Sorry folks I'm still slammed for the moment.

On the 48db crossover.... These TH boxes have a phase problem at 125hz or so, and I want steep cutoffs on each end of the usable range and cut down on xmax limits.

Let me see now what the heck am I running:

2 1000w per side amps, one Crest and one Tsunami on lows for a total of 4kw,

1 Crest ca12 at 12oow per side, 3 cabs per side

1 crest 2501 at 250 per side 3 horns per side

1/2 ashley 1400 on exciters

Monitors are 3 stewart pa-1400 channels with 3 boxes each.

Total of 3 monitor mixes increasing to 4.

Side fill left, sidefill right, center, and drummer mixes.

I have another ca-12 for the lows but it needs my undivided attention for a day before I risk running it in combat.

That would free up the two 1kw per ch amps for monitors.

My OT12 A-10's are gonna need the ports blocked on the stage side as I'm getting a lot of 400hz feedback I have to cut.

Yeah.. at 114 db at the booth and 106 at the back of the room I'd say it's pretty loud. Clear as glass.

You are all right about the distortion. Seems the monitors are never loud enough untill they are distorting. I tried overloading

one monitor eq at roughly 1/2 power and the band was content with it there versus the other feeds running clean.

Very screwey. Top notch performers however, love the system.

On monitors, someone reminded me of an often forgotten issue.

The bigger and better the monitor system the louder the band will play. Hmmmm. Very true, i forgot..

On the 48db crossover.... These TH boxes have a phase problem at 125hz or so, and I want steep cutoffs on each end of the usable range and cut down on xmax limits.

Let me see now what the heck am I running:

2 1000w per side amps, one Crest and one Tsunami on lows for a total of 4kw,

1 Crest ca12 at 12oow per side, 3 cabs per side

1 crest 2501 at 250 per side 3 horns per side

1/2 ashley 1400 on exciters

Monitors are 3 stewart pa-1400 channels with 3 boxes each.

Total of 3 monitor mixes increasing to 4.

Side fill left, sidefill right, center, and drummer mixes.

I have another ca-12 for the lows but it needs my undivided attention for a day before I risk running it in combat.

That would free up the two 1kw per ch amps for monitors.

My OT12 A-10's are gonna need the ports blocked on the stage side as I'm getting a lot of 400hz feedback I have to cut.

Yeah.. at 114 db at the booth and 106 at the back of the room I'd say it's pretty loud. Clear as glass.

You are all right about the distortion. Seems the monitors are never loud enough untill they are distorting. I tried overloading

one monitor eq at roughly 1/2 power and the band was content with it there versus the other feeds running clean.

Very screwey. Top notch performers however, love the system.

On monitors, someone reminded me of an often forgotten issue.

The bigger and better the monitor system the louder the band will play. Hmmmm. Very true, i forgot..

After reading the patent a couple of times, it states that the throat chamber has a small volume that acts as an low pass filter but does not have a (significant) effect on the low frequency response of the cabinet.So does this infringe on the TH idea?

I think this is what seperates cabinets like the t18, C15 (and those mentioned in this topic) from a tapped horn as patented, as these cabinets rely on a quite large throat chamber to get a significant low frequency response. Whereas a tapped horn following the patent doesn't.

Still leaves a grey line between effect on low frequency response or not but most models clearly pass.

Best regards Johan

Hi,

As this thread seems to have grown into the unofficial Danley patent thread, and without wanting to get too involved in the ongoing patent discussion (patent lawyers do make a fine living of arguing about what the definition of the word "is" is); I don't think one can get very far in describing the validity or applicability of a patent when there is little to no agreement on nomenclature, or accuracy in describing what we are talking about.

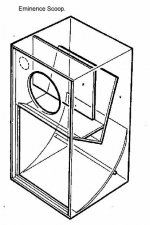

E.g.: the classic form of a scoop enclosure is a direct radiator with a rear-loaded horn, see: the enclosed Eminence sketch or the classic JBL C34 and C55. Nowadays, on the www, the term scoop is frequently used for all kinds of loudspeakers that do not conform to this classic model, ranging from "horn-loaded port" reflex enclosures to Cerwin Vega's EL-36B Earthquake Subwoofer. Somewhen along the time line the direct radiator wandered into the mouth of the rear-loading horn (e.g.: HOG2, Stipe Ercegovic, 2006). These driver in mouth rear-loaded horns are by present definition tapped horns, and should be technically treated as such. They may not have been tapped horns at the point of their conception, as the designer didn't know of the acoustic principles that would qualify his design as a tapped horn, but rather viewed it as a direct radiator with a back-loaded horn, which-as we now know-is not correct. In my opinion the first picture djk showed in Post #310 clearly fits the description of a tapped horn a la Tom Danley, as to the second or the one jbell references in Post #297: I have not found any internal design details, and consequently can offer no opinion.

The Transflex, various pipes, TQWT, end-loaded transmission lines and back-loaded horns all have been thrown into the discussion and all miss the point that in conception and design the tapped horn is a new and unique application of the laws of acoustics to the problem of low frequency reproduction. As close as I can tell, prior to Tom Danley's work there were no horns with relatively small mouth dimensions, wide frequency bandwidth and a reasonably flat frequency response extending below the free air resonance of the horn driver; and he achieved these characteristics through a unique way of driving a horn with both sides of the driver at different points of the horn, in other words both sides of the driver are energizing a tap inside the horn, and one of the taps can be the classic horn throat. I have no doubt, he deserves a patent for the uniqueness of his insights. If there had been anything obvious or self-evident about his invention, somebody would have done it much earlier.

William Cowan's, Walt de Jong's and Volvotreter's simple tapped horn enclosures all seem to fit the bill, and do not fit another specific enclosure form. Particularly WC's work is a great starting point for an understanding of tapped horns. All are very straight forward executions of a tapped horn and not transflexes or transmission lines. Maybe after knowing about tapped horns and with the fine analytical tools available today one can make the case that there are similarities, but that's about where it ends.

And finally, David McBean's Hornresp program has made it possible to design reasonable approximations of tapped horns, and from the time sequence it is pretty obvious that Danley's work triggered the interest in this type of horn design and David's very fine work, i.e.: Tapped Horn Wizard.

That's the long winded way of saying: I agree with iand's conclusion in Post #290.

Regards,

P.S.: Sorry screamer, I really like the pictures, do you have any more?

As this thread seems to have grown into the unofficial Danley patent thread, and without wanting to get too involved in the ongoing patent discussion (patent lawyers do make a fine living of arguing about what the definition of the word "is" is); I don't think one can get very far in describing the validity or applicability of a patent when there is little to no agreement on nomenclature, or accuracy in describing what we are talking about.

E.g.: the classic form of a scoop enclosure is a direct radiator with a rear-loaded horn, see: the enclosed Eminence sketch or the classic JBL C34 and C55. Nowadays, on the www, the term scoop is frequently used for all kinds of loudspeakers that do not conform to this classic model, ranging from "horn-loaded port" reflex enclosures to Cerwin Vega's EL-36B Earthquake Subwoofer. Somewhen along the time line the direct radiator wandered into the mouth of the rear-loading horn (e.g.: HOG2, Stipe Ercegovic, 2006). These driver in mouth rear-loaded horns are by present definition tapped horns, and should be technically treated as such. They may not have been tapped horns at the point of their conception, as the designer didn't know of the acoustic principles that would qualify his design as a tapped horn, but rather viewed it as a direct radiator with a back-loaded horn, which-as we now know-is not correct. In my opinion the first picture djk showed in Post #310 clearly fits the description of a tapped horn a la Tom Danley, as to the second or the one jbell references in Post #297: I have not found any internal design details, and consequently can offer no opinion.

The Transflex, various pipes, TQWT, end-loaded transmission lines and back-loaded horns all have been thrown into the discussion and all miss the point that in conception and design the tapped horn is a new and unique application of the laws of acoustics to the problem of low frequency reproduction. As close as I can tell, prior to Tom Danley's work there were no horns with relatively small mouth dimensions, wide frequency bandwidth and a reasonably flat frequency response extending below the free air resonance of the horn driver; and he achieved these characteristics through a unique way of driving a horn with both sides of the driver at different points of the horn, in other words both sides of the driver are energizing a tap inside the horn, and one of the taps can be the classic horn throat. I have no doubt, he deserves a patent for the uniqueness of his insights. If there had been anything obvious or self-evident about his invention, somebody would have done it much earlier.

William Cowan's, Walt de Jong's and Volvotreter's simple tapped horn enclosures all seem to fit the bill, and do not fit another specific enclosure form. Particularly WC's work is a great starting point for an understanding of tapped horns. All are very straight forward executions of a tapped horn and not transflexes or transmission lines. Maybe after knowing about tapped horns and with the fine analytical tools available today one can make the case that there are similarities, but that's about where it ends.

And finally, David McBean's Hornresp program has made it possible to design reasonable approximations of tapped horns, and from the time sequence it is pretty obvious that Danley's work triggered the interest in this type of horn design and David's very fine work, i.e.: Tapped Horn Wizard.

That's the long winded way of saying: I agree with iand's conclusion in Post #290.

Regards,

P.S.: Sorry screamer, I really like the pictures, do you have any more?

Attachments

tb46 said:Hi,

The Transflex, various pipes, TQWT, end-loaded transmission lines and back-loaded horns all have been thrown into the discussion and all miss the point that in conception and design the tapped horn is a new and unique application of the laws of acoustics to the problem of low frequency reproduction. As close as I can tell, prior to Tom Danley's work there were no horns with relatively small mouth dimensions, wide frequency bandwidth and a reasonably flat frequency response extending below the free air resonance of the horn driver; and he achieved these characteristics through a unique way of driving a horn with both sides of the driver at different points of the horn, in other words both sides of the driver are energizing a tap inside the horn, and one of the taps can be the classic horn throat. I have no doubt, he deserves a patent for the uniqueness of his insights. If there had been anything obvious or self-evident about his invention, somebody would have done it much earlier.

tb46 has hit the nail precisely on the head here; its Tom's new method of analysing and designing a tapped horn for a specific purpose that is the key to the patent, not whether the result ends up looking not dissimilar to BLH/scoops.

A patent can be granted for a new method of designing something if it gives some advantages that had not previously been realised -- like a new recipe using existing ingredients, but instead of just mixing them at random and hoping it tells you exactly how to get a Yorkshire pudding to rise properly

I've had exactly this type of argument with patent examiners on many occasions; sometimes you have to rewrite the patent or restrict the claims to avoid prior art, sometimes you have to persuade them that what you've come up with is novel -- and a valid reply to "It's obvious to anyone skilled in the art" (one reason for not granting a patent) is indeed "If it's so obvious then why did nobody in the past xx years think of it?".

Ian

To repeat what I stated earlier:

The tapped horn is nothing "new", Tom Danley made it work.

I don't question his patent issues, once again , he made it work.

Down here in south Florida no one has ever seen Danley's boxes or are aware of the USC1.... untill now. Word of them is getting around already and I am directing people to both Manufacturers.

Not that anyone has the money right now.

The tapped horn is nothing "new", Tom Danley made it work.

I don't question his patent issues, once again , he made it work.

Down here in south Florida no one has ever seen Danley's boxes or are aware of the USC1.... untill now. Word of them is getting around already and I am directing people to both Manufacturers.

Not that anyone has the money right now.

If one would be accused of TH patent infringement, one had to proove that the method described in the TH patent wasnt used in order to design the horn. How this proof would look is what i dont know. Well, sometimes it might be easy to see if the patent was involved, for example if the design was build in direct connection to a thread called "LIVE SOUND Specific Tapped Horn thread..."  But as long as noone complains...

But as long as noone complains...

Enough of the patent crap

Get the thread back on subject!

I still haven't got the B&C driver to match

Danleys output. Yet I got the 12 within a Db. of the Mini.

For close to the same price

as the 15" B&C I can go with 2 Lab12's and get in the 140 plus Db range (group of 4). 400 Lt cabinet. I haven't decided on exact layout yet. I am leaning toward having the drivers at an angle in the mouth.

Think something like Post #9 at the beginning of this thread. That way I can keep the width manageable. But I am curious how this will effect sound. If it all. Speculations?

Get the thread back on subject!

I still haven't got the B&C driver to match

Danleys output. Yet I got the 12 within a Db. of the Mini.

For close to the same price

as the 15" B&C I can go with 2 Lab12's and get in the 140 plus Db range (group of 4). 400 Lt cabinet. I haven't decided on exact layout yet. I am leaning toward having the drivers at an angle in the mouth.

Think something like Post #9 at the beginning of this thread. That way I can keep the width manageable. But I am curious how this will effect sound. If it all. Speculations?

FlipC said:Enough of the patent crap

Get the thread back on subject!

I still haven't got the B&C driver to match

Danleys output. Yet I got the 12 within a Db. of the Mini.

For close to the same price

as the 15" B&C I can go with 2 Lab12's and get in the 140 plus Db range (group of 4). 400 Lt cabinet. I haven't decided on exact layout yet. I am leaning toward having the drivers at an angle in the mouth.

Think something like Post #9 at the beginning of this thread. That way I can keep the width manageable. But I am curious how this will effect sound. If it all. Speculations?

I'd really like to see your dual Lab12 HR input/response screens. I've been trying for some time to get a reasonable dual Lab12 design going because I like those drivers. They seem to have a very good price/performance ratio. At the moment, I'm looking very seriously at a Ciare SW12.00 TH design because it seems to be the best driver for a small (< 250L) TH that can get down to the mid-30's. But, it's quite power hungry and I'd like to get a bit more efficiency. The Lab12's might just do this. So, I would really appreciate seeing your design.

craigwalsh -

S1 = 143.00e-4;

S2 = 168.00e-4;

S3 = 2593.44e-4;

S4 = 2842.00e-4;

L12 = 8.10e-2;

L23 = 302.50e-2;

L34 = 19.00e-2;

Sd=506.70cm2

Bl=15.00Tm

Cms=3.40E-04m/N

Rms=1.60Ns/m

Mmd = 146.50g

Le=1.50mH

Re=4.30ohm

TH 2P

At what SPL do you want to hit those 30 Hz notes?

The cut off on the above is 32hz as is. I cant recall coming up with anything in the 250Lt range that will hit into the 30's. But again I guess it will depend on the volume level you are looking for.

I would love to build a TH to cover just 20-40 Hz. at 130 plus DB.

That would be lovely. The only thing I have ever built like that was some 18 cft McCauley 6174 reflex.

tb46 -

In pic one with its push pull you loose diaphragm area. Since this is a Pro PA. The clarity gained from a push pull isn't as important as over SPL.

As far as the second one. That is 2 separate subs.

I do like the resonator there. Do you have either HR or Akabak inputs for this? I am learning Akabak but dont have a clue as to how to input a resonator as such.

My thinking is more along the lines

of a Th 115 style where both drivers are at a V in the mouth but aren't vertical like the pic on Post #9. I have only been sketching so far.

S1 = 143.00e-4;

S2 = 168.00e-4;

S3 = 2593.44e-4;

S4 = 2842.00e-4;

L12 = 8.10e-2;

L23 = 302.50e-2;

L34 = 19.00e-2;

Sd=506.70cm2

Bl=15.00Tm

Cms=3.40E-04m/N

Rms=1.60Ns/m

Mmd = 146.50g

Le=1.50mH

Re=4.30ohm

TH 2P

At what SPL do you want to hit those 30 Hz notes?

The cut off on the above is 32hz as is. I cant recall coming up with anything in the 250Lt range that will hit into the 30's. But again I guess it will depend on the volume level you are looking for.

I would love to build a TH to cover just 20-40 Hz. at 130 plus DB.

That would be lovely. The only thing I have ever built like that was some 18 cft McCauley 6174 reflex.

tb46 -

In pic one with its push pull you loose diaphragm area. Since this is a Pro PA. The clarity gained from a push pull isn't as important as over SPL.

As far as the second one. That is 2 separate subs.

I do like the resonator there. Do you have either HR or Akabak inputs for this? I am learning Akabak but dont have a clue as to how to input a resonator as such.

My thinking is more along the lines

of a Th 115 style where both drivers are at a V in the mouth but aren't vertical like the pic on Post #9. I have only been sketching so far.

Hi FlipC,

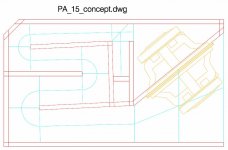

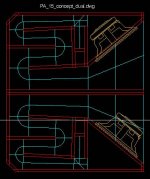

Picture 1, Post #349, was just to show the concept of a box that can be arranged in multiples with the magnet pointing into the throat chamber or into the mouth, or as a dual with side by side speakers in a push-pull arrangement (thus the two drivers). Picture 2, Post #350, shows two of these enclosures mounted against each other. What looks like a resonator is just the L12 section of the horn, but could well be room for a resonator. What I like about this internal arrangement is that it lends itself to easier tuning and experimenting than some of the other tapped horn enclosures. Even an extension of the horn length can be achieved without changing the driver chamber, throat or mouth by simply increasing the depth of the enclosure. In other words these pictures are mainly a layout concept.

In the "Collaborative Tapped horn project", Post #1177 Mavo shows how to model a tapped horn including a 1/4 WL resonator. In Post #1187 Cordraconis did "AkAbak TH's for Dummies" with explanations (from that I nearly got it ). Cordraconis, MaVo and jnb have all kinds of interesting helpful information for AkAbak on pages: 46-48 of the big thread. Hope that helps.

). Cordraconis, MaVo and jnb have all kinds of interesting helpful information for AkAbak on pages: 46-48 of the big thread. Hope that helps.

Regards,

Picture 1, Post #349, was just to show the concept of a box that can be arranged in multiples with the magnet pointing into the throat chamber or into the mouth, or as a dual with side by side speakers in a push-pull arrangement (thus the two drivers). Picture 2, Post #350, shows two of these enclosures mounted against each other. What looks like a resonator is just the L12 section of the horn, but could well be room for a resonator. What I like about this internal arrangement is that it lends itself to easier tuning and experimenting than some of the other tapped horn enclosures. Even an extension of the horn length can be achieved without changing the driver chamber, throat or mouth by simply increasing the depth of the enclosure. In other words these pictures are mainly a layout concept.

In the "Collaborative Tapped horn project", Post #1177 Mavo shows how to model a tapped horn including a 1/4 WL resonator. In Post #1187 Cordraconis did "AkAbak TH's for Dummies" with explanations (from that I nearly got it

Regards,

Message from David McBean

IMPORTANT UPDATE - HORNRESP VERSION 21.10

Hi Everyone,

Yesterday I discovered that the input data validation and error-handling routines that had worked so well in the Visual Basic 3 implementation of Hornresp (and also in the Visual Basic 6 development environment) produced somewhat different results when compiled into the VB6 production version of the program.

This rather serious inconsistency was caused by a problem with Visual Basic 6 itself, rather than being due to any coding bug in the program. As a matter of urgency though, I have changed the routines so that Hornresp again now operates as it should.

I strongly recommend that you upgrade to the new release. Sorry for any inconvenience caused by the incorrect operation of the old VB6 input validation routines.

Could you please spread the word regarding the new Hornresp release via any other Forums that you might visit. Many thanks.

Kind regards,

David

IMPORTANT UPDATE - HORNRESP VERSION 21.10

Hi Everyone,

Yesterday I discovered that the input data validation and error-handling routines that had worked so well in the Visual Basic 3 implementation of Hornresp (and also in the Visual Basic 6 development environment) produced somewhat different results when compiled into the VB6 production version of the program.

This rather serious inconsistency was caused by a problem with Visual Basic 6 itself, rather than being due to any coding bug in the program. As a matter of urgency though, I have changed the routines so that Hornresp again now operates as it should.

I strongly recommend that you upgrade to the new release. Sorry for any inconvenience caused by the incorrect operation of the old VB6 input validation routines.

Could you please spread the word regarding the new Hornresp release via any other Forums that you might visit. Many thanks.

Kind regards,

David

FlipC said:For close to the same price

as the 15" B&C I can go with 2 Lab12's and get in the 140 plus Db range (group of 4). 400 Lt cabinet. I haven't decided on exact layout yet. I am leaning toward having the drivers at an angle in the mouth.

Think something like Post #9 at the beginning of this thread. That way I can keep the width manageable. But I am curious how this will effect sound. If it all. Speculations?

craigwalsh said:I'd really like to see your dual Lab12 HR input/response screens. I've been trying for some time to get a reasonable dual Lab12 design going because I like those drivers. They seem to have a very good price/performance ratio. At the moment, I'm looking very seriously at a Ciare SW12.00 TH design because it seems to be the best driver for a small (< 250L) TH that can get down to the mid-30's. But, it's quite power hungry and I'd like to get a bit more efficiency. The Lab12's might just do this. So, I would really appreciate seeing your design.

What if dual Lab12s are used in 'isobaric' configuration, mounted face to face? One driver close to the mouth and the other driver firing into the horn will result in the drivers seeing a stiffer acoustic spring, hopefully the horn cross section will get smaller and push-pull will cancel distortion.

Yeah, I've got laying around a couple of first generation Shiva 12s that the Lab12 is based on and did an isobaric max BW calc awhile back out of curiosity when WC first posted his TH designs. Loading it into HR and shortening it up yields a nominally flat response from 40 - 160 Hz/125 dB/2pi space/Xmax/300 W each driver/~252 L net once damped, so I imagine isobaric Lab12s will do about the same.

GM

GM

I would expect the Lab12 drivers to be able to handle more than 300 watts of power each, given the combined loading of Isobaric and TH, before reaching xmax. Screamersusa, found the power handling to dramatically increase for the Kappalite 4015 drivers which he is now using.

Also lengthening the horn enough to reach the mid 30s would be good. Then one can have a PA sub which is compact compared to TD's LabSubwoofer or Wayne's 12Pi, both of which use dual Lab12 drivers.

But then max spl in the region of 130db plus would make the design a worthy candidate. Otherwise, venturing on this line of thought would be fruitless.

Thanks GM for your informative posts which keeps firing imaginations while also often pulling one back to technical correctness.

Also lengthening the horn enough to reach the mid 30s would be good. Then one can have a PA sub which is compact compared to TD's LabSubwoofer or Wayne's 12Pi, both of which use dual Lab12 drivers.

But then max spl in the region of 130db plus would make the design a worthy candidate. Otherwise, venturing on this line of thought would be fruitless.

Thanks GM for your informative posts which keeps firing imaginations while also often pulling one back to technical correctness.

You're welcome!

Yes, it seems reasonable to me that a bone fide TH will have a greater acoustic power potential than the simple end loaded pipe horns. Regardless, an isobaric loading reduces throat size, so at a near 6:1 CR, I imagine it will be thermally limited, though in each case, not actually having built/measured one yet, I'm stuck with whatever a sim predicts and/or my experiences with FL compression horns.

GM

Yes, it seems reasonable to me that a bone fide TH will have a greater acoustic power potential than the simple end loaded pipe horns. Regardless, an isobaric loading reduces throat size, so at a near 6:1 CR, I imagine it will be thermally limited, though in each case, not actually having built/measured one yet, I'm stuck with whatever a sim predicts and/or my experiences with FL compression horns.

GM

- Home

- Loudspeakers

- Subwoofers

- Live sound specific Tapped Horn thread...