Occam Audio DIY Kit's

I did the design work on the Occam Audio Kits. If you have any questions about these feel free to ask me directly. One thing that we have really tried to do is to make sure the kits are easy to do. We are now including a DIY video to walk people through finishing/crossover/assembly. We are also including fool proof acrylic crossover boards so the end user can feel confident their kit will sound the way it was designed. If you do not want to buy our kits, we offer free kit designs using quality drivers so you can just download the schematics and box diagram and source your own components.

I did the design work on the Occam Audio Kits. If you have any questions about these feel free to ask me directly. One thing that we have really tried to do is to make sure the kits are easy to do. We are now including a DIY video to walk people through finishing/crossover/assembly. We are also including fool proof acrylic crossover boards so the end user can feel confident their kit will sound the way it was designed. If you do not want to buy our kits, we offer free kit designs using quality drivers so you can just download the schematics and box diagram and source your own components.

Jeff,

I've already got the SR-71 components. However I can see myself making many pairs of DIY speakers in the near future. I will certainly keep your kits in mind for my next set. Its nice to know there is an expert out there.

I'm not intimidated by assembling a crossover. I'm an electrical engineer and spend a good chunk of my time design electronics. Following and wiring a crossover schematic, no sweat.

The acrylic board is a nice idea. Its great for those who are not electronically inclined.

I've already got the SR-71 components. However I can see myself making many pairs of DIY speakers in the near future. I will certainly keep your kits in mind for my next set. Its nice to know there is an expert out there.

I'm not intimidated by assembling a crossover. I'm an electrical engineer and spend a good chunk of my time design electronics. Following and wiring a crossover schematic, no sweat.

The acrylic board is a nice idea. Its great for those who are not electronically inclined.

Re: Occam Audio DIY Kit's

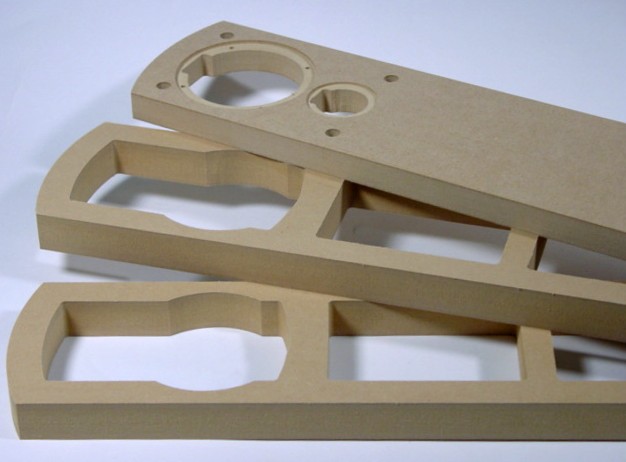

I do have a question Jeff. On the cabinets, with curved tops and bottoms, were they kerfed, or were they made from multiple sectioned cuts of MDF, then layered/glued together to form a solid curved frame? Just curious.

jeff k said:I did the design work on the Occam Audio Kits. If you have any questions about these feel free to ask me directly. One thing that we have really tried to do is to make sure the kits are easy to do. We are now including a DIY video to walk people through finishing/crossover/assembly. We are also including fool proof acrylic crossover boards so the end user can feel confident their kit will sound the way it was designed. If you do not want to buy our kits, we offer free kit designs using quality drivers so you can just download the schematics and box diagram and source your own components.

I do have a question Jeff. On the cabinets, with curved tops and bottoms, were they kerfed, or were they made from multiple sectioned cuts of MDF, then layered/glued together to form a solid curved frame? Just curious.

RE:

The mtm is made from layered MDF, while the MTM 7 is made like a traditional box from 1" MDF, then it is sanded to shape. Both processes are more costly and time consuming than traditional rectangular boxes. You can see examples of this on the products page of www.occamaudio.com where we sell the boxes unfinished.

The mtm is made from layered MDF, while the MTM 7 is made like a traditional box from 1" MDF, then it is sanded to shape. Both processes are more costly and time consuming than traditional rectangular boxes. You can see examples of this on the products page of www.occamaudio.com where we sell the boxes unfinished.

Re: RE:

You are correct. I should have finished checking out the site before running my mouth. I have a bad habit of doing such things. Unfortunately, even at my age, I somehow never learn.

The only thing about your products that I don't really swoon over, are the black stands. Somehow, I would prefer a curved and veneered stand instead. If the cabinets have curved tops and bottoms, a curved stand would add to the asthetic pleasure of the total project. Just my opinion though, FWIW.

jeff k said:The mtm is made from layered MDF, while the MTM 7 is made like a traditional box from 1" MDF, then it is sanded to shape. Both processes are more costly and time consuming than traditional rectangular boxes. You can see examples of this on the products page of www.occamaudio.com where we sell the boxes unfinished.

You are correct. I should have finished checking out the site before running my mouth. I have a bad habit of doing such things. Unfortunately, even at my age, I somehow never learn.

The only thing about your products that I don't really swoon over, are the black stands. Somehow, I would prefer a curved and veneered stand instead. If the cabinets have curved tops and bottoms, a curved stand would add to the asthetic pleasure of the total project. Just my opinion though, FWIW.

I've got the cabinets finished now and nicely sanded. It took a little more bondo than I would have liked, but its done. Now I'm wondering how to go about painting. I did some research and found that a shellac sealer is a good place to start. I read that "BIN" sealer/primer is good stuff so I bought a can at home depot. When I went to appy this stuff I was surprised how thin it is. I brushed the stuff on and was very disappointed, it seemed impossible to keep the brush strokes from showing. In the end I sanded most of it away.

Whats the trick to using this stuff? Do I have to put on several coats then sand it flat? I'm going for a black satin finish. Should I be using another technique?

Whats the trick to using this stuff? Do I have to put on several coats then sand it flat? I'm going for a black satin finish. Should I be using another technique?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.