Hello Fellow DIYers.

My name is Sanathan and I am from Bangalore.

I have got a few questions. Hope some one answers.

"Weather Stripping"

"Caulking"

"Polyester Fiberfill - for stuffing a sub up"

"Polyurethene Glue"

"Silicone Glue"

Any help will be very helpful for me in finding these things here.

Bye.

My name is Sanathan and I am from Bangalore.

I have got a few questions. Hope some one answers.

"Weather Stripping"

"Caulking"

"Polyester Fiberfill - for stuffing a sub up"

"Polyurethene Glue"

"Silicone Glue"

Any help will be very helpful for me in finding these things here.

Bye.

Locally available materials.

Hi ssSai,

I am not going to give you sources for the materials you listed. I don't have a source. However it is apparent that you want

1. A sealant

2. Glue ( for wood work I guess)

3. Acoustic absorbent

The glue we use here is PVA and Fevicol PVA is the most popular one. It is milky white when fresh and tries to a semi transparent stiff (not brittle) mass. Meant for use in woodwork. They have a quick set version which is pale yellow in colour and it dries in something like 10 to 20 minutes. Needs several hours to attain full strength. Normal fevicol takes hours to set and probably 24 hours to attain full strength.

You can also use Fevicol to seal gaps in your woodwork ( from the inside). I guess you want to use caulking for that purpose. I use a mix of fevicol and wood dust to seal all internal joints. Works very well.

For the acoustic absorbent you can use the stuffing in the new generation pillows that cost about Rs150/- each. It is filled with Racron made by Reliance and is the same as Dacron. It will work - how effective it is remains to be seen. Fiber Glass ( acoustic variety) is available in rolls. I used to buy them once . Its very hard to use and leaves your hands full of glass pieces (!) for a long time. It is also known to cause cancer. I never knew at the time. Better avoid it like the plague.

You can also use cotton , especially silk cotton ( highly inflamable) . Get it fluffed up when you buy it. I have used it . I would tend to try and make do with Racron !

Why do you want to stuff the whole box with absorbent ? For a sub you could get away with no absorbent. Better check your design again.

Cheers.

Hi ssSai,

I am not going to give you sources for the materials you listed. I don't have a source. However it is apparent that you want

1. A sealant

2. Glue ( for wood work I guess)

3. Acoustic absorbent

The glue we use here is PVA and Fevicol PVA is the most popular one. It is milky white when fresh and tries to a semi transparent stiff (not brittle) mass. Meant for use in woodwork. They have a quick set version which is pale yellow in colour and it dries in something like 10 to 20 minutes. Needs several hours to attain full strength. Normal fevicol takes hours to set and probably 24 hours to attain full strength.

You can also use Fevicol to seal gaps in your woodwork ( from the inside). I guess you want to use caulking for that purpose. I use a mix of fevicol and wood dust to seal all internal joints. Works very well.

For the acoustic absorbent you can use the stuffing in the new generation pillows that cost about Rs150/- each. It is filled with Racron made by Reliance and is the same as Dacron. It will work - how effective it is remains to be seen. Fiber Glass ( acoustic variety) is available in rolls. I used to buy them once . Its very hard to use and leaves your hands full of glass pieces (!) for a long time. It is also known to cause cancer. I never knew at the time. Better avoid it like the plague.

You can also use cotton , especially silk cotton ( highly inflamable) . Get it fluffed up when you buy it. I have used it . I would tend to try and make do with Racron !

Why do you want to stuff the whole box with absorbent ? For a sub you could get away with no absorbent. Better check your design again.

Cheers.

Thank you. A piece of advice for you.

Thank you for the advice.

The one on caluking was very important, cos I really did not know what it meant.

Well, regarding the last line, I am not stuffing the whole box. I will have to do it by listening after stuffing. Its pretty subjective in nature.

I would like you to give this URL a try, its very informative.

http://www.integracaraudio.com/caraudio/resources/fiberfill/

Thank you for the advice.

The one on caluking was very important, cos I really did not know what it meant.

Well, regarding the last line, I am not stuffing the whole box. I will have to do it by listening after stuffing. Its pretty subjective in nature.

I would like you to give this URL a try, its very informative.

http://www.integracaraudio.com/caraudio/resources/fiberfill/

Stuffing.

Material used for stuffing boxes vary in performance. The best ones are made specifically as sound absorbents. The structure and size of the fibers is crucial. This means that all fibrous filling material will not be equally effective.

Test it out by filling a known box with some material and checking the resonance before and after a fill.

But 30 % increase in volume ? I am not quite sure about that. Getting up to 10 % has been difficult. Maybe the Dacron material is better. You should also keep in mind that all fibrous material has volume and this will reduce the volume of air in the box. This will probably be more significant in small boxes and with more stuffing. Do some tests and you can be sure of the results.

Caulking material.

You get Silicone sealant in long tubes. Costs about Rs150 or so. It is smelly till it sets. Like Fevicol it is pasty ( more viscous than Fevicol ) and sets into a stiff rubbery mass. It is possible to strip it off by pulling it hard ( after setting ) . But you can't do this with flexible and soft base material ( like speaker cones!).

Sealing Driver frames.

You can use foam polyurethane sheets used by the car seat makers. It comes in various colours. The 5mm thick sheet is fine. I use this all the time. They compress fully and seal very well. You don't really need to glue it except to the box to keep it in place.

Cut a 1/2 inch wide strip and stick it all around the edge of teh cut out. Make sure the ends are glued well to avoid a leak. I normally cut the ends at 45 degrees.

Cheers.

Material used for stuffing boxes vary in performance. The best ones are made specifically as sound absorbents. The structure and size of the fibers is crucial. This means that all fibrous filling material will not be equally effective.

Test it out by filling a known box with some material and checking the resonance before and after a fill.

But 30 % increase in volume ? I am not quite sure about that. Getting up to 10 % has been difficult. Maybe the Dacron material is better. You should also keep in mind that all fibrous material has volume and this will reduce the volume of air in the box. This will probably be more significant in small boxes and with more stuffing. Do some tests and you can be sure of the results.

Caulking material.

You get Silicone sealant in long tubes. Costs about Rs150 or so. It is smelly till it sets. Like Fevicol it is pasty ( more viscous than Fevicol ) and sets into a stiff rubbery mass. It is possible to strip it off by pulling it hard ( after setting ) . But you can't do this with flexible and soft base material ( like speaker cones!).

Sealing Driver frames.

You can use foam polyurethane sheets used by the car seat makers. It comes in various colours. The 5mm thick sheet is fine. I use this all the time. They compress fully and seal very well. You don't really need to glue it except to the box to keep it in place.

Cut a 1/2 inch wide strip and stick it all around the edge of teh cut out. Make sure the ends are glued well to avoid a leak. I normally cut the ends at 45 degrees.

Cheers.

of the 3 ashok suggested i prefer dacron. fiberglass helps too except it is tough to work with. cotton wool does little at freq below 400hz.

GE silicones sell a lot of caulking compounds in India any building materials store will give you these. dont go to the stores that sell tiles and comodes but to one that sells white cement, fevicol, wood screws, etc...

GE silicones sell a lot of caulking compounds in India any building materials store will give you these. dont go to the stores that sell tiles and comodes but to one that sells white cement, fevicol, wood screws, etc...

Indian equivalents DO Work.

Hi! Navin and thank you for the info. Really this thread is getting better and better for me.

As a new DIYer would do, I went to a store selling plywood and other sorts of wood for furniture. I asked him whether I could get MDF board, and the answer was a odd stare as though I was from MARS, anyway I atleast could convince him that I am no ailen by telling him that the board is made of saw dust and infact they compress saw dust into a board. He then asked me whether I was looking for a "Vertical board". When I had a look at it, the board looked pretty much like MDF (I had seen a closeup pic on the net). I yet need to find a source to get the MDF.

Mr.Vivek, Hi to you too. I would seriously ask you to give a visit to the URL I have posted. Because from what I can infer, you think that by just displacing the air within the subwoofer using anything you fancy you get it to look a lot larger. I really do not think Coir can do anything what Dacron (or whatever FibreFill) can do. Check the URL out and help me out in case I am wrong OK -

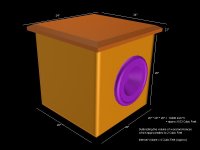

I also was fooling around with a software called 3dMax. I tried to visualize my subwoofer. Any criticisms.

Hi! Navin and thank you for the info. Really this thread is getting better and better for me.

As a new DIYer would do, I went to a store selling plywood and other sorts of wood for furniture. I asked him whether I could get MDF board, and the answer was a odd stare as though I was from MARS, anyway I atleast could convince him that I am no ailen by telling him that the board is made of saw dust and infact they compress saw dust into a board. He then asked me whether I was looking for a "Vertical board". When I had a look at it, the board looked pretty much like MDF (I had seen a closeup pic on the net). I yet need to find a source to get the MDF.

Mr.Vivek, Hi to you too. I would seriously ask you to give a visit to the URL I have posted. Because from what I can infer, you think that by just displacing the air within the subwoofer using anything you fancy you get it to look a lot larger. I really do not think Coir can do anything what Dacron (or whatever FibreFill) can do. Check the URL out and help me out in case I am wrong OK -

I also was fooling around with a software called 3dMax. I tried to visualize my subwoofer. Any criticisms.

Attachments

I have my doubts about coir but I have never used it. Untill one uses it I would not guess.

MDF is common in b'bay. Nuwood is one brand but there many others. If you are using laminate you also get pre laminated MDF albeit only upto 18mm. Try askign for Nuwood. Better still ick up a mag called Society Interiors or similar and look for ads for MDF. many manufactuers advertise in these Interior mags.

MDF is common in b'bay. Nuwood is one brand but there many others. If you are using laminate you also get pre laminated MDF albeit only upto 18mm. Try askign for Nuwood. Better still ick up a mag called Society Interiors or similar and look for ads for MDF. many manufactuers advertise in these Interior mags.

Sai,

Nuwood is very common in Banglore. That is the one I bought to make my speaker boxes. I bought it from a shop in Yeshwanthpur. You can also try in shops in Rajajinagar. Should not be a problem. The 4x4 feet board (18mm) cost me about Rs. 600.

And Sai, there is no Mr. in diyaudio.com.

Nuwood is very common in Banglore. That is the one I bought to make my speaker boxes. I bought it from a shop in Yeshwanthpur. You can also try in shops in Rajajinagar. Should not be a problem. The 4x4 feet board (18mm) cost me about Rs. 600.

And Sai, there is no Mr. in diyaudio.com.

mdf

Sai,

The MDF sheets that I bought had MDF stamped in blue ink on the board. I think it was Nuwood. In any case , unlike particle boards you cannot see large wood particles in MDF. There is a softer board available that initially looks deceptively like MDF. It is no good and powders easily. Make sure you get the right thing.

I am surprised that your supplier did not know what MDF is. Really strange.

Cheers.

Sai,

The MDF sheets that I bought had MDF stamped in blue ink on the board. I think it was Nuwood. In any case , unlike particle boards you cannot see large wood particles in MDF. There is a softer board available that initially looks deceptively like MDF. It is no good and powders easily. Make sure you get the right thing.

I am surprised that your supplier did not know what MDF is. Really strange.

Cheers.

"I also was fooling around with a software called 3dMax. I tried to visualize my subwoofer. Any criticisms."

sai..

the visualisation looks good...! just a suggestion...Why dont u try making the sub enclosure as just a cube and try putting a heavy piece of tinted glass or something on Top!

What driver do u plan to use ...?

Is the design sealed or ported...?

sai..

the visualisation looks good...! just a suggestion...Why dont u try making the sub enclosure as just a cube and try putting a heavy piece of tinted glass or something on Top!

What driver do u plan to use ...?

Is the design sealed or ported...?

Acoustic Absorbant:

I had once used coir in one of my speakers...I dint find it as effective as the racron fiberfill stuff. My guess is, the absorption is less because the fibres are a lot thicker or the absorption isnt uniform because its a natural fibre and might have some kind of a regular pattern. Also coir had a tendency to settle, that is it loses its 'flufiness'. In addition absorbs moisture. Result was fungii...

On the other hand, racron does not absorb moisture nor does it settle down easily... but to have a good absorption u need to have a high density of material...loose bunches of these does not produce enough LF attenuation...I learnt this when i was experimenting on a simple transmission line which finally ended up as a set of cheap dorm speakers.(What you see in picture are those common pioneer car speakers. They sounded horrible compared to the jbl's i've put in now) For a volume of approximately 4.7 litres i had to use almost 1/2 the stuff from a regular sized pillow to absorb the higher order frequencies and smoothen out the unwanted line induced harmonics. The line was tuned to around 80hz originally.

I had once used coir in one of my speakers...I dint find it as effective as the racron fiberfill stuff. My guess is, the absorption is less because the fibres are a lot thicker or the absorption isnt uniform because its a natural fibre and might have some kind of a regular pattern. Also coir had a tendency to settle, that is it loses its 'flufiness'. In addition absorbs moisture. Result was fungii...

On the other hand, racron does not absorb moisture nor does it settle down easily... but to have a good absorption u need to have a high density of material...loose bunches of these does not produce enough LF attenuation...I learnt this when i was experimenting on a simple transmission line which finally ended up as a set of cheap dorm speakers.(What you see in picture are those common pioneer car speakers. They sounded horrible compared to the jbl's i've put in now) For a volume of approximately 4.7 litres i had to use almost 1/2 the stuff from a regular sized pillow to absorb the higher order frequencies and smoothen out the unwanted line induced harmonics. The line was tuned to around 80hz originally.

My configuration (with the problem of choosing an amplifier).

Hello Ashok,

I already got an address (Thippasandra, Indranagar) where I can get MDF from "Nuwood". I yet have to visit it. Good to know as to how to make sure of its authenticity. I will check for the "MDF" stamped in blue.

Hello Ajju,

I wonder how Vivek got away with a coir stuffing. No one would have thought about the effect of its "weight" and also "weather". Its good that now, every one knows that "Coir" is a big NO-No as far as stuffing a sub up is concerned.

I HAVE A QUESTION ARISING AFTER READING THE POSTS.

??? WHAT WAS THE FUNGI DOING INSIDE THE SUBWOOOFER ???

MY ANSWER IS ---------------- LISTENING TO MUSIC. (Can anyone beat me in creativity???

)

)

Some people who have read this post already know about my sub configuration.

I am getting a "Adire Audio Shiva" 12" subwoofer driver.

The amplifier is posing some diffuculties. I wish I can get hold of a "AVA 250" dedicated subwoofer amplifier from "Adire Audio". But getting it all the way from the US is working out a bit tooooooo costly. The freight charges quoted was $172 (USD) to get it via air mail. Also you have the problem of customs.

Since this will be my first DIY project I want a "Sealed Enclosure". I have already been adviced to go for a "Ported" because I have approximately 4 cu.ft., but I am not confident about making one.

I will be keeping the subwoofer in its bare bone condition for some time because I plan to make a pair of full range speakers for my stereo setup. I will match all the three later with nice veeners maybe. I have already given thoughts about the "tinted glass". Its strange, but were you the one who told my dad to give me this advice??

Ajju, where did you get the JBLs from. I am yet undecided as to what drivers I will be using for my stereo setup.

Hello Ashok,

I already got an address (Thippasandra, Indranagar) where I can get MDF from "Nuwood". I yet have to visit it. Good to know as to how to make sure of its authenticity. I will check for the "MDF" stamped in blue.

Hello Ajju,

I wonder how Vivek got away with a coir stuffing. No one would have thought about the effect of its "weight" and also "weather". Its good that now, every one knows that "Coir" is a big NO-No as far as stuffing a sub up is concerned.

I HAVE A QUESTION ARISING AFTER READING THE POSTS.

??? WHAT WAS THE FUNGI DOING INSIDE THE SUBWOOOFER ???

MY ANSWER IS ---------------- LISTENING TO MUSIC. (Can anyone beat me in creativity???

Some people who have read this post already know about my sub configuration.

I am getting a "Adire Audio Shiva" 12" subwoofer driver.

The amplifier is posing some diffuculties. I wish I can get hold of a "AVA 250" dedicated subwoofer amplifier from "Adire Audio". But getting it all the way from the US is working out a bit tooooooo costly. The freight charges quoted was $172 (USD) to get it via air mail. Also you have the problem of customs.

Since this will be my first DIY project I want a "Sealed Enclosure". I have already been adviced to go for a "Ported" because I have approximately 4 cu.ft., but I am not confident about making one.

I will be keeping the subwoofer in its bare bone condition for some time because I plan to make a pair of full range speakers for my stereo setup. I will match all the three later with nice veeners maybe. I have already given thoughts about the "tinted glass". Its strange, but were you the one who told my dad to give me this advice??

Ajju, where did you get the JBLs from. I am yet undecided as to what drivers I will be using for my stereo setup.

MDF and marine ply

Dear Mister Navinbhai,

(See how intimidated I am by you now...)

I prefer to use "exterior grade" MDF rather than "interior grade", just because I presume that anything designed to lie exposed to water and sun will have better dimensional tolerance to weathering and temperature changes. Exterior grade 25mm MDF was about Rs.65/sft.

Third reason for me to use MDF is because I find it harder to find 25mm ply. MDF at 25mm (or even more) is easy to find. (I don't know why some of the others on this thread say MDF is hard to find... it's certainly easy to find even in New Bombay, let alone Bombay.)

However, the comparison between MDF and ply probably is merely academic, because both need to be deadened. I prefer to use tiles or bituminised felt or 12mm glass sheets stuck to the inner surface to "weigh it down" and deaden it. After such treatment, I suspect both ply and MDF will be equally good. And then I prefer to finish the outside using wood veneer, which adds another 4mm of ply to the walls, making it a composite effectively. And I prefer to stick the veneer using Araldite instead of the carpenter-standard Fevicol, because Araldite has a lot of "body". This makes the Araldite itself another layer, making the wall even more of a composite structure. With all this internal and external layering, I feel the difference between ply and MDF may become less relevant.

And then I prefer to finish the outside using wood veneer, which adds another 4mm of ply to the walls, making it a composite effectively. And I prefer to stick the veneer using Araldite instead of the carpenter-standard Fevicol, because Araldite has a lot of "body". This makes the Araldite itself another layer, making the wall even more of a composite structure. With all this internal and external layering, I feel the difference between ply and MDF may become less relevant.

My two bits. What do you think?

regards,

Tarun

Dear Mister Navinbhai,

(See how intimidated I am by you now...)

In my limited experience, I seem to feel that MDF sounds deader than any ply. Secondly, you'll have to look closely to ensure that the chap is selling you good, real, marine ply. There is a lot of spurious and counterfeit ply going around. For instance, a good brand of ply in Western India is "Guna". There is a lot of counterfeit ply with the "Guna" label. Real "Guna ply" is easily one and a half times as heavy as a cheaper brand of commercial ply; I've used both (not for speakers, but for furniture. That's where I learned about counterfeit ply.) With MDF, I find it easier to just look at the sheet and know that it's real MDF, and the weight and sound tells me its quality.navin said:BTW why MDF. marine ply is just as good if not better. [/B]

I prefer to use "exterior grade" MDF rather than "interior grade", just because I presume that anything designed to lie exposed to water and sun will have better dimensional tolerance to weathering and temperature changes. Exterior grade 25mm MDF was about Rs.65/sft.

Third reason for me to use MDF is because I find it harder to find 25mm ply. MDF at 25mm (or even more) is easy to find. (I don't know why some of the others on this thread say MDF is hard to find... it's certainly easy to find even in New Bombay, let alone Bombay.)

However, the comparison between MDF and ply probably is merely academic, because both need to be deadened. I prefer to use tiles or bituminised felt or 12mm glass sheets stuck to the inner surface to "weigh it down" and deaden it. After such treatment, I suspect both ply and MDF will be equally good.

My two bits. What do you think?

regards,

Tarun

Re: MDF and marine ply

tarun, u have covered all the points....getting the good stuff requires knowledge of wood. the best guide is kg/sq. ft. the higher the better. araldite is much better than fevicol. it lasts forever. once you build a cabinet using araldite you wont be able to take it apart. besides araldite is water resistant to can handle hot humid climes of bombay a bit better.

here is my take....

I started out using 35mm MDF (rs. 80 / sq. ft) and found out hick wood stores too much energy.

so in my later cabiets I reduced the wood to 18mm and increased bracing so that all cabinet resonances were in the upper midbass freq. these freq were damped using dacron or fiberglass. dacron is easier to work with but more expensive.

my latest cabinet is in the works. i did post a few pics a few months ago. the cabinet is 48" x 10" x 16" (HWD).

the sides of the cabinet uses 3 layers of 3mm MDF (external grade) and 3 layers of 4mm marine ply. i braced the cabinet at 4", 5", 6", 7" and 8" intervals using 35mm external MDF. the front and back are 35mm MDF.

the six layers are bent (pre stressing the wood reduces flex).

then i applied a layer of fiberglass matting on the inside bonded with resin.

then i got som 1.5mm lead sheet from Pydhonie (near Crawford market). 3' x 8' of lead sheet weighs 40kgs and cost Rs 1836. should be enough to damp both cabinets and also leave some for the center channel and DVD player.

now i will apply the lead sheet with araldite to some of the walls.

I normally use 1.5 mm veneer but this time I am painting the cabinets black.

Now as far as intimidation is concerned you better stop calling me Bhai. You dont want the "real" Bhais to take umbrage to this. And the next time anyone calls me Mr. a Moderator will pay them a visit. to quote Jason L "There are 8 moderators. All over 7 feet tall. All over 17 stone. All trained athletes with bulging muscles and hair trigger reflexes. Each moderator is equipped with two low slung colt 45's, night vision glasses and armour piercing tracer shells."

tcpip said:Dear Mister Navinbhai,

(See how intimidated I am by you now...)

In my limited experience, I seem to feel that MDF sounds deader than any ply. Secondly, you'll have to look closely to ensure that the chap is selling you good, real, marine ply. There is a lot of spurious and counterfeit ply going around. For instance, a good brand of ply in Western India is "Guna". There is a lot of counterfeit ply with the "Guna" label. Real "Guna ply" is easily one and a half times as heavy as a cheaper brand of commercial ply; I've used both (not for speakers, but for furniture. That's where I learned about counterfeit ply.) With MDF, I find it easier to just look at the sheet and know that it's real MDF, and the weight and sound tells me its quality.

I prefer to use "exterior grade" MDF rather than "interior grade", just because I presume that anything designed to lie exposed to water and sun will have better dimensional tolerance to weathering and temperature changes. Exterior grade 25mm MDF was about Rs.65/sft.

Third reason for me to use MDF is because I find it harder to find 25mm ply....However, the comparison between MDF and ply probably is merely academic, because both need to be deadened. I prefer to use tiles or bituminised felt or 12mm glass sheets stuck to the inner surface to "weigh it down" and deaden it. After such treatment, I suspect both ply and MDF will be equally good.And then I prefer to finish the outside using wood veneer, which adds another 4mm of ply to the walls, making it a composite effectively. And I prefer to stick the veneer using Araldite instead of the carpenter-standard Fevicol, because Araldite has a lot of "body". This makes the Araldite itself another layer, making the wall even more of a composite structure. With all this internal and external layering, I feel the difference between ply and MDF may become less relevant.

My two bits. What do you think?

regards,

Tarun

tarun, u have covered all the points....getting the good stuff requires knowledge of wood. the best guide is kg/sq. ft. the higher the better. araldite is much better than fevicol. it lasts forever. once you build a cabinet using araldite you wont be able to take it apart. besides araldite is water resistant to can handle hot humid climes of bombay a bit better.

here is my take....

I started out using 35mm MDF (rs. 80 / sq. ft) and found out hick wood stores too much energy.

so in my later cabiets I reduced the wood to 18mm and increased bracing so that all cabinet resonances were in the upper midbass freq. these freq were damped using dacron or fiberglass. dacron is easier to work with but more expensive.

my latest cabinet is in the works. i did post a few pics a few months ago. the cabinet is 48" x 10" x 16" (HWD).

the sides of the cabinet uses 3 layers of 3mm MDF (external grade) and 3 layers of 4mm marine ply. i braced the cabinet at 4", 5", 6", 7" and 8" intervals using 35mm external MDF. the front and back are 35mm MDF.

the six layers are bent (pre stressing the wood reduces flex).

then i applied a layer of fiberglass matting on the inside bonded with resin.

then i got som 1.5mm lead sheet from Pydhonie (near Crawford market). 3' x 8' of lead sheet weighs 40kgs and cost Rs 1836. should be enough to damp both cabinets and also leave some for the center channel and DVD player.

now i will apply the lead sheet with araldite to some of the walls.

I normally use 1.5 mm veneer but this time I am painting the cabinets black.

Now as far as intimidation is concerned you better stop calling me Bhai. You dont want the "real" Bhais to take umbrage to this. And the next time anyone calls me Mr. a Moderator will pay them a visit. to quote Jason L "There are 8 moderators. All over 7 feet tall. All over 17 stone. All trained athletes with bulging muscles and hair trigger reflexes. Each moderator is equipped with two low slung colt 45's, night vision glasses and armour piercing tracer shells."

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Indian equivalents of the following DIY items.