That was the trickiest part of my build, too, but I did get it to work. I don't have any photos...

I do remember that the part of the holey brace that extends into the top corner between the drivers is very narrow.

Rest assured that it is definitely possible. I wish I could tell you how I did it exactly and provide photos.

I do remember that the part of the holey brace that extends into the top corner between the drivers is very narrow.

Rest assured that it is definitely possible. I wish I could tell you how I did it exactly and provide photos.

I don't have a "mono" mode or any other easy way to try true mono.

Play a mono recording

You don't know what you're missing  Much of the best music ever recorded was recorded in mono, and on valve gear, all that great jazz, for example, from the beginning of time till the late 50's early 60's. In fact much of it sounding better that the early stereo recordings where instruments were often panned too hard.

Much of the best music ever recorded was recorded in mono, and on valve gear, all that great jazz, for example, from the beginning of time till the late 50's early 60's. In fact much of it sounding better that the early stereo recordings where instruments were often panned too hard.

I'm always open to expanding my listening experiences. If you suggest some particularly well-recorded mono stuff I'd be happy to try to find it and give it a listen. I love (most) jazz but some of those old recordings are simply terrible. For example, as much as I love Django Reinhardt - much of the material I have found is almost unbearable to listen to. Sounds like a 70s am pocket radio.

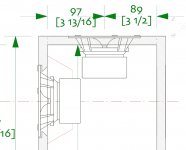

Magnets are so close

This is what it looks like when I try to lay out the holey brace. I intended to us a 4mm rebate. 3mm for the driver 1mm for the gasket in 15mm BB ply. That gives me 57.5mm from the back of the baffle to the back of the driver magnet. Top driver is centered and front driver is 3 7/8 from the bottom of the top baffle. I may be off a mm on the depth but I usually cut the rebate mount the driver and measure it again before finalizing the brace.

That method worked well for the brace in this pair of GR Slim cabinets.

This is what it looks like when I try to lay out the holey brace. I intended to us a 4mm rebate. 3mm for the driver 1mm for the gasket in 15mm BB ply. That gives me 57.5mm from the back of the baffle to the back of the driver magnet. Top driver is centered and front driver is 3 7/8 from the bottom of the top baffle. I may be off a mm on the depth but I usually cut the rebate mount the driver and measure it again before finalizing the brace.

That method worked well for the brace in this pair of GR Slim cabinets.

Attachments

My drivers are not that close, IIRC. If things really are that close, you could change your plan and surface mount the drivers. They left the bezel on the P7.2HD nice and thin to allow for it. Also, just cut the holey brace off square so it fits against both drivers.

EDIT: I don't know how I forgot this, but I just remembered that I had to cut off the top corner piece of my holey brace to retrofit the P7.2HD drivers in there. So yes, you are definitely going to need to just cut it off square so it butts up against both magnets.

EDIT: I don't know how I forgot this, but I just remembered that I had to cut off the top corner piece of my holey brace to retrofit the P7.2HD drivers in there. So yes, you are definitely going to need to just cut it off square so it butts up against both magnets.

Last edited:

Thank you Cogitech. I was wondering how you made yours fit. From what I remember your speakers needed spacers for mounting. So even if i flush mount them it only gains 4mm clearance. still so very close.

I am thinking about lowering the front driver a little. Maybe Dave can weigh in on that idea.

I am thinking about lowering the front driver a little. Maybe Dave can weigh in on that idea.

Mine needed spacers only because the P7.2HD are a couple of mm deeper from the bottom of the rim to the bottom of the magnet than the EL70.

What I failed to mention is that the P7.2HD magnet is slightly larger in diameter than EL70. That's actually the reason I had to trim that smaller corner piece off the holey brace.

I should pop a driver off and take a pic or two. I honestly think you can make it work just fine without relocating the driver. On the other hand, I doubt it would make much difference if you dropped the front drivers down a few mm. If a pic or two of mine will help, let me know and I will do that tomorrow

What I failed to mention is that the P7.2HD magnet is slightly larger in diameter than EL70. That's actually the reason I had to trim that smaller corner piece off the holey brace.

I should pop a driver off and take a pic or two. I honestly think you can make it work just fine without relocating the driver. On the other hand, I doubt it would make much difference if you dropped the front drivers down a few mm. If a pic or two of mine will help, let me know and I will do that tomorrow

Last edited:

You've both got me thinking I must have made my microTowers wrong all those years ago, because the P7.2HD fit fine in them. Top driver in centre and front driver in the default position in the plans.

Also, they seem to have fit fine in von Ah's microTowers, too.

Also, they seem to have fit fine in von Ah's microTowers, too.

Last edited:

Other than in clearance terms, unlikely to be hyper-critical anyway. I remember doing a similar enclosure with a slightly deeper form-factor, but the MicroTowers have that square aesthetic & are probably a better compromise in positioning too (assuming the top driver fits  ). Nice to see them getting an outing in the sun again.

). Nice to see them getting an outing in the sun again.

I have some ideas that may be workable.

1) Laminate 1/4 inch oak to the top plate and still use 4mm rebate. estimate the top driver moves up approx 6mm

2) use 18 mm top plate with 1/2 inch rabbit . top driver in 4 mm rebate moves up 6mm . adjust box volume with thicker bottom plate

3) Double up on the top plate. With 4mm rebate top driver moves up 15mm chamfer top driver opening.

Please let me know what you think of these ideas.

I really appreciate your help on these cabinets. I have liked the idea of the micro tower for a long time.

1) Laminate 1/4 inch oak to the top plate and still use 4mm rebate. estimate the top driver moves up approx 6mm

2) use 18 mm top plate with 1/2 inch rabbit . top driver in 4 mm rebate moves up 6mm . adjust box volume with thicker bottom plate

3) Double up on the top plate. With 4mm rebate top driver moves up 15mm chamfer top driver opening.

Please let me know what you think of these ideas.

I really appreciate your help on these cabinets. I have liked the idea of the micro tower for a long time.

I have some ideas that may be workable.

1) Laminate 1/4 inch oak to the top plate and still use 4mm rebate. estimate the top driver moves up approx 6mm

2) use 18 mm top plate with 1/2 inch rabbit . top driver in 4 mm rebate moves up 6mm . adjust box volume with thicker bottom plate

3) Double up on the top plate. With 4mm rebate top driver moves up 15mm chamfer top driver opening.

Please let me know what you think of these ideas.

I really appreciate your help on these cabinets. I have liked the idea of the micro tower for a long time.

I like all those ideas equally, but I need to elaborate on #1 a bit.

Embarrassingly, this is yet one more detail about my build that I completely overlooked and perfectly explains why I did not have any issue retrofitting the P7.2HDs into my cabinets.

When I built my cabinets, I didn't have a router (still don't) so I had no easy way to create a rebate for flush-mount EL70s. What I did instead was cut circles out of 1/4" plywood and laminate it on the top and a small square section of the front. This was easy for me with simple tools and created the rebate/flush-mount effect that I wanted.

The result, from an engineering standpoint, is that the drivers are actually surface mounted - giving me extra "wiggle room" between the drivers.

Now I am really curious what von Ah's cabinets are like - because the P7.2HDs seem to have slipped right in.

I am very sorry if my failure to mention all of this earlier has created issues for your build, Signal lost.

No worries my friend. All my builds have issues some external but most are internal.

Scott and Dave have been so generous with their plans that I have built a few of their designs. The holey braces have always been the most time consuming part. Just trying to get that right before the glue starts flowing.

Scott and Dave have been so generous with their plans that I have built a few of their designs. The holey braces have always been the most time consuming part. Just trying to get that right before the glue starts flowing.

- Home

- Loudspeakers

- Full Range

- microTower Revisited