Brass Escutcheon Pins

http://www.paxtonhardware.com/Fasteners/Fasteners.html

Work great for point-to-point wiring.

http://www.paxtonhardware.com/Fasteners/Fasteners.html

Work great for point-to-point wiring.

Answering you all, because pzoltan cannot write in english..nor i can!?

SATJI

Jól néz ki!

Regards,

Carlos

Monsieur Audiofan

Je va remetez pour vous mon "junkbasket"

S'ill vous plais, remetez pour moi

Merci (hahaha!... kidding)

Carlos

Palesha, thank you the picture and the words:

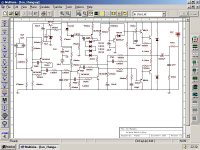

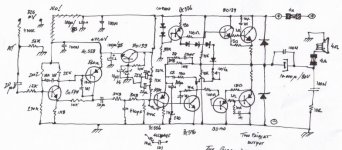

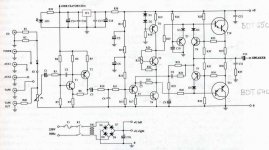

The amplifier is really 30 watts into 8 ohms... and has a lot of protections on it...i cut them all to test without.... in 4 ohms can reach 100 watts in simulation (cannot trust too much such things!), and simulation cannot say to us the sound quality too.

My modified Sony... and a lot of other brands... a have a lot of schematics here, almost the same, with many brands....seems to be easier to construct... i cannot compare, because the Sony modified i am hearing every day, this one only simulated... cannot compare...no honest comparison...have to assemble to hear... a have a long strip waiting for assembling.

Regards,

Carlos

TYIMO, you know what is good!

SZIA ZOLTAN

ZOLÍ

Carlos

DJK, thank you the information about the name, and i apreciate you think this assembly is easy.

brass escutcheon pins are the name.

Thank you

Regards,

Carlos

Now i will put for Roberto, from Italy, the informations to construction the modified Íon.

bye all of you

Carlos

Carlos

SATJI

Jól néz ki!

Regards,

Carlos

Monsieur Audiofan

Je va remetez pour vous mon "junkbasket"

S'ill vous plais, remetez pour moi

Merci (hahaha!... kidding)

Carlos

Palesha, thank you the picture and the words:

The amplifier is really 30 watts into 8 ohms... and has a lot of protections on it...i cut them all to test without.... in 4 ohms can reach 100 watts in simulation (cannot trust too much such things!), and simulation cannot say to us the sound quality too.

My modified Sony... and a lot of other brands... a have a lot of schematics here, almost the same, with many brands....seems to be easier to construct... i cannot compare, because the Sony modified i am hearing every day, this one only simulated... cannot compare...no honest comparison...have to assemble to hear... a have a long strip waiting for assembling.

Regards,

Carlos

TYIMO, you know what is good!

SZIA ZOLTAN

ZOLÍ

Carlos

DJK, thank you the information about the name, and i apreciate you think this assembly is easy.

brass escutcheon pins are the name.

Thank you

Regards,

Carlos

Now i will put for Roberto, from Italy, the informations to construction the modified Íon.

bye all of you

Carlos

Carlos

Attachments

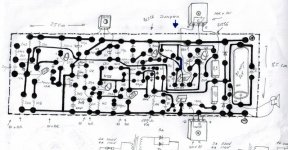

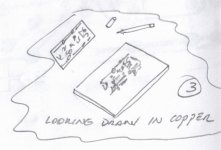

The last scratch you see as the board is transparent.

This one is only the copper side...make a copy, cut with scissors, fixed on the cooper side of the phenolic or fiberglass board, and with a hammer, and a thin point metal marker, hit it without power... small hits, only to put a week mark on copper metal surface... those markers, will be used to reference and center the machine to drill the holes, and last thing to do is to paint circles around holes, and taking a look at the cooper side scratch, connect the lines together in your "in construction board".

When finished, give a triple check!

If checked and good work, put it on "Percloreto de ferro", Iron Percloret, or other material you use to corrode copper in your country, them, remove the "non painted" copper because ink will protect the painted places against the acid atack!... when finished wash and polish with sponge, or soap with sand, some week abrasive material, or use a very low grain sandpaper.

I always, put solder on all the copper to protect against weather effects... solder forms quick an oxide layer that protect the solder point and the copper.

If you like, when assembled, adjusted and tested, clean copper side with thinner, and pass on it a fast varnish. Check if varnish is conductive or not...normally they are not!

now i will put some images,

Carlos

This one is only the copper side...make a copy, cut with scissors, fixed on the cooper side of the phenolic or fiberglass board, and with a hammer, and a thin point metal marker, hit it without power... small hits, only to put a week mark on copper metal surface... those markers, will be used to reference and center the machine to drill the holes, and last thing to do is to paint circles around holes, and taking a look at the cooper side scratch, connect the lines together in your "in construction board".

When finished, give a triple check!

If checked and good work, put it on "Percloreto de ferro", Iron Percloret, or other material you use to corrode copper in your country, them, remove the "non painted" copper because ink will protect the painted places against the acid atack!... when finished wash and polish with sponge, or soap with sand, some week abrasive material, or use a very low grain sandpaper.

I always, put solder on all the copper to protect against weather effects... solder forms quick an oxide layer that protect the solder point and the copper.

If you like, when assembled, adjusted and tested, clean copper side with thinner, and pass on it a fast varnish. Check if varnish is conductive or not...normally they are not!

now i will put some images,

Carlos

Attachments

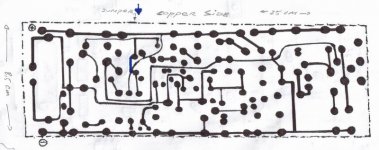

Looking at the scratch, and already referenced

Reference by holes drilled or marks on the board, small depressions...hit week please, if not board brokes.

Now you take a look in the scratch and connect with marker pen the points together.... draw the strips.

Carlos

Reference by holes drilled or marks on the board, small depressions...hit week please, if not board brokes.

Now you take a look in the scratch and connect with marker pen the points together.... draw the strips.

Carlos

Attachments

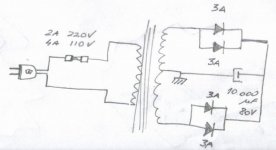

Remotion of tr6 made no difference!

In simulation, no difference, remotion of TR6 and all their passive elements that is working together, condenser, 680K resistor, diode and transistor itself where removed.

No change, so, may be only de-thump circuit.

This way, circuit is becoming simpler and simpler... if people said already good with the overcurrent protection (i always cutt them out), imagine what sound will give without those problematic circuits.

I prefer stone age method.... transistors in big quantities, with power and dissipation to suppott a short circuit in output, transistor excited maximum audio, for the time we need to perceive that sounds disappear, removal of soap under shower and go to pull outlet.

Here in Brazil we have 3 minimum shower a day, because of temperature high.... with soap and shampoo.... daily... this way, this time is important, because you switch on your equipment when arriving from street and go directly into the shower.

Carlos

In simulation, no difference, remotion of TR6 and all their passive elements that is working together, condenser, 680K resistor, diode and transistor itself where removed.

No change, so, may be only de-thump circuit.

This way, circuit is becoming simpler and simpler... if people said already good with the overcurrent protection (i always cutt them out), imagine what sound will give without those problematic circuits.

I prefer stone age method.... transistors in big quantities, with power and dissipation to suppott a short circuit in output, transistor excited maximum audio, for the time we need to perceive that sounds disappear, removal of soap under shower and go to pull outlet.

Here in Brazil we have 3 minimum shower a day, because of temperature high.... with soap and shampoo.... daily... this way, this time is important, because you switch on your equipment when arriving from street and go directly into the shower.

Carlos

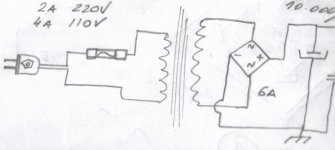

Power transistors, use two pairs...

And the models, please, ask Palesha Mahendra. I think the good one is 2SC5200 and his complementary.

Use two pairs to be strong and safe.

It channel heat sink must have 2000 squared centimeters, add all your fins... count side A plus side B and multiplied by the number of fins, also include base area.

And, if your country is hot, better to put transistors directly into heatsink, with silicone thermal compound, check first if transistor is really flat, and also if heatsink is a flat surface... clean it deeply before put compound, do not put too much strengh in screw, compound must go out as excess of butter inside the bread. Can remove excess with Gasoline, Kerozene, Airplane fuel and a lot of chemicals.

Please, if hot your place, isolate one heatsink (positive) related to the other (negative)...if this is the case, and isolate with wood also, heatsinks related to metal chassis.

I will not constructed next monthes... a big list is waiting... i am crazy to receive my AKSA.

Carlos

And the models, please, ask Palesha Mahendra. I think the good one is 2SC5200 and his complementary.

Use two pairs to be strong and safe.

It channel heat sink must have 2000 squared centimeters, add all your fins... count side A plus side B and multiplied by the number of fins, also include base area.

And, if your country is hot, better to put transistors directly into heatsink, with silicone thermal compound, check first if transistor is really flat, and also if heatsink is a flat surface... clean it deeply before put compound, do not put too much strengh in screw, compound must go out as excess of butter inside the bread. Can remove excess with Gasoline, Kerozene, Airplane fuel and a lot of chemicals.

Please, if hot your place, isolate one heatsink (positive) related to the other (negative)...if this is the case, and isolate with wood also, heatsinks related to metal chassis.

I will not constructed next monthes... a big list is waiting... i am crazy to receive my AKSA.

Carlos

I receive a lot of material from hungary

i do not understand a word! all he said was misunderstood i suppose.

Just because i do not know if he said:

- Put in the forum

- Do not put in the forum

to be or not to be... that's the question... to be bad or to be good, i will put them, unless Hungarian will like the pappers he sent.

Sorry for you and me, we cannot understand nothing... but watts is watts, ohms is ohms and we can understand some numbers.

Carlos

i do not understand a word! all he said was misunderstood i suppose.

Just because i do not know if he said:

- Put in the forum

- Do not put in the forum

to be or not to be... that's the question... to be bad or to be good, i will put them, unless Hungarian will like the pappers he sent.

Sorry for you and me, we cannot understand nothing... but watts is watts, ohms is ohms and we can understand some numbers.

Carlos

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Ion Obelisk