Can-you try at -3dB of max level ?yes, flirting for max S/N. It'll be less Harmonic distortion at lower level but the S/N will be worse.

Can-you try at -3dB of max level ?

yes. have to make new test CD. BTW - recording at slow speed. 4X.

-RM

Richard,

The pics in forum show horizontal but when selected are

rotated 90 degrees or was that intentional? or was that fixed?

I dont know why it does that.

Waly did it.

-RM

Let's see .. you use 2 different chains of electronics, which produce different levels and types of distortion ... and the problem is the speaker?? So, if I have a car, and I try two different engines in it, and the car changes in behaviour between them, the way to resolve that difference is to experiment with the tyres ... ???So I play some music through a different amp, NAD 720BEE and find that where

I listen to it at a fairly healthy level I get that drilled, solid state type distortion

that will lead me to an ear ache/head ache.

I put my Dynaco Stereo 70 Series II amp in and don't have that problems unless I just

crank it up to 3/4 full on the pre amp.

George,

I just wanted to let you know how helpful, how timely, how selflessly

you find the links for us all, that everyone is discussing or talking about here.

I appreciate it and I am as guilty as others in not posting or forgetting where

I found something or forget the name of the article...or what ever other reason.

You are the glue that helps us all collaborate.

In advance, Parakalo, the Retsina is on me.

I just wanted to let you know how helpful, how timely, how selflessly

you find the links for us all, that everyone is discussing or talking about here.

I appreciate it and I am as guilty as others in not posting or forgetting where

I found something or forget the name of the article...or what ever other reason.

You are the glue that helps us all collaborate.

In advance, Parakalo, the Retsina is on me.

Vaccy

There are first order effects and lesser ones. I suspect you only play with well designed and made transducers. If you want to observe the lesser issues try using cheap drivers above their optimum frequency range!

For large area cheap systems the ceiling loudspeakers can cost less than ten dollars. So all bets are off as to pistonic behavior. Oh yeah they also often have whizzer cones.

Now one of the secrets to getting the best out of such a system is to walk around listening to the system and then rolling off the high end until it no longer sounds horrible.

There are first order effects and lesser ones. I suspect you only play with well designed and made transducers. If you want to observe the lesser issues try using cheap drivers above their optimum frequency range!

For large area cheap systems the ceiling loudspeakers can cost less than ten dollars. So all bets are off as to pistonic behavior. Oh yeah they also often have whizzer cones.

Now one of the secrets to getting the best out of such a system is to walk around listening to the system and then rolling off the high end until it no longer sounds horrible.

Last edited:

Vacuuphile,

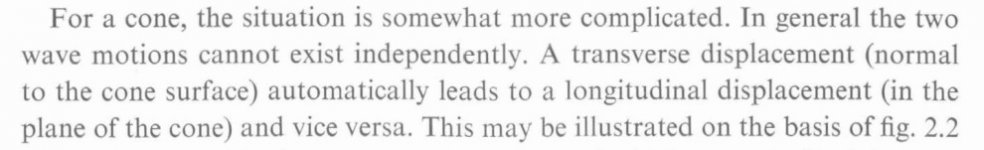

It seems you are selectively reading this. The analysis seems to be based on an idealized conic profile, many speakers use a curvilinear cone so all the is moot. Even in the articles that George put up they are saying the same, in an idealized condition this is a way to measure and calculate these conditions, nothing is ever in that condition outside of the mathematics.

It seems you are selectively reading this. The analysis seems to be based on an idealized conic profile, many speakers use a curvilinear cone so all the is moot. Even in the articles that George put up they are saying the same, in an idealized condition this is a way to measure and calculate these conditions, nothing is ever in that condition outside of the mathematics.

Attachments

fas42Let's see .. you use 2 different chains of electronics, which produce different levels and types of distortion ... and the problem is the speaker?? So, if I have a car, and I try two different engines in it, and the car changes in behaviour between them, the way to resolve that difference is to experiment with the tyres ... ???

Well actually the tyres are a valid experiment...say going from a

small block chevy to a big block chevy handling, traction, slip angle,

etc...it's just not the source of the issue, or it is the source and

new tyres will be a benefit. Well you get what I'm saying....

But the horn thing really got me wondering about the guy. I think he

has some links over on a brand name of the speaker I own forum to his site.

It appears he's done his homework and has many plots etc.

However, I've heard the same problems (for me at least) with different horn configurations in many "professional" live sound and other events, venues, etc.

I'm not sure how to discriminate between amp distortion, compression driver

distortion, or horn distortion. Would a rubberized coating on the inside of the

horn help?

Vacuuphile,

It seems you are selectively reading this. The analysis seems to be based on an idealized conic profile, many speakers use a curvilinear cone so all the is moot. Even in the articles that George put up they are saying the same, in an idealized condition this is a way to measure and calculate these conditions, nothing is ever in that condition outside of the mathematics.

Is this similar to (para-phrased)..."for every action there is an equal and

opposite action"

Sync,

I have no idea of whose compression driver Klipsch is using these days. I will also say that some of the plastic horns out there are made of some very thin injection molded plastic and they can have some fairly strong resonant problems with the horns walls if not reinforced well. If as Frank was saying the sound is not bothering you with one amp and is with another I would think you are looking at a FR problem, it may not be the speaker as Frank is saying. I don't know the sound of the Cornwall's for can't talk from any personal experience with those. Many times a horn is very directional as frequency rises and this can cause what you are talking about. The common complaint is that the horn sounds horny, a megaphone type sound, or horn shout as we call it. Does that speaker use a 1" driver and is it a screw on driver or is it mounted by two or three bolts through the flange?

I have no idea of whose compression driver Klipsch is using these days. I will also say that some of the plastic horns out there are made of some very thin injection molded plastic and they can have some fairly strong resonant problems with the horns walls if not reinforced well. If as Frank was saying the sound is not bothering you with one amp and is with another I would think you are looking at a FR problem, it may not be the speaker as Frank is saying. I don't know the sound of the Cornwall's for can't talk from any personal experience with those. Many times a horn is very directional as frequency rises and this can cause what you are talking about. The common complaint is that the horn sounds horny, a megaphone type sound, or horn shout as we call it. Does that speaker use a 1" driver and is it a screw on driver or is it mounted by two or three bolts through the flange?

Ahhh ... you've just mentioned one of my secrets - a system often sounds horrible, and walking around any which way doesn't make it better, or worse! Rolling off the high end is equivalent to taking lots of aspirin, or swigging plenty of red plonk - anything to dull the pain! Going to the doctor, fixing the cause of the "horribleness" is definitely a better option, IMHO ...Now one of the secrets to getting the best out of such a system is to walk around listening to the system and then rolling off the high end until it no longer sounds horrible.

No wonder so many audio reinforcement systems sound so f'ing awful ...

Yes, it's a system thing, a super powerful engine will need the right sort of tyre profile and compound to get that potential on the ground - but, say nominally equivalent hp donks will have different characteristics in themselves, and trying to make the car behave on the road in exactly equivalent ways just by altering tyres is a terribly roundabout way of getting there,fas42

Well actually the tyres are a valid experiment...say going from a

small block chevy to a big block chevy handling, traction, slip angle,

etc...it's just not the source of the issue, or it is the source and

new tyres will be a benefit. Well you get what I'm saying....

Differentiating the cause of a distortion can be difficult, I agree. I certainly would have always pointed the finger at the speakers in my early audio days - but, I had an acoustic epiphany one notable day, and everything changed from then on. These days I always assume the speakers are good enough, apart from the obvious stuff, and work totally on the preceding chain - this gets me to a remarkably good level of reproduction; and then upgrading drivers, etc, would just be icing on the cake.

Fas42, Simon7000,

Funny thing, that is always what I used to do when I was out going

to venues, I'd always walk around just having a listen just to hear it.

Or to find that one spot that wouldn't give me a headache...and it

doesn't take me long to hear the bad stuff, just a few seconds being

exposed to it and I know I'll move or put ear plugs in. I don't go out without them.

Kindhorman,

These Cornwalls are from the late 70's early 80s. Let me see what

they are, they haven't been opened in a long time. The horns are

cast aluminum, and coated with automotive rubber undercarriage

coating for damping.

More as I find out.

Funny thing, that is always what I used to do when I was out going

to venues, I'd always walk around just having a listen just to hear it.

Or to find that one spot that wouldn't give me a headache...and it

doesn't take me long to hear the bad stuff, just a few seconds being

exposed to it and I know I'll move or put ear plugs in. I don't go out without them.

Kindhorman,

These Cornwalls are from the late 70's early 80s. Let me see what

they are, they haven't been opened in a long time. The horns are

cast aluminum, and coated with automotive rubber undercarriage

coating for damping.

More as I find out.

Are the figures to scale?Just a little molding press I designed to mold audio parts. A bit of deflection analysis was required, lever arm calculations and shear forces for the number of bolts needed.

That was my ex partner in the picture, he is 6' tall. The plattens were 4" with 14" tall gussets, the open height for the molds was 90", the top of the press without the top cylinder was 16' and it barely fit under a 21' ceiling height. The side rods are 6" diameter and the main cylinder was a 3000 psi cylinder and the entire press was controlled by an Allen Bradley PLC. The Floor had to be cut out and re-poured to 16 inches thickness. The entire structure could tilt about 110 degree for molding position. There are water manifolds on upper and lower platens that feed temperature controlled coolant to the molds and put out hundreds of gallons per minute. You can't see the molding machine but it was a two tiered setup with the injection system on the bottom and the heating and cooling system above with 15 tons of chilling and a gas fired boiler for heat. We could hold +/1 about 2 degree F on the tooling surfaces with thermocouples in the tooling. Machine output was 450 lbs per minute.

The moving portion of the press weighed 40,000 lbs and the two side stands were another 15,000 lb.

The moving portion of the press weighed 40,000 lbs and the two side stands were another 15,000 lb.

Last edited:

Both the tweeter exponential horn.

Bass/mid is 600Hz exponential horn.

1 inch compression driver tweeter EV T-35 or similar. Probably K-79-K

1.5 inch compression driver bass mid Atlas K55-V or similar but w/Ceramic magnet.

It appears to be based on the University SAHF driver. I'll guess the K-55-G,

also based on the Atlas driver.

I have it written down somewhere safe, which means I"ll find it when I don't need

it any longer.

Bass/mid is 600Hz exponential horn.

1 inch compression driver tweeter EV T-35 or similar. Probably K-79-K

1.5 inch compression driver bass mid Atlas K55-V or similar but w/Ceramic magnet.

It appears to be based on the University SAHF driver. I'll guess the K-55-G,

also based on the Atlas driver.

I have it written down somewhere safe, which means I"ll find it when I don't need

it any longer.

Cough...cough...clearning throat.Just a little molding press I designed to mold audio parts.

What little audio parts were you molding ?

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II