if you crossed it over at say 200hz or lower and stacked a bunch of panels together and loaded the horn to push a whole lot of air with very little diaphram excursion it should work fine.

Yup. Horn loading a stack of panels will result in reducing the excursion of the diaphragms, same is it does for a single diaphragm. So, the maximum SPL output capability will not be any greater than if you used the same number of stacked panels built with larger D/S spacing without the horn.

But, now that I think about it, one difference with the horn loaded case is that you would be able to use lower bias and drive voltages with the horn loaded stack, which would be an advantage. No higher output, but potentially an easier/safer build.

This is very similar in concept to the ESL AMT discussed here:

http://www.diyaudio.com/forums/planars-exotics/153220-electrostatic-amt-18.html#post1981873

http://www.diyaudio.com/forums/planars-exotics/153220-electrostatic-amt-18.html#post1981869

Replacing a simple ESL panel with an array of AMT pleats reduces the required excursion of each of the ESL panels which make the pleats. But, the resulting maximum SPL output capability is the same if the frontal radiating area is the same. The advantage is the ability to use lower bias and drive voltages since the excursion requirements are reduced.

Yup. Horn loading a stack of panels will result in reducing the excursion of the diaphragms, same is it does for a single diaphragm. So, the maximum SPL output capability will not be any greater than if you used the same number of stacked panels built with larger D/S spacing without the horn.

How do you figure? Why wouldn't the horn increase the output SPL like it does in every other application?

How do you figure? Why wouldn't the horn increase the output SPL like it does in every other application?

The horn will increase the output SPL of the ESL. But, the horn reduces the excursion(ie output) of the ESL by the same amount. So, the net gain in output capability is zero.

Perhaps reviewing post #93 will help:

http://www.diyaudio.com/forums/planars-exotics/190023-horn-loaded-electrostatic-10.html#post2613309

AMT = Air Motion Transformer

Last edited:

Except that the factor that limits the output SPL of the ELS is excursion so if the horn reduces excusion at the same SPL then you turn it up. It may not increase efficiency per se' but power handling and maximum output would be increased greatly.

Remember the factor that limits the maximum output SPL of ESLs is Force per unit area.

This is a byproduct of the physical restraint of obtainable voltage gradient in the gaps between diaphragm and stator before the air conducts and arcing or corona results.

Review post #71 and #76

http://www.diyaudio.com/forums/planars-exotics/190023-horn-loaded-electrostatic-8.html#post2604197

http://www.diyaudio.com/forums/planars-exotics/190023-horn-loaded-electrostatic-8.html#post2609347

I beg to differ on the thought that there will be no net gain from proper horn loading. A well designed horn can give you 9 db and better gain over a normal room loading. There is a gain in efficiency due to the better acoustical impedance matching of the diaphragm to the horn throat versus an open air loading.

Carry this to it's simple conclusion. Force over unit area will not change. But the effect of the same force over unit area in a horn will create a gain in acoustical output linked to the design of the horns passband and therefore possible gain.

Less movement of the diaphragm will create more acoustical pressure if the diaphragm can meet this simple requirement.

There must be enough force over unit area to overcome the greater pressure seen on the diaphragm at the horn throat.

The multiple diaphragm method will most likely solve this problem.

And it has been precisely this problem that has stalled previous attempts to successfully horn load an ESL. Overcoming the increased acoustical loading or more simply greater air pressure on the surface of the ESL membrane.

I for one think You guys may be on to something.

Carry this to it's simple conclusion. Force over unit area will not change. But the effect of the same force over unit area in a horn will create a gain in acoustical output linked to the design of the horns passband and therefore possible gain.

Less movement of the diaphragm will create more acoustical pressure if the diaphragm can meet this simple requirement.

There must be enough force over unit area to overcome the greater pressure seen on the diaphragm at the horn throat.

The multiple diaphragm method will most likely solve this problem.

And it has been precisely this problem that has stalled previous attempts to successfully horn load an ESL. Overcoming the increased acoustical loading or more simply greater air pressure on the surface of the ESL membrane.

I for one think You guys may be on to something.

Hello mwmkravchenko,

I think I understand what you are getting at, let me try and restate it to check.

Suppose I have an ESL panel with 3mm excursion limit that reaches its excursion limit in the desired bandwidth at the drive voltage which produces peak force per unit area before arcing. For this example, lets say the SPL measured at 100Hz is 100dB.

Now, add a horn sized and designed to increase the airloading on the ESL placed at the horns throat by a factor of 3. The same peak drive voltage will now only provide peak diaphragm excursions of 1mm. The horn will take this 1/3 less output and provide 9.5dB of gain resulting in the same 100dB measured.

Next, stack 2 more panels behind the original one and drive it with the same voltage. Diaphragm excursion will increase to 3mm, and the measured output will now be 109.5dB. Is this what you were getting at? If so, I agree.

But, rather than stack the 2 additional panels behind the first and adding a large horn, you could simple place the 2 additional panels to the left and the right of the original. The excursion of all 3 panels would be 3mm and the measured SPL would 109.5dB. The width would probably be similar or smaller than the horn and the construction much simpler.

I think I understand what you are getting at, let me try and restate it to check.

Suppose I have an ESL panel with 3mm excursion limit that reaches its excursion limit in the desired bandwidth at the drive voltage which produces peak force per unit area before arcing. For this example, lets say the SPL measured at 100Hz is 100dB.

Now, add a horn sized and designed to increase the airloading on the ESL placed at the horns throat by a factor of 3. The same peak drive voltage will now only provide peak diaphragm excursions of 1mm. The horn will take this 1/3 less output and provide 9.5dB of gain resulting in the same 100dB measured.

Next, stack 2 more panels behind the original one and drive it with the same voltage. Diaphragm excursion will increase to 3mm, and the measured output will now be 109.5dB. Is this what you were getting at? If so, I agree.

But, rather than stack the 2 additional panels behind the first and adding a large horn, you could simple place the 2 additional panels to the left and the right of the original. The excursion of all 3 panels would be 3mm and the measured SPL would 109.5dB. The width would probably be similar or smaller than the horn and the construction much simpler.

I was just going over that in my thinking and I would have to agree with you on that one,bolserst.

The ideas that I had concerning horn loading an ESL was not so much to improve gain but to help increase the dispersion angle of the panel to help reduce the beaming effect at the higher end of its bandwidth.

A 4" or 3" wide panel is not that bad at all but if you increase the width to 6" to 10" the problem becomes very prominent as you increase the width of the panel.

I know that we have discussed many different methods to combat this issue,But I am still curious as to if a horn might be a viable alternative at least for the midrange frequency's and up.

jer

The ideas that I had concerning horn loading an ESL was not so much to improve gain but to help increase the dispersion angle of the panel to help reduce the beaming effect at the higher end of its bandwidth.

A 4" or 3" wide panel is not that bad at all but if you increase the width to 6" to 10" the problem becomes very prominent as you increase the width of the panel.

I know that we have discussed many different methods to combat this issue,But I am still curious as to if a horn might be a viable alternative at least for the midrange frequency's and up.

jer

Well I started this thread and my intention was to increase gain. A horn typically narrows the dispertion and increases beaming in higher frequencies in dynamic drivers but by using a narrow throat and wide mouth I suppose it could possibly improve upon an ELS. My question to bolserst is; does an ELS typically reach arching before it reaches it's excursion limit?

Hi,

Mark reminded of the imho one deciding factor a Horn is all about....impedance matching. The Q arises as to why the Horn works for Dynamic speakers as Driver and why it may work differently or not with an ESL. Imho the answer depends on the ESLs dimensions.

If build with appropriate dimensions the acoustic impedance the panel sees can be made real, the optimum situation. Dynamic drivers are usually working under complex conditions and the Horn increases the real part of the acoustic impedance, hence the efficiency of the coupling of the diaphragm to air. A horn could only be helpful to a small Panel. But the horn would counter the smallness and increase dimensions. A large panel on the other hand is best without any kind of baffle. The double or multiple diaphragm panel really increases the SPL because of increasing the force per unit of area.

Jauu Calvin

Mark reminded of the imho one deciding factor a Horn is all about....impedance matching. The Q arises as to why the Horn works for Dynamic speakers as Driver and why it may work differently or not with an ESL. Imho the answer depends on the ESLs dimensions.

If build with appropriate dimensions the acoustic impedance the panel sees can be made real, the optimum situation. Dynamic drivers are usually working under complex conditions and the Horn increases the real part of the acoustic impedance, hence the efficiency of the coupling of the diaphragm to air. A horn could only be helpful to a small Panel. But the horn would counter the smallness and increase dimensions. A large panel on the other hand is best without any kind of baffle. The double or multiple diaphragm panel really increases the SPL because of increasing the force per unit of area.

Jauu Calvin

Last edited:

I only had time to skim the last couple of pages but one thought struck me as interesting.

If the horn was to lessen the ESL excursion as a result of horn loading, wouldn't that be sort of the holy grail?

We're always fighting high voltages and large D/S. If there's a way to keep the spl up, reduce the d/s and thus reduce the voltages it would seem like worthwhile to me?

I might have missed something important and will re-read the pages later this evening. This was just a spontaneous reflection on something bolerst wrote.

If the horn was to lessen the ESL excursion as a result of horn loading, wouldn't that be sort of the holy grail?

We're always fighting high voltages and large D/S. If there's a way to keep the spl up, reduce the d/s and thus reduce the voltages it would seem like worthwhile to me?

I might have missed something important and will re-read the pages later this evening. This was just a spontaneous reflection on something bolerst wrote.

If the horn was to lessen the ESL excursion as a result of horn loading, wouldn't that be sort of the holy grail? We're always fighting high voltages and large D/S. If there's a way to keep the spl up, reduce the d/s and thus reduce the voltages it would seem like worthwhile to me?

Keeping D/S down while increasing SPL output is indeed a tough proposition for low frequencies. The horn can help with this for a given panel. But, if you move your panel from the throat to the mouth of the horn, increase the panel size to that of the mouth, and get rid of the horn…you will have the same max SPL capability with the same reduced excursion as for the horn loaded smaller panel. The frontal area would be the same in both cases, but the horn would add considerable depth.

My question to bolserst is; does an ELS typically reach arching before it reaches it's excursion limit?

Of course it all depends on how you design it. Most ESLs do arc or form corona before reaching excursion limits. But some designers/builders choose to use smaller D/S spacing than is needed for the LF bandwidth of their ESL panel. Usually, this is to allow the use of smaller/cheaper transformers and amplifiers to reach peak output in the midrange. It doesn’t make sense to me because you can only play them loud when playing music without heavy bass content. But, not everybody has the same priorities.

The key point to remember is that the max force per unit area is not dependent on D/S spacing. It is dependent on voltage gradient in the gap. Choose the D/S required to keep the diaphragm from hitting the stators at the LF bandwidth limit you desire, and this dictates the bias voltage and stator drive voltages required to reach the max force condition before arcing.

I know that we have discussed many different methods to combat this issue,But I am still curious as to if a horn might be a viable alternative at least for the midrange frequency's and up.

For midrange and up where ka>3 (ie wavelength is considerably smaller than the smallest dimension of your ESL panel) the airload the ESL “sees” will be resistive in nature and horns will provide gain as expected. But, remember that all ESLs have by nature a response that rises with frequency. So, if you boost the output of midrange and higher frequencies with a horn you will have a more difficult time getting an ESL woofer to match up in output capability.

I think I understand what you are getting at, let me try and restate it to check.

bolserts Yes you understand.

Calvin yes you have it right to.

See below to have your cake and eat it to.

Well you guys remind me of the ESL fundamentals and in a different thread there was a sketch done of a larger panel stack with a side exit. That would provide enough air velocity from the electrostatic panels to take proper use of the horn loading.

Keep this in mind that in an optimal horn the air is pressurized and basically behaves as a fluid right off of the area creating the pressure front. So you could create a panel stack that exited out on edge, much more conducive for horn loading.

Horn I understand well.

The second problem always inherent in the horn loading dilemma is that a large throat area is not conducive to a good horn design.

The thin side exit stack idea would solve that problem to.

I have a few clients that would be interested in this if I could get it working. Heck I would be interested if I could get this working.

Time, more time!

Well you guys remind me of the ESL fundamentals and in a different thread there was a sketch done of a larger panel stack with a side exit. That would provide enough air velocity from the electrostatic panels to take proper use of the horn loading.

Keep this in mind that in an optimal horn the air is pressurized and basically behaves as a fluid right off of the area creating the pressure front. So you could create a panel stack that exited out on edge, much more conducive for horn loading.

What you are describing (...large panel stack with a side exit...) is an ESL AMT(Air Motion Transformer).

I’m guessing you may have seen some sketches in the Electrostatic AMT thread:

http://www.diyaudio.com/forums/planars-exotics/153220-electrostatic-amt.html

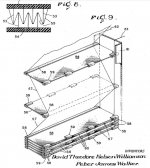

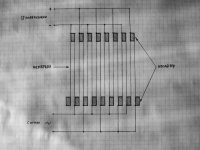

Attachments #1 & #2 are some figures pulled from US patents 3,008,013 & 3,136,867.

Attachment #3 is a drawing of a stator-less AMT posted toward the end of the AMT thread.

What do you think the advantages would be to horn loading an AMT vs. the AMT by itself?

.

Attachments

yes the one on the right is the sketch I was remembering.

The center diagram looks interesting. As does the left most one.

So we are not the first to have thought of this?

Hah.

There is nothing new in audio.

Only better materials in some instances.

This is looking more feasible as you show examples.

Depends on my work load , but I think I will give this a try.

I'm only four designs behind right now.

The center diagram looks interesting. As does the left most one.

So we are not the first to have thought of this?

Hah.

There is nothing new in audio.

Only better materials in some instances.

This is looking more feasible as you show examples.

Depends on my work load , but I think I will give this a try.

I'm only four designs behind right now.

It isn't going and never will!. If I recall correctly I think it was Baxandall who pointed out in his writings on ESL's that the motor strength generated by an ESL is around 1/40th that of a moving coil motor.

When we achieve a good impedance match to the air with a horn the driver has to do some serious work. The (acoustic) load has a dominant real part (as in real and imaginary, when describing complex impedances) ESL's are found lacking when loaded in this way and the addition of a rear chamber will only make matters worse. Analogous to electrical power, acoustic power is the product of pressure and particle velocity. It is in the pressure department that weak motors tend to stall.

Keith

When we achieve a good impedance match to the air with a horn the driver has to do some serious work. The (acoustic) load has a dominant real part (as in real and imaginary, when describing complex impedances) ESL's are found lacking when loaded in this way and the addition of a rear chamber will only make matters worse. Analogous to electrical power, acoustic power is the product of pressure and particle velocity. It is in the pressure department that weak motors tend to stall.

Keith

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Horn loaded electrostatic ??