An interesting approach in this camera slider

And once again: @fluid to the rescue!

So simple it was first time right (enough ;-) ). It's a little less compact and limits the maximum motion of the system a bit, but that's ok for me.

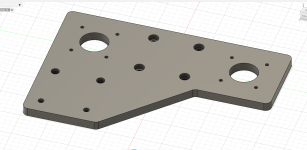

And a sneak preview of the microphone holder:

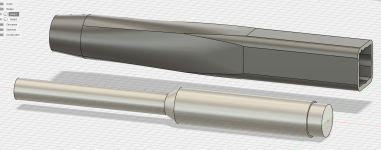

It looks like the cable just fits the slot in the profile.

This is not true. There is open source code from NTK that is similar to how the NFS works. The theory behind how the NFS works was not invented by Klippel. Many people know how to do it, what there isn't yet is all the parts made to work together.But 'till now only Geddes and Klippel know how to do it, and they won't tell.

Earl's approach is not the same. He has been open about how it works so it is unfair and untrue to say he won't tell.

Ascend used an NFS to create a compensation curve. Klippel has offered that function in a cheaper product for a long time. It requires you have an anechoic response in the first place, it is not a way to get one without already having one. That would work well for production line checks just like the setup seen in Kii's factory.

You can't use it to remove the sound of the room from the speakers in listening.

Almost everything you have said is either untrue or misunderstood. Tom is making good progress, perhaps soon there will be something that has all the parts together.

Klippel can get rid of the room it would be a goddamn gift to humanity because you could trow all that crappy room correction software out and have perfect solution.

A double bass array gets rid of a load of interfering freqs.

Well... you exclude the room from the processed data collected with a microphone, not the sound coming out of the speaker and into your ears. But once you have that information you could indeed use it in concert with a "room correction" system to provide guidance on what shouldn't be EQ'd. But in the end, the intent of room correction isn't to remove the room, but rather to minimize the undesirable effects of lower frequency reflections.You measure the sound the speaker generates in 2 positions and you can exclude the room. So when you use the same speaker and you know how to exclude the room it doesn't matter if you play sweeps or music to get rid of the room.

Still a grey area in between in my opinion. It does mean you measure the speaker in its intended position in the room. Because it is about the interaction of the room with the sound radiation of the speaker.Well... you exclude the room from the processed data collected with a microphone, not the sound coming out of the speaker and into your ears. But once you have that information you could indeed use it in concert with a "room correction" system to provide guidance on what shouldn't be EQ'd. But in the end, the intent of room correction isn't to remove the room, but rather to minimize the undesirable effects of lower frequency reflections.

Thank you for the resume. The thread is very long and has a lot of distracting posts. But it is a fascinating topic.This is not true. There is open source code from NTK that is similar to how the NFS works. The theory behind how the NFS works was not invented by Klippel. Many people know how to do it, what there isn't yet is all the parts made to work together.

Earl's approach is not the same. He has been open about how it works so it is unfair and untrue to say he won't tell.

Ascend used an NFS to create a compensation curve. Klippel has offered that function in a cheaper product for a long time. It requires you have an anechoic response in the first place, it is not a way to get one without already having one. That would work well for production line checks just like the setup seen in Kii's factory.

You can't use it to remove the sound of the room from the speakers in listening.

Almost everything you have said is either untrue or misunderstood. Tom is making good progress, perhaps soon there will be something that has all the parts together.

I’ll toss this into the mix just for curiosity’s sake, not with the expectation that anyone will actually pursue it. In the astrophotography game one of the recent trends is to use direct drive brushless dc motors to point telescopes with sub-arc second precision. The diy wing of that pursuit includes making their own motors, which tend to be large diameter pancake-shaped affairs with a large diameter central hole. It turns out that a particular form of used washing machine motor can be modified to work nicely in the required very slow very precise positioning mode. Here’s more than you wanted to know about Smartdrive washing machine motors.

Hang an arm off of a such a motor, add a rotary position encoder, and you have a super precision, zero backlash angular mic positioner needing no belts or gears! They’re even super quiet when run in dc torque motor mode.

…yeah, I know. $20 gets you a working stepper motor…

Few

EDIT: it looks like the washing machine motors have cored windings, so they’ll likely exhibit cogging that would interfere with positioning. Back to building a coreless version from scratch I guess!

Hang an arm off of a such a motor, add a rotary position encoder, and you have a super precision, zero backlash angular mic positioner needing no belts or gears! They’re even super quiet when run in dc torque motor mode.

…yeah, I know. $20 gets you a working stepper motor…

Few

EDIT: it looks like the washing machine motors have cored windings, so they’ll likely exhibit cogging that would interfere with positioning. Back to building a coreless version from scratch I guess!

Last edited:

Kind of why I mentioned a 1500mm boom arm, plus whatever you loose on the cross connection coupling for the motors. I like the ideas. It is brilliant! And Fluid's refinement of your roller motor mount is true engineering. As complicated as it truly needs to be, and no more. The mic shroud is brilliant. Have you allowed the push button on the XLR connector to have room internally with a channel? I remember that you showed a channel on your rendering.The fit is better than expected. But measurement volume is getting rather small.

View attachment 1301121

Actually, this makes me wonder about a different approach.

So there was some discussion about moving speaker vs moving microphone.

A moving speaker solution is practically a lot easier to do.

What happens with all the math if we do a quasi moving microphone approach, by just simply using the moving speaker and than swap the position of the mic and speaker position?

Or maybe just simply pick 3 or 4 different positions (coordinates) in the room?

This can even be done by keeping the mic at one position, and just turn it towards the new position of the speaker.

So there was some discussion about moving speaker vs moving microphone.

A moving speaker solution is practically a lot easier to do.

What happens with all the math if we do a quasi moving microphone approach, by just simply using the moving speaker and than swap the position of the mic and speaker position?

Or maybe just simply pick 3 or 4 different positions (coordinates) in the room?

This can even be done by keeping the mic at one position, and just turn it towards the new position of the speaker.

There is an obnoxious whine...

For the movie above, the motors can be turned off, so it's completely silent. The vertical motor has to stay on (it is off by default, don't ask me how I know) and that makes the whining noise. It needs some tweaking, but I'm pleased with the progress so far.

For the movie above, the motors can be turned off, so it's completely silent. The vertical motor has to stay on (it is off by default, don't ask me how I know) and that makes the whining noise. It needs some tweaking, but I'm pleased with the progress so far.

Last edited:

Actually, this makes me wonder about a different approach.

So there was some discussion about moving speaker vs moving microphone.

A moving speaker solution is practically a lot easier to do.

What happens with all the math if we do a quasi moving microphone approach, by just simply using the moving speaker and than swap the position of the mic and speaker position?

Or maybe just simply pick 3 or 4 different positions (coordinates) in the room?

This can even be done by keeping the mic at one position, and just turn it towards the new position of the speaker.

The approaches I've seen up till now all take (in principle) a snapshot of the sound (field) at two closed surfaces around the speaker. Everywhere at once. As that would require a lot of microphones ( n ), this is split up into n measurements with 1 microphone. This is the same as long as everything is stationary. Nothing in the room (including the speaker) should change/move. The boom and microphone motion is a necessary evil.

For now I'm sticking with the approach taken as Klippel does it, open source software is available and the hardware setup still seems feasible. If we keep searching for better (illusionary?) solutions, we might never get there. But if someone comes up with (proof of) something better, in any sense, I'm all ears.

I totally get what you're saying.For now I'm sticking with the approach taken as Klippel does it, open source software is available and the hardware setup still seems feasible. If we keep searching for better (illusionary?) solutions, we might never get there. But if someone comes up with (proof of) something better, in any sense, I'm all ears.

The thing is that the hardware side of things will barely change no matter what you do.

So my question is completely focused on the mathematical implementation.

Fyi. I am not looking for better (which is a word without much meaning imo).

I am searching for the most practical implementation.

Which I still don't really see. But anyway, we had that discussion before.

Btw. Let me be clear that I think you're still doing amazing work. 👍👍👍

If it makes any noise while not moving, that tells me the voltage holding it still is generated by PWM. Full DC voltage could be applied, but that may increase heating of the coils, perhaps by too much. Ideally, a lower voltage DC could be applied to brake the motors, or alternatively a string-and-weight system added to balance out gravity pulling it down. This of course would double the weight of the vertically moving system, so may not be acceptable.There is an obnoxious whine...

For the movie above, the motors can be turned off, so it's completely silent. The vertical motor has to stay on (it is off by default, don't ask me how I know) and that makes the whining noise. It needs some tweaking, but I'm pleased with the progress so far.

I wonder if the code is microstepping and stopping in between two poles. If so, it could instead stop at the nearest pole and hold it with the voltage fully on. The position would end up off by less than the distance the motor travels between two poles, hopefully less than a mm or so.

As usual, all applicable engineering tradeoffs apply.

As far the loud moving noise, I would take a look into Trinamic stepper drivers, like the TMC2208/09, TMC2100 etc etc

They are A LOT more quiet (as in almost totally silent)

Here a very quick example that I could find;

I have used them in the past and they work extremely well.

Would be definitely the goto in these kind of applications.

As for having noise being on hold, I don't know, usually they shouldn't really do that, so I am a bit confused by it

(or just simply misreading).

They are A LOT more quiet (as in almost totally silent)

Here a very quick example that I could find;

I have used them in the past and they work extremely well.

Would be definitely the goto in these kind of applications.

As for having noise being on hold, I don't know, usually they shouldn't really do that, so I am a bit confused by it

(or just simply misreading).

- Home

- Design & Build

- Software Tools

- Klippel Near Field Scanner on a Shoestring