Finish

I think I'm beginning to see the problem with mdf.

-still doesn't seem too drastic though.

I was planning to try get a nice gloss finish, which is when the mdf issue came up.

-as I said, I've not done this before, but I imagine that in order to get a nice gloss finish, I would have to build up a fairly thick layer of whatever the finish was. I would also imagine that this mystery gloss layer would be light, and brittle. Surely this would help the mdf situation???

-If my gloss finish were to involve some sort of resin, I could even put e few layers of fiberglass fabric in too.

I know that ideally I should just ditch the mdf already, but assuming I'm a stubborn mule and I'll use it anyway, am I on the right track yet?

I think I'm beginning to see the problem with mdf.

-still doesn't seem too drastic though.

I was planning to try get a nice gloss finish, which is when the mdf issue came up.

-as I said, I've not done this before, but I imagine that in order to get a nice gloss finish, I would have to build up a fairly thick layer of whatever the finish was. I would also imagine that this mystery gloss layer would be light, and brittle. Surely this would help the mdf situation???

-If my gloss finish were to involve some sort of resin, I could even put e few layers of fiberglass fabric in too.

I know that ideally I should just ditch the mdf already, but assuming I'm a stubborn mule and I'll use it anyway, am I on the right track yet?

Re: Finish

Inside and out that is actually a better solution than laminating with formica/aborite...

dave

Raphael Shaw said:I could even put e few layers of fiberglass fabric in too.

Inside and out that is actually a better solution than laminating with formica/aborite...

dave

Progress

OK, I have started the boxes, but they will take a while.

- I am very interested in the EnABL process, I have been reading some good threads on it and it sounds very cool. I will carry on reading. In the mean-time, I'm going to practice EnABL'ing some cheap drivers that I have which have a similar size & shape paper cone to the the FE167e. I will let you all know how it goes.

-Also, I know this is usually the last thing to think about, and I'm only just beginning, but I was thinking about feet for the Demetri cabinet. As far as I can tell there is no real advantage to spikes... Any thoughts? I would like to put them on something though, for cosmetic reasons. I assume that with the Demetri design it would be good to keep it very close to the ground (not on stilts).

So I thought of making some small brass feet (round bottom).

-any thoughts??

I'm still unsure about a finish too. Gloss will be something new for me.

-has anyone done a gloss finish on fiber-glass/polyester resin.

-I guess it will be fairly straight forward.

OK, I have started the boxes, but they will take a while.

- I am very interested in the EnABL process, I have been reading some good threads on it and it sounds very cool. I will carry on reading. In the mean-time, I'm going to practice EnABL'ing some cheap drivers that I have which have a similar size & shape paper cone to the the FE167e. I will let you all know how it goes.

-Also, I know this is usually the last thing to think about, and I'm only just beginning, but I was thinking about feet for the Demetri cabinet. As far as I can tell there is no real advantage to spikes... Any thoughts? I would like to put them on something though, for cosmetic reasons. I assume that with the Demetri design it would be good to keep it very close to the ground (not on stilts).

So I thought of making some small brass feet (round bottom).

-any thoughts??

I'm still unsure about a finish too. Gloss will be something new for me.

-has anyone done a gloss finish on fiber-glass/polyester resin.

-I guess it will be fairly straight forward.

No Worries

Oh, well. done it now.

At least this way the sides will be braced a little better.

Thanks for the updated plans.

I have a question about the holey brace in the middle.

-why is it important that the two holes behind the driver are symmetrically positioned?

-and based on that reasoning, surely it's equally important that the angle just below the magnet is mirrored above it?

Oh, well. done it now.

At least this way the sides will be braced a little better.

Thanks for the updated plans.

I have a question about the holey brace in the middle.

-why is it important that the two holes behind the driver are symmetrically positioned?

-and based on that reasoning, surely it's equally important that the angle just below the magnet is mirrored above it?

Re: No Worries

It isn't important that it is symetrical. The 2 big holes are there to open up as much space as possible (with as little work as possible) and still retain a mechanical path directly from the back of the driver to the back of the box. This last is one of the suble design touches that i should be more explicit about...

dave

Raphael Shaw said:-why is it important that the two holes behind the driver are symmetrically positioned?

-and based on that reasoning, surely it's equally important that the angle just below the magnet is mirrored above it?

It isn't important that it is symetrical. The 2 big holes are there to open up as much space as possible (with as little work as possible) and still retain a mechanical path directly from the back of the driver to the back of the box. This last is one of the suble design touches that i should be more explicit about...

dave

Calculator for cone from flat material

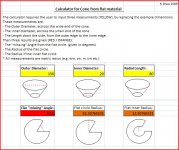

I have made this simple Excel calculator for making EnABL pattern stencils. It calculates the angle of a flat disc which would make a cone of a desired pitch, using easily measurable dimensions.

BudP must have used something similar here:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=100399&perpage=25&pagenumber=1

I hope it's usefull. Perhaps it could be added to the EnABL-Process thread???

*! -Oops, I can't attach an excel spredsheet.

I'll find somewhwere to post it, and add a link.

-or just ask, and I'll mail it to you.

Here is a screenshot, so you can get an Idea...

Raphael Shaw said:

- I am very interested in the EnABL process, I have been reading some good threads on it and it sounds very cool. I will carry on reading. In the mean-time, I'm going to practice EnABL'ing some cheap drivers that I have which have a similar size & shape paper cone to the the FE167e. I will let you all know how it goes.

I have made this simple Excel calculator for making EnABL pattern stencils. It calculates the angle of a flat disc which would make a cone of a desired pitch, using easily measurable dimensions.

BudP must have used something similar here:

Here is a sample cone you can cut out and make into a cone, either an innie or an outie. As you can see the block size in a ring set changes with the actual diameter that it must cover. The lisp program that I have performs all of these calculations and draws the resultant conic section as a flat surface. I have converted it ot a jpeg format for your convenience The specifications need to be for: The large cone opening diameter, or the diameter just at the lowest edge of the surround where it overlaps the cone. The small cone opening diameter, or where the center dome actually touches the cone surface. The material thickness, a guess will do. The length down the cone surface from the surround lower edge to the top edge of dome attachment, on the cone.

http://www.diyaudio.com/forums/showthread.php?s=&threadid=100399&perpage=25&pagenumber=1

I hope it's usefull. Perhaps it could be added to the EnABL-Process thread???

*! -Oops, I can't attach an excel spredsheet.

I'll find somewhwere to post it, and add a link.

-or just ask, and I'll mail it to you.

Here is a screenshot, so you can get an Idea...

Attachments

Ok, so down at the tip of Africa, I've been asured that Fostex no longer do the 167, and that the 166 is exactly the same.

-Sounds fishy to me, but there you have it.

So, after a 90 day import period, to only supplier in Cape Town, has 166s for me, instead of the 167s I ordered.

Is there perhaps a small mod I could do to the Deitri boxes I've nearly completed, which will make them '166 ready'?

-How major are the diferences?

-Sounds fishy to me, but there you have it.

So, after a 90 day import period, to only supplier in Cape Town, has 166s for me, instead of the 167s I ordered.

Is there perhaps a small mod I could do to the Deitri boxes I've nearly completed, which will make them '166 ready'?

-How major are the diferences?

Raphael Shaw said:Ok, so down at the tip of Africa, I've been asured that Fostex no longer do the 167, and that the 166 is exactly the same.

He is full of it. 166 may look the same from the front, but it is not the same driver at all -- i'd guess they didn't pay enuff attention and ordered the wrong driver and are now trying to stick you with their mistake ... you may be able to make it work by adding series resistance.

(I just recently received 21 FE167...)

So, after a 90 day import period, to only supplier in Cape Town, has 166s for me, instead of the 167s I ordered.

I'd be very tempted to get your money back and get a stock set from Madisound (make sure they check that the whizzers are on straight before they send them overseas). Depends on how willing you are to wait vrs how much you want to compromise all the work you've done.

http://www.madisound.com/catalog/product_info.php?products_id=271

How major are the diferences?

The FE166 really wants to be in a horn. Differences are substantial.

dave

planet10 said:

He is full of it. 166 may look the same from the front, but it is not the same driver at all -- i'd guess they didn't pay enuff attention and ordered the wrong driver and are now trying to stick you with their mistake

...

Differences are substantial.

-Thought so.

Thanks a lot for the response. I'll do what I can to source the 167s.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- ML TQWT for Fostex FE167e