Freddi - yes, it will be interesting to try moving the xo point up and down 150-750hz and see whether the 18" helper woofers or 12" fanes do the punch better... Much the same as Mr. Norman Bates has done with his experimenting.

Cake - yes, that sums it all up nicely!

Helper woofers will be a pair of PA460 Dayton 18" woofers in a (gasp) bass reflex box, only because these drivers really really wanted BR rather than sealed.

The rest of the full range duty will be Fane 12-250TC drivers... They seem to want a rather large box if sealed, like 19 ft3 for qtc=.707... qtc = .792 with 6 ft3, that might be enough... Bass reflex, they seem to be rather peaky due to the somewhat high qts, unless tuned low/small box to compensate, which pushes them towards a sealed response anyway...

I wonder if they would work in P10's Em-ken for 12lta?

Cake - yes, that sums it all up nicely!

Helper woofers will be a pair of PA460 Dayton 18" woofers in a (gasp) bass reflex box, only because these drivers really really wanted BR rather than sealed.

The rest of the full range duty will be Fane 12-250TC drivers... They seem to want a rather large box if sealed, like 19 ft3 for qtc=.707... qtc = .792 with 6 ft3, that might be enough... Bass reflex, they seem to be rather peaky due to the somewhat high qts, unless tuned low/small box to compensate, which pushes them towards a sealed response anyway...

I wonder if they would work in P10's Em-ken for 12lta?

I wonder if they would work in P10's Em-ken for 12lta?

Our miniOnkens are finely tuned for each driver, it is very unlikely you can just drop a driver in. Not that it doesn’t happen, we have a 2.5 microSize box that works for both the metal and paper Alpair 6.2, and the 4.7 litre millisize is the same (except for driver details) for the 3.5” Alpair 6.2p and the 4.5” FF125wk.

dave

I ordered a 2 way version of this. Linkwitz-Riley 3-Way Active Crossover [XOVER-3] – Xkitz Electronics

Last edited:

Our miniOnkens are finely tuned for each driver, it is very unlikely you can just drop a driver in.

Thanks Dave, that's what I thought but was hoping maybe otherwise... Specs were rather different than I recalled, looking between the 12lta and Fane 12-250tc. Is it possible to scale things based on Vas or Qts proportions? Any plans to do a Fane 12-250 design?

mkane, I almost went for those as well at one point.. ended up with a 3 way Dbx234 instead so I can vary things easily by knob until it sounds best, then maybe replace with something solid state, or not.

Yep, plan is to play around in the 150-750 range with the adjustable xo to see where my tastes lie for "punch"... see if it's better thru the woofers or thru the Fane FR, and balance that with trying to keep the vocals on the FR drivers.

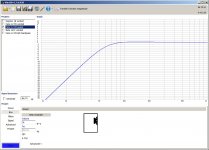

Sealed does look fine for the Fane, just big cabinets... why didn't I check this before? I think I just looked at the Mfr recommended box size of something like 1-2 ft3, ha! Looks ok to me in a 6 ft3 box, 4 ft3 as Dave said seems to be pushing it, qtc = .846.

I'd like to try it sealed, and also in Xrk's Xki design. Aperiodic would be good too, but I lack the skills as of yet to try and do that in HR. Need more time to play around with it and learn it.. but that time never seems to arrive, haha. My plan is to prototype the boxes in 3/4" OSB to see how they sound vs each other. Any other ideas/thoughts?

Sealed does look fine for the Fane, just big cabinets... why didn't I check this before? I think I just looked at the Mfr recommended box size of something like 1-2 ft3, ha! Looks ok to me in a 6 ft3 box, 4 ft3 as Dave said seems to be pushing it, qtc = .846.

I'd like to try it sealed, and also in Xrk's Xki design. Aperiodic would be good too, but I lack the skills as of yet to try and do that in HR. Need more time to play around with it and learn it.. but that time never seems to arrive, haha. My plan is to prototype the boxes in 3/4" OSB to see how they sound vs each other. Any other ideas/thoughts?

Yep, that's what I'm using in winISD.Qt = 0.64 on the datasheet i downloaded today.

I thought OSB was supposed to be even stiffer than ply,w ith better damping?

You're scaring me!Aperiodic midTweeter is easy, just a lot of “drill & try”.

Easy to a practiced ear perhaps... Come on down to Ohio, I'll supply beer & music and drill the holes, you just have to listen...

Attachments

Correction was only due to your earlier reference of Qt - 0.846.

Not if you get proper plywood.

Well in this case there is a small bump before roll-off, not much to work out. Since you don’t need the bass extension you just start drilling small holes (say 6-10mm D) in the back as far away as you can get from the driver. Damp this/these exits — i use compressed fiberglass or high density open cel foam — drill more holes until the bass sounds good, at the 100 litre size you may be happy with sealed. If you have a full-on commitment to aperiodic you could probably go 50-75 litres.

The bump, if you don’t completely get rid of it, can also be ameriolated with an assymetric XO with the HP set a little higher than the traget point (really only an issue at your lowest target XO frequencies).

dave

I thought OSB was supposed to be even stiffer than ply,w ith better damping?

Not if you get proper plywood.

You're scaring me!

Well in this case there is a small bump before roll-off, not much to work out. Since you don’t need the bass extension you just start drilling small holes (say 6-10mm D) in the back as far away as you can get from the driver. Damp this/these exits — i use compressed fiberglass or high density open cel foam — drill more holes until the bass sounds good, at the 100 litre size you may be happy with sealed. If you have a full-on commitment to aperiodic you could probably go 50-75 litres.

The bump, if you don’t completely get rid of it, can also be ameriolated with an assymetric XO with the HP set a little higher than the traget point (really only an issue at your lowest target XO frequencies).

dave

if you made a removable and replaceable port panel that sets on cleats, then you could experiment to your heart's content with drilling, etc. Planet10 could suggest damping material to use on the back side of the ports. I made a 5 cubic foot cabinet in 1966 loaded with a $12.95 cast frame 12" fullrange Allied Knight speaker - it was first tuned with 6 holes bored in the panel (not bad) - then I found the nomogram for ducts - that screwed it up as I had no understanding of motor strength

Ah - I think we just have similar/confusing terminology, Qtc is total Q including box from winISD, Qts is total driver Q from Mfr. I was speaking in relation to hitting a "flat" tune of Qtc = .707, with roughy a 19 ft3 box - where the 6ft and 4 ft3 boxes had higher, somewhat overdamped Qtc values up around .792 and .846 respectively, when loaded with that Fane.Correction was only due to your earlier reference of Qt - 0.846.

Keep drilling until bass sounds good... at what point or at what sound do you tell that you've over done it and have too much drilled area? I'd probably be happy with the sealed response in a large enough box, like th 6 ft3 one, but it would be great to get it smaller than that! 75 L is like.. 2.6 ft3, big difference in size.

Thanks Dave

Freddi, removable/replaceable panel is definitely a good idea if we are drilling. Probably drinking and drilling.

Last edited:

Qtc = .707, with roughy a 19 ft3 box

My sim said an undamped box of 354 litres = 12.5ft3.

I have seen some suspicious results reported of late from WinISD.

dave

Keep drilling until bass sounds good... at what point or at what sound do you tell that you've over done it and have too much drilled area? I'd probably be happy with the sealed respons

Use GM’s click test or measure the impedance and tune for lowest value (do a search).

This tuning not fully explored, but good enuff.

dave

I'd venture to guess that its human error on my part... I'll double check all the entered parameters, that's a pretty big differenceMy sim said an undamped box of 354 litres = 12.5ft3.

I have seen some suspicious results reported of late from WinISD.

My rule — and it has worked well over at least near 100 designs — is to use factory numbers first. The tests us diyers do far too often pick the T/S numbers off the curves in a much less useful place and typically Qt as measured is higher than factory.

I only use my T/S measures for matching and as a starting point if there is no factory data.

dave

I only use my T/S measures for matching and as a starting point if there is no factory data.

dave

Use GM’s click test or measure the impedance and tune for lowest value (do a search).

My rule — and it has worked well over at least near 100 designs — is to use factory numbers first. The tests us diyers do far too often pick the T/S numbers off the curves in a much less useful place and typically Qt as measured is higher than factory.

Thanks Dave, will do. Is there a setting or anything obvious in winISD that I may have set wrong that people typically screw up? For instance, I don't have any options under the advanced tab clicked - like "sim VC inductance".

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Full Range Build, 12" driver...