Oh come on, they aren't that big. That's just a little 18" midrange and a 21" woofer.

Adorably petite.

I talked with John while he was building them but haven't been able to chat since the show.

The Coax is the now discontinued P.Audio 18" coax. It has a 1.4" compression driver IIRC. The woofer is an MCM 21" driven by a plate amp. Crossover is 170Hz 4th order and 1250Hz 2nd order electrical. Mid & Hi section about 112dB/Watt @ 1M. Baffle size approx 24X48", 12" deep. 115 lbs

each

I'm pretty familiar with the 18" coax as John had them alone on OB back in '09 and we worked on the crossover together. I covet those drivers. It would be fun to hear them with the 21" for support.

It would be fun to hear them with the 21" for support.

The Coax is the now discontinued P.Audio 18" coax. It has a 1.4" compression driver IIRC. The woofer is an MCM 21" driven by a plate amp. Crossover is 170Hz 4th order and 1250Hz 2nd order electrical. Mid & Hi section about 112dB/Watt @ 1M. Baffle size approx 24X48", 12" deep. 115 lbs

each

I'm pretty familiar with the 18" coax as John had them alone on OB back in '09 and we worked on the crossover together. I covet those drivers.

Here's a photo of the Widow Makers Deux from the Lone Star Audio Fest. Big, clean sound coming from a 5 or 6 watt amp. Them 5 or 6 watts will hurt you. Killers.

I dont understand much passive xo´s so those coils looks cool to my eyes

WMD specifications

For those who are interested, here are the specs for the current configuration as presented at LSAF in Dallas last week using an 18" mid bass:

Model designation: MAS-WMD-A-STP

Baffle design for ULF & mid bass: Semi-cardioid – Dipole. H.F. mono-pole from approximately 3.5 KHz up.

Impedance: 8 Ohms nominal. Minimum magnitude: 6.8 ohms @ 650 Hz.

Half space reference efficiencies @ 1 meter: ULF: 94 db/Watt nominal (1.6%). Mid-HF: 106 db/Watt nominal (25%).

System on axis frequency response at a typical listening distance of 8 feet: 24 Hz – 18.75 KHz +/- 3.5 dB assuming 36” minimum distance from rear and side wall(s).

Sub ULF driver: 21” cast aluminum frame. 4” voice coil. Paper cone.

Mid bass driver: 15” or 18” cast aluminum frame. 4” voice coil. Paper cone. Coaxial layout. 18” subject to availability.

H.F. driver: 3” class Titanium/Nomex compression with 1.4” exit. Circumferential machined aluminum phase plug.

H.F. driver is coaxially mounted at the rear of the 15” or 18” mid-bass & loaded by a short horn - wave guide combination. Wave guide provided by the mid-bass cone.

Driver magnet assembly weights: Sub (21 lb.), Mid (20 lb.), H.F. (10 lb.)

Minimum recommended power: 1500 Milliwatts. (Mid bass - H.F. driver)

Max power input in watts (RMS): ULF 250, Mid 175, H.F. 75.

Max output full range: 110 dB @ 1 meter. Above 35 Hz: 114 dB@ 1 meter. All output and efficiency specifications assume typical residential half space conditions.

Electrical-Acoustic cross-over points: 170 Hz & 1,750 Hz.

ULF crossover: Electrical (Active) & acoustic combination: 5th order.

Mid bass – compression driver crossover: 2nd order passive spread frequency L/R slopes with frequency specific traps. No pad on compression driver.

Baffle construction: 1.5” baffle plate. Sides, wings & bottom plate ¾”. All MDF panel with appropriate glue & fasteners. All wood work performed on modern CNC equipment.

Standard trim: Sanded & sealed New Zealand Riata White Pine or Wire Brushed Red Oak base, side & top trim. Jet black or optic white removable front grill cloth. Satin black all remaining surfaces.

Plate amp: 250 WRMS class AB-1 with auto start-standby. Upper cut off frequency & output level are adjustable. Initial values are factory set. 120 VAC. 60 Hz. High & low level input capable. Amplifier to Sub amplifier interconnect cables (1 pair) are included.

It is recommended the partnering amplifier includes a low level sub output for best performance. Low level sensitivity for full sub amp output is 0.75 Volts.

Dimensions: 24” wide X 13” deep X 46.5” height.

Quality gold over brass binding post accept banana plug and wire leads up to 10 Ga.

Adjustable tip toes.

Net weight: 135 lb. each. Shipping weight: 185 lb. each.

For those who are interested, here are the specs for the current configuration as presented at LSAF in Dallas last week using an 18" mid bass:

Model designation: MAS-WMD-A-STP

Baffle design for ULF & mid bass: Semi-cardioid – Dipole. H.F. mono-pole from approximately 3.5 KHz up.

Impedance: 8 Ohms nominal. Minimum magnitude: 6.8 ohms @ 650 Hz.

Half space reference efficiencies @ 1 meter: ULF: 94 db/Watt nominal (1.6%). Mid-HF: 106 db/Watt nominal (25%).

System on axis frequency response at a typical listening distance of 8 feet: 24 Hz – 18.75 KHz +/- 3.5 dB assuming 36” minimum distance from rear and side wall(s).

Sub ULF driver: 21” cast aluminum frame. 4” voice coil. Paper cone.

Mid bass driver: 15” or 18” cast aluminum frame. 4” voice coil. Paper cone. Coaxial layout. 18” subject to availability.

H.F. driver: 3” class Titanium/Nomex compression with 1.4” exit. Circumferential machined aluminum phase plug.

H.F. driver is coaxially mounted at the rear of the 15” or 18” mid-bass & loaded by a short horn - wave guide combination. Wave guide provided by the mid-bass cone.

Driver magnet assembly weights: Sub (21 lb.), Mid (20 lb.), H.F. (10 lb.)

Minimum recommended power: 1500 Milliwatts. (Mid bass - H.F. driver)

Max power input in watts (RMS): ULF 250, Mid 175, H.F. 75.

Max output full range: 110 dB @ 1 meter. Above 35 Hz: 114 dB@ 1 meter. All output and efficiency specifications assume typical residential half space conditions.

Electrical-Acoustic cross-over points: 170 Hz & 1,750 Hz.

ULF crossover: Electrical (Active) & acoustic combination: 5th order.

Mid bass – compression driver crossover: 2nd order passive spread frequency L/R slopes with frequency specific traps. No pad on compression driver.

Baffle construction: 1.5” baffle plate. Sides, wings & bottom plate ¾”. All MDF panel with appropriate glue & fasteners. All wood work performed on modern CNC equipment.

Standard trim: Sanded & sealed New Zealand Riata White Pine or Wire Brushed Red Oak base, side & top trim. Jet black or optic white removable front grill cloth. Satin black all remaining surfaces.

Plate amp: 250 WRMS class AB-1 with auto start-standby. Upper cut off frequency & output level are adjustable. Initial values are factory set. 120 VAC. 60 Hz. High & low level input capable. Amplifier to Sub amplifier interconnect cables (1 pair) are included.

It is recommended the partnering amplifier includes a low level sub output for best performance. Low level sensitivity for full sub amp output is 0.75 Volts.

Dimensions: 24” wide X 13” deep X 46.5” height.

Quality gold over brass binding post accept banana plug and wire leads up to 10 Ga.

Adjustable tip toes.

Net weight: 135 lb. each. Shipping weight: 185 lb. each.

For those who are interested, here are the specs for the current configuration as presented at LSAF in Dallas last week using an 18" mid bass:

Model designation: MAS-WMD-A-STP

Baffle design for ULF & mid bass: Semi-cardioid – Dipole. H.F. mono-pole from approximately 3.5 KHz up.

Impedance: 8 Ohms nominal. Minimum magnitude: 6.8 ohms @ 650 Hz.

Half space reference efficiencies @ 1 meter: ULF: 94 db/Watt nominal (1.6%). Mid-HF: 106 db/Watt nominal (25%).

System on axis frequency response at a typical listening distance of 8 feet: 24 Hz – 18.75 KHz +/- 3.5 dB assuming 36” minimum distance from rear and side wall(s).

Sub ULF driver: 21” cast aluminum frame. 4” voice coil. Paper cone.

Mid bass driver: 15” or 18” cast aluminum frame. 4” voice coil. Paper cone. Coaxial layout. 18” subject to availability.

H.F. driver: 3” class Titanium/Nomex compression with 1.4” exit. Circumferential machined aluminum phase plug.

H.F. driver is coaxially mounted at the rear of the 15” or 18” mid-bass & loaded by a short horn - wave guide combination. Wave guide provided by the mid-bass cone.

Driver magnet assembly weights: Sub (21 lb.), Mid (20 lb.), H.F. (10 lb.)

Minimum recommended power: 1500 Milliwatts. (Mid bass - H.F. driver)

Max power input in watts (RMS): ULF 250, Mid 175, H.F. 75.

Max output full range: 110 dB @ 1 meter. Above 35 Hz: 114 dB@ 1 meter. All output and efficiency specifications assume typical residential half space conditions.

Electrical-Acoustic cross-over points: 170 Hz & 1,750 Hz.

ULF crossover: Electrical (Active) & acoustic combination: 5th order.

Mid bass – compression driver crossover: 2nd order passive spread frequency L/R slopes with frequency specific traps. No pad on compression driver.

Baffle construction: 1.5” baffle plate. Sides, wings & bottom plate ¾”. All MDF panel with appropriate glue & fasteners. All wood work performed on modern CNC equipment.

Standard trim: Sanded & sealed New Zealand Riata White Pine or Wire Brushed Red Oak base, side & top trim. Jet black or optic white removable front grill cloth. Satin black all remaining surfaces.

Plate amp: 250 WRMS class AB-1 with auto start-standby. Upper cut off frequency & output level are adjustable. Initial values are factory set. 120 VAC. 60 Hz. High & low level input capable. Amplifier to Sub amplifier interconnect cables (1 pair) are included.

It is recommended the partnering amplifier includes a low level sub output for best performance. Low level sensitivity for full sub amp output is 0.75 Volts.

Dimensions: 24” wide X 13” deep X 46.5” height.

Quality gold over brass binding post accept banana plug and wire leads up to 10 Ga.

Adjustable tip toes.

Net weight: 135 lb. each. Shipping weight: 185 lb. each.

Thank you!

Added a felt ring around the front of the 3.5" Vifa. My woodworking skills aren't good enough to properly sink the Vifa to smooth out the treble frequencies so it got a ring of felt. Added bonus: it makes the 3.5" driver look bigger and helps balance it out visually against the 15" woofer.

It definitely smooths out the treble. It works well with some gear and is too laid back with mellower components. But it's easy to do (use a bowl and an exacto knife) and easy to remove if you don't like the results.

It definitely smooths out the treble. It works well with some gear and is too laid back with mellower components. But it's easy to do (use a bowl and an exacto knife) and easy to remove if you don't like the results.

Attachments

Last edited:

We're going to call this one Ultra stupid mistakes.

My Ultra's are about two years old now and the project has taught me a lot about how the little things in speaker building really add up sonically. Call it speaker building 101. Here are a number of tweaks and misadventures conveniently listed so you may avoid them.

In no particular order...

1. Ultra small gaps around the tweeters. Tiny little gaps under the tweeter were so small I never saw them when mounting the Vifa drivers but they were just enough gap to seriously mess with the midrange. Filled the gaps with rope caulk and the midrange filled out.

2. Too much rope caulk. Figures, right? Fix one issue and cause another. I'd gone after the gaps in the baffle pretty aggressively with rope caulk and ended up putting on at least one too many strands of the stuff around the back of the Vifa. Removed this obstruction from the rear of the Vifa and it opened up the sound nicely. As Pano said earlier in this thread, you gotta let them Vifa's breath.

3. Smoothed out the area behind the Vifa. There are stepped ridges in the wood behind the Vifa from routing. I put duct tape over the routed ridges smoothing them out. It went from being a series of ridges to being more like a horn flare. Frankly, if I was building the Utras again the Vifa's would have a bigger back hole. This tweak was done at the same time the excess rope calk was removed and it really opened up the sound. The sound is definitely more three dimensional and palatable. Adds magic.

4. Moved the Vifa wire away from the woofers. The wire leading to the Vifa was right next to the GRS woofer magnet. Moving it cleared out an edginess that shouldn't have been there.

5. Changed the position of the wire round inductors so their centers faced away from the big iron inductor. This improved clarity.

6. Added a felt ring around the front of the 3.5" Vifa. See the last post.

7. Added the woofer trap John described to improve the midrange. Originally added an 18 gauge inductor just to see if the improvement was worthwhile. It was. Then upgraded to a 14 gauge inductor and added the $1 bypass cap. That was also an improvement. These changes added refinement to the midrange.

The "duhh" moment was moving the wire away from the woofer magnet. You wonder how you can be so dense some times and let something so obvious mess things up.

The "aaahhhh" moment was opening up the back of the 3.5" drivers. It sounded good before it was completely opened up but it got substantially better after the change. For lack of better words there is more there there now.

My Ultra's are about two years old now and the project has taught me a lot about how the little things in speaker building really add up sonically. Call it speaker building 101. Here are a number of tweaks and misadventures conveniently listed so you may avoid them.

In no particular order...

1. Ultra small gaps around the tweeters. Tiny little gaps under the tweeter were so small I never saw them when mounting the Vifa drivers but they were just enough gap to seriously mess with the midrange. Filled the gaps with rope caulk and the midrange filled out.

2. Too much rope caulk. Figures, right? Fix one issue and cause another. I'd gone after the gaps in the baffle pretty aggressively with rope caulk and ended up putting on at least one too many strands of the stuff around the back of the Vifa. Removed this obstruction from the rear of the Vifa and it opened up the sound nicely. As Pano said earlier in this thread, you gotta let them Vifa's breath.

3. Smoothed out the area behind the Vifa. There are stepped ridges in the wood behind the Vifa from routing. I put duct tape over the routed ridges smoothing them out. It went from being a series of ridges to being more like a horn flare. Frankly, if I was building the Utras again the Vifa's would have a bigger back hole. This tweak was done at the same time the excess rope calk was removed and it really opened up the sound. The sound is definitely more three dimensional and palatable. Adds magic.

4. Moved the Vifa wire away from the woofers. The wire leading to the Vifa was right next to the GRS woofer magnet. Moving it cleared out an edginess that shouldn't have been there.

5. Changed the position of the wire round inductors so their centers faced away from the big iron inductor. This improved clarity.

6. Added a felt ring around the front of the 3.5" Vifa. See the last post.

7. Added the woofer trap John described to improve the midrange. Originally added an 18 gauge inductor just to see if the improvement was worthwhile. It was. Then upgraded to a 14 gauge inductor and added the $1 bypass cap. That was also an improvement. These changes added refinement to the midrange.

The "duhh" moment was moving the wire away from the woofer magnet. You wonder how you can be so dense some times and let something so obvious mess things up.

The "aaahhhh" moment was opening up the back of the 3.5" drivers. It sounded good before it was completely opened up but it got substantially better after the change. For lack of better words there is more there there now.

Thanks for sharing your experiences!

Hey Barry....

Thanks for sharing your Ultra journey! I too am amazed at how seemingly unrelated little differences can add up to a huge difference in over all performance. Applies to simple speakers like the Manzanita or Ultra, and very complex speakers like the Widow Maker Deux. A little less diffraction here, a slight tweeter position on the baffle there... and so it goes. Even more so with crossovers. That is one of the fun things about these two simple dipoles. The engineering is not that simple, but they are so easy to experiment with, or should I say on. Enjoy!

Hey Barry....

Thanks for sharing your Ultra journey! I too am amazed at how seemingly unrelated little differences can add up to a huge difference in over all performance. Applies to simple speakers like the Manzanita or Ultra, and very complex speakers like the Widow Maker Deux. A little less diffraction here, a slight tweeter position on the baffle there... and so it goes. Even more so with crossovers. That is one of the fun things about these two simple dipoles. The engineering is not that simple, but they are so easy to experiment with, or should I say on. Enjoy!

Added a felt ring around the front of the 3.5" Vifa. My woodworking skills aren't good enough to properly sink the Vifa to smooth out the treble frequencies so it got a ring of felt. Added bonus: it makes the 3.5" driver look bigger and helps balance it out visually against the 15" woofer.

It definitely smooths out the treble. It works well with some gear and is too laid back with mellower components. But it's easy to do (use a bowl and an exacto knife) and easy to remove if you don't like the results.

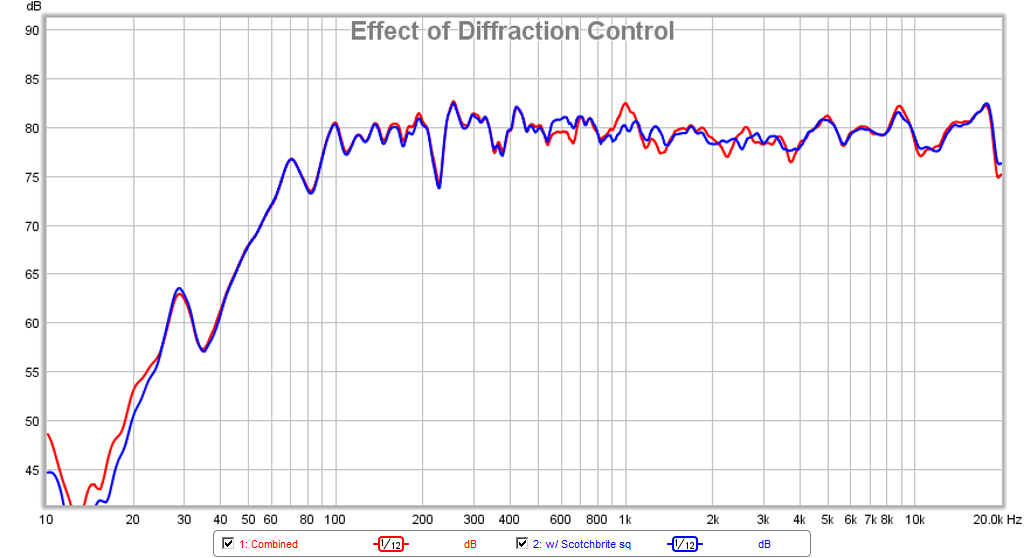

Yes this does indeed smooth out the treble. It's audible and measurable. Scotchbrite scouring pads (not as pretty as felt) work even better. Make it not round and it works even better. Round is the worst shape for diffraction.

More info here:

http://www.diyaudio.com/forums/full-range/280331-fr58ex-ac130f1-micro-fast.html

Thanks Barry for the rundown. It's fun to learn and discover with speakers like these.

Ditto on the felt ring, it does sound better. Subtle, but an improvement. That led me to build a pair of Manzanitas that were covered in faux fur. They sounded good, but everyone but me thought they looked silly. Wonder if I have photos somewhere?

They sounded good, but everyone but me thought they looked silly. Wonder if I have photos somewhere?

Ditto on the felt ring, it does sound better. Subtle, but an improvement. That led me to build a pair of Manzanitas that were covered in faux fur.

Very smart and elegant design. Congratulations!

Sent from my Nexus 5 using Tapatalk

John - the need to play is strong. I've played with various resistor values for a while and just dropped the value of the tweeter capacitor to hear what that does. Next up is inductors ...

xrk971 - Scotchbrite for the surrounds is the funniest, geekiest tweak ever. And I mean that in the absolute best way possible. Everyone in these forums comes up with some of the greatest ideas. Your thread on the foam board cornu horns is as much fun as this thread.

blue934 - Several years back I built some baffles with natural finish fronts and black sides. I wanted to go for the same Ikea look again for the Ultra's, especially after seeing John's Ultra Plus speakers at the Dallas show. The Ultra Plus has an 8" driver over the two 15" woofers and it just looked so much better than the tiny little 3.5". It sounded great, too. It was my favorite speaker of the show that year.

Pano - Would love to see the faux fur photos. The old baffles I made had felt on the back of them and it helped them vanish sonically so it may get done to the Ultras eventually. Frankly the Ultras already do a great vanishing act but all the little tweaks do add up.

I don't want to lose the wood fronts as it's a very nice visual on a rather imposing speaker. And the Ikea-look speakers are in front of actual Ikea record shelves so everything ties together visually. It's the same reason the side wings were not made narrower towards the top - leaving them wide looks mahvelous!

xrk971 - Scotchbrite for the surrounds is the funniest, geekiest tweak ever. And I mean that in the absolute best way possible. Everyone in these forums comes up with some of the greatest ideas. Your thread on the foam board cornu horns is as much fun as this thread.

blue934 - Several years back I built some baffles with natural finish fronts and black sides. I wanted to go for the same Ikea look again for the Ultra's, especially after seeing John's Ultra Plus speakers at the Dallas show. The Ultra Plus has an 8" driver over the two 15" woofers and it just looked so much better than the tiny little 3.5". It sounded great, too. It was my favorite speaker of the show that year.

Pano - Would love to see the faux fur photos. The old baffles I made had felt on the back of them and it helped them vanish sonically so it may get done to the Ultras eventually. Frankly the Ultras already do a great vanishing act but all the little tweaks do add up.

I don't want to lose the wood fronts as it's a very nice visual on a rather imposing speaker. And the Ikea-look speakers are in front of actual Ikea record shelves so everything ties together visually. It's the same reason the side wings were not made narrower towards the top - leaving them wide looks mahvelous!

- Home

- Loudspeakers

- Multi-Way

- Fast, fun, Inexpensive OB project