Here is a very informative article.

http://www.surface.tulane.edu/pdf/surface science of Tin Oxide.pdf

jer

http://www.surface.tulane.edu/pdf/surface science of Tin Oxide.pdf

jer

Correct. The early Licron (product 1755) used Tin Oxide, but Licron Crystal (product 1756) uses a conductive polymer.The data sheet lists some unnamed "proprietary polymers"; which are likely the conductive components.

You may recall a discussion in the coatings thread concerning the shelf life of Staticide 6300 and Licron Crystal.

Both use conductive polymers that:

"...are susceptible to bacteria once they are exposed to air in their liquid state. The product will “spoil” much the same way milk will spoil from bacteria exposure after a short period of time even if it’s kept cold. As the product "spoils" the resistivity increases until the the coating no longer conducts. However, once the liquid (while still “fresh”) is applied and dries to a film, it no longer is susceptible to bacteria."

The shelf life for Licron in the spray can seems to be much longer, but unspecified.

The Tech Rep I talked to said 2 years was a good rule of thumb.

As far as coating application, I agree that there is little concern for adding mass. Even two heavy wet coatings add little mass.

http://www.diyaudio.com/forums/planars-exotics/186840-david-lucas-esl-6.html#post3610816

im not afraid of thick coating  i am afraid of losing conductivity after i sold the pair. for now they sound good again as loud as the original and the faint windy noise when playing loud test tones are gone to. it was the adhesion of the mylar near the edge of the stator frame, i ran some cyanoacrylate down where the mylar meets the stator. since cyanoacrylate so thin it works itself in between the stator and the plastic leaving no goo or buildup. result is clean sounding stator without having to redo the whole thing (only used few drops)

i am afraid of losing conductivity after i sold the pair. for now they sound good again as loud as the original and the faint windy noise when playing loud test tones are gone to. it was the adhesion of the mylar near the edge of the stator frame, i ran some cyanoacrylate down where the mylar meets the stator. since cyanoacrylate so thin it works itself in between the stator and the plastic leaving no goo or buildup. result is clean sounding stator without having to redo the whole thing (only used few drops)

. im happy. next time i use better glue

. im happy. next time i use better glue

Last edited:

When I first sprayed my fresh can of the Crystal version, I sprayed it into a paper towel to fully purge the filler tube.

It appeared as if it was the very same material and color only a bit lighter then the original Licron formula.

It looked as if it was ground a lot finer and more refined.

It had made such a big hit in the industry that it does not surprise me that they are trying to use such fancy words as proprietary.

It is too bad, I guess we will never really know!!

Except that it does work!!

I was still using my 12 year old can of Licron until earlier this year when a Pinhole formed from a rust spot on the can and caused what was left to leak out everywhere, one day when I just happened to not be home that day, and ruined the top of my dresser cabinet.

I want to to use it for a particular experiment since it had a much lower resistance than Crystal does if it is sprayed on thicker.

It was directly driven a electrically segmented Diaphragm idea that I had wanted to try and now you can't even get the stuff anymore!!

FWIW

jer

It appeared as if it was the very same material and color only a bit lighter then the original Licron formula.

It looked as if it was ground a lot finer and more refined.

It had made such a big hit in the industry that it does not surprise me that they are trying to use such fancy words as proprietary.

It is too bad, I guess we will never really know!!

Except that it does work!!

I was still using my 12 year old can of Licron until earlier this year when a Pinhole formed from a rust spot on the can and caused what was left to leak out everywhere, one day when I just happened to not be home that day, and ruined the top of my dresser cabinet.

I want to to use it for a particular experiment since it had a much lower resistance than Crystal does if it is sprayed on thicker.

It was directly driven a electrically segmented Diaphragm idea that I had wanted to try and now you can't even get the stuff anymore!!

FWIW

jer

Last edited:

It's simple. 6um film weighs 8g per m^2. According to tds there are 10% of SnO2 per volume. Recommended use is 236 ml per 20 m^2. This leaves us with 12 ml of Licron per m^2. SnO2 @ density of 7 g per cm^3 & 10 volume % yeilds 12x0.1x7=8.4g per m^2.

Sure 8.4 g per m^2 is negligibly small in regard to 8 g per m^2 weight of 6um Mylar.

Sure 8.4 g per m^2 is negligibly small in regard to 8 g per m^2 weight of 6um Mylar.

Hi, I recently rebuilt the panels on my ML Clarity and could not use Licron Crystal as it wasn't available in my area and couldn't be shipped due to it being a hazardous good.

I found a company called Shanghai HuZheng Nanotech on Alibaba and placed an order for their anti-static coating (min 1 litre) for US$80.

The company rep Annie said it was similar to Techspray Licron Crystal which others have used on the forum.

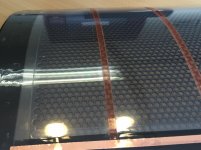

Huzheng said to dilute their coating 1:1 with alcohol and it would achieve a resistivity of E7 to E9 and dry to approx 2 microns thick. They said this was a new coating and would last for 10 years at least. I spray tested it on the undamaged portion of the old Mylar after cleaning and it seemed to stick on perfectly (see pics of the iridescent coating). I tried scratching it with my finger, but it stuck on.

After consulting with Rob from ERAudio, I decided to go with his tried and tested coating. See the second pic (the light black line close to the spars is the coating). I hadn't planned to test coatings and rebuilding the panels again.

I have about half a litre of the coating left and can put it in small bottles and send it across if anyone is interested.

I found a company called Shanghai HuZheng Nanotech on Alibaba and placed an order for their anti-static coating (min 1 litre) for US$80.

The company rep Annie said it was similar to Techspray Licron Crystal which others have used on the forum.

Huzheng said to dilute their coating 1:1 with alcohol and it would achieve a resistivity of E7 to E9 and dry to approx 2 microns thick. They said this was a new coating and would last for 10 years at least. I spray tested it on the undamaged portion of the old Mylar after cleaning and it seemed to stick on perfectly (see pics of the iridescent coating). I tried scratching it with my finger, but it stuck on.

After consulting with Rob from ERAudio, I decided to go with his tried and tested coating. See the second pic (the light black line close to the spars is the coating). I hadn't planned to test coatings and rebuilding the panels again.

I have about half a litre of the coating left and can put it in small bottles and send it across if anyone is interested.

Attachments

THE rainbow colour reminds me of the static spray that works with humidity . Just like soap and THE pva glue. I ordered 200 grams of Carbon black pigment yesterday. To see if I can make anything that comes close to the exl63 coating. Since I kind of having problems with my current Licron coating.

I used tattoo ink With high consentrate of Carbon black , but because there is a binder in that stuff (water based) I cant just use it with solvents like acetone and mek and polyurethane wich dissolves in both.

It does work with alcohol, but getting an even coating is hard , it tends to dry up spotty and ugly.

I used tattoo ink With high consentrate of Carbon black , but because there is a binder in that stuff (water based) I cant just use it with solvents like acetone and mek and polyurethane wich dissolves in both.

It does work with alcohol, but getting an even coating is hard , it tends to dry up spotty and ugly.

Last edited:

@neil5m Could you somewhat elaborate.

Which material is it? Does company sell directly?

Hi Alex, apologies for the delayed reply. I just know it is an alcohol based liquid. Smells solvent like, not like the black marker or like glue (fishy smell). Model No: RB-048. I'll send some across to you in a small bottle. Since its a liquid, its cheap to send by normal mail.

Just go on to Alibaba and type Shanghai HuZheng Nano Tech (this is the link: Shanghai Huzheng Nano Technology Co., Ltd. - Heat Insulation UV Coating,Self-Cleaning Coating). There is a live chat feature where you can message a representative. They have several coatings including an Antimony Tin Oxide antistatic coating in a liquid form. The minimum order is 1 litre.

The lady I spoke to was Annie Li. She knows English and is helpful. Her email is lij@hznano.com. She can pass on your questions to the technical team. They replied to mine regarding resistivity etc. They sell directly and ship it to you.

Details of the Coating (RB-048) and ATT-065

Product Introduction

With conductive nano-material’s ultra fine particle size, it has a better transparency, especially the use of nano-inorganic composite conductive material make it with good surface hardness, strong tolerable of high temperature and long-term efficiency advantages. It can be widely applied to the materials for electronics, information, packaging, transport, transparent light emitting.

Product Name:Transparent antistatic coating

Huzheng’s new anti-static coatings, based on the technology of electroactive polymers, provide a safe, long-lasting solution to electrostatic charge problems. RB-048 is compatible with many different materials, work in dry or humid environments, and dissipate static charge buildup in milliseconds, when grounded. They can be applied by spraying, spin coating, or brush application processes that ensure uniform, thin films.

Huzheng's anti-static coatings are customizable:

Huzheng’s unique anti-static coatings can be customized to meet your needs. Potential applications include electronic packaging, metal, marble, textile,PP film, PET film ,air-dry or clean room systems, window or screen displays, or even aircraft canopies. Our anti-static coatings work equally well in dry or humid environments.

Coating Types:

Transparent colorless anti-static coating: RB-048

Transparent conductive coating (blue): ATT-065

Coating 1: RB-048

Product Name: Transparent colorless anti-static coating

Code: RB-048

CAS No.: 2588-1237-78

Appearance: Colorless and transparent liquid

Other Names: conductive paint

MF: ATO

Main Raw Material: ATO solution

Major ingredient:High polymer

PH value: 5.5

Density: 0.88g/ml

Conductivity: 1 x 107-9Ω.cm

Solvent: Alcohol

Surface drying time: 4-5 minutes

Average particle size: 5-10 nm

Curing temperature: Room temperature

Adhesion: 0 level

Application fields: Electronics product packaging, anti-static coating, synthetic fiber, Kraft paper, plastic molding products, plastic sheeting, polycarbonate, vinyl chloride, methyl acrylate, ABS plastic plate.

Application: brush- coating, spray- coating and roll coating

Coating 2: ATT-065

Product Name: Transparent conductive coating

Code: ATT-065

Appearance:Blue liquid

Major ingredient: Nano oxide

PH value: 8.0±0.5

Density: 1.45g/cm3

Conductivity: 1 x 104-5Ω.cm

Solvent: Water

Surface drying time:10-15 minutes

Average particle size:5-10 nm

Curing temperature: Room temperature

Adhesion: 0 level

Main Applications: It can be applied to the producing of of transparent electrodes and soft circuits, compartment glass, walls, floors and other surface coating treatment of electronic information room. Other fields of electronic signal shielding, electromagnetic wave shielding as well as anti-static.

Environmental performance:Safe and environmental protection

Attachments

Hi, I recently rebuilt the panels on my ML Clarity and could not use Licron Crystal as it wasn't available in my area and couldn't be shipped due to it being a hazardous good.

I found a company called Shanghai HuZheng Nanotech on Alibaba and placed an order for their anti-static coating (min 1 litre) for US$80.

The company rep Annie said it was similar to Techspray Licron Crystal which others have used on the forum.

Huzheng said to dilute their coating 1:1 with alcohol and it would achieve a resistivity of E7 to E9 and dry to approx 2 microns thick. They said this was a new coating and would last for 10 years at least. I spray tested it on the undamaged portion of the old Mylar after cleaning and it seemed to stick on perfectly (see pics of the iridescent coating). I tried scratching it with my finger, but it stuck on.

After consulting with Rob from ERAudio, I decided to go with his tried and tested coating. See the second pic (the light black line close to the spars is the coating). I hadn't planned to test coatings and rebuilding the panels again.

I have about half a litre of the coating left and can put it in small bottles and send it across if anyone is interested.

Is it the RB-048 coating?

Yes Jonas, It is the RB-048 coating. I still have some and can send to you. I gave details in a reply to Alex. See post #30 in this thread.Is it the RB-048 coating?

well, i re coated them and added the traces that connect to the aluminium strips...2 months back

i am NOT PLEASED! i had them all nice and assembled. but again losing output 2 months later. i get sick of this crap. in my opinion licron sucks. a freshly panel i got a reading of 80 to 120 M Ohm. just 2 coins on the panel and measure. it is not a proper square/ohm reading and not with high voltage.

After 2 months some panels dont have a reading at all on the 200Meg setting..... but on a original panel i get 6-20 Mega ohm...... pretty low. but its not the true resistance. it is just a comparison. if i want to replicate original panels i should get the same resistance with the same measure method and meter. regardless of measuring method. since i use the same for both. i might be moving to another city but then i will conduct some tests for a coating, since i get sick of the magic randomly vanishing licron, witch cost a pretty dime as well. i go back to what quad used either carbon or combination of carbon and graphite. at least there coating stays for 30 years.

i recoated oen panel with carbon (to low resistance) but output is higher then any panel coated with licron.... the vanishing goes ever so slightly so i did not even notice it on the best sounding speaker. but now i know they did lose ouput since my left speaker is playing as loud as the good sounding right speaker with 1 panel less, and there is even a difference in output between the panels on the left one, i can hear that without even measuring. so the one coated with carbon makes up for the shitty ones and still sounds louder then the right speaker.

i do have to admit this test panel has way to low resistance (<1 Meg)and when driven hard it will flash over to the coating. so upping that is a must, not only because of migration, but also power handling. since the old ESL63 does not have a coating on the copper clad

i am NOT PLEASED! i had them all nice and assembled. but again losing output 2 months later. i get sick of this crap. in my opinion licron sucks. a freshly panel i got a reading of 80 to 120 M Ohm. just 2 coins on the panel and measure. it is not a proper square/ohm reading and not with high voltage.

After 2 months some panels dont have a reading at all on the 200Meg setting..... but on a original panel i get 6-20 Mega ohm...... pretty low. but its not the true resistance. it is just a comparison. if i want to replicate original panels i should get the same resistance with the same measure method and meter. regardless of measuring method. since i use the same for both. i might be moving to another city but then i will conduct some tests for a coating, since i get sick of the magic randomly vanishing licron, witch cost a pretty dime as well. i go back to what quad used either carbon or combination of carbon and graphite. at least there coating stays for 30 years.

i recoated oen panel with carbon (to low resistance) but output is higher then any panel coated with licron.... the vanishing goes ever so slightly so i did not even notice it on the best sounding speaker. but now i know they did lose ouput since my left speaker is playing as loud as the good sounding right speaker with 1 panel less, and there is even a difference in output between the panels on the left one, i can hear that without even measuring. so the one coated with carbon makes up for the shitty ones and still sounds louder then the right speaker.

i do have to admit this test panel has way to low resistance (<1 Meg)and when driven hard it will flash over to the coating. so upping that is a must, not only because of migration, but also power handling. since the old ESL63 does not have a coating on the copper clad

Last edited:

WrineX

Sorry to hear...

WHat about rubbing in graphite first and then a layer of licron?

well rubbing in graphite is a no no no go :0 its messy and will fall of over time. adding licron wont do anything since the the resistance will be of the one with the lowest Resistance.(the graphite that is

i just might have to buy a commercial product or make something of my own. i know acryl will stick well to mylar, also polyurethane will do the job, but it is harder to dilute(acetone, but it evaporates to quick to spray)

it is still allot of work to balance the medium/carbon/and the stuff to dilute. to get to a good resistance and well balanced thickness for spray application without the carbon wondering around in the medium or form droplets. as well as having a coating that most of the ingredients evaporates to leave a very thin coating.

i bought a blender to get the carbon suspended in the medium, works rather good, but i think i will remove the blades and put them in my left over spindle that can reach up to 20K rpm to do some shear mixing.

aaah well, if you dont try ........ you never know.

i must admit it feels a bit like a massive failure to have to take them apart again

Last edited:

Jim Strickland Acoustat....used Ampex magnetic coating...it works..last...we got get some...yes no maybe...... see pic from heating.....with a hair dryer...

panting it on....Wow.....I think that's Roy E....an Jim in front of whit I wish I had a new pr of M3s..............................

panting it on....Wow.....I think that's Roy E....an Jim in front of whit I wish I had a new pr of M3s..............................

Attachments

Last edited:

@WrineX,

There are basically 2 main products on avail.

Conductive polymer in acrylic or urethane based binder which could be Licron or Staticide as well as others you you search diligently enough.

The second one is plain polyamide which is hygroscopic thus retaining water on the surface which is somewhat conductive. Polyamide does not adhere well so phenol is used to promote it. Making proper coating is not easy as it sounds aka painting the fence with the brush vs painting the car. Practice makes it perfect. So start with small pieces of film and make it consistent. Clean the film properly. ESL manufacturers most likely use some kind of surface activation.

In regard to carbon or aquadag you are going to use. Soot or carbon black has a flake kind of form that creates chain/screen structure that conducts withing the binder. Ball like shaped colloidal graphite is suspended in isolation binder making near perfect isolator. So unless you know how to make fiber like carbon particles this method is useless. BTW there is a guy on you tube claiming to make nanotubes by household blender.

There are basically 2 main products on avail.

Conductive polymer in acrylic or urethane based binder which could be Licron or Staticide as well as others you you search diligently enough.

The second one is plain polyamide which is hygroscopic thus retaining water on the surface which is somewhat conductive. Polyamide does not adhere well so phenol is used to promote it. Making proper coating is not easy as it sounds aka painting the fence with the brush vs painting the car. Practice makes it perfect. So start with small pieces of film and make it consistent. Clean the film properly. ESL manufacturers most likely use some kind of surface activation.

In regard to carbon or aquadag you are going to use. Soot or carbon black has a flake kind of form that creates chain/screen structure that conducts withing the binder. Ball like shaped colloidal graphite is suspended in isolation binder making near perfect isolator. So unless you know how to make fiber like carbon particles this method is useless. BTW there is a guy on you tube claiming to make nanotubes by household blender.

@WrineX,

There are basically 2 main products on avail.

Conductive polymer in acrylic or urethane based binder which could be Licron or Staticide as well as others you you search diligently enough.

The second one is plain polyamide which is hygroscopic thus retaining water on the surface which is somewhat conductive. Polyamide does not adhere well so phenol is used to promote it. Making proper coating is not easy as it sounds aka painting the fence with the brush vs painting the car. Practice makes it perfect. So start with small pieces of film and make it consistent. Clean the film properly. ESL manufacturers most likely use some kind of surface activation.

In regard to carbon or aquadag you are going to use. Soot or carbon black has a flake kind of form that creates chain/screen structure that conducts withing the binder. Ball like shaped colloidal graphite is suspended in isolation binder making near perfect isolator. So unless you know how to make fiber like carbon particles this method is useless. BTW there is a guy on you tube claiming to make nanotubes by household blender.

yes i know this guy (Robert Murray-Smith), he does allot with carbon and graphite etc. but all things are not the proper product he calls it . at least maybe in a crude form they are. i got carbon black from a paint supplier, and i can get conductivity pretty easy. it is harder to hit the 20-50Meg on my meter and my measure method (this is not the actual resistance but my comparison). it is easy to undershoot and overshoot until not able to measure at all. or to get a very low resistance. anyhow with acrylic or polyurethane and this carbon black it is possible. the best bet to have any control is making the coating so that you have to use 2 or 3 coats. this way the lack of control when coating is devided by 3 so i get a more even coating then using a thicker one that reaches right conductivity with only one coat.

you can Taylor it more easy to with the amount of coats.

as you mentioned carbon black is very often , not able to make the links when diluted to heavy. using the blender increased the amount i could dilute it, also powder is not easy to disperse in a liquid without forming globs. with a blender this is not a problem. if you want to do it by hand use a paint Technic,first make a paste then dilute. use a flat surface and a heavy smooth object to massage the carbon and liquid into a paste. (it a bit like cooking , you never add flower straight into the saus, first make a paste

btw is there anyone that could make a measurement with just 2 coins spaced 1-2 cm apart on a quad membrane ? since i get a pretty low reading witch would not hold against migration talked about in all patents of quad/walker. so either they did not care much or what i measure is essential way way way much higher then the reading suggests

from the 2 choices i prefer the polyurethane or acrylic. and not the polyamide since i dont like coatings that are affected by moisture.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Licron Crystal lifetime?

![Nov20_2002_01%2020[1].jpg](/community/data/attachments/481/481928-142c92b0a1129df3501d6248ba82c0fa.jpg)

![images[9].jpg](/community/data/attachments/481/481930-aebd6944208d4a7cbc1ceef4988ee808.jpg)

![Acoustat%20pics[1].jpg](/community/data/attachments/481/481939-cbd7e1615146187627eb14ab839c1bd5.jpg)

![images[9] (2).jpg](/community/data/attachments/481/481942-e5bc68e0ca74d863b99b1e856047ebc3.jpg)