kevin,

i might consider going for a portable vac instead of a pump; assuming i can't find an air pump with better suction power.

fallendragon,

may i ask what intex model you have? i didn't notice that the pump in the link was rechargeable, the ones i got to check out were all ac powered.

cheers

i might consider going for a portable vac instead of a pump; assuming i can't find an air pump with better suction power.

fallendragon,

may i ask what intex model you have? i didn't notice that the pump in the link was rechargeable, the ones i got to check out were all ac powered.

cheers

Apparently called 66628, they are on uk eBay right now for £12.99, just do a search on intex air pump.

It's not the quietest thing I've ever come across, but via an airtight food cannister it sure does the trick of drying the records.

Slightly changing the subject, I emptied the cannister the other day, I think most of the liquid had evaporated or been turned to areosol in the process but the grunge collected was nothing short of horrifying

Graham

UK

It's not the quietest thing I've ever come across, but via an airtight food cannister it sure does the trick of drying the records.

Slightly changing the subject, I emptied the cannister the other day, I think most of the liquid had evaporated or been turned to areosol in the process but the grunge collected was nothing short of horrifying

Graham

UK

I've no idea how to attach more then one photo at a time, so here's the external, which as you can see is simply a gutted TD150 (bought like that from eBay for less then £5, I could never be so cruel to a Thorens)

I made an 'SME' plate out of some thick hard plastic with a Dremmel to fit the cutout on the armboard, the connector is for plastic wiring conduit (it fitted the pipes I was using)

The wand is plastic central heating pipe with a slot cut in it, shaved flat underneath and two 'ribbons' of microfibre duster glued either side of the slot. (I'm trying actual nylon velvet ribbon on some spare tubes I'm making next)

I've considered playing with motor drive but am basically happy with my manual system of an 'alchemist' record stablizer thingy (again off eBay, I didn't like the effect on my record deck, but it works perfectly for this) with some thick 'sticky' rubber glued to the bottom for better grip and to protect the label.

The whole is put in a WAY oversized box made of ofcuts of ply

Graham

UK

I made an 'SME' plate out of some thick hard plastic with a Dremmel to fit the cutout on the armboard, the connector is for plastic wiring conduit (it fitted the pipes I was using)

The wand is plastic central heating pipe with a slot cut in it, shaved flat underneath and two 'ribbons' of microfibre duster glued either side of the slot. (I'm trying actual nylon velvet ribbon on some spare tubes I'm making next)

I've considered playing with motor drive but am basically happy with my manual system of an 'alchemist' record stablizer thingy (again off eBay, I didn't like the effect on my record deck, but it works perfectly for this) with some thick 'sticky' rubber glued to the bottom for better grip and to protect the label.

The whole is put in a WAY oversized box made of ofcuts of ply

Graham

UK

Attachments

This is the inside, as you can see dead simple, from the intex air pump the pipe goes to an airtight food container and from there connects directly to the connector on the 'SME' plate above holding the wand. Again the connectors are for plastic wiring conduit.

It's not wildly convenient having to lift the deck to get at the container, but I figure it would take forever to get any significant amount of fluid in it anyway, gunge, now thats another matter..

Works incredibly well and cost way under £30, thats got to be a bargain!

One day I'll get around to giving it a nice coat of varnish, but right now I'm just enjoying finally having clean records

Graham

UK

It's not wildly convenient having to lift the deck to get at the container, but I figure it would take forever to get any significant amount of fluid in it anyway, gunge, now thats another matter..

Works incredibly well and cost way under £30, thats got to be a bargain!

One day I'll get around to giving it a nice coat of varnish, but right now I'm just enjoying finally having clean records

Graham

UK

Attachments

Graham, very nice! Conceptually not too different from mine. (Pix further back in thread.) I used a VPA cleaning wand upgrade I bought from elusivedisc.com.. Yours looks good too, and I like your plumbing arrangement a bit better than mine, but the goal was the same.

Incidentally I have not had to empty my slop bottle so far..

I'm using a homebrew cleaning solution that is a couple of liters of distilled water, about 10% alcohol, and a couple of drops of Kodak Photo-Flo as a wetting agent. I usually rinse with a little distilled water. Seems to work well enough, not to harsh and way cheaper than the stuff VPI or Nitty Gritty sells.

Incidentally I have not had to empty my slop bottle so far..

I'm using a homebrew cleaning solution that is a couple of liters of distilled water, about 10% alcohol, and a couple of drops of Kodak Photo-Flo as a wetting agent. I usually rinse with a little distilled water. Seems to work well enough, not to harsh and way cheaper than the stuff VPI or Nitty Gritty sells.

hi guys, it seems that if all goes well, i'll be starting my build this weekend. a couple of questions though...

- what would be the general dimensions of the box?

- how noisy is the air pump inside the box?

- would lining the insides of the box tame the noise (assuming the air pump screams a lot)?

- would it be helpful to make a small hole of some sort at the side of the box to let all those hot air out? i'm assuming with all that vacuuming going on, there would some amount of hot air expelled by the pump trapped inside the box.

thanks a lot

ps nice setup FD

- what would be the general dimensions of the box?

- how noisy is the air pump inside the box?

- would lining the insides of the box tame the noise (assuming the air pump screams a lot)?

- would it be helpful to make a small hole of some sort at the side of the box to let all those hot air out? i'm assuming with all that vacuuming going on, there would some amount of hot air expelled by the pump trapped inside the box.

thanks a lot

ps nice setup FD

KevinKR, thats because I shamelessly nicked your design in the first place! I was going to use the VPI upgrade wand, but the postage to the UK was just stupid (way more then the actual wand) so decided to make my own..

I've been wondering what cleaning solution others used, I've been using l'art du son which you make up to 5L with distilled water, it's pretty good in that the records sound great but I'm not totally convinced its the best actual cleaner, there's more noise left then i would expect and is this great sound due to the fact it's actually leaving something behind..

Kimmy my box is 41X34cm by a massive 25cm deep (the dimensions were of course to fit the TD150 chassis, the huge depth because when I made it I hadn't decided on which vacuum to use and thought it might be considerably bigger then the Intex I ended up with. simply make yours to whatever size you need. The pump is noisy, but it doesn't scream, and putting it inside the enclosed box does shut it up a bit It never runs for that long though at a time so heat etc is no problem

It never runs for that long though at a time so heat etc is no problem

all the best

Graham

I've been wondering what cleaning solution others used, I've been using l'art du son which you make up to 5L with distilled water, it's pretty good in that the records sound great but I'm not totally convinced its the best actual cleaner, there's more noise left then i would expect and is this great sound due to the fact it's actually leaving something behind..

Kimmy my box is 41X34cm by a massive 25cm deep (the dimensions were of course to fit the TD150 chassis, the huge depth because when I made it I hadn't decided on which vacuum to use and thought it might be considerably bigger then the Intex I ended up with. simply make yours to whatever size you need. The pump is noisy, but it doesn't scream, and putting it inside the enclosed box does shut it up a bit

all the best

Graham

Mine is open front and rear, and the pump I used is quite noisy..

Graham, I'm glad mine was an inspiration... Yours is sufficiently original in detail that I would argue that rather than it being nicked it is your interpretation of the idea.. My only original contribution was the slop bottle - motivated by my desire not to breathe in the crud recently removed from my record grooves and a desire to avoid odd shaped stains on the wall behind the cleaner.

Yours is sufficiently original in detail that I would argue that rather than it being nicked it is your interpretation of the idea.. My only original contribution was the slop bottle - motivated by my desire not to breathe in the crud recently removed from my record grooves and a desire to avoid odd shaped stains on the wall behind the cleaner.

Graham, I'm glad mine was an inspiration...

greetings fellow tweakers,

my first post to this forum,.....

I was inspired to build an RCM by a friend from another audio forum, taperssection.com

I also studied this thread quite a bit in designing my RCM.

I just finished building it out, and am really pleased with the results. And, as a total bonus, Sarge, the spousal unit, has given it the WAF rating of 10++

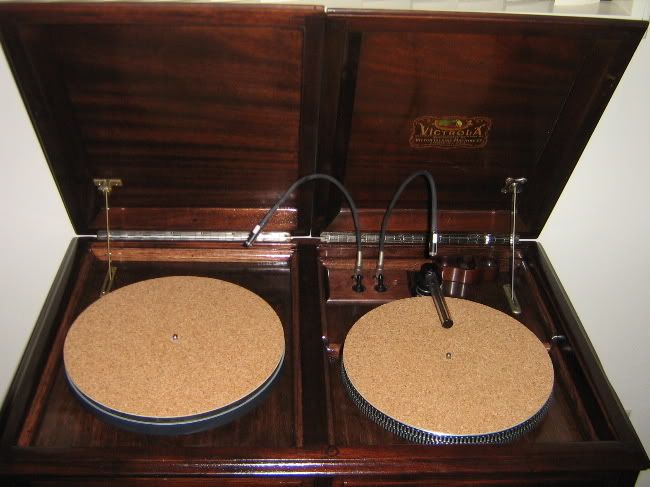

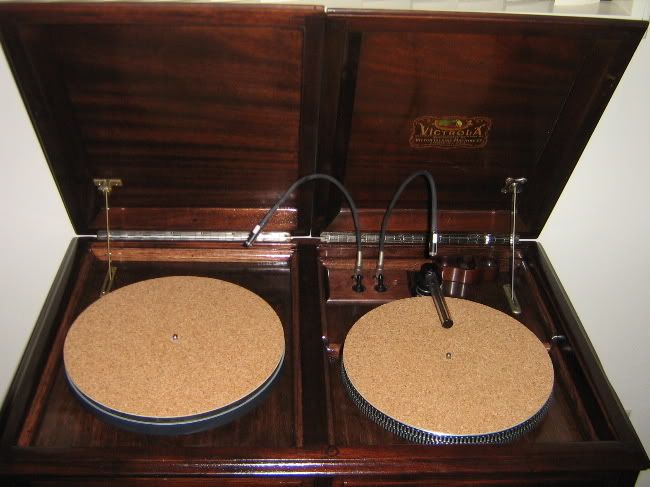

So, here it is, my RCM, the Vactrola:

http://taperssection.com/index.php/topic,108013.0.html

my first post to this forum,.....

I was inspired to build an RCM by a friend from another audio forum, taperssection.com

I also studied this thread quite a bit in designing my RCM.

I just finished building it out, and am really pleased with the results. And, as a total bonus, Sarge, the spousal unit, has given it the WAF rating of 10++

So, here it is, my RCM, the Vactrola:

http://taperssection.com/index.php/topic,108013.0.html

OK,... so I blew it in my first post, not realizing that the photos could not be seen if you were not a member of taperssection.com

Here are a couple of photos, and, the photobucket pic folder for the set:

from this album:

http://smg.photobucket.com/albums/v12/MokesPics/The Vactrola RCM by Moke/

this is the text from my original post at the other forum:

Here are a couple of photos, and, the photobucket pic folder for the set:

from this album:

http://smg.photobucket.com/albums/v12/MokesPics/The Vactrola RCM by Moke/

this is the text from my original post at the other forum:

I was inspired by Carl Becks - Ugly Audio Room thread, where he highlighted his record cleaning machine (rcm).

So, I looked into, and purchased the VPI vacuum cleaning mechanism, and started trying to design a cabinet to mount it all in, or, purchase a cabinet to do the same.

I wanted a two platter cleaning system, of a wet cleaning manual side, and a mechanized vacuuming side.

Sarge bought me an old Victor Victrola cabinet, that had no working componentry in it; it was a gutted cabinet, that was advertised as a bathroom pullman cabinet. It was trashed, and in need if allot of work.

This was the perfect base to begin with.

The only real problem for my two platter system was that the left side of the cabinet was never intended to be opened, and was glued and nailed closed (ring-shank nails!).

I, as carefully as humanly possible, removed the fixed lid, and started to work in a manual deck, at the same time, designing in a mechanized deck.

I soon realized that there was a severe offset between the VPI OEM height specs, and my deck height, which required either an isolated riser for the pickup tube, or, designing in a two level deck, with the pickup tube on the upper level,and the tt being on the step down level.

Now with a cabinet at hand, I started into the actual electro-mechanical designs.

In all of my researching, and reading of other forums, regarding the building and design of this, everyone else wanted a motor-drive table, yet, nobody had actually installed a drive motor that I could find.

So, my first mechanical effort was to fabricate in a drive motor, and the rest of the electro-mechanical system to support that.

This is far from as easy as it might sound on the surface:

I had to re-suspend the mechanized-side turntable, from that of its shaft-ended end delrin bearing, to that of a ball bearing load carrying structure that was immediately below the platter; so that I could attach an axial-drive motor off the end of the turntable shaft. No small order!

So I researched and found a small thrust bearing that would do that job.

I then had to shorten the bronze bushing, in order to expose more shaft, in order to be able to attach a solid shaft drive collar to tie the motor and tt to each other (the motor has a .25" shaft, and the tt had a .28 shaft, so this required a redrilling of the steel shaft connector). When the bushing was shortened, I then had to notch the tt drive shaft to hold the set screw of the connecting collar.

The motor is mounted to an isolated, flexible base, of oak, and is floated onto rubber o-rings by mounting screws at two locations, so as to provide flexibility to the motor drive. The motor mount is also spring suspended with an oem mount.

So there is ample flexibility in the motor mount.

The motor is reversible, 6 rpm, high-torque, and was something i had in my garage for years (a $110 savings!).

I rigged a safety system of a GFCI circuitry to run my components from; the vacuum, motor drive, and LED's

Because I had to rig with a two level deck on the mechanized side, I had to redesign the hook for the lid support.

I also had to totally fabricate the lid support for the manual side (left). I made it of brass that I already had on hand.

The cork platter mats are from a garden supply center and are bases for interior planters. They are glued to a stiff plastic backing. They are exactly the same diameter as an album, so they were easy to align and get center drilled.

This has been a very serious effort in my spare time over the last month. I have a ton of thoughts that I'll edit in later, or repost at a later time.

Until then,....

I give you the Victor Vactrola RCM by Moke,......

finally got the kick in the butt to finish this oft-delayed project.

tada!

not much of a looker but it sucks pretty good. except for some minute traces of liquid deposited very near the record's label, it works quite well.

a couple of things to be improved;

a better looking wand and end-cap

record clamp

replace blu-tack with something better hehe

record cleaner porn

thanks for the inspiration guys!

tada!

not much of a looker but it sucks pretty good. except for some minute traces of liquid deposited very near the record's label, it works quite well.

a couple of things to be improved;

a better looking wand and end-cap

record clamp

replace blu-tack with something better hehe

record cleaner porn

thanks for the inspiration guys!

Hey Kimmy, it looks great! I love the use of the little cupboard, at least you can get to your bottle (though if it's like mine it'll probably only need emptying about once a decade and somewhere to keep all thise brushes, pads bottles etc that seem to collect around mine. Nice pump too, what is it?

and somewhere to keep all thise brushes, pads bottles etc that seem to collect around mine. Nice pump too, what is it?

Have you powered your turntable? If so tell us about it, as while i don't feel the loss at all, indeed quite the opposite, I keep feeling I *should* power mine and it would be fun to do

And if you haven't how are you turning it?

All the best

Graham

Have you powered your turntable? If so tell us about it, as while i don't feel the loss at all, indeed quite the opposite, I keep feeling I *should* power mine and it would be fun to do

And if you haven't how are you turning it?

All the best

Graham

hi graham, thanks for the compliment!

the cupboard-type enclosure was done out of necessity, unfortunately . i initially planned on having a pullout drawer below the cupboard door to hold the record inner sleeves. now i wish i had done so

. i initially planned on having a pullout drawer below the cupboard door to hold the record inner sleeves. now i wish i had done so

the vac is of a piranha brand (sorry, no box or model number as i got it from a thrift shop). it pretty much look like this...

http://cgi.ebay.com.au/ws/eBayISAPI.dll?ViewItem&item=190246218773

the platter is hand spun hehe, no motor yet. it would be nice to have though

you were right, it might take a decade before the bottle gets filled up. after cleaning a couple of lps, i can barely find traces of crud or liquid in the slop bottle.

one caveat though, this vac screams

thinking of padding the insides of the cabinet with foamy material, hoping to lessen the noise.

regards

the cupboard-type enclosure was done out of necessity, unfortunately

the vac is of a piranha brand (sorry, no box or model number as i got it from a thrift shop). it pretty much look like this...

http://cgi.ebay.com.au/ws/eBayISAPI.dll?ViewItem&item=190246218773

the platter is hand spun hehe, no motor yet. it would be nice to have though

you were right, it might take a decade before the bottle gets filled up. after cleaning a couple of lps, i can barely find traces of crud or liquid in the slop bottle.

one caveat though, this vac screams

thinking of padding the insides of the cabinet with foamy material, hoping to lessen the noise.

regards

Matt,

Do you have the model number of the Poineer turntable you used?

I want to use your exact set up as I have a motor that will work perfectly. I have had a hard time finding a turntable that has the platter spindle setup like the one you used.

Any info would be appreciated.

Thanks,

Dave

Do you have the model number of the Poineer turntable you used?

I want to use your exact set up as I have a motor that will work perfectly. I have had a hard time finding a turntable that has the platter spindle setup like the one you used.

Any info would be appreciated.

Thanks,

Dave

Just came across this thread -- very beautiful work here. I thought I would add a couple of recipes for record cleaning fluid that I've used............

Stock solution:

80% (by volume) distilled or deionized water

20% (by volume) isopropyl alcohol

To each quart/liter of stock solution, add:

Recipe 1.

10 drops of Kodak Photo-Flo 200

4 drops of regular blue Windex

----or---

Recipe 2

20 drops of Kodak Photo-Flo 200

3 drops of regular blue Windex

Recipe 1 is from Cordesman in The Absolute Sound many years ago.

Recipe 2 is from Audio Asylum and claimed to be same as VPI cleaning fluid.

My local pharmacy will order 99% isopropyl alcohol for me so that's what I use. Don't use stuff labeled rubbing alcohol as that might have other chemicals in it, but that's probably well-known to most here.

Phil

Stock solution:

80% (by volume) distilled or deionized water

20% (by volume) isopropyl alcohol

To each quart/liter of stock solution, add:

Recipe 1.

10 drops of Kodak Photo-Flo 200

4 drops of regular blue Windex

----or---

Recipe 2

20 drops of Kodak Photo-Flo 200

3 drops of regular blue Windex

Recipe 1 is from Cordesman in The Absolute Sound many years ago.

Recipe 2 is from Audio Asylum and claimed to be same as VPI cleaning fluid.

My local pharmacy will order 99% isopropyl alcohol for me so that's what I use. Don't use stuff labeled rubbing alcohol as that might have other chemicals in it, but that's probably well-known to most here.

Phil

Lots of cool looking machines in here. Right now I am just using a modded shop vac attatchment with a VPI cleaning brush, and an old turntable I found at the side of the street with a cork matt on it.

I made the cleaning fluid out of 99.9% iso alchohol (had a mom and pop drug store order it for me), distilled water (not lab grade but if I can find some pure water I will use it), and a drop of Triton X-114. Bought a bottle of it here that should last me a long long time http://chemassociates.com/shopsite/Chemassoc2/

Anyway the tables you guys did look cool. Might have to keep an eye out for the perfect table at the thrift store and maybe order that VPI upgrade set.

I've been told never to use photoflow as it will leech your vinyl.

I made the cleaning fluid out of 99.9% iso alchohol (had a mom and pop drug store order it for me), distilled water (not lab grade but if I can find some pure water I will use it), and a drop of Triton X-114. Bought a bottle of it here that should last me a long long time http://chemassociates.com/shopsite/Chemassoc2/

Anyway the tables you guys did look cool. Might have to keep an eye out for the perfect table at the thrift store and maybe order that VPI upgrade set.

I've been told never to use photoflow as it will leech your vinyl.

Yes, some cool record cleaners here! I just picked up a Kenmore magic blue vac for $5. Got a few old TT's I can use as cleaning platters- probably do the hand method.

I have also been researching cleaners. What I keep hearing mentioned on threads in sound archival circles (ARSCLIST) is Tergitol, namely Tergitol 15-S-3 (oil soluble surfactant) and 15-S-9 (water soluble surfactant).

Found some for sale at Talas; ~$20 a pint for each. Sounds pricey, but then you realize you only use 0.25 parts of each in 100 parts deionized water!! I would bet most of the $$ record cleaning solutions out there use this stuff. Anyone here tried it?

More info- go to bottom of this link-

http://www.vinylengine.com/care-and-handling-recorded-sound-materials.shtml

If it's good enough for the National Library of Canada AND The Library of Congress, it's good enough for me!

I have also seen the 'Disc Doctor' stuff recommended on the ARSCLIST as a good ready-made cleaner.

-Kent

I have also been researching cleaners. What I keep hearing mentioned on threads in sound archival circles (ARSCLIST) is Tergitol, namely Tergitol 15-S-3 (oil soluble surfactant) and 15-S-9 (water soluble surfactant).

Found some for sale at Talas; ~$20 a pint for each. Sounds pricey, but then you realize you only use 0.25 parts of each in 100 parts deionized water!! I would bet most of the $$ record cleaning solutions out there use this stuff. Anyone here tried it?

More info- go to bottom of this link-

http://www.vinylengine.com/care-and-handling-recorded-sound-materials.shtml

If it's good enough for the National Library of Canada AND The Library of Congress, it's good enough for me!

I have also seen the 'Disc Doctor' stuff recommended on the ARSCLIST as a good ready-made cleaner.

-Kent

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- My DIY record cleaner.