There are several aproaches of the concept.

Basic ultra simplified one method:

divide core layer in to pie pieces with same odd number of winding in each.

Wind odd number of layers in section wind even number of lyers on top in different direction.

Then next even section and so on repeating until finished.

Ouch i´m a bad teacher please chip in someone better at explaining.

Don´t worry, I could understand you. I´ll try this also.Is that Svetlana or EH?

The tubes and the boxes are Mullard, but I read somewhere that they are making them in Russia, with the original Mullard achinery. True???

I was thinking of using Kynar covered wire wrap wire.

But it has been mentioned that it has a high dissipative factor and possible piezo effects in which may not be a problem for my particular application.

It does have thick covering though and withstands voltages above 10kv with no punch through.

Very impressive for such a coating of your typical wire wrap wire.

These guys seem to have some very good prices,But you must call them to request that you get a wire with a heaver coating if they have any in stock,

Magnet Wire - Paramount Wire Co.

And this company has a very good selection of quality wire but is of typical prices as copper isn't as cheap as it used to be,

magnets, wire, shrink tubing, solenoids, electromagnets and driver electronics at PlanetEngineers.com

These prices aren't as bad also,

wire and cable

These are all of the links that I have saved so far.

I had a company for a 1000' spool of 30ga. wire wrap wire for around $30 but I seemed to have lost the link.

It can be Googled up very easily though.

There are lots of company's out there but only a few distributors that sell small bulk quantities with decent prices.

Keep on DIYing !!

jer

P.S. The description in post #20 was kind of what I was referring to.

But it has been mentioned that it has a high dissipative factor and possible piezo effects in which may not be a problem for my particular application.

It does have thick covering though and withstands voltages above 10kv with no punch through.

Very impressive for such a coating of your typical wire wrap wire.

These guys seem to have some very good prices,But you must call them to request that you get a wire with a heaver coating if they have any in stock,

Magnet Wire - Paramount Wire Co.

And this company has a very good selection of quality wire but is of typical prices as copper isn't as cheap as it used to be,

magnets, wire, shrink tubing, solenoids, electromagnets and driver electronics at PlanetEngineers.com

These prices aren't as bad also,

wire and cable

These are all of the links that I have saved so far.

I had a company for a 1000' spool of 30ga. wire wrap wire for around $30 but I seemed to have lost the link.

It can be Googled up very easily though.

There are lots of company's out there but only a few distributors that sell small bulk quantities with decent prices.

Keep on DIYing !!

jer

P.S. The description in post #20 was kind of what I was referring to.

Last edited:

Here in Argentina (called "the third world"), this kind of materials didn´t exist, at the extreme that I couldn´t find cores unwinded. I supose that there, in the first world thinks are much better. I´ll use simple standard enameled copper wire ha same for motors ans common transformers.

I designed and ordered from factory a pair of toroidal output transformers for KT88 push-pull 60W project.

3) Properly designed toroids for push-pull amps don't need air gap, neither fixed neither distributed. In fact, air gap would kill all advantages of toroid core. You can use software simulation with permeability curves and DC bias to evaluate side effect caused by output tube idle current imbalance.

I've got desired results only on 3rd run of samples. Need to say, it was quite complex, time consuming and expensive enterprise.

I wish it's simple as that...

Toroids are prone to "saturation" or working on improper part of magnetization curve.

Secondly, gap, together with proper cross-section and number of turns is commonly used in SE amps to allow the core to operate at linear part of B-H curve, of course for steel.

Thirdly gap is linearizing dependence of permeability on DC bas.

So, regardless of the amount you want to spend, I would advise to get custom core with permeability around 4000-8000, AND, most importantly very linear curve, boxed, period

FT-3L by Hitachi, for instance. Anyway look for transverse annealed ones. Either amorph or noncrystalline.

Having done that - very cost prohibitive! Nice results...

WHY THEN?

Relatively low permeability makes it as insensitive to DC bias as C-core is, but without the gap present.

Linearity of B-H from zero bias up makes it free from even harmonics in magnetization current and, subsequently at the output... which is not the case with ANY electrical steel.

In regard to winding you need to keep coupling between primaries and secondary(-ies) equal. And all the windings should be evenly distributed on the core.

In case of amorph/noncrystalline cores adding the gap OR use of impregnated (not boxed) cores kills material peculiarity

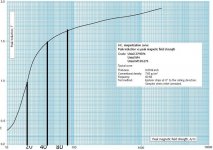

P.S. attached are real B-H curves of a material with Mue around 15000 Bmax approx 0.4T

P.P.S. Do not be afraid to gap toroidal core, if it's made of steel - no difference to the C-core then - too much ado about nothing.

Attachments

My bad, please read NANOcrystalline instead noncrystalline in a previous post

"Don´t worry, be happy..." told a song.

Don´t worry, I could understand you. I´ll try this also.

The tubes and the boxes are Mullard, but I read somewhere that they are making them in Russia, with the original Mullard achinery. True???

I did some googling and I read that they bought the Mullard name, and the tubes are from New Sensor, known from Electro Harmonix, Sovtek, Svletlana (S-logo not winged C) etc..

I did some googling and I read that they bought the Mullard name, and the tubes are from New Sensor, known from Electro Harmonix, Sovtek, Svletlana (S-logo not winged C) etc..

May be, who knows???. I haven´t them at hand, but I´ll see them. Tomorrow I answer you.

Sorry if my english is not too good.

Osvaldo no te preocupes

Don't worry about your English it's readable

Gracias, Thanks,

José

Audiofanatic

Sorry if my english is not too good.

Don't worry about your English it's readable

Gracias, Thanks,

José

Audiofanatic

May be, who knows???. I haven´t them at hand, but I´ll see them. Tomorrow I answer you.

Sorry if my english is not too good.

Your english is fine, don't worry about it. Anyway I was just curious about the tubes.

Your english is fine, don't worry about it. Anyway I was just curious about the tubes.

The base of the tube are some strange way. I was familiarized with the normal cylinder with the pins in the base (Ej 6DQ6, EL36, 6V6, etc.), in place it has some rugocity in the vertical zone of the base. A detail of minor importance, I believe.

I´ll go ´vacations this friday, so I´ll be away from any computer. So this two weeks are for pleasure and winding, ja ja ja...

I wish it's simple as that...

Toroids are prone to "saturation" or working on improper part of magnetization curve.

Secondly, gap, together with proper cross-section and number of turns is commonly used in SE amps to allow the core to operate at linear part of B-H curve, of course for steel.

Thirdly gap is linearizing dependence of permeability on DC bas.

So, regardless of the amount you want to spend, I would advise to get custom core with permeability around 4000-8000, AND, most importantly very linear curve, boxed, period

FT-3L by Hitachi, for instance. Anyway look for transverse annealed ones. Either amorph or noncrystalline.

Having done that - very cost prohibitive! Nice results...

WHY THEN?

Relatively low permeability makes it as insensitive to DC bias as C-core is, but without the gap present.

Linearity of B-H from zero bias up makes it free from even harmonics in magnetization current and, subsequently at the output... which is not the case with ANY electrical steel.

In regard to winding you need to keep coupling between primaries and secondary(-ies) equal. And all the windings should be evenly distributed on the core.

In case of amorph/noncrystalline cores adding the gap OR use of impregnated (not boxed) cores kills material peculiarity

P.S. attached are real B-H curves of a material with Mue around 15000 Bmax approx 0.4T

P.P.S. Do not be afraid to gap toroidal core, if it's made of steel - no difference to the C-core then - too much ado about nothing.

Not simple but being done already. I used my own CAD software (written with Python and LibreOffice GUI front-end) for simulation. Otherwise it would be too problematic to calculate leakage inductance, stray capacitance, and DC bias effect, which depend upon core size, material, winding/layout parameters.

Transformers built with custom M4 CRGO toroid core. Works fine even if tubes have 7mA imbalance each.

I don't think Amorphous/Nanocrystalline is fine for 60W toroidal output transformer, it would be simply too big. Max flux density for these kind of material is 1.2T only.

Making air gaps in toroid cores is a dumb idea (at least for push-pull audio application). The main advantage of toroid core is that it built from continuous strip of metal ribbon without cuts. For transformer with fixed air gap better to use EI or double C core, no need to mess with toroids.

A picture of v1.1 assembly with my toroids, and 6L6GC / KT88 shown below.

Attachments

Not simple but being done already.

I don't think Amorphous/Nanocrystalline is fine for 60W toroidal output transformer, it would be simply too big. Max flux density for these kind of material is 1.2T only.

A picture of v1.1 assembly with my toroids, and 6L6GC / KT88 shown below.

Nice amp, BTW.

The leakage inductance is not that hard to calculate... just two lengthy equations for two rectangular pieces of copper with the opposite currents in them.

So the max flux density is 1.9..2.1T in your x-formers?!

P.S. It's hard to judge x-former size by the pic.

Please excuse me if I am way off scale estimating core size (80*50*30 mm D/d/h)

My best guestimate would be 2500 turns on primary half. That gives around 80 amp*turns at 7ma of disbalance.

Which is equal to 1.6T offset and 0.2T headroom at MAX.

That said you probably have turns twice as low. Which still yeilds 1.5T offset and 0.3T headroom. See attach for M4.

So full power frequency is around 40Hz, and harmonics at low end are not even near acceptable level.

I doubt that anybody uses amp at full power, though.

Even with the core twice as large it would still be 1T of offset...

Going back to FT-3L or equivalent, same core wolume, with Mueff of 2000 - you would get about 0.2T offset, meaning you'll get about 1T headroom...

Distortion you can easily estimate, comparing magnetization curves or dependence of Mueff vs excitation

Attachments

Nice amp, BTW.

The leakage inductance is not that hard to calculate... just two lengthy equations for two rectangular pieces of copper with the opposite currents in them.

So the max flux density is 1.9..2.1T in your x-formers?!

P.S. It's hard to judge x-former size by the pic.

Please excuse me if I am way off scale estimating core size (80*50*30 mm D/d/h)

My best guestimate would be 2500 turns on primary half. That gives around 80 amp*turns at 7ma of disbalance.

Which is equal to 1.6T offset and 0.2T headroom at MAX.

That said you probably have turns twice as low. Which still yeilds 1.5T offset and 0.3T headroom. See attach for M4.

So full power frequency is around 40Hz, and harmonics at low end are not even near acceptable level.

I doubt that anybody uses amp at full power, though.

Even with the core twice as large it would still be 1T of offset...

Going back to FT-3L or equivalent, same core wolume, with Mueff of 2000 - you would get about 0.2T offset, meaning you'll get about 1T headroom...

Distortion you can easily estimate, comparing magnetization curves or dependence of Mueff vs excitation

I used different custom made M4 cores, ranging from 120 to 150 mm external diameter and max height allowed by winding machinery. Internal diameter was determined by best balance between winding fit from one side and max cross-section area from another. Since I used preliminary simulation in software, it was quite easy to avoid complete fill of central hole till shuttle can't pass by during real manufacturing process.

The main advantage of toroid transformer is that you can make almost any core in small quantity for reasonable price, and you don't need a corresponding bobbin for winding.

Your assumption of B/H/mu values is based on data obtained by manufacturer on Epstein frame. It is in some degree correct only if you use very small toroid approximately 80x50x25 mm (permeability of M4/M5 may reach 50,000 in 1.15 - 1.6T region).

Once you have larger core, or core with cuts/gaps like EI/double C core, permeability will drop significantly, making transformer less vulnerable to DC offset.

My finished 60W audio PP toroid weights about 4kg. Comparable 70W Plitron PAT-4070-CFB weights 5.62 kg, 60W EI transformer made by Hashimoto - 4.1 kg. So it doesn't seem to be over-sized. Hashimoto may sustain 4mA DC imbalance, Plitron - no data. My unit have both 4/8 Ohm secondary taps, Plitron PAT-4070-CFB - only 5 Ohm.

The cores I unwind are about 17000 gauss inside the cross sectional area. I don´t remember exactly, but there were 710 turns for a 220V supply, and a cross area of aproximate 3cm * 3cm, 9sq cm. (I´m in the job, and away from it), but for me, usually making IE cores of about 12000 gauss, seem so much. Respect the leakage inductance, is about 3 orders of magnitude below the open circuit primary inductance measured with a digital RLC meter, then about a mHy while L is 8Hy. But really my mistake was the bifilar wound, too much stray capacitance. A question I´m self doing is if grounding the core will be better or worst...

Let´s try.

Let´s try.

Osvaldo, there is a Brazil near you, you can try to search for transformer/core manufacturer here. I'm sure there are many.

You surelly ignore that our politics, in particular our "presidenta" (¿?) (female of President, that doesn´t exist in spanish dictionary) and some of her followers, make us strong difficult to import anything, big enterprises included.

There are several weeks I´m waiting for a book and zockets for my amps, because they are stored somewhere in the aduana.

A question I´m self doing is if grounding the core will be better or worst...

Don't ground the core.

- Home

- Amplifiers

- Tubes / Valves

- Homebrew Toroidal Output Transformer