Dan was refering to permanent demagnitization, not AC flux modulation.

Try not to forget that part of what I was doing was to make an effort to clearly differentiate between the two phenomena, something that nobody else appears to be overly interested in pointing out. Sure, alnico's coercive force is lower than the other common types, but it's kinda silly to dwell on that to obscure its superior characteristics for high quality speaker applications. Proper alnico magnetic circuit design can even stymie the worst efforts of warranty-voiding audio abusers who are liable to hook your speakers to an arc welder amp and then clip it into them indefinitely.

Pan,

I always try polite and I seem to fail.

Err. Yes. But what distortion? and do you, as you claim, find the relevant info easily on a manufacturer's website? Vifa, Peerless etc mainly publish FR graphs. Seas has THD graphs in addition to that. Some manufacturers may have waterfall plots with their inherent interpretation problems due to windowing etc. Typically the measurements used different setups each time, even within a same manufacturer. Take simple FR: some have full space anechoic measurements (say, Seas) in a small box. The FR shows a clear baffle step. Others, say Peerless, use half space measurements. No baffle step.

You went to two manufacturer's websites and deduced relative performance from the data published there (Aura 10" vs Excel 10" woofers). So, *you* claimed that.

I generally commented on what I saw as your naive view of taking a few published and not well standardized measurements as basis of comparison. For instance:

This sounds suspiciously as if you took the naturally faster rolloff of a low Q woofer as an indication for "inferior bass response".

Back to resolution. THD ad IMD will impact resolution to some degree (by producing masking effects if severe enough and if in a vulnerable point of the Fletcher Munson curve, i.e. in lower and mid bass where the curve still slopes down heavily), but as steady state measurements actually only tell you what tones the driver will produce which were *not* in the original signal. Resolution means, how well does the driver render tones which *were* in the original signal. Specifically we talk about time domain here, not frequency domain. As such, for instance, the driver with higher resolution may have the same THD and IMD, and a *less* even FR, than another driver with less resolution. Why? because an even FR may indicate a smoothening out through woolly (inexact) rendering, due to high energy storage. Besides, FR deals with steady state response in the frequency domain.

And I really don't see much info on manufacturer's specs regarding readily comparable data on time domain performance decay (energy storage). The best I have seen are Siegfried Linkwitz's measurements (and comments!) on www.linkwitzlab.com, for instance

http://www.linkwitzlab.com/frontiers-2-M2.htm

and

http://www.linkwitzlab.com/mid_dist.htm

If you take the time to peruse that material, you may come to a more nuanced view on judging drivers on the basis of a few data.

I always try polite and I seem to fail.

Resolution and distortion is related don´t you think?

Err. Yes. But what distortion? and do you, as you claim, find the relevant info easily on a manufacturer's website? Vifa, Peerless etc mainly publish FR graphs. Seas has THD graphs in addition to that. Some manufacturers may have waterfall plots with their inherent interpretation problems due to windowing etc. Typically the measurements used different setups each time, even within a same manufacturer. Take simple FR: some have full space anechoic measurements (say, Seas) in a small box. The FR shows a clear baffle step. Others, say Peerless, use half space measurements. No baffle step.

"Can anyone deduct resolution performance (and dynamic compression etc) from frequency response graphs and manufacturer's spec sheets alone?"

I don´t thihnk anyone ever claimed that but to some degree yes, if the measuremetns are good and detailed enough. Resolution needs low HD/ID distortion, flat FR and fast decay.

You went to two manufacturer's websites and deduced relative performance from the data published there (Aura 10" vs Excel 10" woofers). So, *you* claimed that.

I generally commented on what I saw as your naive view of taking a few published and not well standardized measurements as basis of comparison. For instance:

you´ll see that the performance are not superior on the Aura woofer. Even the W22 has better upper bass than the Aura woofers

This sounds suspiciously as if you took the naturally faster rolloff of a low Q woofer as an indication for "inferior bass response".

Back to resolution. THD ad IMD will impact resolution to some degree (by producing masking effects if severe enough and if in a vulnerable point of the Fletcher Munson curve, i.e. in lower and mid bass where the curve still slopes down heavily), but as steady state measurements actually only tell you what tones the driver will produce which were *not* in the original signal. Resolution means, how well does the driver render tones which *were* in the original signal. Specifically we talk about time domain here, not frequency domain. As such, for instance, the driver with higher resolution may have the same THD and IMD, and a *less* even FR, than another driver with less resolution. Why? because an even FR may indicate a smoothening out through woolly (inexact) rendering, due to high energy storage. Besides, FR deals with steady state response in the frequency domain.

And I really don't see much info on manufacturer's specs regarding readily comparable data on time domain performance decay (energy storage). The best I have seen are Siegfried Linkwitz's measurements (and comments!) on www.linkwitzlab.com, for instance

http://www.linkwitzlab.com/frontiers-2-M2.htm

and

http://www.linkwitzlab.com/mid_dist.htm

If you take the time to peruse that material, you may come to a more nuanced view on judging drivers on the basis of a few data.

In addition to muddying the discussion by being another Bill F.,  I'd like to caution those who are eager to compare different drivers for the sake of determining the relative merits of their magnet types.

I'd like to caution those who are eager to compare different drivers for the sake of determining the relative merits of their magnet types.

Unless the two drivers being compared are otherwise absolutely identical, I believe the sonic signature of the magnet type will be so buried beneath other differences that comparison would be silly.

Even where T/S parameters are identical, subtly different diaphragm/suspension systems can have very different sonic signatures.

Setting that aside and looking just at the motor, a lot of sonically significant things happen at the gap/VC interface. The topology (over/underhung), the ratio of VC height to gap height, inductance modulation, pole and top-plate shape and dimensions, the presence and position of shorting rings, the gap flux-density gradient from top to bottom, etc., etc. All probably have quite a bit more to do with the final sound than magnet type.

Even comparing drivers from the same manufacturer would probably be pointless since motor components likely aren't the same.

Unless the two drivers being compared are otherwise absolutely identical, I believe the sonic signature of the magnet type will be so buried beneath other differences that comparison would be silly.

Even where T/S parameters are identical, subtly different diaphragm/suspension systems can have very different sonic signatures.

Setting that aside and looking just at the motor, a lot of sonically significant things happen at the gap/VC interface. The topology (over/underhung), the ratio of VC height to gap height, inductance modulation, pole and top-plate shape and dimensions, the presence and position of shorting rings, the gap flux-density gradient from top to bottom, etc., etc. All probably have quite a bit more to do with the final sound than magnet type.

Even comparing drivers from the same manufacturer would probably be pointless since motor components likely aren't the same.

The 10" mid driver, (PD sourced, I think, but it could have been Eminence) used in older Turbosound PA systems was replaced with a new model with a neodymium magnet several years ago. It was an exact replacement, and sounded no different to the older alnico model, but was just smaller and lighter.

I have nothing 'against' neodymium, and if I were a speaker designer, I would probably use it in preference to alnico for some designs where maximum flux/magnet volume and/or light weight were the overriding considerations. But it simply is not as temperature insensitive as alnico. And if the overwhelming indictment against alnico is supposed to be its low coercivity, why not go to samarium cobalt which doesn't have that problem or the particular weaknesses of neo?

thoriated said:But it simply is not as temperature insensitive as alnico.

So all those PA companies that use neo magnet drivers, usually running at near 100% duty rating, night after night, end up with demagnetised drivers?

So all those PA companies that use neo magnet drivers, usually running at near 100% duty rating, night after night, end up with demagnetised drivers?

They sure do, until they cool down. An additional nonlinearity (even in smaller amounts) you would be better off without when high quality is your prime objective, IMO. None of which is meant to imply that said nonlinearity will in any way make neo speakers sound 'bad'. Probably the effect would be mild soft euphony and a degradation in image stability and loss of small detail in dynamic material. Again, if you insist on the argument that one must need massively overpower his speakers, therefore he mustn't use alnico drivers, I strongly disagree.

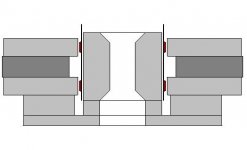

Perhaps alnico's demagnetization threshold makes it a good candidate for a HyperDynamics dual-gap topology. The counter-wound VCs cancel each other's inductive "push," so (unless I'm having a Friday moment) I believe the magnet's field should remain undisturbed at any VC power level. I find this a facinating topology.

Attachments

I'd love to see some data where the magnet structure reached 70 or 80 deg C, yet the voice coil still holds together, and the increase in DCR from thermal heating doesn't completely swamp the effect from magnet heating.thoriated said:

They sure do, until they cool down. An additional nonlinearity (even in smaller amounts) you would be better off without when high quality is your prime objective, IMO. None of which is meant to imply that said nonlinearity will in any way make neo speakers sound 'bad'. Probably the effect would be mild soft euphony and a degradation in image stability and loss of small detail in dynamic material. Again, if you insist on the argument that one must need massively overpower his speakers, therefore he mustn't use alnico drivers, I strongly disagree.

By the time a voice coil can generate enough heat to raise the magnet to 150+ deg C, it's well above 200 deg C itself, and possibly above 240 deg C, thereby setting the cone on fire (yes, I have seen that happen as well! Amazing what happens when one gets a little crazy with a QSC PLX3402 on a speaker - 3400W will melt down and literally catch a speaker on fire in a hurry).

The voice coil will exhibit a LOT more sensitivity loss than the magnet, at a quicker rate as well. Thermal mass of a typical pro-sound driver is extremely high; take a 6 pound magnet, add 8 pounds of steel. That's a LOT of mass (and a LOT of radiating area) to heat up. The little 40 gram voice coil will heat a lot quicker and to a much higher degree.

I've thermal-stressed drivers by the hundreds in our test lab. I've gotten motors to the temperature where they are too hot to keep your hand on them for more than 4-5 seconds (around 60 deg C), but never been able to push one past that without the voice coil dying. Even neo units.

Neo is making a BIG push into PA use because it offers low weight, small size (easier to pack multiple drivers into a given box size), and more than enough reliability - even SH grade. Ferrite is still choice number 2 because of cost, ease of assembly (everyone's lines are set up to build with it) and reliability. AlNiCo really comes up short in price and coercivity. And SmCo? That's REALLY pricey, and nearly unobtainable - it's virtually unused in the loudspeaker industry. It's not as strong as neo, and its big advantage in thermal issues aren't that big of a deal in reality. That's why it's pretty much limited to mil/aero uses where operation over extreme temperature ranges is needed.

IMHO, if you have a budget and aren't concerned about weight, go ferrite. There's really not much better in terms of price/performance. If weight or physical size is a concern, then neo. AlNiCo should be reserved for nostalgic use or where you need extremely high temperature operation (such as in industrial motors - nothing you'd get in a speaker).

Dan Wiggins

Adire Audio

You're observations on loudspeaker nonlinear behavior are quite fascinating, thank you Dan. I think that Bill was worried to what might happen to the magnetic properties progressively from small signal (small heating) levels on - I presume that there is no "on/off" behavior but a hysteresis curve, which most likely would be different for different magnet materials. Very few of us, I believe, will operate loudspeakers at "close to destruction" amplitude (unless you are a PA professional or dance club owner) - what are your observations as far as magnetic material influence goes, for small to medium level applications?

Thanks you again for your insight.

Cheers

Thanks you again for your insight.

Cheers

I'm explicitly talking about temporary (e.g. reversible) changes in magnetic material properties that manifest themselves far below temperatures where the thermal destruction of any moving assemblies is imminent, and the chart I posted earlier is of primary applicability here.

The realm where the VC is operating above 100C is another subject entirely and is not my primary concern.

The realm where the VC is operating above 100C is another subject entirely and is not my primary concern.

Couple things to note...

Ferrite has a POSITIVE temperature coefficient of coercivity. That means the hotter it is, the harder it is to demagnetize (it gets stiffer in terms of coercivity). This is also the situation where you have large fields, and higher power heating. The harder you run your driver with a ferrite magnet, the better it gets from a sag standpoint.

The BH curves for AlNiCo in the 2nd quandrant for typical blends (AlNiCo 5, 6, and 5CC grades) are considerably softer than Ferrite or Neo. And the knee it as much lower flux levels that Ferrite or Neo (see http://www.arnoldmagnetics.com/products/alnico/alnico_cast_curve_5-800.htm for AlNiCo curves, and http://www.arnoldmagnetics.com/products/ferrite/ferrite_AC-5.htm for typical Ferrite curves). Your droop with AlNiCo from voice coil fields is much greater than Ferrite, and in fact you can permanently demagnetize the AlNiCo magnet at much lower power levels than Ferrite.

For instance, assume a voice-coil induced field of 500 Oersteds. With typical AlNiCo 6, you're down 30% as compared to no voice coil field. For Ferrite (at 20 deg C), you're down ~2% at the same voice coil induced field. In fact, you'd need roughly 5X that field (2500 Oersteds) to get the same loss in Ferrite as the AlNiCo.

Ferrite, when it does drop, does so dramatically and quickly; it reaches its limit and "dies" quickly. AlNiCo drops off at a much slower rate, but starts a lot sooner.

AlNiCo's saving grace is that it can handle high temperatures and has high remenance as compared to Ferrite.

Ferrite gets better as you heat it (up to the Curie point), has extremely strong coercivity, and is low cost.

Neo has extremely high remenance, handles temperature OK (not as good as Ferrite or AlNiCo), and has very high coercivity.

For magnets in dynamic fields, you should be concerned with coercivity first and foremost. AlNiCo simply comes up short in this application. Yes, it can take higher temperatures, but rarely if ever is motor warming a big concern. For high power situations where you would get heating, you have VERY strong field strengths, meaning coercivity is the issue.

It's like BL versus power compression. We all know what power compression is, but it's a long term effect - it takes time to happen. Loss of efficiency due to BL compression (BL drop with excursion) is instantaneous; it happens on every cycle. You can add all the cooling you want to the motor, but you can only cure BL compression by designing a flat BL curve over excursion.

Likewise with magnetic strength. You can cool or heat a motor as much as you want, and over time (minutes of time, taken to heat up a motor structure) that may make a difference. However, on the VERY FIRST big peak of music, we're reaching coercivity modulation - lots of voice coil flux to counter the magnet's own field. AlNiCo simply doesn't match Ferrite or Neo.

In the case you're arguing for - dynamics without power/temperature concerns, AlNiCo is actually a worse performer because of the low coercivity. It is high temperature situations (like PA use) where AlNiCo shines its best (which is, IMHO, still behind Neo and Ferrite).

Dan Wiggins

Adire Audio

Ferrite has a POSITIVE temperature coefficient of coercivity. That means the hotter it is, the harder it is to demagnetize (it gets stiffer in terms of coercivity). This is also the situation where you have large fields, and higher power heating. The harder you run your driver with a ferrite magnet, the better it gets from a sag standpoint.

The BH curves for AlNiCo in the 2nd quandrant for typical blends (AlNiCo 5, 6, and 5CC grades) are considerably softer than Ferrite or Neo. And the knee it as much lower flux levels that Ferrite or Neo (see http://www.arnoldmagnetics.com/products/alnico/alnico_cast_curve_5-800.htm for AlNiCo curves, and http://www.arnoldmagnetics.com/products/ferrite/ferrite_AC-5.htm for typical Ferrite curves). Your droop with AlNiCo from voice coil fields is much greater than Ferrite, and in fact you can permanently demagnetize the AlNiCo magnet at much lower power levels than Ferrite.

For instance, assume a voice-coil induced field of 500 Oersteds. With typical AlNiCo 6, you're down 30% as compared to no voice coil field. For Ferrite (at 20 deg C), you're down ~2% at the same voice coil induced field. In fact, you'd need roughly 5X that field (2500 Oersteds) to get the same loss in Ferrite as the AlNiCo.

Ferrite, when it does drop, does so dramatically and quickly; it reaches its limit and "dies" quickly. AlNiCo drops off at a much slower rate, but starts a lot sooner.

AlNiCo's saving grace is that it can handle high temperatures and has high remenance as compared to Ferrite.

Ferrite gets better as you heat it (up to the Curie point), has extremely strong coercivity, and is low cost.

Neo has extremely high remenance, handles temperature OK (not as good as Ferrite or AlNiCo), and has very high coercivity.

For magnets in dynamic fields, you should be concerned with coercivity first and foremost. AlNiCo simply comes up short in this application. Yes, it can take higher temperatures, but rarely if ever is motor warming a big concern. For high power situations where you would get heating, you have VERY strong field strengths, meaning coercivity is the issue.

It's like BL versus power compression. We all know what power compression is, but it's a long term effect - it takes time to happen. Loss of efficiency due to BL compression (BL drop with excursion) is instantaneous; it happens on every cycle. You can add all the cooling you want to the motor, but you can only cure BL compression by designing a flat BL curve over excursion.

Likewise with magnetic strength. You can cool or heat a motor as much as you want, and over time (minutes of time, taken to heat up a motor structure) that may make a difference. However, on the VERY FIRST big peak of music, we're reaching coercivity modulation - lots of voice coil flux to counter the magnet's own field. AlNiCo simply doesn't match Ferrite or Neo.

In the case you're arguing for - dynamics without power/temperature concerns, AlNiCo is actually a worse performer because of the low coercivity. It is high temperature situations (like PA use) where AlNiCo shines its best (which is, IMHO, still behind Neo and Ferrite).

Dan Wiggins

Adire Audio

Yep, definitely hysteresis curves! AlNiCo has very soft curve; Ferrite is quite square. Neo is darn near a perfect square! AlNiCo starts losing strength quite early and easily - it cannot hold up its own field very well at all in the presence of an external magnetic field. Ferrite and Neo do a lot better.RussianBlue said:You're observations on loudspeaker nonlinear behavior are quite fascinating, thank you Dan. I think that Bill was worried to what might happen to the magnetic properties progressively from small signal (small heating) levels on - I presume that there is no "on/off" behavior but a hysteresis curve, which most likely would be different for different magnet materials. Very few of us, I believe, will operate loudspeakers at "close to destruction" amplitude (unless you are a PA professional or dance club owner) - what are your observations as far as magnetic material influence goes, for small to medium level applications?

Thanks you again for your insight.

Cheers

If you're using an amplifier analogy, you can think of remenance as output power, and coercivity as output conductance (inverse of output impedance). A high remenance would mean a high power amp - you can generate a lot of output! A low coercivity (low conductance - high impedance), though, means that as the load on the amp gets harder (lower impedance), the amp (magnet) has more loss (lower remenance) in output power (flux).

You get more "modulation" of the signal on the load with a high output impedance (low conductance); likewise with a magnet that has a low coercivity - it cannot maintain its field strength, and so the BL of the driver drops (and with it the attendant loss in efficiency, gain in Q, etc).

Dan Wiggins

Adire Audio

it (alnico) cannot hold up its own field very well at all in the presence of an external magnetic field. Ferrite and Neo do a lot better.

I cannot forbear noting that such a blanket assertion flies directly in the face of the reversible characteristics figures given for these materials.

The existence of such a situation in reality would also have made the prosound industry's continued preference for alnico for decades when ferrite was available nonsensical.

Hmm, the data and the hysteresis curves all point to the fact that AlNiCo demagnetizes at much lower field strengths than Ferrite or Neo. And that it drops off in strength in the presence of weak fields much sooner and to a larger degree than Ferrite or Neo.thoriated said:

I cannot forbear noting that such a blanket assertion flies directly in the face of the reversible characteristics figures given for these materials.

Perhaps your experience with prosound drivers (sound reinforcement) needs to be updated? I don't know of any modern prosound drivers that use AlNiCo. They all use Ferrite or Neo. And it's been that way for probably 30 years.

The existence of such a situation in reality would also make the prosound industry's continued preference for alnico for decades when ferrite was available nonsensical.

Perhaps you're thinking of musical instrument drivers? In that case, AlNiCo is still used a lot, but precisely because of the distortions (compressions) that it introduces. It's like using little 10W amps heavily overdriven. They do that to generate high levels of distortion which is part of the "sound" being produced. In these cases AlNiCo is still quite popular.

But for sound reproduction/reinforcement, Ferrite and Neo are pretty much the exclusive magnets used (save for some few compression drivers that use AlNiCo more as an homage to vintage roots, rather than accuracy).

Dan Wiggins

Adire Audio

Ah yes, Dan, compression you say. In a sense, then, would it be accurate to describe the "Alnico Sound" as a "soft" compression effect with probably some low order distortions? I imagine this, in conjunction with the typical class a tube amplifier distortions is the sound that made the rock guitar sounds of the 60s so famous?

On a different note: what do you think of the idea that a smooth FR curve in lsp drivers can show (and mean) smoothing due to energy stored? Can "resolving power" and impulse response accuracy be predicted by the FR graph? Again, very nice discussion, thank you.

Cheers

On a different note: what do you think of the idea that a smooth FR curve in lsp drivers can show (and mean) smoothing due to energy stored? Can "resolving power" and impulse response accuracy be predicted by the FR graph? Again, very nice discussion, thank you.

Cheers

IMHO, absolutely. Likewise with the strap motor versus a full round motor - the saturation is different in the motor. Or baskets - the acoustic loading of the old classic slotted basket from Celestion versus the open baskets used in standard sound reinforcement/sound reproduction.RussianBlue said:Ah yes, Dan, compression you say. In a sense, then, would it be accurate to describe the "Alnico Sound" as a "soft" compression effect with probably some low order distortions? I imagine this, in conjunction with the typical class a tube amplifier distortions is the sound that made the rock guitar sounds of the 60s so famous?

It's also why so many guitar amps of today still use classic cone shapes from the original manufacturers, and why the US and British cones still dominate - it's partly the actual water content of the cone that makes a characteristic "sound". You can actually hear the differences between the exact same cone geometries when produced in Mexico or China as compared to Kentucky.

In musical instrument drivers, the driver itself is part of the instrument - it is to create a new sound. In all other drivers (sound reinforcement or home reproduction), the job of the driver is to simply reproduce what it is given, not introduce distortions on its own.

In musical instrument speakers, generation of distortion is usually highly sought!

I don't buy into a lot of that. Give me a waterfall plot or spectral contamination plot any day. So many of the stored energy measurements made and "worshipped" today are, IMHO, inherently inaccurate. The problem is measurement within the near field.

On a different note: what do you think of the idea that a smooth FR curve in lsp drivers can show (and mean) smoothing due to energy stored? Can "resolving power" and impulse response accuracy be predicted by the FR graph? Again, very nice discussion, thank you.

Cheers

The near field is, by definition, an acoustic volume in front of a piston that does not maintain a linear SPL-to-distance relationship. In fact, SPL can DECREASE as you move towards the piston, inside the near field. You can get peaks and dips in the frequency response, and the location of these peaks and dips in frequency will change as the distance from the piston changes.

The near field extends out to approximately d^2/l, where d is the effective radiating diameter of the piston, and l is the wavelength of interest. Thus as the frequency or driver size increases, we find that the near field goes out further. For a typical 6.5" woofer, d ~= 13 cm. That would mean that at a measurement distance of 1" (2.5cm), we find a wavelength of (169/2.5) 67.6cm, or a frequency of ~500 Hz would be the upper limit of data that is NOT in the nearfield. Measurements above this frequency would be suspect.

IMHO, to find stored energy (resonance, it used to be called until the new vogue term popped up) you should use a waterfall, or use a spectral contamination plot averaged over time. Both are great. I know the argument is to use near field measurements to avoid the room, but then the answer is to either use a large measurement room, or gate your measurements. But to measure in the near field is, IMHO problematic and does not give an accurate or even realistic picture of the performance of a driver.

Dan Wiggins

Adire Audio

DW -

I see that you cannot or will not respond to the industry preference for alnico between the end of WWII and the late '70's when the price of cobalt increased by such a large amount.

You appear to concede the point here.

An absolute greater resistance to flux modulation as well as a tempco sensitivity of 0.01 for HC (flux modulation) is vastly preferable in my book to one of -0.6, or +0.3 for that matter.

Alnico is greatly superior in both characteristics to ferrite or neodymium, a fact generally accepted by knowledgable people.

Unless you can cite reversible figures indicating otherwise, I don't know why you even bother with such broad brush assertions.

I see that you cannot or will not respond to the industry preference for alnico between the end of WWII and the late '70's when the price of cobalt increased by such a large amount.

You appear to concede the point here.

An absolute greater resistance to flux modulation as well as a tempco sensitivity of 0.01 for HC (flux modulation) is vastly preferable in my book to one of -0.6, or +0.3 for that matter.

Alnico is greatly superior in both characteristics to ferrite or neodymium, a fact generally accepted by knowledgable people.

Unless you can cite reversible figures indicating otherwise, I don't know why you even bother with such broad brush assertions.

Hmmm, ferrite started coming on strong in the 70s when good reliable formulations that could produce usable remenance came about. Prior to that most ferrite magnet formulations simply didn't have enough remenance to be worthwhile. It wasn't preference for AlNiCo! It was because there wasn't a viable alternative.thoriated said:DW -

I see that you cannot or will not respond to the industry preference for alnico between the end of WWII and the late '70's when the price of cobalt increased by such a large amount.

You appear to concede the point here.

And neo - which originally was MUCH more expensive than AlNiCo - took off precisely BECAUSE of its coercivity - it simply holds up much better than AlNiCo. If you want to argue counter, then I guess you're free to do so, but the way the industry has moved - to ferrite and neo - seems to run completely counter to your argument.

The reality is that AlNiCo is about the same cost as N42SH grade neo today, when purchased in typical driver manufacturer quantities. AlNiCo isn't used because it's not as good as neo, not because it's more expensive.

An absolute greater resistance to flux modulation as well as a tempco sensitivity of 0.01 for HC (flux modulation) is vastly preferable in my book to one of -0.6, or +0.3 for that matter.

BUT YOU'RE COMPLETELY WRONG! The hard facts are that AlNiCo has a MUCH lower coercivity, begins to lose strength in the presence of an external magnetic field WAY before ferrite or neo! Look at the posted BH curves I provided. If you know how to read them you'll see that AlNiCo simply folds under external "pressure" well before ferrite or neo.

If you want resistance to flux modulation, then run AWAY from AlNiCo. EVERY source will show you that, because that's what the BH curves show!

And you keep rambling on about tempco. OK, if the ambient temperature varies a lot then yes, AlNiCo can be desirable. But have you ever run a driver with significant power over time? I have, hundreds of times. You do know that I make loudspeakers and drivers for a living? And have done so for about a decade now? It takes a LOT of continuous power over a very long time to get any significant change in motor temperature.

Of course, compare that to what happens to the voice coil's DCR. You keep wanting to press this point that MAY result in a few tenths of a dB of SLOW compression (ramps that will take minutes either way) but completely ignore that to generate that much heating you have a LOT more heat in the voice coil. and hence have several dB (2, 3, 4 or more) compression.

Not to mention the large loss in flux that you get from quick, high amplitude transients with AlNiCo BECAUSE IT HAS LOW COERCIVITY! That is instantaneous and unavoidable. It does not take time to build up, and it is not a few percent.

Look at the example I gave above with the 500 Oersted field. A fill 30% loss for AlNiCo! With a tempco of 0.2% per degC for ferrite, I'd have to have a temperature change of 150 deg C to reach that same loss! You have to have a temperature SO HIGH that the voice coil would char to reach what AlNiCo does with a standard mid-power level. 500 Oersteds isn't that large at all - you'll get that with just a few hundred Watts into a 3" voice coil of typical 1" length.

Bunk. Pure and simple. There's not a shred of data to back up your assertion. AlNiCo will DISTORT its flux much more than ferrite or neo, which CAN lead to pleasant distortions. Much like overdriving tube amps, or using improperly designed horn speakers.

Alnico is greatly superior in both characteristics to ferrite or neodymium, a fact generally accepted by knowledgable people.

Unless you can cite reversible figures indicating otherwise, I don't know why you even bother with such broad brush assertions.

Try to keep preference and objectivity seperate! Some may PREFER the sound of AlNiCo, but of course others do not. Preference shouldn't be used to justify why AlNiCo is better especially in regards to flux compression when the data you even posted runs counter.

Just look at the BH curves for yourself! You'll quickly see that AlNiCo actually ALLOWS flux modulation more than ferrite or neo, not resist it like you mistakenly contend.

You keep harping on about tempco and such, when the bottom line is that is, for all intents of loudspeakers, a meaningless number. You'll never get significant heating of the motor to cause a significant change in remenance without 10X+ the problem in the voice coil. Or even the magnet itself in how it holds up to the presence of an external field.

I guess if you want to sweat the tiny little issues and completely ignore the much greater, easy to hear problems, well, be my guest. I'd personally rather solve the big problems than ignore them...

Dan Wiggins

Adire Audio

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- If neodymium is all that great . . .