Hi,

what about a name like The Dedicated Follower?

I like it, it could be TDF (maybe this mean something...

)

)Hey Vladimir,

Yes, I think RIFA's need more time to burn in (if they ever will). I can generate white noise from cool edit, but i think wife will kill me after 15 min

Regards

I would kill myself even after 1min with 6V RMS at the output. Of course, I use a resistor load instead of speakers connected.

During such an experiment, you will be able to listen some slight electromechanical noise from the inside of your amp. After 20 hours, this noise becomes lower, almost vanishes. At this moment sound becomes clearn.

Last edited:

Hi,

what about a name like The Dedicated Follower?

Hi, WuYit

I like you proposal, and would like to insert "shunt" somehow, maybe

The Shunt Dedicated Follower.

The shunt idea passes through all stages of the amp.

Hi, WuYit

I like you proposal, and would like to insert "shunt" somehow, maybe

The Shunt Dedicated Follower.

The shunt idea passes through all stages of the amp.

I think You choose a good name.

I would kill myself even after 1min with 6V RMS at the output. Of course, I use a resistor load instead of speakers connected.

During such an experiment, you will be able to listen some slight electromechanical noise from the inside of your amp. After 20 hours, this noise becomes lower, almost vanishes. At this moment sound becomes clearn.

Thanks, I also wanted to put the ressistors, i suppose they should be 8Ohms, what abt wattage?

Thanks, I also wanted to put the ressistors, i suppose they should be 8Ohms, what abt wattage?

I would choose 4...6 Ohms resistors, maybe assembled from several ones, total wattage 20...50W. During the burning-in, we must produce large high-frequency currents through the circuit.

I would choose 4...6 Ohms resistors, maybe assembled from several ones, total wattage 20...50W. During the burning-in, we must produce large high-frequency currents through the circuit.

I did like u said, and yes i can hear some noise inside the amp. What makes that noise?

Vladimir, Im astonished of that noice I can hear from my amp???? Could I do the same thing to an push-pull design? I know there are no output caps there...Im confused.

Any part, any wire have their own electro-mechanical resonant frequencies. The less noise you can here from the very beginning - the better amp (parts-wise and design-wise). Big electrolytic caps usually contribute to this noise, less noise - better cap (theirfore I prefer electrolytics with polymeric electrolyte). There are quite a big electromagnetic forces inside the big electrolytics, unfortunately, manufacturers do not usually care what happens inside big electrolytic cap at 1...20kHz, and exactly what mechanisms contribute to the dielectric losses angle parameter. Parts and wires interact with electromagnetic fields, this also cause some micro-vibrations.

Class AB amps also produce noise.

During the burning-in, some stresses are annealed due to complex thermo-vibro-electrical mechanisms, and mechanical and electrical properties of materials are changed a bit, in positive way.

Any part, any wire have their own electro-mechanical resonant frequencies. The less noise you can here from the very beginning - the better amp (parts-wise and design-wise). Big electrolytic caps usually contribute to this noise, less noise - better cap (theirfore I prefer electrolytics with polymeric electrolyte). There are quite a big electromagnetic forces inside the big electrolytics, unfortunately, manufacturers do not usually care what happens inside big electrolytic cap at 1...20kHz, and exactly what mechanisms contribute to the dielectric losses angle parameter. Parts and wires interact with electromagnetic fields, this also cause some micro-vibrations.

Class AB amps also produce noise.

During the burning-in, some stresses are annealed due to complex thermo-vibro-electrical mechanisms, and mechanical and electrical properties of materials are changed a bit, in positive way.

Does this mean that its possible to record the white noise signal on a CD and check the player also?

Im burning my amp for 5 hours and the level of the noise is same, the left chanell is pretty quiet, the noise is produced on the right one.

Does this mean that its possible to record the white noise signal on a CD and check the player also?

Im burning my amp for 5 hours and the level of the noise is same, the left chanell is pretty quiet, the noise is produced on the right one.

These effects are audible at relatively high values of 1...20kHz currents passing through the amp, so it is not expected to be audible in CD. At the same time, even with small currents, burning-in effects are possible, they need longer times.

I can not quite get the situation with your different channels behaviour, is the design not symmetric or could contain different parts?

Try to determine what is the main source of the noise in your case.

Both chanells are identical, but as a load on the right one (the one where i could hear the noise) i used a 4Ohm russian wire ressistor. When i change it with carbon ressistor with same value, noise gone, its absolutely quiet now. This burning-in gaves a very good results, sounds much better then before.

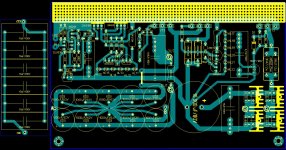

.....I have layout this schematic , may be output capacitor are not in right position , I think in circle would be better arangement . It's first atempt , I will do another PCB , I'm waiting your comments to improve , or layout something diferent .....

Regards Alex.

Regards Alex.

Attachments

At the moment, I have a doubt about the arrangement of film caps at the left side of PCB. The area between the PCB traces to which the film caps connected should be decreased somehow. Better to put traces close to each other, and to connect caps by individual traces.

Another rule to be observed, first the signal must pass through film caps, and after them through electrolytics. Consider 1000uF 63V Elna Silmic caps for electrolytics, if possible. You may consider to put electrolytics outside (not far from) the PCB, as a "cluster" assembly.

Another rule to be observed, first the signal must pass through film caps, and after them through electrolytics. Consider 1000uF 63V Elna Silmic caps for electrolytics, if possible. You may consider to put electrolytics outside (not far from) the PCB, as a "cluster" assembly.

Last edited:

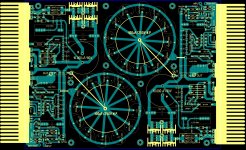

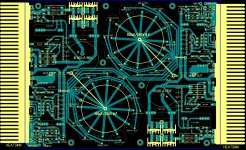

...... both channels ,on the same printed circuit ,film capacitors are mounted in the head surrounded by elytcaps , I think it's better now .

Regards Alex.

Looks nice, Alex, however, the ring-like PCB traces where "-" of all Lytics are sitting is not good, I would even say not acceptable. Better to make radial-like traces to these "-", maybe on the opposite side of PCB, similar like to "+" pins of the Lytics.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Integrated No NFB Son of Follower