Is there a reason why you wouldn’t solder after crimping?

why crimping at all, when you're soldering after?

I'm only using needle end wire connectors, of those needing crimping, so soldering pins to pcb instead of multi-strand wire (messier when thick)

and those - I'm slightly crimping them to wire, then soldering to wire then heatshrinking

OK, everyone is having own fave poison, but non-soldered connectors aren't mine

I was wondering if there were any mods for the F6 that could increase the output power. I’ve tried searching but I’m new to the diy space (I’ve been pretty busy though, and built aleph 60 monos, ACA, and now F6).

I love the sound of the F6, but I have relatively hard to drive bookshelves (85db 4ohm) and wondered if there was a way to give a little more headroom as my pre amp is usually at 90% +

im getting some diy tang bang horns soon but was just exploring options.

is it the Jensen transformers limiting output or can I add more output fets similar to how the alephs work?

oh, and thanks for the great build guide - it was super helpful

I love the sound of the F6, but I have relatively hard to drive bookshelves (85db 4ohm) and wondered if there was a way to give a little more headroom as my pre amp is usually at 90% +

im getting some diy tang bang horns soon but was just exploring options.

is it the Jensen transformers limiting output or can I add more output fets similar to how the alephs work?

oh, and thanks for the great build guide - it was super helpful

Not quite sure how that would look in each amps internal wiring .. so a single channel input (e.g. left channel) from the balanced pre would be used to drive the speaker inputs on both boards and I take the outputs from both boards and wire them to the same speaker binding posts (e.g) left channel.

And that’s it - that is safe?

Where does the balanced part come in as on the aleph there is a whole input stage with a jumper to select between balanced/unbalanced.

I am not an electrical engineer so I don’t really feel super comfortable just doing things without getting a little more info on this.

Thanks though for the idea - it sounds good to me!

And that’s it - that is safe?

Where does the balanced part come in as on the aleph there is a whole input stage with a jumper to select between balanced/unbalanced.

I am not an electrical engineer so I don’t really feel super comfortable just doing things without getting a little more info on this.

Thanks though for the idea - it sounds good to me!

Picking the balanced output from one channel from the preamp:

XLR Pin 1 goes to signal ground on one board.

XLR Pin 2 goes to + input on the Right board

XLR Pin 3 goes to + input on the Left board

(I accomplished this by wiring the XLR to the RCAs, minding the need for only one ground connection to either RCA)

The speaker outputs will stay wired the same as a single stereo amp:

"+" output on R board goes to right + speaker post

"g" output on R board goes to right - speaker post

"+" output on L board goes to left + speaker post.

"g" output on L board goes to left - speaker post

Then hook up the speaker to the two + speaker posts.

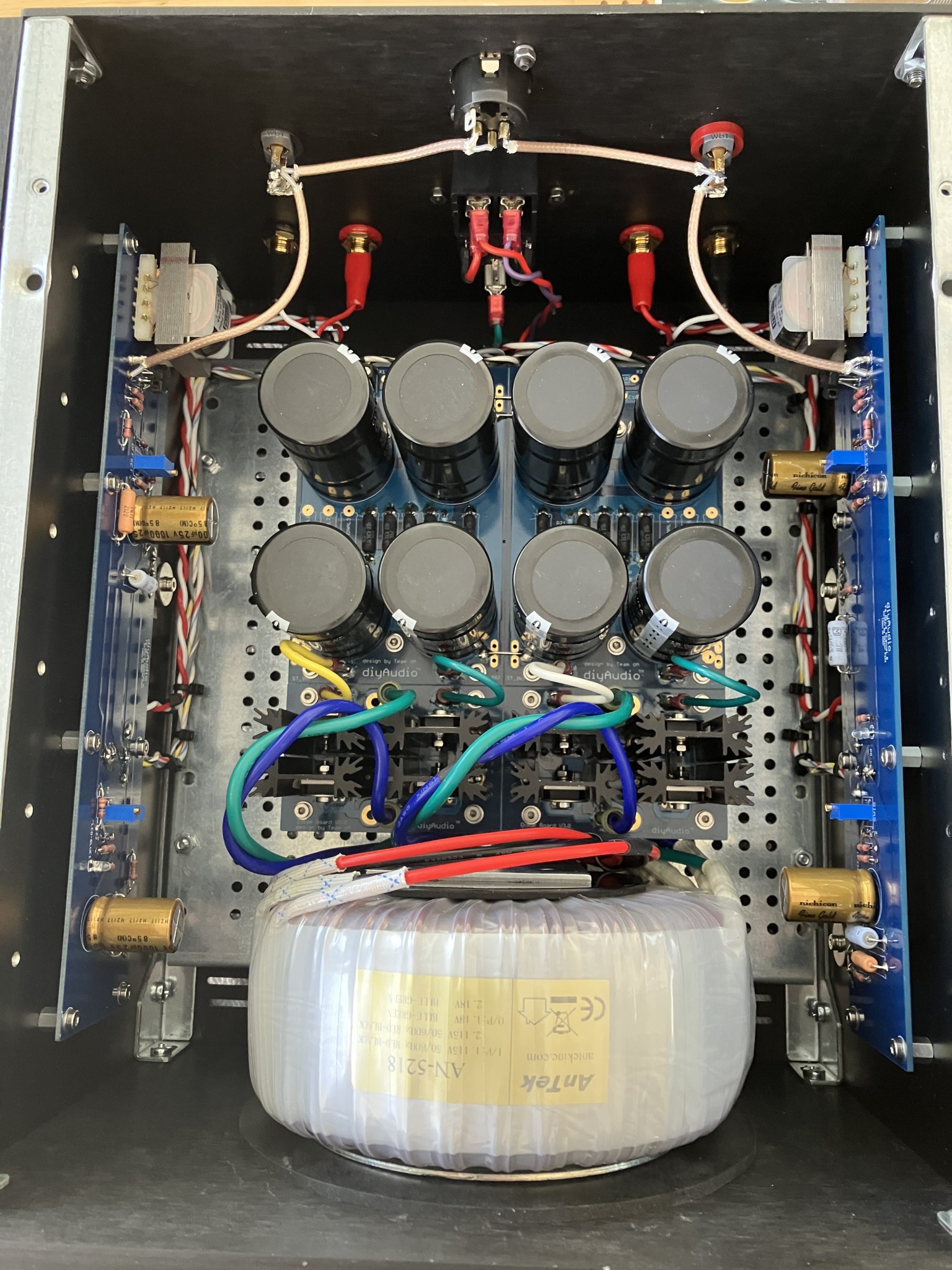

I know someone has a schematic around here. Best I can do is a picture.

Requires two stereo F6s. @6L6 heard these and was amazed. Lots of oomph.

XLR Pin 1 goes to signal ground on one board.

XLR Pin 2 goes to + input on the Right board

XLR Pin 3 goes to + input on the Left board

(I accomplished this by wiring the XLR to the RCAs, minding the need for only one ground connection to either RCA)

The speaker outputs will stay wired the same as a single stereo amp:

"+" output on R board goes to right + speaker post

"g" output on R board goes to right - speaker post

"+" output on L board goes to left + speaker post.

"g" output on L board goes to left - speaker post

Then hook up the speaker to the two + speaker posts.

I know someone has a schematic around here. Best I can do is a picture.

Requires two stereo F6s. @6L6 heard these and was amazed. Lots of oomph.

The F6 can benefit from a higher voltage power supply, given consideration for the limitations of its input stage.

I have modified my F6 considerably, as documented elsewhere in this thread. In brief, a diamond buffer style input stage drives a set of FQH44N10 Mosfets through the Jensen signal transformer. Power rails are +/- 26.5V and bias current is presently 1.6A.

Finding a suitable set of output Mosfets can be somewhat tricky, as the ones I have are no longer in production. Some of the easier ones would be IRFP140 or IRFP150. There are also some interesting candidates from IXYS.

This amp drives my Vandersteen 3As with plenty of authority and has become my favorite winter amplifier.

I have modified my F6 considerably, as documented elsewhere in this thread. In brief, a diamond buffer style input stage drives a set of FQH44N10 Mosfets through the Jensen signal transformer. Power rails are +/- 26.5V and bias current is presently 1.6A.

Finding a suitable set of output Mosfets can be somewhat tricky, as the ones I have are no longer in production. Some of the easier ones would be IRFP140 or IRFP150. There are also some interesting candidates from IXYS.

This amp drives my Vandersteen 3As with plenty of authority and has become my favorite winter amplifier.

I was wondering if there were any mods for the F6 that could increase the output power. I’ve tried searching but I’m new to the diy space (I’ve been pretty busy though, and built aleph 60 monos, ACA, and now F6).

I love the sound of the F6, but I have relatively hard to drive bookshelves (85db 4ohm) and wondered if there was a way to give a little more headroom as my pre amp is usually at 90% +

im getting some diy tang bang horns soon but was just exploring options.

is it the Jensen transformers limiting output or can I add more output fets similar to how the alephs work?

oh, and thanks for the great build guide - it was super helpful

There is a modified F6 project by the name of "F6 Nitrous" that 2 picoDumbs did:

https://www.diyaudio.com/community/threads/the-diyaudio-firstwatt-f6.258613/post-5145918

Thanks for the great replies. @6sX7 - thank you for the photo and explanation - that’s plenty to go on and I’ve just ordered the second boards and parts for a second F6 as they are quick to put together and I have parts from the first build left over mostly.

I’ll give that a try as I love the sound of the F6 - closer to my parasound halo JC5, but sweeter and more delicate in the detail but less grip in bass but not in anyway bass light if that makes sense. I prefer the F6 for my late night listening as in my small room it can get plenty loud. I believe the JC5 is JFET input with mosfet output so a similar sound characteristic is logical despite the massive power differences (it’s class A for first 12W)

And thanks to others for ideas - these are things I’ll bookmark and look at down the line.

I’ll give that a try as I love the sound of the F6 - closer to my parasound halo JC5, but sweeter and more delicate in the detail but less grip in bass but not in anyway bass light if that makes sense. I prefer the F6 for my late night listening as in my small room it can get plenty loud. I believe the JC5 is JFET input with mosfet output so a similar sound characteristic is logical despite the massive power differences (it’s class A for first 12W)

And thanks to others for ideas - these are things I’ll bookmark and look at down the line.

Last edited:

No advantage to the 5218 other than oversized and, thus, underworked.

The orientation may help. Gets it as far away from the signal xformers as possible. I think they are most orthogonal like that but having a hard time visualizing the fields. E-cores and inductors are much easier to grasp in my brain.

The orientation may help. Gets it as far away from the signal xformers as possible. I think they are most orthogonal like that but having a hard time visualizing the fields. E-cores and inductors are much easier to grasp in my brain.

@6sX7 So I actually just figured out the hum. I first loosened the donut and tried rotating it to no avail so I detached it and tried it in vertical but no better. I noticed hum dropped to almost nothing with the donut at 45 degrees. I also found that just moving it away from the AC IEC inlet solved the hum.

Moving the donut close to one or other transformer did not change the hum, so I’ve concluded it’s the donut picking up ac line noise.

In my Alephs I had the CRC and donut side by side and have zero hum, but in the build guide the power was all central from back to front and I tried to replicate. I did buy the mountings to get the donut vertical rather than flat so I’ll use that now (hum dependent) it will give me more room for a back to front PSU.

It means I have to do a bit of a rebuild and I’ll get the donut as far from the IEC as possible and may flip the boards 180 to get the transformers away from the antek.

But I’ll play around with the arrangement and find the best one, and I’ll let you know what the final result is.

Thanks for the help!

suggestions:

1. flip donut to front as you mention.

2. keep AC leads from IEC to donut short as possible, down the middle.

3. same for leads from donut to rectifiers. (don't have to shorten them, just ziptie so they pull towards the middle.

4. flip boards so MOSFETs are on lower half of sinks (better heat management) Either front to back or left to right, pick one. Front to back would keep the transformers as far apart as possible.

5. run input signal wires along board edge closest to the chassis top, farthest away from any AC lines. Front to back board swap would keep MOSFETs away from them.

1. flip donut to front as you mention.

2. keep AC leads from IEC to donut short as possible, down the middle.

3. same for leads from donut to rectifiers. (don't have to shorten them, just ziptie so they pull towards the middle.

4. flip boards so MOSFETs are on lower half of sinks (better heat management) Either front to back or left to right, pick one. Front to back would keep the transformers as far apart as possible.

5. run input signal wires along board edge closest to the chassis top, farthest away from any AC lines. Front to back board swap would keep MOSFETs away from them.

Wait a minute... what determines whether you can mount a mosfet directly to the heatsink vs. electrically insulated via Keratherm? I see all the diy firstwatt designs electrically insulate the output devices from the heatsink, but I've seen it done directly to the heatsink as well in other amps. Is it possible that some shredded Keratherm might have messed things up for me on my F6?

whether or not the heatsink floats or grounds. For the Modushop chassis, the main mosfet heatsinks screw together as part of the chassis and ground out. The mosfets should be insulated. When remounting, I clean the heatsink surface and apply a new keratherm piece JIC.

Even for the PSU, I always insulate as I don't want to have to remember the hard way that the heatsink is live.

Even for the PSU, I always insulate as I don't want to have to remember the hard way that the heatsink is live.

Last edited:

all mosfets in TO247 case must have isolator

only if you see big IXYS pucks in amp construction, there is no need for isolator, it's already done in part body itself

now, no need to think about state of your isolator - just use ohmmeter - set to MegaOhms, and you must see reading out of range, probing between drain pin and heatsink

of course that channel pcb/PSU must be disconnected in any way of chassis - remove any sort of connection between audio GND and chassis, for that measurement

only if you see big IXYS pucks in amp construction, there is no need for isolator, it's already done in part body itself

now, no need to think about state of your isolator - just use ohmmeter - set to MegaOhms, and you must see reading out of range, probing between drain pin and heatsink

of course that channel pcb/PSU must be disconnected in any way of chassis - remove any sort of connection between audio GND and chassis, for that measurement

- Home

- Amplifiers

- Pass Labs

- F6 Illustrated Build Guide