The power supply I used is a basic full wave symmetrical supply, using a bridge rectifier, capacitors, and centre tapped transformer, which I hard wired using the said components.

There is a PCB now available Power-686: Power Supply Board for Modulus-686 and other high-power amps.

Dave.

There is a PCB now available Power-686: Power Supply Board for Modulus-686 and other high-power amps.

Dave.

I ordered the power-686 yesterday and will be using that for my build. Was just interested in how you designed your build!

How are the capacitors to your liking?

How are the capacitors to your liking?

The power supply I used is a basic full wave symmetrical supply, using a bridge rectifier, capacitors, and centre tapped transformer, which I hard wired using the said components.

There is a PCB now available Power-686: Power Supply Board for Modulus-686 and other high-power amps.

Dave.

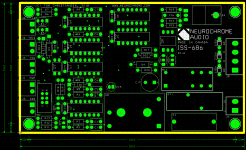

Just a quick update on the Intelligent Soft Start (ISS-686): 2.90 x 5.00 inches (approx. 74 x 128 mm). The 2U ModuShop chassis is specified as 80 mm in height, so this should fit inside on the rear panel (or anywhere else in the chassis for that matter).

It'll enter the fab this weekend and should be arrive here in two weeks. If the prototyping goes well, I'll be able to start shipping these boards by the first full week of June. The production boards will be gold plated (ENIG) and manufactured in Canada.

This is not your typical eBay soft start. That's why I label it an intelligent soft start or ISS-686. I was heavily inspired by the design of the HP 14570A power controller and the ISS-686 is basically one channel of an HP 14570A, sans mains filter. Those who are curious about this design can find the service manual for the 14570A at Artek Manuals and the like places. The article about the power controller in the HP Journal (12/1982) is a worthwhile read as well (thanks BrianL for the nudge).

Here's the executive summary: Arcing is a common issue with relay switching. This arcing creates radiated RF energy which can couple into other equipment and result in clicks and pops whenever the relay turns on/off. The arcing also burns away the relay contact points, resulting in a reduced service life of the relay. To combat this, I implemented an electronic switch which routes the mains power through the soft start NTC for the first few mains cycles before the relay is engaged. Once the relay has closed, the NTC is removed from the circuit. On power-down, the process is reversed. This minimizes the voltage across the switch contacts, thereby lengthening their life.

Another issue with relay switching is the power dissipated in the relay coil. To address this, I implemented a simple little RC-based circuit, which uses a current pulse to engage the relay and lowers the coil voltage to about 40 % of the full voltage (which is still about 4x the typical hold voltage of the relay), thereby increasing the lifespan of the relay coil.

Another sign of intelligent life in the ISS-686 is the design of the relay/electronic switch drive. The circuit supports the use of both toggle power switches and momentary (doorbell) switches. I managed managed to do this and get the switch/relay timing right using off-the-shelf logic ICs, eliminating the need for programmable parts (yay!).

In addition, the ISS-686 features an opto-isolated 12V trigger input and a 6-pin interface for a protection circuit. It also provides a +5V auxiliary output for those who desire such a thing. Oh, and STDBY/ON indication with a bicolour LED.

Tom

It'll enter the fab this weekend and should be arrive here in two weeks. If the prototyping goes well, I'll be able to start shipping these boards by the first full week of June. The production boards will be gold plated (ENIG) and manufactured in Canada.

This is not your typical eBay soft start. That's why I label it an intelligent soft start or ISS-686. I was heavily inspired by the design of the HP 14570A power controller and the ISS-686 is basically one channel of an HP 14570A, sans mains filter. Those who are curious about this design can find the service manual for the 14570A at Artek Manuals and the like places. The article about the power controller in the HP Journal (12/1982) is a worthwhile read as well (thanks BrianL for the nudge).

Here's the executive summary: Arcing is a common issue with relay switching. This arcing creates radiated RF energy which can couple into other equipment and result in clicks and pops whenever the relay turns on/off. The arcing also burns away the relay contact points, resulting in a reduced service life of the relay. To combat this, I implemented an electronic switch which routes the mains power through the soft start NTC for the first few mains cycles before the relay is engaged. Once the relay has closed, the NTC is removed from the circuit. On power-down, the process is reversed. This minimizes the voltage across the switch contacts, thereby lengthening their life.

Another issue with relay switching is the power dissipated in the relay coil. To address this, I implemented a simple little RC-based circuit, which uses a current pulse to engage the relay and lowers the coil voltage to about 40 % of the full voltage (which is still about 4x the typical hold voltage of the relay), thereby increasing the lifespan of the relay coil.

Another sign of intelligent life in the ISS-686 is the design of the relay/electronic switch drive. The circuit supports the use of both toggle power switches and momentary (doorbell) switches. I managed managed to do this and get the switch/relay timing right using off-the-shelf logic ICs, eliminating the need for programmable parts (yay!).

In addition, the ISS-686 features an opto-isolated 12V trigger input and a 6-pin interface for a protection circuit. It also provides a +5V auxiliary output for those who desire such a thing. Oh, and STDBY/ON indication with a bicolour LED.

Tom

Attachments

Tom,

Would i need one ISS-686 per POWER-686, this in case i decide to build a dual mono build? Or can one ISS-686 deal with two transformers and two POWER-686 modules?

Would i need one ISS-686 per POWER-686, this in case i decide to build a dual mono build? Or can one ISS-686 deal with two transformers and two POWER-686 modules?

You can use the ISS-686 with any mains transformer and any power supply.

I suppose I can change the name to ISS rather than ISS-686 if that makes more sense. I kinda like ISS-686, though.

Tom

.Just a quick update on the Intelligent Soft Start (ISS-686): 2.90 x 5.00 inches (approx. 74 x 128 mm). The 2U ModuShop chassis is specified as 80 mm in height, so this should fit inside on the rear panel (or anywhere else in the chassis for that matter).

It'll enter the fab this weekend and should be arrive here in two weeks. If the prototyping goes well, I'll be able to start shipping these boards by the first full week of June. The production boards will be gold plated (ENIG) and manufactured in Canada.

This is not your typical eBay soft start. That's why I label it an intelligent soft start or ISS-686. I was heavily inspired by the design of the HP 14570A power controller and the ISS-686 is basically one channel of an HP 14570A, sans mains filter. Those who are curious about this design can find the service manual for the 14570A at Artek Manuals and the like places. The article about the power controller in the HP Journal (12/1982) is a worthwhile read as well (thanks BrianL for the nudge).

Here's the executive summary: Arcing is a common issue with relay switching. This arcing creates radiated RF energy which can couple into other equipment and result in clicks and pops whenever the relay turns on/off. The arcing also burns away the relay contact points, resulting in a reduced service life of the relay. To combat this, I implemented an electronic switch which routes the mains power through the soft start NTC for the first few mains cycles before the relay is engaged. Once the relay has closed, the NTC is removed from the circuit. On power-down, the process is reversed. This minimizes the voltage across the switch contacts, thereby lengthening their life.

Another issue with relay switching is the power dissipated in the relay coil. To address this, I implemented a simple little RC-based circuit, which uses a current pulse to engage the relay and lowers the coil voltage to about 40 % of the full voltage (which is still about 4x the typical hold voltage of the relay), thereby increasing the lifespan of the relay coil.

Another sign of intelligent life in the ISS-686 is the design of the relay/electronic switch drive. The circuit supports the use of both toggle power switches and momentary (doorbell) switches. I managed managed to do this and get the switch/relay timing right using off-the-shelf logic ICs, eliminating the need for programmable parts (yay!).

In addition, the ISS-686 features an opto-isolated 12V trigger input and a 6-pin interface for a protection circuit. It also provides a +5V auxiliary output for those who desire such a thing. Oh, and STDBY/ON indication with a bicolour LED.

Tom

Very cool. Do you already have a guesstimate for the parts costs?

Now I'm torn on the name. I don't want to shoo people away with the -686. I may just revert to ISS - Intelligent Soft Start. Or SoftStart McSoftStartFace. Who knows?!

The BOM currently sits at $44-something. I need to tweak it a bit as I added a feature after I created that Mouser project. So $44-something plus a few RCs, a transistor, and a LED. My rough estimate is "about $50".

I haven't settled on the board pricing yet. In my recent survey, many of you associated North American manufacturing with a higher quality product and were willing to pay a bit more to receive a quality product made in North America. While the survey was running, I started developing a relationship with a PCB manufacturer in Ontario, Canada. Their pricing is obviously higher than the many Chinese board houses, but their capabilities and quality level are also higher. Based on your responses in my market analysis, I think the Canadian manufacturing is a better overall fit - both for you and for me and my business. Stay tuned...

Tom

The BOM currently sits at $44-something. I need to tweak it a bit as I added a feature after I created that Mouser project. So $44-something plus a few RCs, a transistor, and a LED. My rough estimate is "about $50".

I haven't settled on the board pricing yet. In my recent survey, many of you associated North American manufacturing with a higher quality product and were willing to pay a bit more to receive a quality product made in North America. While the survey was running, I started developing a relationship with a PCB manufacturer in Ontario, Canada. Their pricing is obviously higher than the many Chinese board houses, but their capabilities and quality level are also higher. Based on your responses in my market analysis, I think the Canadian manufacturing is a better overall fit - both for you and for me and my business. Stay tuned...

Tom

Last edited:

The ISS now has its own description page: ISS: Intelligent Soft Start

You can see the full feature list there.

Tom

You can see the full feature list there.

Tom

Now I'm torn on the name. I don't want to shoo people away with the -686. I may just revert to ISS - Intelligent Soft Start. Or SoftStart McSoftStartFace. Who knows?!

Tom

sOFTsTART

PS Like the mADE iN cANADA too!

Would i need one ISS-686 per POWER-686, this in case i decide to build a dual mono build? Or can one ISS-686 deal with two transformers and two POWER-686 modules?

With the amount of supply capacitance you have on two Power-686 boards, I would use one ISS per Power-686.

Tom

Would i need one ISS-686 per POWER-686, this in case i decide to build a dual mono build? Or can one ISS-686 deal with two transformers and two POWER-686 modules?

I should have done the math rather than relying on gut instinct when I wrote. Here's how the math shakes out:

Energy stored in each supply (when fully charged): 0.5*22000e-6*70^2 = 54 J.

The energy stored in two supplies would be double that. No surprise there. That's 108 J.

The energy stored in the transformer itself should be added to this number. How much that is will depend on the transformer chosen, but given that the NTC I use in the soft start is rated for 250 J (and catastrophic failure at twice that), there's plenty of room for the transformer inrush, even with two Power-686 boards connected.

Some will also rightfully argue that the NTC won't see the full inrush energy of the capacitors as it's only on for a few mains cycles until the relay engages. That's a fair argument as well. Though, I do suspect the capacitors are mostly charged by the time the relay switches in and the NTC gets a rest.

So to summarise: One ISS per chassis should do.

Tom

I ordered the power-686 yesterday and will be using that for my build. Was just interested in how you designed your build!

How are the capacitors to your liking?

The Capacitors are very much to my liking.

Ive had Hypex, Tube, and various other amplifiers in my system, and so far this is the one I like best. In fact from now on its unlikely ill be building any other amplifiers.

Ive had Hypex, Tube, and various other amplifiers in my system, and so far this is the one I like best. In fact from now on its unlikely ill be building any other amplifiers.

That's a pretty strong endorsement. Feedback like that is what makes me get up in the morning and design circuits. Thank you.

Tom

Tom,

I got KEF LS50 8 Ohm / 85 dB sensitivity. I listen to regular volume levels 20-30W at most I think ... I got modulus 86. Do you think modulus 686 would drive those speakers better? I assume 686 has six time lower output impedance ... Is that the factor in terms of sound quality?

Tio

I got KEF LS50 8 Ohm / 85 dB sensitivity. I listen to regular volume levels 20-30W at most I think ... I got modulus 86. Do you think modulus 686 would drive those speakers better? I assume 686 has six time lower output impedance ... Is that the factor in terms of sound quality?

Tio

...I assume 686 has six time lower output impedance ...

Block diagrams show 686 is bridged (more about that feature here: Bridged and paralleled amplifiers - Wikipedia) so think if for executed circuit every thing was same (say two bridged Mod-86 modules) doubles up on output impedance and load ballast that amp will see is worse in its half of what speakers datasheet will report, their individual nice data is available over their website so it was easy create below comparison although note that Y axis have bit different scales.

Attachments

Output impedance (determines damping factor) is largely determined by the overall amount of feedback available in the system. Since the LM3886 is wrapped in the feedback loop of the controlling op-amp, the number of LM3886 units is not the prime determiner. Either '86 or '686, pictured above has excellent damping factor. Just the electrical connections between amp and speaker as well as even a moderate length of speaker cable will have far more resistance than the output impedance of either amp.

I got KEF LS50 8 Ohm / 85 dB sensitivity. I listen to regular volume levels 20-30W at most I think ... I got modulus 86. Do you think modulus 686 would drive those speakers better?

If your regular listening level is 20-30 W (average), you're guaranteed to clip on the peaks, in which case the MOD686 will provide a definite improvement. If the tallest signal peak you ever see is 30 W, then either amp should provide the same performance.

I was surprised to find that the MOD686 drove my test speakers (Dali 3A) better than I remembered the MOD86 driving those speakers. That said, the two experiences were years apart and took place in different locations. I'd also just spent the past two months working 12-14 hour days to complete the MOD686, so of course I'm going to like it. That's how cognitive biases work...

I do use my 4xMOD86 every day to drive my LXmini speakers. That's a very nice combination indeed, but I do find that I get a little harshness or strained sound at very loud listening levels. It's subtle but it is there.

The Modulus-686 did not have this harshness, so I'm thinking I'm starting to get a little clipping going at the high volume levels on the Modulus-86.

The next step would be to get the MOD686 on the LXmini but I've been totally swamped with the Power-686 and ISS designs. I hope a fully built MOD686 amp materializes over the summer. Then I can compare.

Another approach would be to measure the output of the MOD86 during the loud passages in the music with a storage scope. Like I really need another excuse to buy a new scope...

Output impedance (determines damping factor) is largely determined by the overall amount of feedback available in the system.

[...]

Just the electrical connections between amp and speaker as well as even a moderate length of speaker cable will have far more resistance than the output impedance of either amp.

Precisely.

Tom

Last edited:

- Home

- Vendor's Bazaar

- Modulus-686: 380W (4Ω); 220W (8Ω) Balanced Composite Power Amp with extremely low THD