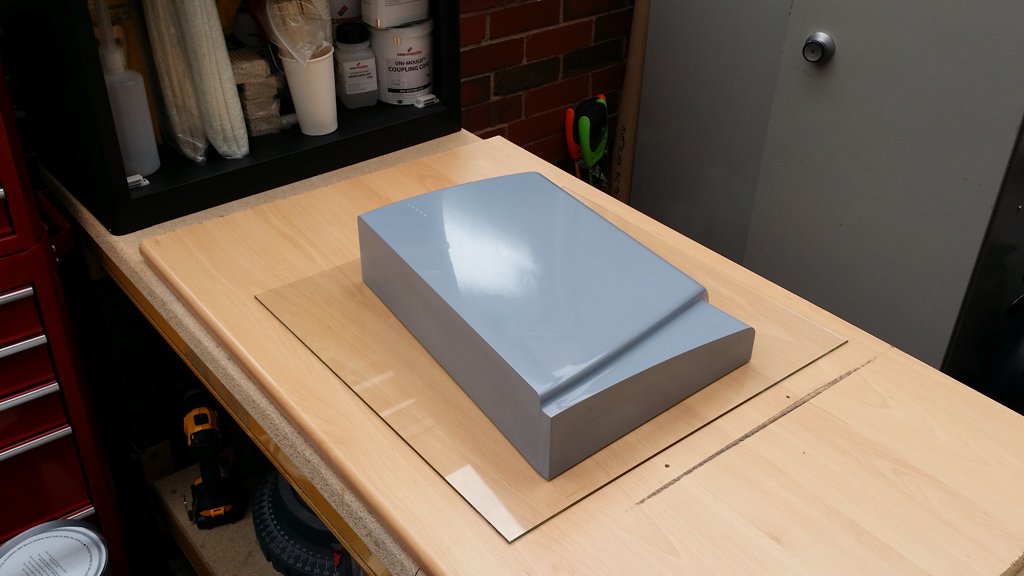

Made some progress on the subwoofer. Construction is laminated 50mm MDF with 30mm thick wall sections.

And preparing one of the sides of the standmount to create a mould. What your seeing here is the prep work. Since this is a two sided part its placed on a flat surface and what this will do is create a flange that allows the two halves of the mould to seal against and align.

This last shot shows the filleting wax used to seal around the part against the flange so the gel coat doesn't run under.

Made some progress on the subwoofer. Construction is laminated 50mm MDF with 30mm thick wall sections.

And preparing one of the sides of the standmount to create a mould. What your seeing here is the prep work. Since this is a two sided part its placed on a flat surface and what this will do is create a flange that allows the two halves of the mould to seal against and align.

This last shot shows the filleting wax used to seal around the part against the flange so the gel coat doesn't run under.

Attachments

It's odd, but I expressly do NOT like the "bumped-out" side-subs on the Rockport designs..

But on your's it actually looks "right".

(..The Rockports tend to look "heavy" or "bloated" by comparison.)

Still, it's pretty similar.

Suggestions:

1. Try sampling models with side subs having a slightly more "oval" blacked-out extension (slight narrowing toward the baffle) to better mirror the front's progressive narrowing toward the tweeter. (..tough to describe.)

2. I'd also consider mirroring the baffle's profile on the bump-out white section. In other words: NOT having it perfectly rounded-off toward the "rear" of the loudspeaker (following the sub's profile), but rather a nice tapered-effect similar to the baffle (as it extends to the top & bottom from the midranges; and instead of the hard-angle "flat" look of the baffle - continue with a nice curve profile to rear of the speaker (subtly "shading-in" the depth to where it blend's in perfectly with the width of the rear panel). This in particular would set it apart visually from the Rockport side-firing designs IMO.

But on your's it actually looks "right".

(..The Rockports tend to look "heavy" or "bloated" by comparison.)

Still, it's pretty similar.

Suggestions:

1. Try sampling models with side subs having a slightly more "oval" blacked-out extension (slight narrowing toward the baffle) to better mirror the front's progressive narrowing toward the tweeter. (..tough to describe.)

2. I'd also consider mirroring the baffle's profile on the bump-out white section. In other words: NOT having it perfectly rounded-off toward the "rear" of the loudspeaker (following the sub's profile), but rather a nice tapered-effect similar to the baffle (as it extends to the top & bottom from the midranges; and instead of the hard-angle "flat" look of the baffle - continue with a nice curve profile to rear of the speaker (subtly "shading-in" the depth to where it blend's in perfectly with the width of the rear panel). This in particular would set it apart visually from the Rockport side-firing designs IMO.

Attachments

Last edited:

Beautiful workmanship and design, but I don't like the sub. It would work better in room as 4 separate enclosure a la Audiokinesis Swarm or as a pair of dual opposed. Depending upon how much EQ is needed to get them flat, there's potentially going to be a huge amount of heat in that enclosure.

I like the side firing LF drivers. One of my current projects is using a pair of 12's in each cab to Allison load like the AR9.

I like the side firing LF drivers. One of my current projects is using a pair of 12's in each cab to Allison load like the AR9.

Great looking work. There is actually someone discussing your router over at the reprap forums.

What Brett says, having two Dual Opposed subs would be better for sonics than a single 4 device sub.

That said you'd also get better force cancellation if you got rid of the bottom firing sub driver, or placed another one on the top and had 5 inside the same cabinet. You could use passive radiators and have two real sub drivers, one mounted on top, one mounted below with three passives along the sides. For real performance though, in a dual opposed design, you want one driver with the magnet facing outwards, although making that visually attractive might be hard. If you had the bottom driver with the magnet facing outside and increased the height of the feet it sits on, or created an elevated plinth like B&W do for their 800 series, then it wouldn't look bad.

I do like the aesthetics of the sub, it's just not the best you could do for the technical performance where you ideally want as many drivers facing out as you have facing in with all the drivers firing in directions designed to cancel out all movement that would shake the cabinet.

That said you'd also get better force cancellation if you got rid of the bottom firing sub driver, or placed another one on the top and had 5 inside the same cabinet. You could use passive radiators and have two real sub drivers, one mounted on top, one mounted below with three passives along the sides. For real performance though, in a dual opposed design, you want one driver with the magnet facing outwards, although making that visually attractive might be hard. If you had the bottom driver with the magnet facing outside and increased the height of the feet it sits on, or created an elevated plinth like B&W do for their 800 series, then it wouldn't look bad.

I do like the aesthetics of the sub, it's just not the best you could do for the technical performance where you ideally want as many drivers facing out as you have facing in with all the drivers firing in directions designed to cancel out all movement that would shake the cabinet.

Shinobiwan,

love those smooth finish alu plates

what process was it to change the color to black n was the words cnc engraved or silkscreen on top of substrate.

Cause i had issues doing the plates as when the raw material alu came, somehow its not poasible to get a 100% smooth finish. Always have nick n scratches

love those smooth finish alu plates

what process was it to change the color to black n was the words cnc engraved or silkscreen on top of substrate.

Cause i had issues doing the plates as when the raw material alu came, somehow its not poasible to get a 100% smooth finish. Always have nick n scratches

Shin... bad on me for not following this thread..... very nice looks, indeed....

but - that 40W laser.... how welll does it work???

Some time ago, I was looking at a 60W unit, specifically for engraving anodized alu panels, but on asking questions on a US forum, I was told it wouldn't work on anodized panels...??

but - that 40W laser.... how welll does it work???

Some time ago, I was looking at a 60W unit, specifically for engraving anodized alu panels, but on asking questions on a US forum, I was told it wouldn't work on anodized panels...??

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- One.20 Construction Diary