Just cut and done a dry fit of the cabinet damping.

As you suggested, Greg, 70% coverage of the back, one side and top.

The picture is of the cabinet upside down just so it could sit in there with the adhesion of gravity for now.

Thoughts, anyone? I have some polyfill as well from my last build so this could be added also...

As you suggested, Greg, 70% coverage of the back, one side and top.

The picture is of the cabinet upside down just so it could sit in there with the adhesion of gravity for now.

Thoughts, anyone? I have some polyfill as well from my last build so this could be added also...

Attachments

Hmm, the goal is to use no more damping than absolutely necessary, so until you've done fully sealed up testing there's no way to know if more is needed plus from just looking at what you're using, it may already ideally be too dense in total for such a small cab designed for a fairly high system tuning.

WRT existing placement, the goal is to line up the padding based on where the driver is radiating, so ~ centered behind and to the side, top of the driver, ditto the face of that exposed brace and since sound radiates off the driver perpendicular to it usually puts the padding ~ centered in the fore/aft position unless the cab's very deep [> ~3x driver depth].

Franking though, now that I've seen it I would of started with just a vertical piece diagonally mounted behind the driver between the baffle and opposite side brace [AKA 'hanging blanket'] with of course a piece on the top plate and only added more damping in the form of [light] stuffing if there were audible resonances you know aren't in the recording.

Note too that most spurious resonances in speakers are driver generated [especially small and/or 'full-range'] and why 'we' here make sure it's braced/ damped to a 'fare-thee-well'.

GM

WRT existing placement, the goal is to line up the padding based on where the driver is radiating, so ~ centered behind and to the side, top of the driver, ditto the face of that exposed brace and since sound radiates off the driver perpendicular to it usually puts the padding ~ centered in the fore/aft position unless the cab's very deep [> ~3x driver depth].

Franking though, now that I've seen it I would of started with just a vertical piece diagonally mounted behind the driver between the baffle and opposite side brace [AKA 'hanging blanket'] with of course a piece on the top plate and only added more damping in the form of [light] stuffing if there were audible resonances you know aren't in the recording.

Note too that most spurious resonances in speakers are driver generated [especially small and/or 'full-range'] and why 'we' here make sure it's braced/ damped to a 'fare-thee-well'.

GM

Is this as you describe?

You're welcome! Yes. I would just slice it enough to let the magnet corner deflect/push through it since I'm not convinced that the material is already much too dense for the app.

GM

Last edited:

You're welcome! Yes.

GM

Fantastic, thanks. Of course, as you say, I cannot do this blind so I will measure and adjust.

A curved curtain seems to be the way.

And lord only knows why photos upload at the wrong orientation....

Attachments

You're welcome! Yes. I would just slice it enough to let the magnet corner deflect/push through it since I'm not convinced that the material is already much too dense for the app.

GM

Roger!

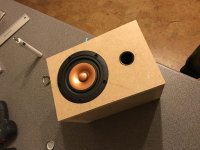

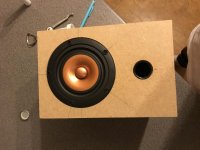

Baffles glued to the cabinet shells!

In the morning I hope to put a 45 chamfer on the vertical edges of the cabinet. Advisable?

PS. Does anyone know why my images are coming up at the wrong orientation? I hate iphones now, gonna switch to Samsung...

In the morning I hope to put a 45 chamfer on the vertical edges of the cabinet. Advisable?

PS. Does anyone know why my images are coming up at the wrong orientation? I hate iphones now, gonna switch to Samsung...

Attachments

Thanks!

For the moment I am trying GM's suggestion of a bass reflex to mate with my subwoofers. Post 39, I think.

Eventually I may build Pensil or compact MLTL because I live n London and never know what's round the corner when it comes to environment!

For the moment I am trying GM's suggestion of a bass reflex to mate with my subwoofers. Post 39, I think.

Eventually I may build Pensil or compact MLTL because I live n London and never know what's round the corner when it comes to environment!

Looking good! It might have gone over my head but did you settle on a bass reflex instead? I recently built Scott’s small bass reflex for the 10p and it sounded awesome!

In the morning I hope to put a 45 chamfer on the vertical edges of the cabinet. Advisable?

Your call; consider the average radius of the 'bend', so let's say it's a 1/2" averaged radius = ~13560"/[2*pi*0.5] = ~4316 Hz. Are you likely to notice or even perceive higher frequencies bending around it or the extreme HF radiating off its two sharp edges? Maybe, but above the telephone BW [~250-3 kHz], not likely, so relative to human hearing perception, probably just cosmetic, though others claim the somewhat cosmetically attractive dashed paint stripes is sufficient on sharp corners.

Much more worthwhile, i.e. easily perceived, is to add vertical felt, open cell foam or similar strips that was popular on NHT and other premium speakers for many years or the felt rings around tweeters beginning back in the '50s and I forget which speaker had a foam covered baffle while others such as Altec, JBL used thick foam as a snap on grill and only quit because too many dissolved in some climates.

GM

Graham, without the same eloquence or experience base to quote on - but with a couple of hundred of builds, mostly with small full range drivers- I’d concur with Greg. While I like the aesthetics of bevel / chamfer to long front edges, and generally try to incorporate such in my finished builds, lacking a large sampling of imperial measurements, I think you gotta go to a very large hypotenuse or radius to gain any real acoustic advantage.

Yeah, there's a very good reason Harry Olson used a 2 ft diameter ball as the reference for his research: http://www.aes.org/tmpFiles/elib/20180829/17816.pdf

Notice how it takes a 1 ft radius to audibly damp/smooth out the HF!

Anyway, lots of info, discussion over the years on the subject and IIRC the very first post on the original 'FR' forum I responded to nearly 20 yrs ago was a Q like Graham's, so a perennially popular, yet still misunderstood subject: harry olson speaker shapes - Google Search

GM

Notice how it takes a 1 ft radius to audibly damp/smooth out the HF!

Anyway, lots of info, discussion over the years on the subject and IIRC the very first post on the original 'FR' forum I responded to nearly 20 yrs ago was a Q like Graham's, so a perennially popular, yet still misunderstood subject: harry olson speaker shapes - Google Search

GM

but above the telephone BW [~250-3 kHz], not likely, so relative to human hearing perception, probably just cosmetic,

GM

Thanks, I may roundover or chamfer just for aesthetics.

Much more worthwhile, i.e. easily perceived, is to add vertical felt, open cell foam or similar strips that was popular on NHT and other premium speakers for many years or the felt rings around tweeters beginning back in the '50s

GM

Something I will probably play with when I do some measurements but I think too late for this build as I would want to integrate anything like this to ensure high WAF factor.

I think you gotta go to a very large hypotenuse or radius to gain any real acoustic advantage.

That's what I thought, I have been reading about diffraction recently and the Impulse Audio youtube just made a good video with measured examples. Again, as above I will have to consider these things as part of a built in system next time!

My thoughts are that possibly these could be test cabinets before I move on to using some BB ply to make the final incarnations. However, I'm not a massive fan of wood grain finish (I may come round to it one day!) so getting a flat painted surface from the ply would be a struggle for me! Thanks for your input!

Yeah, there's a very good reason Harry Olson used a 2 ft diameter ball as the reference for his research: 404 Not Found

GM

Link not working but I will hunt down the info if you can tell me the title? Thanks!

Notice how it takes a 1 ft radius to audibly damp/smooth out the HF!

...a Q like Graham's, so a perennially popular, yet still misunderstood subject: harry olson speaker shapes - Google Search

GM

Yes, I am coming to realise that there are lots of superstitious practices carried out with seemingly not much benefit.

Again, as I have said before in this thread, this process has been the most rich in learning for me so every time you guys chime in I get a whole list of things to consider and research and it keeps me engrossed in my phone for my bed time read. Thank you all!

Last edited:

Huh! It's the proper link, but apparently only as long as it's open in the browser! AES E-Library >> Direct Radiator Loudspeaker Enclosures

GM

GM

Thanks!

Huh! It's the proper link, but apparently only as long as it's open in the browser! AES E-Library >> Direct Radiator Loudspeaker Enclosures

GM

Just got these up and running with only 15 minutes play on them but WOOOOOW. Amazing stuff so far and I've spine tingling already!

I haven't even adjusted my 24db slope crossovers yet and that bulge around 200hz really does give it some punch! I can't wait til these have had some time on them, I've done some measurements and they are dialed in properly!

The upper mid is a little harsh but I have a feeling this will evaporate in time.

I haven't even adjusted my 24db slope crossovers yet and that bulge around 200hz really does give it some punch! I can't wait til these have had some time on them, I've done some measurements and they are dialed in properly!

The upper mid is a little harsh but I have a feeling this will evaporate in time.

Attachments

Graham -notwithstanding my personal experience (bias? ) that B.B. sounds better, I’ve also found that painting exposed edges of MDF can be rather a lot of work- of course I guess that depends on your definition of “good”. That, and I just happen to prefer a speaker enclosure that looks like a piece of bespoke furniture.

But the important thing is that you’re happy with what they’re delivering to your ears.

But the important thing is that you’re happy with what they’re delivering to your ears.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- MLTL Floorstanders for Alpair 7MS