Great to hear, specially from you, Bear.The capability:

drool.

The chassis:

massive overkill

The design:

audacity!

_-_-bear

You make amazing products, makes me proud to hear that you like my first real diy project

It's not a standard chip amp circuit ;-)...Next step is to get a circuit worthy of such royal enclosures!!

I really really love the speed and details of chip amps. But love the sweet tube sound as well, I'm busy at the moment testing / trying a tube buffered chip circuit. Promising so far! But I think I'll have to ask my brother for help though, he's more a diy tube expert

Hi Phil,Hi Pjotter,

Discover your thread..

It's just amazing !!

Really great job !

Phil.

ps : I want the same for my next amp

Thanks for the kind words! Much appreciated to hear feedback!

- Peter

Btw,Hi Pjotter,

Discover your thread..

It's just amazing !!

Really great job !

Phil.

ps : I want the same for my next amp

Let's see if we can get you one of these cases for your next amplifier ;-)

That is such massive overkill. I really like it.

I've seen a couple of chipamps that were marketed at stupid prices. They had massive overkill enclosures with fancy-pants machining. The complexity of this enclosures exceeds these offerings.

You have a great skill, and I will be looking for more from you. I think a more refined design, which uses less material, can match or exceed the wow factor offered by this enclosure.

And I am a little jealous. I freaking recycle everything; I reuse and repurpose old chassis, and I make chassis parts with recycled sheet steel and a metal break. I grind, I file, I paint or buff. It's resource efficient but of course my efforts pale in comparison to this.

I've seen a couple of chipamps that were marketed at stupid prices. They had massive overkill enclosures with fancy-pants machining. The complexity of this enclosures exceeds these offerings.

You have a great skill, and I will be looking for more from you. I think a more refined design, which uses less material, can match or exceed the wow factor offered by this enclosure.

And I am a little jealous. I freaking recycle everything; I reuse and repurpose old chassis, and I make chassis parts with recycled sheet steel and a metal break. I grind, I file, I paint or buff. It's resource efficient but of course my efforts pale in comparison to this.

Hi Fast Eddie!That is such massive overkill. I really like it.

I've seen a couple of chipamps that were marketed at stupid prices. They had massive overkill enclosures with fancy-pants machining. The complexity of this enclosures exceeds these offerings.

You have a great skill, and I will be looking for more from you. I think a more refined design, which uses less material, can match or exceed the wow factor offered by this enclosure.

And I am a little jealous. I freaking recycle everything; I reuse and repurpose old chassis, and I make chassis parts with recycled sheet steel and a metal break. I grind, I file, I paint or buff. It's resource efficient but of course my efforts pale in comparison to this.

Thanks for your comment!

It's because I have access to the machinery and i really wanted something special. I always strive for perfection, in my daily job this is not always desirable, but in audio I can.

I've seen several chip amps offered, for different prices, some of them could almost be called a scam others will really be expensive to make and exclusive to have.

If I could, I would love to make these for a living. Just because they're soooo cool to make! I'm enjoying every single step of the process and it's great to be rewarded with great sound.

I think I've finally found my true passion, it's finally something I feel I could do for ever

If I where to sell these, they're not quite a bargain I suppose. The materials and (machine-) hours are just expensive, but i don't ever want to make an overpriced amp. Oh well, let's see that the future brings.

I don't think your efforts pale in comparison to this, it's just that I have access to the machinery and can aquire the materials easily. Otherwise I'd be doing the same as you. Exactly like I used to do. And if you had access to a machine shop maybe you could be making some similar. Our projects are different but that doesn't mean that mine is better [emoji6]

Thales again for your comment, I really loved reading it and wanted to take the time to reply hence the late reaction.

- Peter

You're absolutely correct; I would do stuff like you if I had access to the equipment.

There is at least one guy that sells chipamps that are as elaborate as yours. He also uses only the very best electronic parts in his builds. His offerings go for over $1000, so there is a market for this stuff. If you really want to market this, you really shouldn't leave anything on the table; you should use the best circuit, best parts, and best layout.

Here's a nice article detailing some of the (often poorly understood) issues concerning chip amps. Taming the LM3886 Chip Amplifier

And I have a question too. What are people using for insulators? I was browsing Digikey and Mouser and it seems there's no turnkey product offered for this application. Everything that looked like it could be made to work had a thermal resistance of 0.5 degrees C/W or more; I was hoping for half that. I saw some stuff on Fleabay that didn't offer specs (said it had "good thermal and insulating qualities" and you can't plug "good" into an equation) and on top of that it was from China. So what's the hot tip?

There is at least one guy that sells chipamps that are as elaborate as yours. He also uses only the very best electronic parts in his builds. His offerings go for over $1000, so there is a market for this stuff. If you really want to market this, you really shouldn't leave anything on the table; you should use the best circuit, best parts, and best layout.

Here's a nice article detailing some of the (often poorly understood) issues concerning chip amps. Taming the LM3886 Chip Amplifier

And I have a question too. What are people using for insulators? I was browsing Digikey and Mouser and it seems there's no turnkey product offered for this application. Everything that looked like it could be made to work had a thermal resistance of 0.5 degrees C/W or more; I was hoping for half that. I saw some stuff on Fleabay that didn't offer specs (said it had "good thermal and insulating qualities" and you can't plug "good" into an equation) and on top of that it was from China. So what's the hot tip?

Hi,

"I think I've finally found my true passion, it's finally something I feel I could do for ever "

"

If this is, go ahead, there is no worse thing to do a job they do not like..

Many things can be done with cnc, and now with 3D printer too.

In my case, most difficult is to make holes for pot, switch, rca socket and so..

Or design a good front panel with engraving.

Other thing about heatsink, I can not found fun or design heatsinks.

My dream was a heatsink like a tree or flower (or something from nature) that I could show out the case, like as a work of art !

About LM3886, I agree, it's cheap, easy to build, with fantastic sounding !

Just for fun, this history :

I showed my new LM to a friend, it's electronics (TV repair), and he said :

"they can not works, too simple and there is not enough components, try something else"

Then I made him listen :

"God!, sorry, forget what I said"

Phil.

"I think I've finally found my true passion, it's finally something I feel I could do for ever

If this is, go ahead, there is no worse thing to do a job they do not like..

Many things can be done with cnc, and now with 3D printer too.

In my case, most difficult is to make holes for pot, switch, rca socket and so..

Or design a good front panel with engraving.

Other thing about heatsink, I can not found fun or design heatsinks.

My dream was a heatsink like a tree or flower (or something from nature) that I could show out the case, like as a work of art !

About LM3886, I agree, it's cheap, easy to build, with fantastic sounding !

Just for fun, this history :

I showed my new LM to a friend, it's electronics (TV repair), and he said :

"they can not works, too simple and there is not enough components, try something else"

Then I made him listen :

"God!, sorry, forget what I said"

Phil.

You're absolutely correct; I would do stuff like you if I had access to the equipment.

There is at least one guy that sells chipamps that are as elaborate as yours. He also uses only the very best electronic parts in his builds. His offerings go for over $1000, so there is a market for this stuff. If you really want to market this, you really shouldn't leave anything on the table; you should use the best circuit, best parts, and best layout.

Here's a nice article detailing some of the (often poorly understood) issues concerning chip amps. Taming the LM3886 Chip Amplifier

And I have a question too. What are people using for insulators? I was browsing Digikey and Mouser and it seems there's no turnkey product offered for this application. Everything that looked like it could be made to work had a thermal resistance of 0.5 degrees C/W or more; I was hoping for half that. I saw some stuff on Fleabay that didn't offer specs (said it had "good thermal and insulating qualities" and you can't plug "good" into an equation) and on top of that it was from China. So what's the hot tip?

Hi Eddie,

Everybody can take a LM3875 or LM3886 IC, a handful of components and start making noise. But i believe it takes a lot more to really make those same IC's really sing. As long as the end product is great quality there will be a market. As long as you can look into your own eyes every morning you wake up, you're doing fine. I believe that offering the best quality one can will make the difference.

I've been working on this one amplifier for about 7 months. I've been trying to learn as much as i can about it, and trying different versions of it. Using different components or circuits. I'm also experimenting with a tube buffer. All of this so i can honestly say that i'm doing the best i can within my possibilities at this moment

Thanks for pointing out that website! I did read it before, but forgot about it, it's nice to rediscover it. And you're right, i think it is often poorly understood how these chips work, or what it takes to make them work like a dream. I don't see myself as an expert or anything like that, but i do think i've did my best by finding as much information as i possibly could.

I'm not sure about buying turnkey heat sinks, i've made my own. And frankly i didn't really calculated anything, there are so many chip amps where the heat sink is just the aluminum casing (3mm alu sheet?)

If you like a smaller heat sink you can probably go for copper.. And if you need anything special, PM me perhaps i can help you out whit that ;-)

Regards,

Peter

Hi,

"I think I've finally found my true passion, it's finally something I feel I could do for ever"

If this is, go ahead, there is no worse thing to do a job they do not like..

Many things can be done with cnc, and now with 3D printer too.

In my case, most difficult is to make holes for pot, switch, rca socket and so..

Or design a good front panel with engraving.

Other thing about heatsink, I can not found fun or design heatsinks.

My dream was a heatsink like a tree or flower (or something from nature) that I could show out the case, like as a work of art !

About LM3886, I agree, it's cheap, easy to build, with fantastic sounding !

Just for fun, this history :

I showed my new LM to a friend, it's electronics (TV repair), and he said :

"they can not works, too simple and there is not enough components, try something else"

Then I made him listen :

"God!, sorry, forget what I said"

Phil.

Hi Phil,

Oh don't get me wrong, i love my job. Machining is really great work. I absolutely don't hate my work.

But i would prefer to be working on audio equipment only because there's a lot more in it than just making a part for a client.

What i really love about making an amplifier like this is the thinking, getting ideas, designing, modeling, testing, do it all over again, think you're ready only to realize that you're still not 100% satisfied. Go back again to change the prototype and once that's done work on the casing. Make the best, meanest, baddest, coolest, case you can think of.

I love the whole creative and problem solving process and i enjoy machining a lot. So for me this would be my dream job ;-) Lets see what the future will bring.

Almost anything can be made by CNC machines. I don't see a 3D printer getting there anywhere soon, also CNC is MUCH faster and cheaper that 3D printing (printing metals). A 3D printer will cost about a million euro's versus about 150K-200K for a CNC machining center.

I know your frustration, when i'm at home and need to drill a hole somewhere i get crazy, it suddenly takes me about a minute or so for every hole. While at my work it will be more like 3-4 seconds. Haha.

What did you had in mind for the heat sinks? Design heat sinks will probably be possible. I wouldn't know where to get them but maybe they can be made ;-)

You're so right about these IC's i've had the same discussion so many times with people. The look on the're face when they hear the chips play is just priceless. I'm still surprised by the purity of the sound. I just love it.

Nice anecdote you got there

Last edited:

Wellllll.....

Finally i've been able to do something again today!

That where all the pictures, perhaps i'll do something again next year.... :

O.k. i'm just kidding, won't happen again... ;D Here are the other pictures:

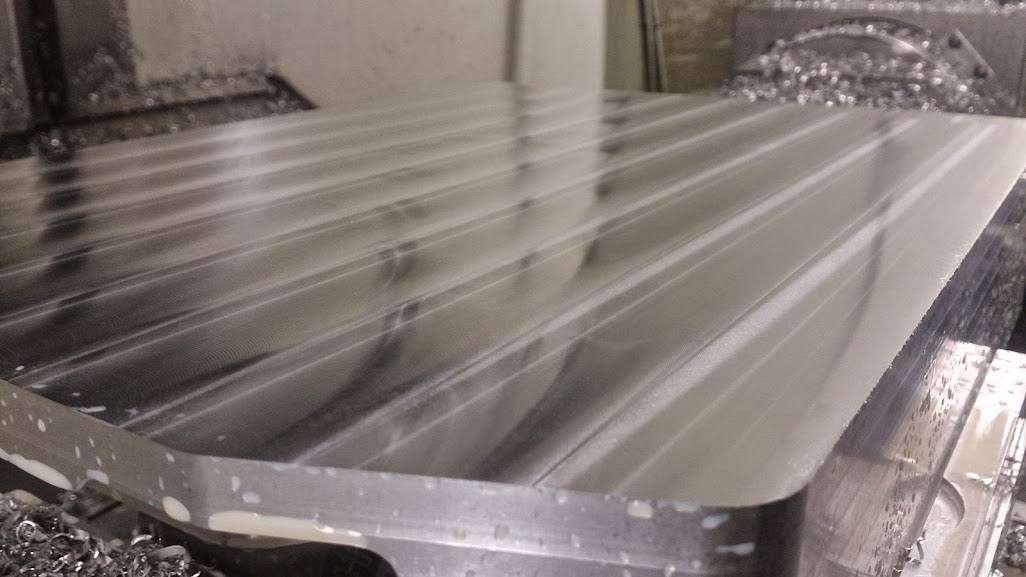

Placed aluminum jaws on the vice and milled them in position. Now i'm 1000% sure everything is perfectly aligned and flat.

Also, i'm sure now that i won't get damaged

Face milled it to the right thickness:

After facing i made the fillet and then i can mill the ribs (is what i was thinkgin at this point)

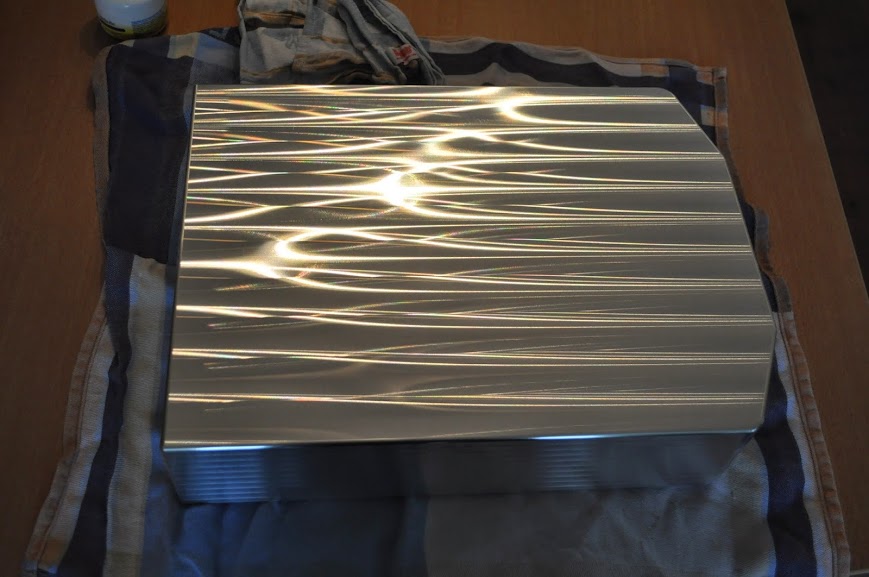

When i started this morning i was still convinced that the ribs would really add something, design wise.

But after i faced it and put the fillet there, i realized that this is how it should be.

I'm glad i changed my mind at the right time.

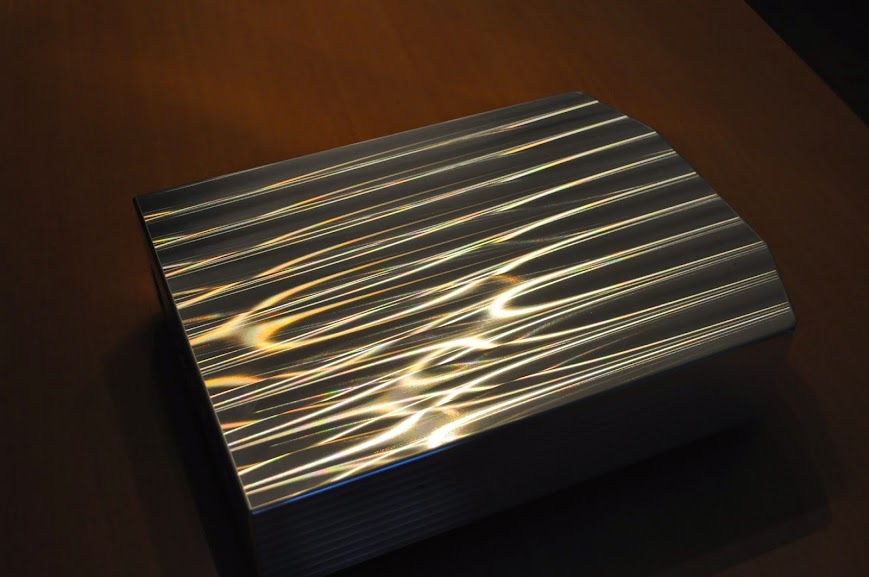

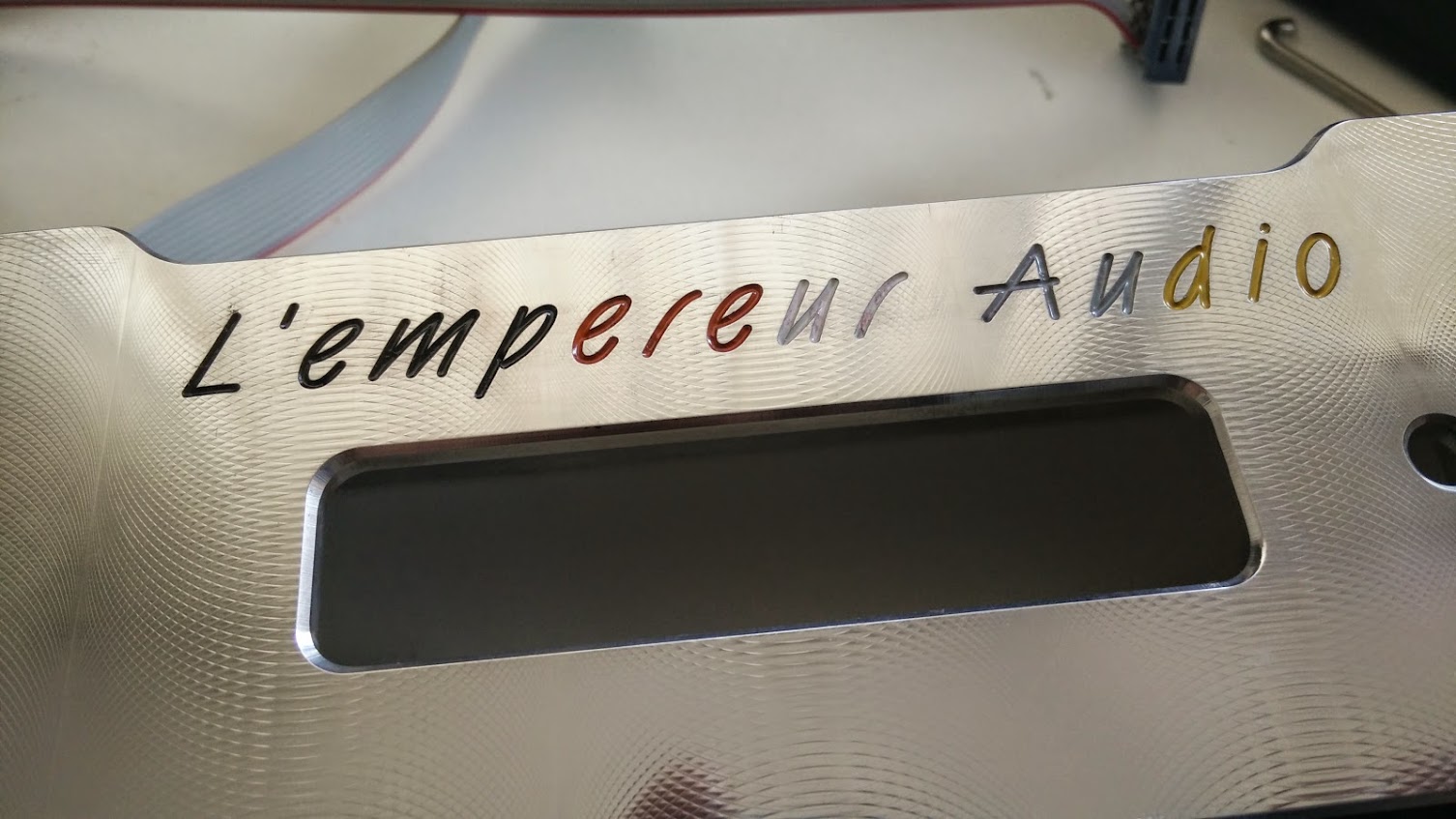

I really like this minimalistic look:

Just to double check if it's really o.k. like this, put back the old front: Yes, it's really good like this

Come home with me, baby...

Very, very happy with the results and sooo proud of it. It's been a joy (and pita every now and then) to build ;D

Also, the electronics will get an upgrade

Finally i've been able to do something again today!

An externally hosted image should be here but it was not working when we last tested it.

That where all the pictures, perhaps i'll do something again next year.... :

O.k. i'm just kidding, won't happen again... ;D Here are the other pictures:

Placed aluminum jaws on the vice and milled them in position. Now i'm 1000% sure everything is perfectly aligned and flat.

Also, i'm sure now that i won't get damaged

Face milled it to the right thickness:

After facing i made the fillet and then i can mill the ribs (is what i was thinkgin at this point)

When i started this morning i was still convinced that the ribs would really add something, design wise.

But after i faced it and put the fillet there, i realized that this is how it should be.

I'm glad i changed my mind at the right time.

I really like this minimalistic look:

Just to double check if it's really o.k. like this, put back the old front: Yes, it's really good like this

Come home with me, baby...

An externally hosted image should be here but it was not working when we last tested it.

Very, very happy with the results and sooo proud of it. It's been a joy (and pita every now and then) to build ;D

Also, the electronics will get an upgrade

Wellllll.....

Very, very happy with the results and sooo proud of it.

As well you should be. Incredible work, and thanks for posting all the photos. Wish I could do half as nice work!

As well you should be. Incredible work, and thanks for posting all the photos. Wish I could do half as nice work!

Hi Carlp,

Thanks for your reply! Nice to hear!

Aluminum amplifier: THE END!

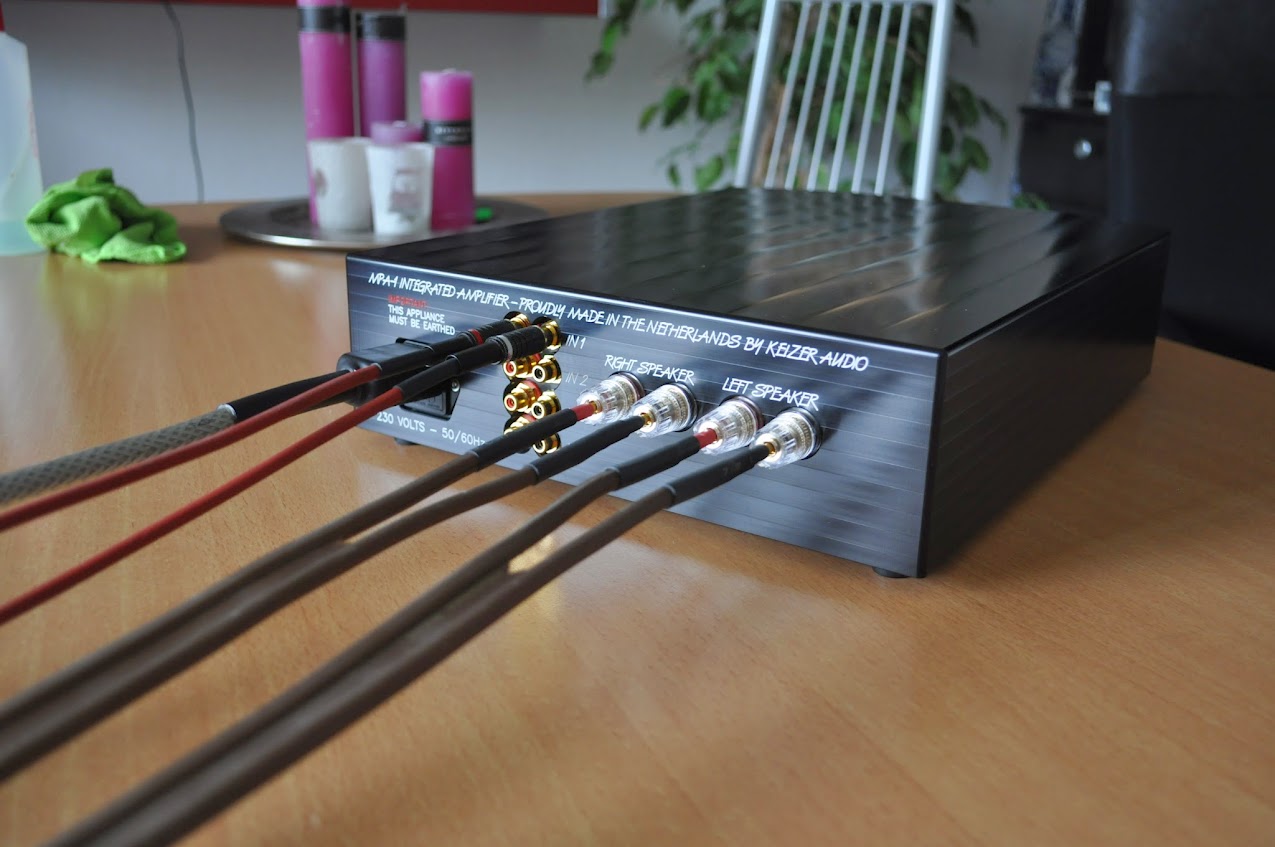

Good evening Gentlemen,

It's been a while, but she's ready now ;D

Past weekend i decided to finish this amplifier completely.

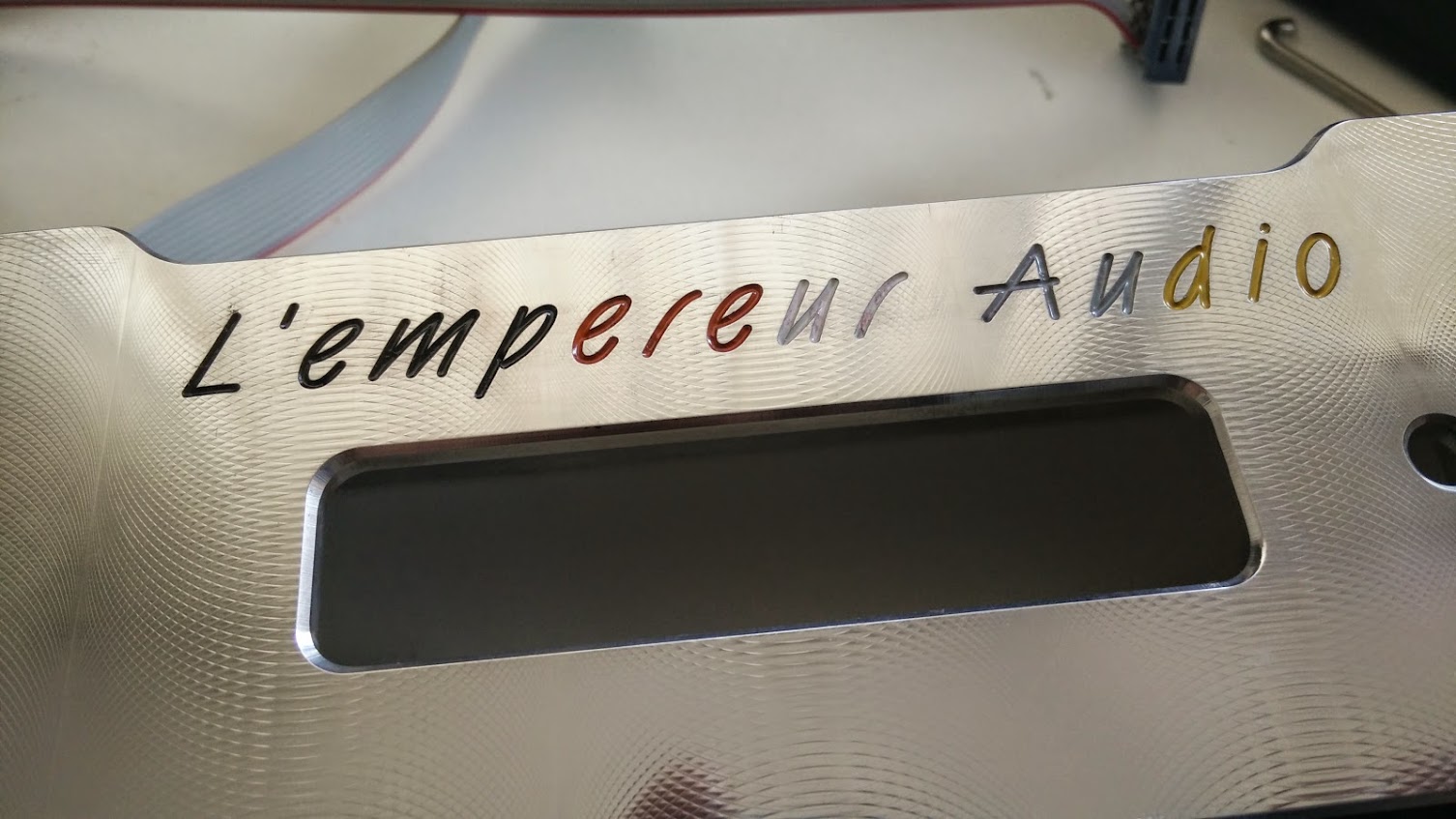

Testing on an old front:

Well, that seemed o.k. let's get serious:

Go Go!

Getting the electronics in place:

Final result:

In good company:

Well, that was it. All finished now and let's see what kind of new project the future will bring

Good evening Gentlemen,

It's been a while, but she's ready now ;D

Past weekend i decided to finish this amplifier completely.

Testing on an old front:

An externally hosted image should be here but it was not working when we last tested it.

Well, that seemed o.k. let's get serious:

An externally hosted image should be here but it was not working when we last tested it.

Go Go!

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Getting the electronics in place:

Final result:

In good company:

An externally hosted image should be here but it was not working when we last tested it.

Well, that was it. All finished now and let's see what kind of new project the future will bring

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Chip Amps

- Introduction and project info