I wish I knew more about them myself, your #s are off though, it's 3201-004 the 1 designates it as no capacitor supplied........I'm sure you knew that though. Torque seems good at ~60 nM-m and the price is less than $100 US dollars. Being a Yank myself, I'd go for the 115V version, but I know why you chose the 24V.

I hope someone with more experience answers our questions. I'm not much help I'm afraid. ;( sorry

Ron

I hope someone with more experience answers our questions. I'm not much help I'm afraid. ;( sorry

Ron

bins, sorry for the delay...

if a terminal type motor, I think this is what you need to do.(three terminals?)

Plug the AC power line into a power bar for circuit protection, and use the switch on the power bar to turn the AC on and off. This should provide a suitable amount of protection for you (obviously use a prudent amount of care, if not comfortable, have someone who is do this for you). Connect a non-polarized plug to the #3 terminal The AC "return", and to the #1 terminal

between #1 and #2 put the phasing capacitor. Note the direction of rotation. Disconnect from terminal #1, and connect to terminal #2 and note direction of rotation. Whichever rotates clockwise is your desired direction.

As I note, bins, if you (or anybody reading anything on diyaudio) is not comfortable or unsure, get help from someone who is comfortable working with 120/220 VAC, a safety precaution

if a terminal type motor, I think this is what you need to do.(three terminals?)

Plug the AC power line into a power bar for circuit protection, and use the switch on the power bar to turn the AC on and off. This should provide a suitable amount of protection for you (obviously use a prudent amount of care, if not comfortable, have someone who is do this for you). Connect a non-polarized plug to the #3 terminal The AC "return", and to the #1 terminal

between #1 and #2 put the phasing capacitor. Note the direction of rotation. Disconnect from terminal #1, and connect to terminal #2 and note direction of rotation. Whichever rotates clockwise is your desired direction.

As I note, bins, if you (or anybody reading anything on diyaudio) is not comfortable or unsure, get help from someone who is comfortable working with 120/220 VAC, a safety precaution

Last edited:

Hey Stew,

Got any insights into the minimum torque ratings? ie; nM-m

To repeat the Stew's warnings with mains power, unless you KNOW what your doing, YOU DON"T! Get help from someone who does, and learn the proper safety steps.

PS; anytime you use the non-polarized plug, the device must be double insulated. Never delete the ground lug.

Ron

Got any insights into the minimum torque ratings? ie; nM-m

To repeat the Stew's warnings with mains power, unless you KNOW what your doing, YOU DON"T! Get help from someone who does, and learn the proper safety steps.

PS; anytime you use the non-polarized plug, the device must be double insulated. Never delete the ground lug.

Ron

minimum torque requirements...

Well, I do know that the Airpax type motors such as those listed by bins are suitable. Remember though that they will be somewhat noisy. For example, the Linn tables and their brethren (Ariston, Dunlap Systemdek, etc) seem to sound better with approximately 72 Volts (AC) feeding the motor. You won't be able to start the table with that , but it will maintain speed and play, so you could spin the platter by hand to start.

If you have access to some kind of adjustable 70V-120V power supply, you can test the limit, using a stethoscope. Adjust the voltage down until it becomes quietest without stalling the motor. A 120 Hz signal from a recorded tone, a trim pot or two, an amplifier and a transformer could do it.

So the torque required is something like (72/120) *(torque at 120 Volts Ac), unless voltage is below the motor's useable voltage range.

Well, I do know that the Airpax type motors such as those listed by bins are suitable. Remember though that they will be somewhat noisy. For example, the Linn tables and their brethren (Ariston, Dunlap Systemdek, etc) seem to sound better with approximately 72 Volts (AC) feeding the motor. You won't be able to start the table with that , but it will maintain speed and play, so you could spin the platter by hand to start.

If you have access to some kind of adjustable 70V-120V power supply, you can test the limit, using a stethoscope. Adjust the voltage down until it becomes quietest without stalling the motor. A 120 Hz signal from a recorded tone, a trim pot or two, an amplifier and a transformer could do it.

So the torque required is something like (72/120) *(torque at 120 Volts Ac), unless voltage is below the motor's useable voltage range.

One other thing to look at is just buying the motor from VPI or Rega. Both sell 300 rpm motors for under $200. You can even buy the motor for a P5 with the small control board. This allows you to use their external power supply, which is one of the best upgrades I have ever done.

Hi Stew,

It is a 4 terminal motor - #1, #1', #2 and #2'. I think #1' and #2' can be joined together so that we will get a total of 3 terminals. The phasing capacitor should be placed between #1 and #2. Do we need to use a fuse circuit for added safety ? If so, what should be the adequate rating for a 240V AC supply ? Please suggest...

Best regards,

Bins.

It is a 4 terminal motor - #1, #1', #2 and #2'. I think #1' and #2' can be joined together so that we will get a total of 3 terminals. The phasing capacitor should be placed between #1 and #2. Do we need to use a fuse circuit for added safety ? If so, what should be the adequate rating for a 240V AC supply ? Please suggest...

Best regards,

Bins.

if a terminal type motor, I think this is what you need to do.(three terminals?)

Plug the AC power line into a power bar for circuit protection, and use the switch on the power bar to turn the AC on and off. This should provide a suitable amount of protection for you (obviously use a prudent amount of care, if not comfortable, have someone who is do this for you). Connect a non-polarized plug to the #3 terminal The AC "return", and to the #1 terminal

between #1 and #2 put the phasing capacitor. Note the direction of rotation. Disconnect from terminal #1, and connect to terminal #2 and note direction of rotation. Whichever rotates clockwise is your desired direction.

As I note, bins, if you (or anybody reading anything on diyaudio) is not comfortable or unsure, get help from someone who is comfortable working with 120/220 VAC, a safety precaution

1' and 2'...

bins, ya the "prime" designation is AC return for each terminal, so essentially a 3 terminal motor (well in this connection scheme, anyways). The tables that use these motors usually state that the power requirement is 12 Watts or there abouts. The Airpax as per your file attachment (3104) motors list the current requirement as 30mA, so only 3.6 watts required. A 1A fuse would allow 12 Watts, but should be suitable (a .5A would still be suitable, but may not take into consideration inlet voltage and current). If your motor ever pulls .5 A, it's likely it has problems.

bins, ya the "prime" designation is AC return for each terminal, so essentially a 3 terminal motor (well in this connection scheme, anyways). The tables that use these motors usually state that the power requirement is 12 Watts or there abouts. The Airpax as per your file attachment (3104) motors list the current requirement as 30mA, so only 3.6 watts required. A 1A fuse would allow 12 Watts, but should be suitable (a .5A would still be suitable, but may not take into consideration inlet voltage and current). If your motor ever pulls .5 A, it's likely it has problems.

Last edited:

Since we're on the topic of TT motor, I'd like to request any further knowledge on the following from any guru here.

I've been experimenting and trying to understand the simple factory supplied Basik PSU to a Philips made MB10 type Linn LP12 motor(110VAC type). All the while it seems alright save a recent replacement of all the capacitors onboard for another lease of life. To describe the Basik supply, its simply Live in series with 0.22uF cap to blue and red wire direct to live for phase shift, the common grey wires are in series to another 0.22uf cap to neutral. Input is 230VAC/50Hz. AFAI recall, this is where I made voltage measurements with a DVM at the motor wire terminals. Common (grey) to Red = 100V, Common to Blue=90V

Meanwhile, I've learnt there's been different methods of wiring up this type of motor for various models of Rega or others, found different voltages at the motor terminals whatever the purpose and intent. I found the latest (or current) P3 Rega upgrade PSU have 75VAC at each phase with the same motor connected up, perhaps this accounted for the weaker spin up than Basik. Its noticed that the higher the voltage the better the starting torque naturally.

I've also found there's a voltage imbalance among the two phases when I started tweaking the Basik psu by adding a resistor in series to the live wire in attempting to obtain 85VAC at the motor terminal. When I measure the other phase there's a significant difference. Its like 85VAC on one phase and 99VAC on the other phase. Do I have to tweak the circuitry to get a near perfect phase voltage to work best? Is it vital for both phases of this type of motor to be best balanced for optimum performance?

Comments please.

P.S. I'm aware that a frequency driven PSU may be the ultimate or best solution for this type of motor but meanwhile I'd prefer to learn more about this simple psu type circuitry.

I've been experimenting and trying to understand the simple factory supplied Basik PSU to a Philips made MB10 type Linn LP12 motor(110VAC type). All the while it seems alright save a recent replacement of all the capacitors onboard for another lease of life. To describe the Basik supply, its simply Live in series with 0.22uF cap to blue and red wire direct to live for phase shift, the common grey wires are in series to another 0.22uf cap to neutral. Input is 230VAC/50Hz. AFAI recall, this is where I made voltage measurements with a DVM at the motor wire terminals. Common (grey) to Red = 100V, Common to Blue=90V

Meanwhile, I've learnt there's been different methods of wiring up this type of motor for various models of Rega or others, found different voltages at the motor terminals whatever the purpose and intent. I found the latest (or current) P3 Rega upgrade PSU have 75VAC at each phase with the same motor connected up, perhaps this accounted for the weaker spin up than Basik. Its noticed that the higher the voltage the better the starting torque naturally.

I've also found there's a voltage imbalance among the two phases when I started tweaking the Basik psu by adding a resistor in series to the live wire in attempting to obtain 85VAC at the motor terminal. When I measure the other phase there's a significant difference. Its like 85VAC on one phase and 99VAC on the other phase. Do I have to tweak the circuitry to get a near perfect phase voltage to work best? Is it vital for both phases of this type of motor to be best balanced for optimum performance?

Comments please.

P.S. I'm aware that a frequency driven PSU may be the ultimate or best solution for this type of motor but meanwhile I'd prefer to learn more about this simple psu type circuitry.

Last edited:

Hi,

More information can be obtained from the following links:

> Armageddon Clone

> Neil's turntable power supply page

Best regards,

Bins.

More information can be obtained from the following links:

> Armageddon Clone

> Neil's turntable power supply page

Best regards,

Bins.

Since we're on the topic of TT motor, I'd like to request any further knowledge on the following from any guru here.

I've been experimenting and trying to understand the simple factory supplied Basik PSU to a Philips made MB10 type Linn LP12 motor(110VAC type). All the while it seems alright save a recent replacement of all the capacitors onboard for another lease of life. To describe the Basik supply, its simply Live in series with 0.22uF cap to blue and red wire direct to live for phase shift, the common grey wires are in series to another 0.22uf cap to neutral. Input is 230VAC/50Hz. AFAI recall, this is where I made voltage measurements with a DVM at the motor wire terminals. Common (grey) to Red = 100V, Common to Blue=90V

Meanwhile, I've learnt there's been different methods of wiring up this type of motor for various models of Rega or others, found different voltages at the motor terminals whatever the purpose and intent. I found the latest (or current) P3 Rega upgrade PSU have 75VAC at each phase with the same motor connected up, perhaps this accounted for the weaker spin up than Basik. Its noticed that the higher the voltage the better the starting torque naturally.

I've also found there's a voltage imbalance among the two phases when I started tweaking the Basik psu by adding a resistor in series to the live wire in attempting to obtain 85VAC at the motor terminal. When I measure the other phase there's a significant difference. Its like 85VAC on one phase and 99VAC on the other phase. Do I have to tweak the circuitry to get a near perfect phase voltage to work best? Is it vital for both phases of this type of motor to be best balanced for optimum performance?

Comments please.

P.S. I'm aware that a frequency driven PSU may be the ultimate or best solution for this type of motor but meanwhile I'd prefer to learn more about this simple psu type circuitry.

Immedia uses a custom 12V version of this Hurst motor, the 5 watt 600 rpm model, in their RPM-1 and RPM-2 tables. Mine is getting noisy after 20 years, so I'm looking into replacing it. I just need to figure out how to convert their nifty 12V supply to 24V (they take 12VAC, convert to 12VDC, and regenerate to 12VAC).

Bins..thanx for the links

I had completely forgot about Niel McBride's pages.

The Hust motors do have a fairly good torque curve, and as stated have been used in a few tables over the years, AR was the first to adopt their motors (I think), in the "modern era. At $30 shipped, they are a huge value.

George Merrill still uses his version of the motor as well (a modified broken in, and measured one) http://www.merrillscillia.com/ms21.html

I had completely forgot about Niel McBride's pages.

The Hust motors do have a fairly good torque curve, and as stated have been used in a few tables over the years, AR was the first to adopt their motors (I think), in the "modern era. At $30 shipped, they are a huge value.

George Merrill still uses his version of the motor as well (a modified broken in, and measured one) http://www.merrillscillia.com/ms21.html

Last edited:

2¢ worth

Using any synchronous motor for turntables there were to areas I had a lot of problems.

One was the power supply. Mains had to much distortion and the motor speed would vary rapidly and was not acceptable so I made a low frequency oscillator. Have a schematic somewhere and will post it if found. This really helped a lot. This also allows speed adjustment, a handy feature.

The "phase" capacitor also proved to be a problem. Watching the voltage across the phase cap showed there was oscillation there also. Ended up with a 90 degree phase splitter on the output of the oscillator and made two low distortion sine waves. This finally got the motor running at constant speed. Starting the motor was by hand. Should have used a cap and a switch for that but did not. Now know better.

The other problem was the pulley. It took the machine shop a lot of attempts to have a pulley that fit perfectly straight on the shaft and would then run dead true when glued in place with loctite bearing retainer. With the 2mm shaft motor I used this was not a trivial task. There were a lot of attempts. It took a 2mm reamer to get the fit right and careful lathe work.

This was a string driven thing and not a belt drive. I prefer the string to the belt but both work.

When finished though must say the sound was pretty good. I think it was written up in Absolute sound but need to check that one also. Made all this for a buddy of mine. Also made his tone arms but that is another story. If I find that stuff will post it.

Lots of luck!! -SUM

-SUM

Using any synchronous motor for turntables there were to areas I had a lot of problems.

One was the power supply. Mains had to much distortion and the motor speed would vary rapidly and was not acceptable so I made a low frequency oscillator. Have a schematic somewhere and will post it if found. This really helped a lot. This also allows speed adjustment, a handy feature.

The "phase" capacitor also proved to be a problem. Watching the voltage across the phase cap showed there was oscillation there also. Ended up with a 90 degree phase splitter on the output of the oscillator and made two low distortion sine waves. This finally got the motor running at constant speed. Starting the motor was by hand. Should have used a cap and a switch for that but did not. Now know better.

The other problem was the pulley. It took the machine shop a lot of attempts to have a pulley that fit perfectly straight on the shaft and would then run dead true when glued in place with loctite bearing retainer. With the 2mm shaft motor I used this was not a trivial task. There were a lot of attempts. It took a 2mm reamer to get the fit right and careful lathe work.

This was a string driven thing and not a belt drive. I prefer the string to the belt but both work.

When finished though must say the sound was pretty good. I think it was written up in Absolute sound but need to check that one also. Made all this for a buddy of mine. Also made his tone arms but that is another story. If I find that stuff will post it.

Lots of luck!!

Has anyone published a design for a voltage control and frequency control that can be used for this purpose. My brother is currently designing mine for me, will post some details when as it evolves.

I would be very keen to see that when its ready

bins, ya the "prime" designation is AC return for each terminal, so essentially a 3 terminal motor (well in this connection scheme, anyways). The tables that use these motors usually state that the power requirement is 12 Watts or there abouts. The Airpax as per your file attachment (3104) motors list the current requirement as 30mA, so only 3.6 watts required. A 1A fuse would allow 12 Watts, but should be suitable (a .5A would still be suitable, but may not take into consideration inlet voltage and current). If your motor ever pulls .5 A, it's likely it has problems.

I made a AC current measurement and on free run, the Philips/Airpax motor consumes 10mA at 230VAC/50hz input. Motor voltage at phase wires was at roughly 75VAC. (Rega PSU board used here)

Transformer VA rating...

Hello Stew,

I am planning to use the airpax motor with an armageddon clone (Armageddon Clone). What should be the transformer rating required (Do we really need a 300/530 VA transformer ) for such a power supply ? Will a transformer with around 100VA or less work as the motor current consumption is small ?

Best regards,

Bins.

Hello Stew,

I am planning to use the airpax motor with an armageddon clone (Armageddon Clone). What should be the transformer rating required (Do we really need a 300/530 VA transformer ) for such a power supply ? Will a transformer with around 100VA or less work as the motor current consumption is small ?

Best regards,

Bins.

I had completely forgot about Niel McBride's pages.

The Hust motors do have a fairly good torque curve, and as stated have been used in a few tables over the years, AR was the first to adopt their motors (I think), in the "modern era. At $30 shipped, they are a huge value.

George Merrill still uses his version of the motor as well (a modified broken in, and measured one) Merrill-Scillia Research | MS21

Attachments

Regulated oscillator and two phase driver amplifier

T1 is the low distortion sine oscillator. Adjust C30 C31 C32 to maybe a 1/3 the value for 60Hz is what my bad memory says. This is 20Hz. Note the oscillator is regulated low distortion sine output. R4 and R17 set the gain of the linear amplifiers. Adjust these two to change the voltage output. Supplies are plus/minus 75 volts. The two outputs are 180 degrees out of phase with one another for driving a transformer or motor. This will drive a small motor just fine to 250ma. As I recall the output of each amp is 35 volts RMS so between the two amps is 70 volts RMS.

Any of these voltages and gains may be changed as you like. The amps are very stable and should work with supplies up to about ±95 volts with the parts shown.

The low voltage supply at C1 and C2 has a lot of ripple because a goal was to not make a lot of heat. Ripple there is like 40 volts peak to peak.

To make a two phase at 90 degrees output place a high pass capacitor set at 60 Hz (assuming 60Hz operation) before R3 and place a low pass set at 60Hz for C11 to R16 . R3 in the impedance there and R16 on the other channel. To start the motor use a capacitor and one amp just like normal and then move the switch to run and hook up the second phase directly. A two phase motor ( AC sync) will not start with a pair of 90 degree signals so a capacitor to start works well.

With this set up the motor cannot run at any speed except the sync speed (this is why it will not start) and will not hunt of vary speed under variable load as will happen with a capacitor used for the second phase.

T1 is the low distortion sine oscillator. Adjust C30 C31 C32 to maybe a 1/3 the value for 60Hz is what my bad memory says. This is 20Hz. Note the oscillator is regulated low distortion sine output. R4 and R17 set the gain of the linear amplifiers. Adjust these two to change the voltage output. Supplies are plus/minus 75 volts. The two outputs are 180 degrees out of phase with one another for driving a transformer or motor. This will drive a small motor just fine to 250ma. As I recall the output of each amp is 35 volts RMS so between the two amps is 70 volts RMS.

Any of these voltages and gains may be changed as you like. The amps are very stable and should work with supplies up to about ±95 volts with the parts shown.

The low voltage supply at C1 and C2 has a lot of ripple because a goal was to not make a lot of heat. Ripple there is like 40 volts peak to peak.

To make a two phase at 90 degrees output place a high pass capacitor set at 60 Hz (assuming 60Hz operation) before R3 and place a low pass set at 60Hz for C11 to R16 . R3 in the impedance there and R16 on the other channel. To start the motor use a capacitor and one amp just like normal and then move the switch to run and hook up the second phase directly. A two phase motor ( AC sync) will not start with a pair of 90 degree signals so a capacitor to start works well.

With this set up the motor cannot run at any speed except the sync speed (this is why it will not start) and will not hunt of vary speed under variable load as will happen with a capacitor used for the second phase.

Attachments

Transformer rating question...

Bump up...

Bump up...

Hello Stew,

I am planning to use the airpax motor with an armageddon clone (Armageddon Clone). What should be the transformer rating required (Do we really need a 300/530 VA transformer ) for such a power supply ? Will a transformer with around 100VA or less work as the motor current consumption is small ?

Best regards,

Bins.

Norton AirPower from Norton Technologies...

Hi,

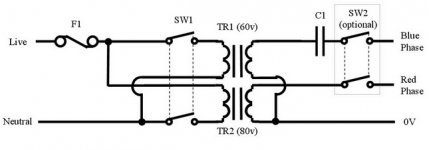

Another famous turntable power supply is available for DIY. Please check this out: http://www.norton-tech.co.uk/

The parts list is:

Best regards,

Bins.

Hi,

Another famous turntable power supply is available for DIY. Please check this out: http://www.norton-tech.co.uk/

The parts list is:

> TR1 60v transformer

> TR2 80v transformer

> C1 0.22uF capacitor

> F1 slow blow in-line fuse*

> SW1 DPST switch

> SW2 DPST switch (optional)

> 1 x 8-pin DIN chassis socket

> 1 x 9-pin DIN line plug

> 1 x enclosure

> TR2 80v transformer

> C1 0.22uF capacitor

> F1 slow blow in-line fuse*

> SW1 DPST switch

> SW2 DPST switch (optional)

> 1 x 8-pin DIN chassis socket

> 1 x 9-pin DIN line plug

> 1 x enclosure

Best regards,

Bins.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Help required for choosing an AC sync motor for a belt driven turntable.