Hi Guys,

Finally I have started building the box, I have all the stuff except the ballast which i will get it in a day or two.

Now i have the following problems.

1. my LCD size is 9.8 inch (wide screen), normally the FFC cable is on the top of the LCD panel, but in my case its at the bottom of it, Will post the internal picture soon. can anybody help me how to deal with this issue?

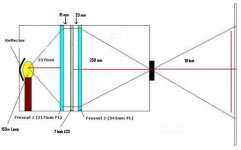

2. in order to keep the box size small I have designed the box in different shape (Please refer to the image). earlier I thought the lamp will fit in the same box, but after realizing the lamp size I had to make some alteration to the box.

Finally I have started building the box, I have all the stuff except the ballast which i will get it in a day or two.

Now i have the following problems.

1. my LCD size is 9.8 inch (wide screen), normally the FFC cable is on the top of the LCD panel, but in my case its at the bottom of it, Will post the internal picture soon. can anybody help me how to deal with this issue?

2. in order to keep the box size small I have designed the box in different shape (Please refer to the image). earlier I thought the lamp will fit in the same box, but after realizing the lamp size I had to make some alteration to the box.

Attachments

Hi Guys

An update on my 7" inch projector build. I received the fresnel lenses and triplet from Lensel, they shipped it out on the very same day they received my D.D. I have opted for a 150w metal halide lamp for the light source. I have successfully striped the 'Super LCD' and am going to start with wood work from tomorrow. Guys i have a few questions

1) Should i go to my local glass shop to get the fresnels cut?

2) How much thickness in 'mm' should the tempered glass be?

3) Will putting a fan above the LCD cause loss of light?

4) Guys i am attaching a design of the box could anyone please guide me.

Is 15mm distance between the 1st fresnel and the LCD and 20 mm distance between the LCD and the 2nd fresnel an accurate measurement or should I change it?

Thanks in advance and best of luck

An update on my 7" inch projector build. I received the fresnel lenses and triplet from Lensel, they shipped it out on the very same day they received my D.D. I have opted for a 150w metal halide lamp for the light source. I have successfully striped the 'Super LCD' and am going to start with wood work from tomorrow. Guys i have a few questions

1) Should i go to my local glass shop to get the fresnels cut?

2) How much thickness in 'mm' should the tempered glass be?

3) Will putting a fan above the LCD cause loss of light?

4) Guys i am attaching a design of the box could anyone please guide me.

Is 15mm distance between the 1st fresnel and the LCD and 20 mm distance between the LCD and the 2nd fresnel an accurate measurement or should I change it?

Thanks in advance and best of luck

Attachments

Hey,

1. Fresnels will most probably not be cut at a glass shop as they'r made of optical acrylic.

Using a grinder or hexo blade to cut them is risky as it can scratch the surface.

Cutting them is difficult (from my personal experience)

One method is to cover them with some plastic and place them under a block of plywood (this will not allow the lens to slip). The portion to be cut needs to be exposed. the rest under the plywood.

Take a Box cutter and run it along the cutting line with some pressure 20-25 times. Once a slight groove develops break it apart using pliers. The lens will break perfectly on this line.

2.I dont use a tempered glass even with a 400w lamp.

A thin one may crack with the heat. use a thick one (i really dont think its needed with a 150w lamp.

(i too used a 150w one initially - very dim imo . use 400w)

3. fan's will let out light. that will have to be dealt with by using other methods

Btw. Did u see my project?

1. Fresnels will most probably not be cut at a glass shop as they'r made of optical acrylic.

Using a grinder or hexo blade to cut them is risky as it can scratch the surface.

Cutting them is difficult (from my personal experience)

One method is to cover them with some plastic and place them under a block of plywood (this will not allow the lens to slip). The portion to be cut needs to be exposed. the rest under the plywood.

Take a Box cutter and run it along the cutting line with some pressure 20-25 times. Once a slight groove develops break it apart using pliers. The lens will break perfectly on this line.

2.I dont use a tempered glass even with a 400w lamp.

A thin one may crack with the heat. use a thick one (i really dont think its needed with a 150w lamp.

(i too used a 150w one initially - very dim imo . use 400w)

3. fan's will let out light. that will have to be dealt with by using other methods

Btw. Did u see my project?

Hey ballistic

Thank you for the prompt reply. I will give it a go and update you with the results. I actually wanted to go in for a 250w or 400w metal halide lamp however the sheer size of it made me change my mind. I did look around the shops in Lohar Chawl but could not find a double ended lamp.

I visited your projector page about a week ago and really liked it. The projected image is really crisp and clear

Great job and thanks once again

Thank you for the prompt reply. I will give it a go and update you with the results. I actually wanted to go in for a 250w or 400w metal halide lamp however the sheer size of it made me change my mind. I did look around the shops in Lohar Chawl but could not find a double ended lamp.

I visited your projector page about a week ago and really liked it. The projected image is really crisp and clear

Great job and thanks once again

Hey Guys

Will an 'A.C. Filter Sheet' put behind the fan stop light from getting out of the box or is there any other material I could use so as to prevent light loss.

While going through Mack’s Projector Page I had come across a picture of some kind of filter behind the fan to prevent light loss. I am uploading the picture could anyone please tell me what that material is?

Thanks in advance

Best Of Luck

Will an 'A.C. Filter Sheet' put behind the fan stop light from getting out of the box or is there any other material I could use so as to prevent light loss.

While going through Mack’s Projector Page I had come across a picture of some kind of filter behind the fan to prevent light loss. I am uploading the picture could anyone please tell me what that material is?

Thanks in advance

Best Of Luck

Attachments

Hi Pheonixraider,

Let me understand you right. I think by "light loss" you mean the light that will show out of the projector only because the fan is open. I am sure you dont mean taking measures to save this light. Light travels in straight lines and all you will have is the light that falls on the LCD-Fresnel area. All other light is inevitably lost unless you want to reflect most of it by some means on the LCD.

To reduce light coming out of the projector, you can put a mesh as you have shown in pictures above, but that will also reduce to an extent the amount of air flow. Another option is vanes. You can cut small vanes in thin wood and place them at about 45 deg angle over the fan assembly.

Let me understand you right. I think by "light loss" you mean the light that will show out of the projector only because the fan is open. I am sure you dont mean taking measures to save this light. Light travels in straight lines and all you will have is the light that falls on the LCD-Fresnel area. All other light is inevitably lost unless you want to reflect most of it by some means on the LCD.

To reduce light coming out of the projector, you can put a mesh as you have shown in pictures above, but that will also reduce to an extent the amount of air flow. Another option is vanes. You can cut small vanes in thin wood and place them at about 45 deg angle over the fan assembly.

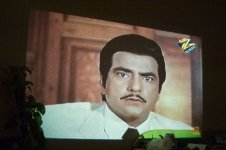

I would like to wish you all a very happy new year, and would like tell you that i have finished my PJ work.

I would like to thank all of you for helping me, without your support and guidance I wouldn't have achieved this.

The raw materials used

- Super 9.8" wide screen LCD with VGA Connect - Rs.4250

- 285 mm Frensel lenses from Lensel, Pune - Rs. 345 each (2nos)

- 315 mm Triplet from Lensel, Pune - Rs. 950

- Osram 400 W MH lamp (Rs. 800) with OSRAM Balast (Rs. 1450)- Rs. 2250

- MDF/Ply for the box - Rs. 500 (Approx)

Attaching the result, I need to do little more tuning but the results are quite promising

I will update more pictures of results and my projector!!

- Cheers!

I would like to thank all of you for helping me, without your support and guidance I wouldn't have achieved this.

The raw materials used

- Super 9.8" wide screen LCD with VGA Connect - Rs.4250

- 285 mm Frensel lenses from Lensel, Pune - Rs. 345 each (2nos)

- 315 mm Triplet from Lensel, Pune - Rs. 950

- Osram 400 W MH lamp (Rs. 800) with OSRAM Balast (Rs. 1450)- Rs. 2250

- MDF/Ply for the box - Rs. 500 (Approx)

Attaching the result, I need to do little more tuning but the results are quite promising

I will update more pictures of results and my projector!!

- Cheers!

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- The Moving Image

- DIY Projectors

- NEW projector from INDIA