I get it,

I never got past FFFFFFFFFFFFFFFFFFFFFFFFF

(but I'm pretty sure my heart skipped a beat when I fired it up for the first time)

I haven't got past 1m high tower 2 way TL. They definitely need a bigger place to shine and optimise placements. A loft attic and weird ceiling angles, limit me to perhaps 1.5m height, on one side of the room. So that also stops a real line array experiment. With more room, the bass would be from front and rear in wall IB.

So for now, my limit would be a small ripole (2x10" bass cab drivers), and something like a single W2-800SL per side (2.1). SK active XO, 24dB/Oct acoustic target) @ 500 Hz. I have a great idea for a waveguide. Probably nothing new. I may have to CAD it and see if it is actually possible to make (3D print) and what I would cost....

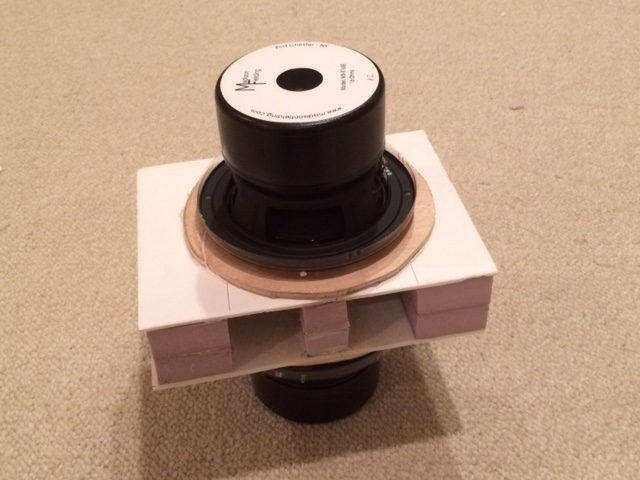

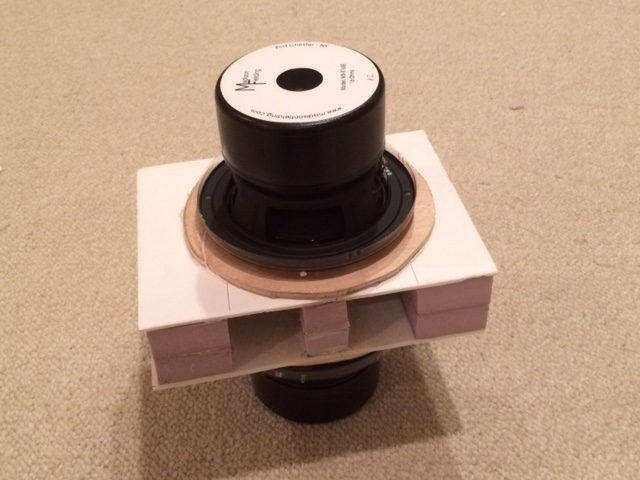

SLOB for dual W5-876SE

I ended up making the slot out of two layers of 1in thick pink XPS foam and two sheets of foam core. I then glued a 3/16in thick Sureply disc (left over from driver cutouts on another project) on top of the foam core for supporting the drivers which are rather heavy as they have huge magnets. There is no way the foam core would have supported their weight. Now I need to find some threaded rod and need to use a jigsaw to cutout the driver holes in the Sureply. There is a spacer block made of XPS in the slot to support the 4th bolt. I can make the compression ratio whatever I need by cutting the exit ports to the appropriate size. The foam is glued with hot melt to tack and Liquid Nails to seal and provide the main structural bond. It will take a few days to fully harden.

I ended up making the slot out of two layers of 1in thick pink XPS foam and two sheets of foam core. I then glued a 3/16in thick Sureply disc (left over from driver cutouts on another project) on top of the foam core for supporting the drivers which are rather heavy as they have huge magnets. There is no way the foam core would have supported their weight. Now I need to find some threaded rod and need to use a jigsaw to cutout the driver holes in the Sureply. There is a spacer block made of XPS in the slot to support the 4th bolt. I can make the compression ratio whatever I need by cutting the exit ports to the appropriate size. The foam is glued with hot melt to tack and Liquid Nails to seal and provide the main structural bond. It will take a few days to fully harden.

Attachments

X, is your XPS slot curved in the back like the way I will be building? I would have thought that the XPS foam would provide all the support for the drivers and that the foam-core would not need to support any of the weight.

It's not curved (yet) because I made it by glueing strips of XPS cut from scraps as I did not have a large sheet that could be cut with a curve in back. I could glue little corner radiused fillets in to make it curved I suppose. The way the driver holes are located relative to how big the slot has to be to accommodate the surround movement, there is not enough XPS foam underneath just the 3 edges to support the compression of 4 bolts or threaded rods, and the final edge rests only on the thin sheet of foam core (covered with a thin ply disc). If the ply were rectangular then probably would have been strong enough to handle it. Anyhow,adding a small block may actually serve to constrict the chamber volume some and increase upper extension. My next concern is how to mount this so it is supported by the baffle and base without sagging or vibrating. My experience from my cardboard SLOB tells me whatever efforts one puts into sturdily mounting the SLOB assembly to prevent vibrations is important. It has a lot of energy in it, and it shakes things like you wouldn't believe. The motion is force cancelling but the pressure generated is not. The two wings that cover the side of the baffle are also subject to a lot of vibration from the tremendous back pressure wave. Those need to be braced as well. I wonder if I shouldn't just make a box for it to slip into and turn it to a ripole or double back a lot loaded system.

Last edited:

Slot loaded open baffle in a car? Or slot loaded bass injection in a car? If I put a sealed chamber on both ends, I end up with the basis of the bass on a famous KEF 104.

Googled that KEF 104 (famous maybe, but didn't realise which model until I searched it. Actually had these for a hifi in a warehouse once...)

Anyway, I cant connect the dots. How is it like a passive radiator reflex?

I like the ripole idea, and you correctly note the pitfalls.

My ideal would use a high eff woofer I possible, since Id guess you lose 12dB or more right off the bat.

I may have my speakers mixed up. If the KEF 104 has a PR then that is not what I was talking about. It's a speaker with two internal opposed force cancellingwoofers driving a chamber that exits in a round port. 4th order bandpass I think.

Edit - it's the 104/2. It has two internal woofers connected by a central force canceling rod. The drivers push air out of a common chamber through a round port. I have heard this speaker is really nice sounding. It has an MTM above it.

Hmm maybe I am building an OB mini version of I went with an MTM.

http://theartofsound.net/forum/showthread.php?32069-KEF-104-2

Last edited:

SLOB progress

After cutting out the driver cutouts, it turns out that the inner chamber is now indeed rounded in the back. I should have not skimped on wood and just used a full rectangular pieces on each side. I am not sure if this is going to hold up with the weight of the drivers. The screws will have good ply to hold onto but the ply is supported by the thin layer of foam core (or the glue holding a layer of foamcore paper to the foam) in the shear direction if I were to place drivers side by side vs top and bottom.

After cutting out the driver cutouts, it turns out that the inner chamber is now indeed rounded in the back. I should have not skimped on wood and just used a full rectangular pieces on each side. I am not sure if this is going to hold up with the weight of the drivers. The screws will have good ply to hold onto but the ply is supported by the thin layer of foam core (or the glue holding a layer of foamcore paper to the foam) in the shear direction if I were to place drivers side by side vs top and bottom.

Attachments

Edit - it's the 104/2. It has two internal woofers connected by a central force canceling rod. The drivers push air out of a common chamber through a round port. I have heard this speaker is really nice sounding. It has an MTM above it.

Hmm maybe I am building an OB mini version of I went with an MTM.

KEF 104/2

Ahhh. Yes that image of the 104\2 makes it all clear.

Am I right in thinking that the SLOB plenum you've built, will 'fire' through a baffle at 90*?

m I right in thinking that the SLOB plenum you've built, will 'fire' through a baffle at 90*?

Yes. One can even make a very short (3in lon) "waveguide" expansion that will buy a few dB gain at expense of upper freq extension.

A quick test with the SLOB assembly (no baffle) indicates that tremendous pressure forces are generated and the foam core/plywood/XPS rattles and buzzes at certain frequencies. I think this needs to be made with sturdy blocks of plywood. It really pumps out air through the exit ports.

You might want to take a look at the various PPSL threads in the subwoofer forum.

http://www.diyaudio.com/forums/subwoofers/177905-thread-those-interested-ppsl-enclosures.html

Les Hudson and DJK have built a lot of these (I have built 2 thus far only for subwoofer duties, XRK even came to help me

http://www.diyaudio.com/forums/subwoofers/268803-15-plenum-ppsl-3.html

If you go for push pull, you cancel a lot of even order HD ( up to 25dB H2 and 10-15dB H4) and the motor inside the slot helps prevent standing waves due to internal dimensions of the slot. For push push better to model the slot with hornresp.

http://www.diyaudio.com/forums/subwoofers/177905-thread-those-interested-ppsl-enclosures.html

Les Hudson and DJK have built a lot of these (I have built 2 thus far only for subwoofer duties, XRK even came to help me

http://www.diyaudio.com/forums/subwoofers/268803-15-plenum-ppsl-3.html

If you go for push pull, you cancel a lot of even order HD ( up to 25dB H2 and 10-15dB H4) and the motor inside the slot helps prevent standing waves due to internal dimensions of the slot. For push push better to model the slot with hornresp.

You might want to take a look at the various PPSL threads in the subwoofer forum.

http://www.diyaudio.com/forums/subwoofers/177905-thread-those-interested-ppsl-enclosures.html

Les Hudson and DJK have built a lot of these (I have built 2 thus far only for subwoofer duties, XRK even came to help me

http://www.diyaudio.com/forums/subwoofers/268803-15-plenum-ppsl-3.html

If you go for push pull, you cancel a lot of even order HD ( up to 25dB H2 and 10-15dB H4) and the motor inside the slot helps prevent standing waves due to internal dimensions of the slot. For push push better to model the slot with hornresp.

I was going to go push pull but that would make the chamber volume very large to be able to hold the massive magnet (although the magnet and basket take up so much volume maybe it's not so bad?). This would lower the upper frequency extension. Normally not an issue for subs but we are trying to use for upper bass low mids in the 300Hz to 400Hz range. I used to model these in Akabak and have found that the main thing to know is there is a cancellation null given by slot depth and a band pass overshoot peak before the null. A quick measurement at slot exit plane confirmed this: 415Hz bandpass peak and 560Hz cancellation null. This will allow me to use a 350Hz XO point with some EQ and a 2nd order LPF to achieve the desired 4th order Butterworth target for a Harsch XO. The TG9FD should be able to use a first order electrical and natural OB falloff to get close to the 2nd order Bessel target. For sure, the TG9 will be employed to move a lot given the shallow slope crossed at 350Hz.

A quick test with the SLOB assembly (no baffle) indicates that tremendous pressure forces are generated and the foam core/plywood/XPS rattles and buzzes at certain frequencies. I think this needs to be made with sturdy blocks of plywood. It really pumps out air through the exit ports.

good to know, thanks. I will build my version with dual 8" out of solid EVA (well laminated). Given what you are saying, I will overbuild it with maybe 20mm (or 30mm) top/bottom (2-3layer laminate) pieces and the curved 70mm x 40mm thick piece from my earlier photos. I think that I need to use either my normal higher density EVA or the cork/EVA for the top/bottom layers. I still have high hopes that the elastomeric EVA with drivers bolted down with solid threaded bolts going all the way through will work to control the vibrations and rattles. Busy this weekend, but I might be able to do something next week.

If the SLOB is too powerful, then a normal dual 8" in W or Z open baffle woofer ala linkwitz or gainphile will be my next plan. If that fails, then a single 8" in a U or H open baffle.

I couldn't find the original thread, dimensions or size driver used, but DJK mentions here that Les Hudson has used ppsl up to 400Hz for Hi-Fi.

http://www.diyaudio.com/forums/subwoofers/213193-origami-dipole-line-source-sub-3.html#post3039484

Anyway you seem to have everything well under control, just thought it useful to mention.

http://www.diyaudio.com/forums/subwoofers/213193-origami-dipole-line-source-sub-3.html#post3039484

Anyway you seem to have everything well under control, just thought it useful to mention.

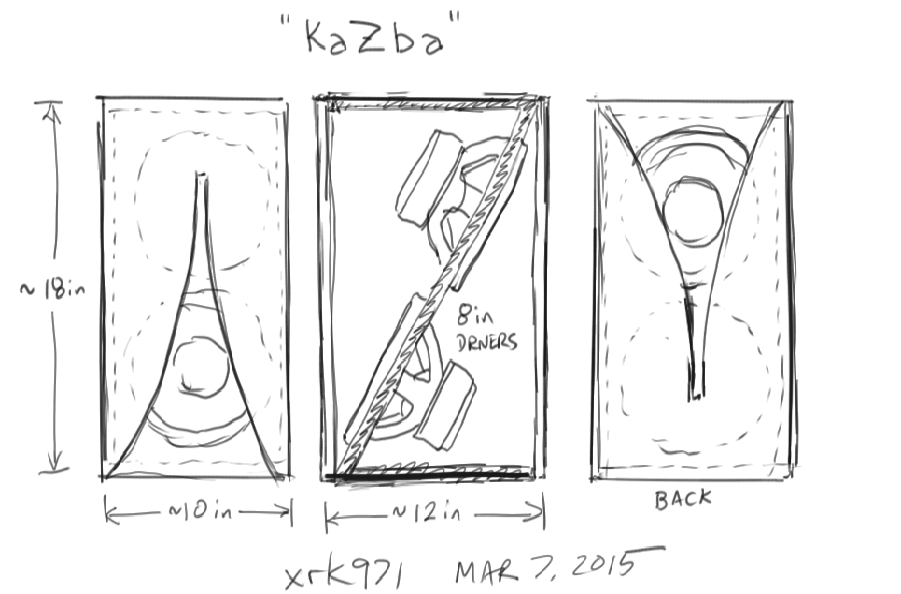

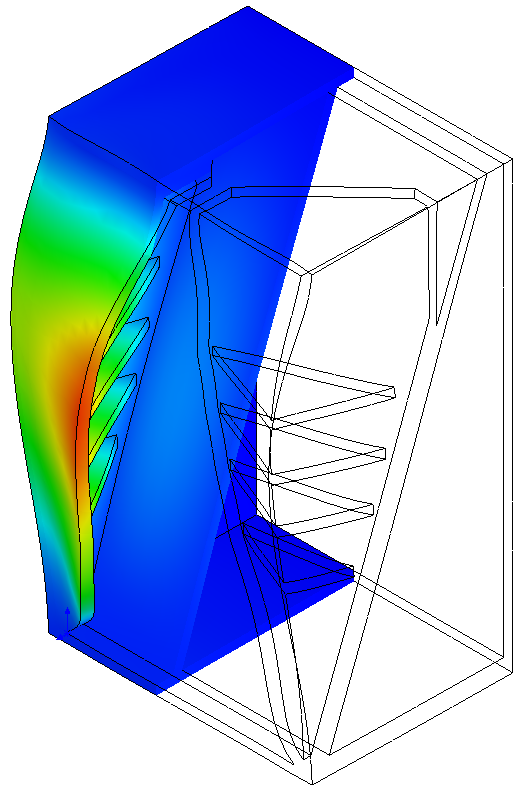

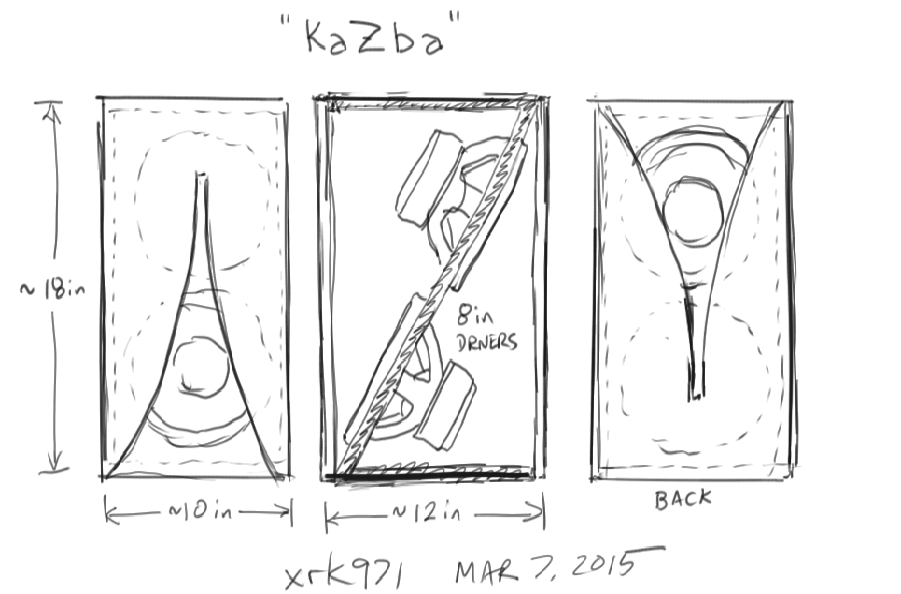

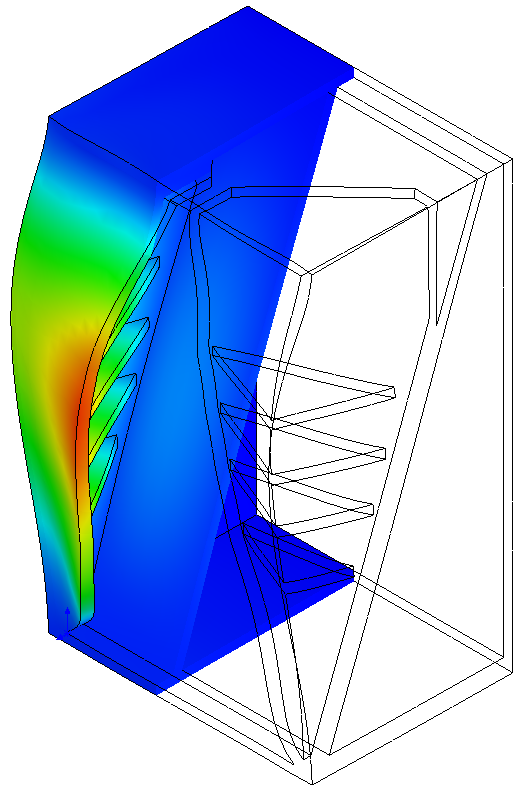

I am rethinking the SLOB. Maybe my KaZba would work better - dipole with higher upper extension yet good slot loading that is aperiodic.

http://www.diyaudio.com/forums/full...zba-dipole-k-aperture-z-baffle-dipole-19.html

I have shown that it can get 35Hz as an OB dipole with a pair of 8in drivers.

Mudjester even helped with analysis of bracing schemes:

And CLS made some beautiful dual 18in ones:

Maybe it will work fine with dual 5in woofers as a desktop bass unit?

http://www.diyaudio.com/forums/full...zba-dipole-k-aperture-z-baffle-dipole-19.html

I have shown that it can get 35Hz as an OB dipole with a pair of 8in drivers.

Mudjester even helped with analysis of bracing schemes:

And CLS made some beautiful dual 18in ones:

Maybe it will work fine with dual 5in woofers as a desktop bass unit?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- OB compact 3way nearfield monitor