I've never worked with foam core board before and was wondering with my idea above of using my infinity 12 inch subs if you guys think I would need more than just foam to support the woofer on the baffle. Some have suggested using plywood on the baffle but I'm trying to completely stay away from wood since I'm in an apartment and it is hard for me to do any woodwork. But if that really is the only way I know a lot of the hardware stores will precut wood so that may be an option

Yes, I use multiple layers all the time. Hot melt is expensive of gluing large layers so use large tube of liquid nails (non VOC type). It also adds CLD to reduce HD. Another thing you need of your driver is a big heavy sub with big magnets is to glue layer of 3/16in underlayment ply (Sureply) and that give enough strength to support sheet mass of driver from ripping screws out. Use liberal bracing internally. Look in Nautaloss thread to see example of foam core bracing for subwoofer.

Has anyone tried to line the inside with glassfibre weave, epoxy and a brush?

You mean glass it like a surfboard? That would make a nice smooth exterior surface but not sure why do the inside?

Rigidity I guess.. First I thought about this when making a corny spiral horn, using glassfibre strips to strengthen the structure, beeing able to use thinner foamboard when shaping the spiral part. I guess you could use it on the outside as well, it will become a sandwich layer with a soft core. When the epoxy dries it becomes stronger than wood, but still with some flexibility.You mean glass it like a surfboard? That would make a nice smooth exterior surface but not sure why do the inside?

Skickat från min D6503 via Tapatalk

Lining the outside of the enclosure is tempting. But instead of fibreglass using carbonfibre sheets. But those needs pressure when gluing, right? The question is how much..

If you line the inside with a few layers of fibreglass and epoxy you probably get the strength needed.

I guess you could make really cool shaped enclosures that would be difficult to make with MDF or plywood and a cool finish with some practice.

Hmmm...

If you line the inside with a few layers of fibreglass and epoxy you probably get the strength needed.

I guess you could make really cool shaped enclosures that would be difficult to make with MDF or plywood and a cool finish with some practice.

Hmmm...

You guys should try some PolyIso roof foam sheets. It comes in many thicknesses (i use 1" for boat building structures) and has a fiberglass scrim layer on both sides. After creating the enclosure as desired,roll on a few layers of catalyzed epoxy......done. Hard as nails, low resonance and light as can be. MDF and plywood are relics compared to today's composite materials. Those that still like the wood look?......laminate the outside with veneer if you want. Block sand the epoxied scrim first........smooth as glass.

Also check out Carbon-Core honeycomb composites.....awesome stuff if using the scored product curved cabinets in 1/10th the time of organics.

Also check out Carbon-Core honeycomb composites.....awesome stuff if using the scored product curved cabinets in 1/10th the time of organics.

WOW, all those threads with these new materials are very interressting !

What do we need to make an enclosure ?

- Internal damping of the material ?

- Rigid no to flex with weight, heat or high energy in the bass to allow it to radiate like a cone itself ?

- Proof at the intersections (so easy to glue and strong enough not to move)

- Heavy to avoid vibration in the low frequencies (if not sandwich structure) and allow the energy to be lost in heat ?

What about lead layer for roof ? Same internal damping Young moduel than baltic ply wood, rigid enough,thin, shaping are easier, and can be proof with some heating ?

Heavy of course ! Can be veneered with EVA, whatever ! Sane but during the work with it (smells if heated !)

Not expensive ! Good choice for low end frequencies enclosures (Bass, woofer) ?

??

What do we need to make an enclosure ?

- Internal damping of the material ?

- Rigid no to flex with weight, heat or high energy in the bass to allow it to radiate like a cone itself ?

- Proof at the intersections (so easy to glue and strong enough not to move)

- Heavy to avoid vibration in the low frequencies (if not sandwich structure) and allow the energy to be lost in heat ?

What about lead layer for roof ? Same internal damping Young moduel than baltic ply wood, rigid enough,thin, shaping are easier, and can be proof with some heating ?

Heavy of course ! Can be veneered with EVA, whatever ! Sane but during the work with it (smells if heated !)

Not expensive ! Good choice for low end frequencies enclosures (Bass, woofer) ?

??

WOW, all those threads with these new materials are very interressting !

What do we need to make an enclosure ?

- Internal damping of the material ?

- Rigid no to flex with weight, heat or high energy in the bass to allow it to radiate like a cone itself ?

- Proof at the intersections (so easy to glue and strong enough not to move)

- Heavy to avoid vibration in the low frequencies (if not sandwich structure) and allow the energy to be lost in heat ?

What about lead layer for roof ? Same internal damping Young moduel than baltic ply wood, rigid enough,thin, shaping are easier, and can be proof with some heating ?

Heavy of course ! Can be veneered with EVA, whatever ! Sane but during the work with it (smells if heated !)

Not expensive ! Good choice for low end frequencies enclosures (Bass, woofer) ?

??

I think if we take speaker building into the high tech realm, let's not waste anytime and make it the same way F1 cars, aircraft, and spacecraft structures are made: carbon fiber faced nomex honeycomb panels. Very stiff and light and good vibration dampening from carbon fiber. Small pieces are reasonably priced nowadays. Here is a place where small samples are available.

http://dragonplate.com/mobile/produ...CUi0HlMDympS2EpiFH6Q6Ti5rRiwZ7LC_0aApNg8P8HAQ

Wow, $250 for a single enclosure with a 5.25" speaker.

That is not a lot compared to speakers with Baltic Birch and then veneered with nice wood. Or all Corian speakers, granite speakers, marble speakers, etc. A box with carbon fiber weave would be very cool visually. The advantage comes in larger sizes where transportability is important. There is also foam core or even cardboard honeycomb faced with plywood that costs less. Quite high tech and lighter but competitive with BB. No contest weight wise.

A great DIY composite is XPS foam faced with thin Sureply subfloor 3/16in plywood. Pretty low cost and super lightweight but strong.

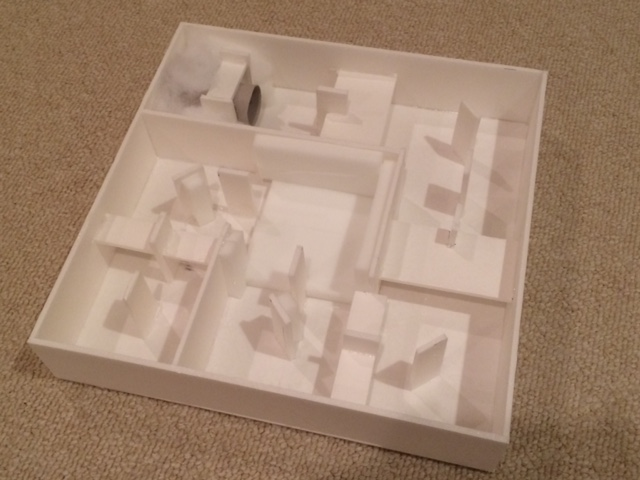

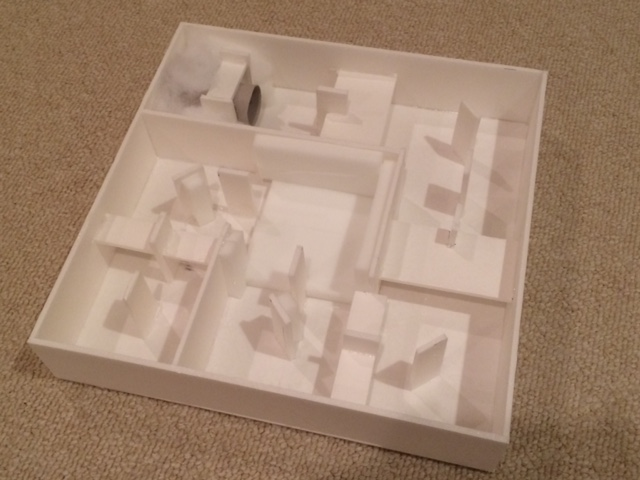

Here is example:

Last edited:

I believe one of the great advantage is to have standalones bafles for each drivers : as it's thin and finelly damped and very rigid : you can make bafles thin so very good for the rear wave of the cone.

A little like Dynaudio made with some of its most expensive speakers but with aluminium and a rubber glue between the mdf cabinet !

So the link Xrq971 gave could be a good bet ! take the 6"x6" for a 4" driver with water cutting or by Dragonfly directly seems possible at acceptable price (lees expensive than the R8 !) : Carbon Fiber Foam Core > EconomyPlate™ Divinycell .25" Foam Core

Carbon Fiber Nomex Honeycomb Core 0.25" x 6" x 6"

Kevlar Composite Products > Kevlar Core Sheets

A little like Dynaudio made with some of its most expensive speakers but with aluminium and a rubber glue between the mdf cabinet !

So the link Xrq971 gave could be a good bet ! take the 6"x6" for a 4" driver with water cutting or by Dragonfly directly seems possible at acceptable price (lees expensive than the R8 !) : Carbon Fiber Foam Core > EconomyPlate™ Divinycell .25" Foam Core

Carbon Fiber Nomex Honeycomb Core 0.25" x 6" x 6"

Kevlar Composite Products > Kevlar Core Sheets

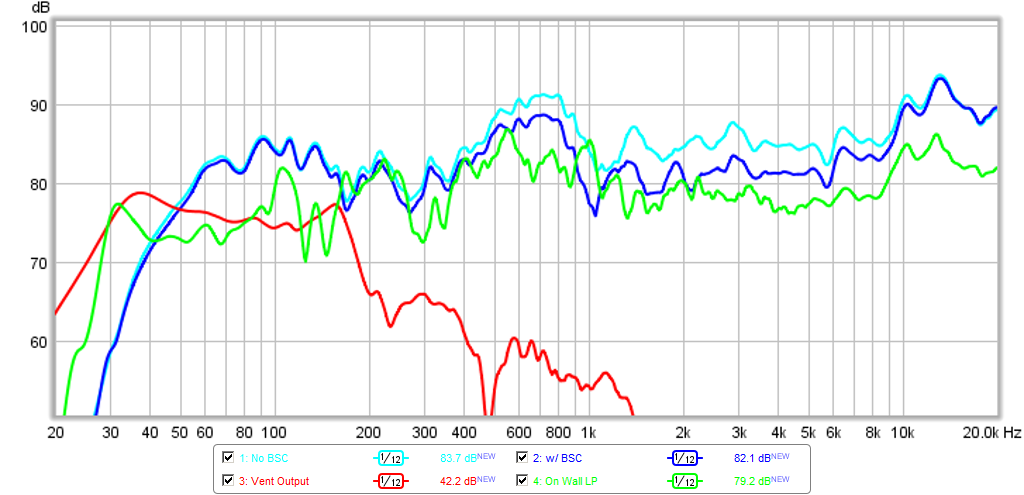

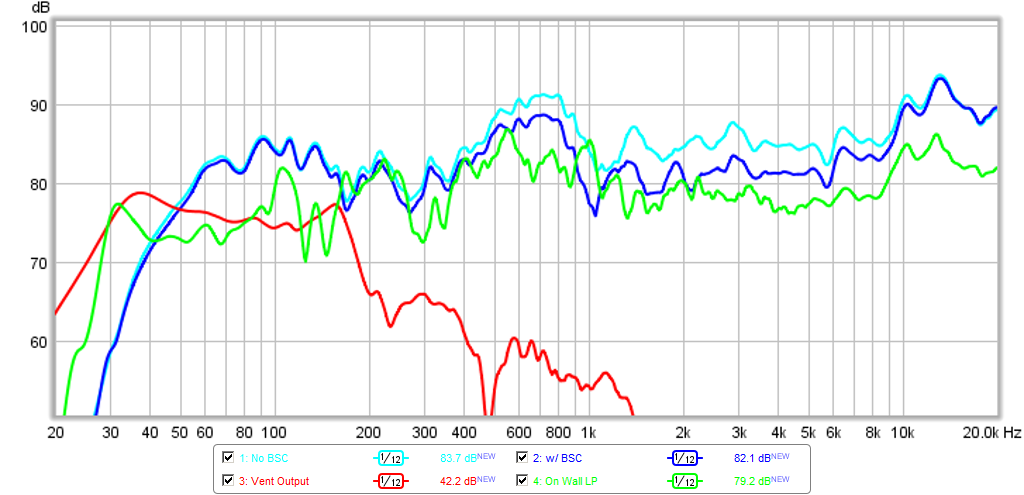

Flat Wall Mount A7.3 MLTL

More info here:

http://www.diyaudio.com/forums/full-range/260758-full-range-wall-home-theater-10.html#post4472884

More info here:

http://www.diyaudio.com/forums/full-range/260758-full-range-wall-home-theater-10.html#post4472884

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?