Boomboxes arrived today...off for work until the week-end but should start playing around soon.

Cheers,

Max

Hi Max,

Which part of France are you from?

I'm in Alsace

Have fun with your project.

Let's keep in touch...

Pierrick

Yes, I also like the value 0.1uF but prefer the other type (MultiCap PPFXS) at this moment. However, what is the reason makes you consider the value or the type of this cap depends on the laser current setting?

The function of C906 for LA9242 is called "tracking gain time constant setting" in the datasheet, and the pot on the pickup is about the laser current setting. Are they related?

I am no expert, but if I was a betting man I'd wager that they are indeed related. That cap (C906) is best left well alone I think - any different cap may well result in a different sound, but whether the drive is working correctly then is open to conjecture. I'd say it sounds better with the original cap because the tracking/gain settings are accurate then. Sometimes it's not wise to replace everything with audiophile 'upgrades' unless you know full well what each part does.

I am no expert, but if I was a betting man I'd wager that they are indeed related. That cap (C906) is best left well alone I think - any different cap may well result in a different sound, but whether the drive is working correctly then is open to conjecture. I'd say it sounds better with the original cap because the tracking/gain settings are accurate then. Sometimes it's not wise to replace everything with audiophile 'upgrades' unless you know full well what each part does.

The original cap in C906 is not bad really and even better than many "audio grade" caps. However, there are many factors that may regard to the choice of C906, and currently I don't know what is the exact one. The laser current setting of course may be one of factors, but why are you so sure it is the exact factor regards to C906?

Last edited:

If the laserunit had in the factory been optimized to the exact C906 value, they did a bad job with my JVC RC EZ31: after a week playing with the Mundorf Supreme silver in oil o,22 uF the Mundorff sounds ways better than the original! I received however today a Black Gate N 0,1 uF, but am hesitating to replace the Mundorf. I will put the Black Gate somewhere in the transport to burn-in and will replace the Mundorf in about two weeks.

What I did notice however, was the difficulties the transport now has to play some older CD-R's. Did anyone noticed this also after replacing the C906?

What I did notice however, was the difficulties the transport now has to play some older CD-R's. Did anyone noticed this also after replacing the C906?

The laser current setting of course may be one of factors, but why are you so sure it is the exact factor regards to C906?

Well it just makes sense - many people have found the sound simply 'gels' with that cap in place. As it's to do with laser gain and not PSU or coupling per-se I think it's best to leave it as the designers intended in this instance, and the sound quality seems to bear this out.

Pure guesswork, and I'm not trying to discourage experimenting in the slightest - it just didn't work out for me

What I did notice however, was the difficulties the transport now has to play some older CD-R's. Did anyone noticed this also after replacing the C906?

C906 has something to do with the laser gain looking at the circuit - replacing it without knowing EXACTLY what you are doing probably does result in some disc playback issues - you could well be altering the gain characteristics of the unit...

The unit probably needs the laser gain re-adjusted using the pot on the side of the circuit board attached to the laser-unit, but as-yet nobody knows how to adjust for optimal playback once C906 is changed.

Well it just makes sense - many people have found the sound simply 'gels' with that cap in place. As it's to do with laser gain and not PSU or coupling per-se I think it's best to leave it as the designers intended in this instance, and the sound quality seems to bear this out.

Pure guesswork, and I'm not trying to discourage experimenting in the slightest - it just didn't work out for me

So that it is your pure guesswork. Okay.

Hello nemo1968,

Thanks for your sharing. The homemade cap is truly interesting to me. Do you have a picture show the inside of the two white blocks? I would like to know how the copper and the cotton are structured.

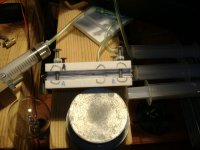

Sorry for late answer but I was busy.I don't have time to open the cap and so I will try to explain how to make it.Take two nonmetalic blocks which can be screwed tightly.Cut 22 pcs. of 12AWG copper foil.11 pcs. are used to form each electrode in our cap.I have made a foils 9cm long.Then cut a cotton isolator sheets to same length of copper and little bit larger and put one layer of cotton on the cap block,than put a sheet of copper on the cotton and leave it few mm over the block edge(see the photo) to can solder side A of cap electrode.On the copper than go a sheet of cotton and must cover all except the few mm over length where you solder.

The same is with electrode B ,Copper-Cotton and than side A again ,Copper-Cotton and so until you spend all the sheets.Before you begin with the sheet placing make holes for the blocks ,put all four screws in one block rotate it so the screws are standing with the heads on the bottom and you have sheets rail when you place them.When you finish just clamp with another

block ,screw them and solder 11 each of electrodes and you have perfect neutral sounding cap.Try to make it during dry weather because you do it of a cotton.You can isolate it against humidity if you want but on the transport I never had troubles with it.If you use it on some tube grid like input cap better isolate it for non humidity to not allow some current leakage.

I hope it was all explained well and if not ask.

Attachments

nemo1968,

The cap looks wonderful! Thanks for your explanation. It is clear and detailed so that I am able to make my own caps. Instead of cottons, how about papers, plastic wraps, or something are used for isolation?

By the way, what is the purpose of the syringes on the pictures? For audio projects, they look so unique and interesting.

The cap looks wonderful! Thanks for your explanation. It is clear and detailed so that I am able to make my own caps. Instead of cottons, how about papers, plastic wraps, or something are used for isolation?

By the way, what is the purpose of the syringes on the pictures? For audio projects, they look so unique and interesting.

nemo1968,

The cap looks wonderful! Thanks for your explanation. It is clear and detailed so that I am able to make my own caps. Instead of cottons, how about papers, plastic wraps, or something are used for isolation?

By the way, what is the purpose of the syringes on the pictures? For audio projects, they look so unique and interesting.

I chosen the cotton because of its dielectric constant factor which is 1.4.The teflon is around 2 and the air is 1.0 if I am not wrong.The intention was minimal loss of signal and as the air capacitor of such value is difficult task the choice was cotton.Natural sound as itself.It is also great as damper in cap even if you don't screw it very tight but in that case you loose some nF.I think that choosing the plastic would be waste of time soundwise but the paper might be nice as the rise seeds are pretty like cotton in dielectric constant table so you can try the Rizla rolls rice paper from tobacco shop.I have tried it in the cable construction and I was satisfied but the cotton sounds better in the cable because of great damping of the leads, I suppose.

Syringes are for air suspension under the turntable as I can not apply traditional springs as the air cushion arm is sensitive about springs level change.In that way I can put my table in the level by pressing the syringe more or less(something like old Citroen cars or the bus).Syringe is attached on the closed tube and the tube is placed under the table.You pump it and that is it.Very powerful ,three syringes can carry around 30kg of that turntable above ground with 15ml of the air injected in 4mm aquarium hose.The table is stable and isolated from feedback.

Last edited:

I chosen the cotton because of its dielectric constant factor which is 1.4.The teflon is around 2 and the air is 1.0 if I am not wrong.The intention was minimal loss of signal and as the air capacitor of such value is difficult task the choice was cotton.Natural sound as itself.It is also great as damper in cap even if you don't screw it very tight but in that case you loose some nF.I think that choosing the plastic would be waste of time soundwise but the paper might be nice as the rise seeds are pretty like cotton in dielectric constant table so you can try the Rizla rolls rice paper from tobacco shop.I have tried it in the cable construction and I was satisfied but the cotton sounds better in the cable because of great damping of the leads, I suppose.

Syringes are for air suspension under the turntable as I can not apply traditional springs as the air cushion arm is sensitive about springs level change.In that way I can put my table in the level by pressing the syringe more or less(something like old Citroen cars or the bus).Syringe is attached on the closed tube and the tube is placed under the table.You pump it and that is it.Very powerful ,three syringes can carry around 30kg of that turntable above ground with 15ml of the air injected in 4mm aquarium hose.The table is stable and isolated from feedback.

Like mentioned earlier thanks for sharing Sir. I have read about the terminator air suspension system as you suggested a few weeks back. It was very interesting and educational at same time when I extrapolated from you Shigaclone transport. Here again with the DIY cap and the explanation of your syringes, I'm impressed about your great ideas. I'm very tempted to try out the copper-cotton stacked cap. Have you experimented with different non-metallic blocks like Lexan or Plexi? Are you presently using saniboard plastic (like cutting surface boards) for the blocks? Also have you tried different types of cotton fabric (thickness and weave)? I guess the thinnest the better and the tightest woven also. In your first post, you mention that this present cap is equivalent to 10nF. As a rule of thumb, can I assume that if I double the cotton-copper layers I will obtain 20nF?

Very appreciated!

Or here for DIY-ers in Canada:

JVC PORTABLE AM/FM CD PLAYER New, RC-EZ31B $25.00 - Toronto Electronics For Sale - Kijiji Toronto

JVC PORTABLE AM/FM CD PLAYER New, RC-EZ31B $25.00 - Toronto Electronics For Sale - Kijiji Toronto

Like mentioned earlier thanks for sharing Sir. I have read about the terminator air suspension system as you suggested a few weeks back. It was very interesting and educational at same time when I extrapolated from you Shigaclone transport. Here again with the DIY cap and the explanation of your syringes, I'm impressed about your great ideas. I'm very tempted to try out the copper-cotton stacked cap. Have you experimented with different non-metallic blocks like Lexan or Plexi? Are you presently using saniboard plastic (like cutting surface boards) for the blocks? Also have you tried different types of cotton fabric (thickness and weave)? I guess the thinnest the better and the tightest woven also. In your first post, you mention that this present cap is equivalent to 10nF. As a rule of thumb, can I assume that if I double the cotton-copper layers I will obtain 20nF?

Very appreciated!

Thanks for compliments and sorry for late answer.

I didn't tested various materials.I am using Cerrock.This is the link:Kerrock

I have plenty of that material and doesn't flex when is screwed so it is perfect for a purpose.It have feel like stone.It is very easy to work with it too, not like plexi.I chosen a cotton which I had around ,just uncolored most natural that I found.I used an old bed cover.Yes ,the thinest the better and more capacity you have from less copper.You can make a value which you wish by adding more layers and you can just disconnect outer layers if you need less capacity.If you need two equal capacitors you can adjust the value of both in a pico range by tightening the screws more or less.Wonderful.....Just have to impregnate them after against humidity so they rest stable.

I think less cotton weave should be better because you have more air in between but it can be also very easy to short electrodes so I chosen a tight weave cotton.

I think i'm going to have to try making a silver and silk version as well as this copper and cotton. thanks so much for sharing, I had thought it should be as easy as this, have you thought about sealing with organic resin the way Duelund does?

I would do caps from silver too but it is too expensive and hard to get.The silk must also be great.I am sealing all with petrol parafin.It is also mechanically good against vibrations.I use it to dead the clock crystals and various other things with great sonic improvement.

Thanks again for all your input Nemo1968. It's on my "to do" list. ;0)Thanks for compliments and sorry for late answer.

I didn't tested various materials.I am using Cerrock.This is the link:Kerrock

I have plenty of that material and doesn't flex when is screwed so it is perfect for a purpose.It have feel like stone.It is very easy to work with it too, not like plexi.I chosen a cotton which I had around ,just uncolored most natural that I found.I used an old bed cover.Yes ,the thinest the better and more capacity you have from less copper.You can make a value which you wish by adding more layers and you can just disconnect outer layers if you need less capacity.If you need two equal capacitors you can adjust the value of both in a pico range by tightening the screws more or less.Wonderful.....Just have to impregnate them after against humidity so they rest stable.

I think less cotton weave should be better because you have more air in between but it can be also very easy to short electrodes so I chosen a tight weave cotton.

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story