wesayso; yes, with 10f spider displacement forces air through weave of spider. This may produce sound, but the numerous little jets of air passing through each little hole also sets up air turbulence, changing way sound waves interact with this air. Some of compressed air is forced down outside of voice coil former, up inside voice coil former and into motor vent cavity, where it adds turbulence for sound leaving backside of dust cap. The only upside to this is voice coil cooling.

Since driver casting is non-ferrous, a small stream of air may be forced into pole vent pressurizing inside of cavity under spider, enabling careful milling of vents with reduced risk of contaminating motor with metal bits. Tempting.

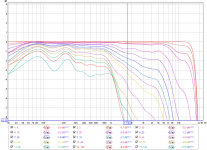

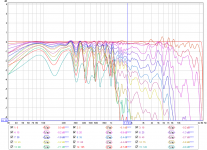

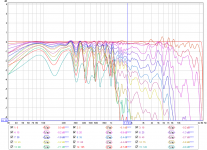

Normalized polar plots:

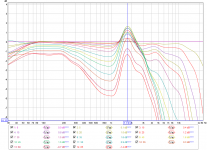

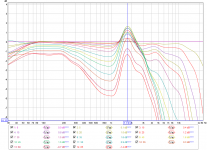

3 cycle frequency dependent windowing plot for bare pipe:

The normalized view is extremely good predictor of off axis response if driver is equalized perfectly flat on axis. With driver in bare pipe roll off going off axis is nearly textbook perfect. The 3cycle windowing is indicative of transient attacks in music source smoothly loosing their edge as radiation progresses off axis.

16 cycle frequency dependent windowing for bare pipe:

Above, the longer windows introduce some ripple. At 16 cycles, above about 2kHz the train of 16 waves is still short enough that room reflections are absent. Below 2kHz, floor, ceiling, and then three wall reflections become an influence. Reflections of fourth wall, the back wall, come into play below about 600Hz. Also as mentioned in prior posting, pipe radiation is likely factor at longer wavelengths. Of note is magnitude and width of consecutive peaks and dips. They are narrow with high Q values, and audibility is generally not considered an issue with human hearing.

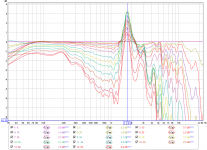

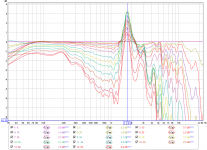

3 cycle frequency dependent windowing for pipe with baffle:

Here we see sound going in mostly 2pi space pattern in octave centered at 1.74kHz. No form of equalization will fix this. Some manner of wave guide is required. At 1kHz a cardioid pattern is indicated, and this collapses to fairly monopole as frequency drops to 200Hz.

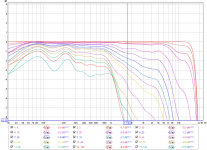

16 cycle frequency dependent windowing for pipe with baffle:

Ripple magnitude in plots below 1kHz are tiny. The cardioid behavior in this region reduces reflections from side walls, front wall, floor and ceiling, and also increases direct sound.

It is easy to see that as baffle size decreases so will cardioid behavior.

Since driver casting is non-ferrous, a small stream of air may be forced into pole vent pressurizing inside of cavity under spider, enabling careful milling of vents with reduced risk of contaminating motor with metal bits. Tempting.

Normalized polar plots:

3 cycle frequency dependent windowing plot for bare pipe:

The normalized view is extremely good predictor of off axis response if driver is equalized perfectly flat on axis. With driver in bare pipe roll off going off axis is nearly textbook perfect. The 3cycle windowing is indicative of transient attacks in music source smoothly loosing their edge as radiation progresses off axis.

16 cycle frequency dependent windowing for bare pipe:

Above, the longer windows introduce some ripple. At 16 cycles, above about 2kHz the train of 16 waves is still short enough that room reflections are absent. Below 2kHz, floor, ceiling, and then three wall reflections become an influence. Reflections of fourth wall, the back wall, come into play below about 600Hz. Also as mentioned in prior posting, pipe radiation is likely factor at longer wavelengths. Of note is magnitude and width of consecutive peaks and dips. They are narrow with high Q values, and audibility is generally not considered an issue with human hearing.

3 cycle frequency dependent windowing for pipe with baffle:

Here we see sound going in mostly 2pi space pattern in octave centered at 1.74kHz. No form of equalization will fix this. Some manner of wave guide is required. At 1kHz a cardioid pattern is indicated, and this collapses to fairly monopole as frequency drops to 200Hz.

16 cycle frequency dependent windowing for pipe with baffle:

Ripple magnitude in plots below 1kHz are tiny. The cardioid behavior in this region reduces reflections from side walls, front wall, floor and ceiling, and also increases direct sound.

It is easy to see that as baffle size decreases so will cardioid behavior.

Thanks sharing detailed survey Barleywater.

Really have to adapt to reading plots that go so detailed with 12-14dB vertical scales .

.

To better understand the two baffle setups is there any chance you would share two pictures.

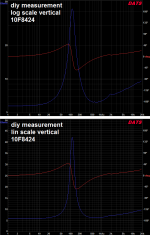

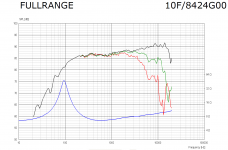

Think some data can be related to manufacture datasheets if one zoom in, below is 10F/8424 datasheet and my diy DATS plots and think 1,74kHz pattern is some reflected in both.

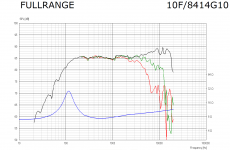

Below is also datasheet 10F/8414 and hardware picture because it seems have the ventilation behind spider.

Really have to adapt to reading plots that go so detailed with 12-14dB vertical scales

To better understand the two baffle setups is there any chance you would share two pictures.

Think some data can be related to manufacture datasheets if one zoom in, below is 10F/8424 datasheet and my diy DATS plots and think 1,74kHz pattern is some reflected in both.

Below is also datasheet 10F/8414 and hardware picture because it seems have the ventilation behind spider.

Attachments

Last edited:

That is really interesting that 8414 has spider ventilation. You would think that is better. Why does 8424 eschew such things?

LOL, I also had to get used to Bw's 1dB per division plots.

I said that looks really ugly for a 10F! But it was just 5dB baffle step loss. It really does look like a step.

LOL, I also had to get used to Bw's 1dB per division plots.

I said that looks really ugly for a 10F! But it was just 5dB baffle step loss. It really does look like a step.

Hi Jeshi,

I googled a littlle more about EVA foam, and i finally find a few sources in France.

What is the density kG/meter cube advised ? I found from 150 kG/1 meter cube to 375 kG/1 meter cube ?

e.g. : Mousses EVA - BL3D

An off topic question, please : what Minidsp do you use in each of you TPA Ampbox by side (Left & Right) : analog or digital ? with which dacs ? (I come from passive world and don't know too much about that but the streamer and I2S DAC!

What is needed ¨for active 3 ways ? 2 minidsp box to be close from each speaker; 2x3TPA amps (are they digital or analog input?); 6 mini dac à la ES9023 à la MiniDSP

Sorry for this last, but input made by X few posts before made me curious !

Something cheaper maybe than TPA Neurochrone from North Europe ? Here on DIYA ?

I have also few drivers from Focal, Audax and rare from Siare to play with, I bet also the 10F or a PRV Audio could interest me for a little speaker à la Eva (cheap enough for my money, fast to make).

Btw I would like to play with RePhase from pos, could it be done with the streamer or dod I also need a MiniShark ?

I googled a littlle more about EVA foam, and i finally find a few sources in France.

What is the density kG/meter cube advised ? I found from 150 kG/1 meter cube to 375 kG/1 meter cube ?

e.g. : Mousses EVA - BL3D

An off topic question, please : what Minidsp do you use in each of you TPA Ampbox by side (Left & Right) : analog or digital ? with which dacs ? (I come from passive world and don't know too much about that but the streamer and I2S DAC!

What is needed ¨for active 3 ways ? 2 minidsp box to be close from each speaker; 2x3TPA amps (are they digital or analog input?); 6 mini dac à la ES9023 à la MiniDSP

Sorry for this last, but input made by X few posts before made me curious !

Something cheaper maybe than TPA Neurochrone from North Europe ? Here on DIYA ?

I have also few drivers from Focal, Audax and rare from Siare to play with, I bet also the 10F or a PRV Audio could interest me for a little speaker à la Eva (cheap enough for my money, fast to make).

Btw I would like to play with RePhase from pos, could it be done with the streamer or dod I also need a MiniShark ?

Last edited:

Thanks sharing detailed survey Barleywater.

Really have to adapt to reading plots that go so detailed with 12-14dB vertical scales.

To better understand the two baffle setups is there any chance you would share two pictures.

Think some data can be related to manufacture datasheets if one zoom in, below is 10F/8424 datasheet and my diy DATS plots and think 1,74kHz pattern is some reflected in both.

Below is also datasheet 10F/8414 and hardware picture because it seems have the ventilation behind spider.

Seing the rear of the 10F, It should be fantastic to putt it on a thin 5 mm honeycomb panel à la Dragonfly to allow the rear to have even more air than a "chamfreined" circular hole ! Then putt this 6"x6" square honeycomb thin bafle on a 10 mm thick EVA front bafle ! Ok, less easy and less fun than 100% EVA (and also more expensive... maybe for no hearable improvement ! ...)

@ Jeshi : how do you calculate the liter volume with a trapezoidal enclosure please ? did you find an online calculator or Something like that ?

Eldam

We both use basic 2x4 analog input miniDSP and dual TPA3116D2 amps (analog input) per miniDSP. So for 3 way stereo you need qnty 2 miniDSP 2x4 and 3 stereo amps as you suggest. This is the least expensive route. MiniDSP allows use of custom or boutique I2S DAC and ADC if you want. There is I2S bus on board. There is also all digital miniDSP 8 channel called nanoDIGI and you supply all your own SPDIF ADC's and have I2S or SPDIF inputs. That costs a lot more. At this time I am quite happy with the sound quality of stock ADC and DAC built in the $80 2x4 miniDSP. The 8 ch miniDSP have a more powerful processor and allow longer digital delays.

Cost will be about $150 for a 4 ch miniDSP with amps.

We both use basic 2x4 analog input miniDSP and dual TPA3116D2 amps (analog input) per miniDSP. So for 3 way stereo you need qnty 2 miniDSP 2x4 and 3 stereo amps as you suggest. This is the least expensive route. MiniDSP allows use of custom or boutique I2S DAC and ADC if you want. There is I2S bus on board. There is also all digital miniDSP 8 channel called nanoDIGI and you supply all your own SPDIF ADC's and have I2S or SPDIF inputs. That costs a lot more. At this time I am quite happy with the sound quality of stock ADC and DAC built in the $80 2x4 miniDSP. The 8 ch miniDSP have a more powerful processor and allow longer digital delays.

Cost will be about $150 for a 4 ch miniDSP with amps.

Thanks X,

Yes I need Something cheap to play a little and mainly to learn.

I plan more a High Efficienty system with a 12" in the low (below 800/1000 hZ) and above ????????????? (many paths to be choosed the day I jump in it)

As I can't decide myself between OB and sealed (also because wood work is difficult like Jeshi inputed with this thread and yours about foam enclosure), I'm back in the race ! Have to say those little 4" with their low cost push to try it (Hey Godzi. thread !) on rapid and easy Foam design !

Many thing to listen to from previous posts (your clips and BarelyW also !)

Yes I need Something cheap to play a little and mainly to learn.

I plan more a High Efficienty system with a 12" in the low (below 800/1000 hZ) and above ????????????? (many paths to be choosed the day I jump in it)

As I can't decide myself between OB and sealed (also because wood work is difficult like Jeshi inputed with this thread and yours about foam enclosure), I'm back in the race ! Have to say those little 4" with their low cost push to try it (Hey Godzi. thread !) on rapid and easy Foam design !

Many thing to listen to from previous posts (your clips and BarelyW also !)

Hi Jeshi,

I googled a littlle more about EVA foam, and i finally find a few sources in France.

What is the density kG/meter cube advised ? I found from 150 kG/1 meter cube to 375 kG/1 meter cube ?

e.g. : Mousses EVA - BL3D

An off topic question, please : what Minidsp do you use in each of you TPA Ampbox by side (Left & Right) : analog or digital ? with which dacs ? (I come from passive world and don't know too much about that but the streamer and I2S DAC!

What is needed ¨for active 3 ways ? 2 minidsp box to be close from each speaker; 2x3TPA amps (are they digital or analog input?); 6 mini dac à la ES9023 à la MiniDSP

Sorry for this last, but input made by X few posts before made me curious !

Something cheaper maybe than TPA Neurochrone from North Europe ? Here on DIYA ?

I have also few drivers from Focal, Audax and rare from Siare to play with, I bet also the 10F or a PRV Audio could interest me for a little speaker à la Eva (cheap enough for my money, fast to make).

Btw I would like to play with RePhase from pos, could it be done with the streamer or dod I also need a MiniShark ?

Eldam, that is great that you found professional EVA for a reasonable price in france, especially with published and controlled densities! I just have to work with the density the manufactures decide.

I just measured my koyo-softboard EVA and it is 257 grams for a 330mm x 200mm x 40mm block. If my math is right I think that comes out to 97KG /cubic meter which is less dense than the types you found.

I checked my EVA yoga block and it appears to be even less dense at around 35kg/m3. When I did transmission tests, this EVA yoga block was more transparent even though it was 5cm thick. I have not tried to build anything with this yoga-block EVA, just did some test measurements. I think right now that denser is definitely better (probably up to a point) and I really want to try some denser EVA than the koyo-softboard.

I think the 150KG/m3 should work fine and maybe better than my EVA. But if you are open to experimenting and sharing, I would be curious how the 280KG/m3 EVA would perform. That stuff looks very cool. MDF wood is around the 500-1000KG/m3 density so the 375KG/m3 is almost up to MDF.

I found an even softer EVA on your web link Mousse EVA Densité :110 kg/m3 Dureté : 25A Couleur : chair Format : 115 x 115 cm

I would double check with them on the thickness of these sheets.

In regards to DSP and amps:

I only have experience with the 2-in 4-out raw miniDSP board.

miniDSP Kits : MiniDSP 2x4 kit

This board has the AD/DA built in so you can just run analog in and out from the board. No need to worry about I2S or other digital connections, but I think they do provide them on one of the pin-outs if you really want to explore it. I just use a pair of YBDZ TPA3116 boards, a Meanwell NES-150-24 and one miniDSP 2x4 and wire it up in analog. Works fine for a stereo pair of 2ways. I just have the one box with 8 binding posts and run "bi-wire" cables. Works like a central control/amp box.

For 3way or 4way speakers, I know several people use a pair of the miniDPS 2x4 with 4 TPA amps (8 total output channels). I think most people centralize the DPS/Amps and then run several pairs of speaker cables. It is easier than trying to make an "active speaker" with the amps and dsp inside the box and run RCA input.

Attachments

Jeshi : how do you calculate the liter volume with a trapezoidal enclosure please ? did you find an online calculator or Something like that ?

I actually measured it with water. The EVA boxes are completely water tight so I just weighed the empty box, filled it with water and measured the weight again. 1gm of water = 1cubic-cm. 1000 cubic-cm = 1L.

When I designed it, I just kind of estimated the volume based on a pyramid. My shape is really a truncated pyramid, so I can estimate the height if it came to a point and then subtract that upper pyramid.

Volume of a pyramid

But really I just guessed and then measured the volume after it was built.

Two new drivers arrived today. TG9FD-10-08 and a small neo tweeter (vifa DQ25SC16-04). This is the tweeter that Zaph really likes and uses in his ZA5 speaker. Wanted to get a small tweeter to try with my Satori to get even closer center-to-center distance. And to give me something to compare to the RS28f tweeter.

Just did some raw driver listening and both sound nice. The TG9 actually sounds really good as a raw driver (no baffle, no box, dipole). I can see why barleywater likes the TC9/TG9 in open baffles. Might do a quick open-baffle with the TG9 and DQ25 in mini 2way.

Some photos, and yes I am pondering a 3way ATC SCM25a / KH310 style speaker with the satori

Just did some raw driver listening and both sound nice. The TG9 actually sounds really good as a raw driver (no baffle, no box, dipole). I can see why barleywater likes the TC9/TG9 in open baffles. Might do a quick open-baffle with the TG9 and DQ25 in mini 2way.

Some photos, and yes I am pondering a 3way ATC SCM25a / KH310 style speaker with the satori

Attachments

Last edited:

Thanks Jeshi for all the inputs,

I saw the volumic mass of lead which have also a good internal damping is 11350 kG/m3

Stiffness measured with Young module : E MPa

- lead : 17 000

- Mdf : 8 000 (so worst)

- birch ply : 15 000 (near from lead )

)

- Silicone rubber/caoutchouc: 100

- Elastomer : 500 to 1000

Internal loss : (vibration damping)

- lead : 0.1 (good)

- Mdf : 0.05 (worst)

- birch ply : 0.1 (same as lead but as density is lower than lead, birch ply is good if you don't need thin bafle !)

- Paris plaster : 0.005 (bad ! I'm surprised here but I bet with fiber in it it can be improved !

- Silicone rubber/caoutchouc : 0.4 ( a dream)

- Elastomer : 0.4 (bigger dream)

- Cork (dense panel) : 0.2 (good but less than the two above !)

Speed of Sound (Km/s) through the material (greater loss if the material is not homogenous like : honeycomb or multiply wood, sandwich, mixed material...)

- lead : 2.6 km/s

- Mdf : 1.8 (better)

- birch ply : 2.2 (near lead but better, certainly due to the glue and multiple difraction of the sound; Mdf seems better but internal loss measurement proves it's not, so speed of air is not a sufisant proof for internal loss : how is made the material stays important : the more internal diffraction due to the structure the better : again honeycomb, obstacles which change the directivity into the material, sandwich : different density : mass-spring effect))

- Silicone rubber/caoutchouc : 0.04 ( a dream, like a snail in marmelade : very slow !)

- Elastomer : 0.15 (much much better than classic material but no better than caoutchouc/rubber

- - Cork (dense panel): 0.35

We can see but for make it easy than multiple sandwich materials is a good thing for a bafle ! natural caoutchouc rubber should be sourced : but we can bet high density foam/Eva can be near (rubber is heavy !)

We can also bet than if too dense, we can loose the internal damping, so a trade off must be found (density of the EVA)

We can also see than woven materials are good : kevlar, aramid, carbon, due to their stifness and high internal diffraction (and as it's light we see it for cones !)

Speed of air through the material is certainly a good indication for the lowest frequencies as the density (both to make obstacle to the high sound pressure and avoid the bafle to have vibration and have a once more driver ) is good with high spl and energy pressure (mortars walls : dense ; lead is certainly good if proof into a cabinet : box in box !)

) is good with high spl and energy pressure (mortars walls : dense ; lead is certainly good if proof into a cabinet : box in box !)

Just 2 cents from a rapid reading without any scientific knowledge and to give some numbers !

I saw the volumic mass of lead which have also a good internal damping is 11350 kG/m3

Stiffness measured with Young module : E MPa

- lead : 17 000

- Mdf : 8 000 (so worst)

- birch ply : 15 000 (near from lead

- Silicone rubber/caoutchouc: 100

- Elastomer : 500 to 1000

Internal loss : (vibration damping)

- lead : 0.1 (good)

- Mdf : 0.05 (worst)

- birch ply : 0.1 (same as lead but as density is lower than lead, birch ply is good if you don't need thin bafle !)

- Paris plaster : 0.005 (bad ! I'm surprised here but I bet with fiber in it it can be improved !

- Silicone rubber/caoutchouc : 0.4 ( a dream)

- Elastomer : 0.4 (bigger dream)

- Cork (dense panel) : 0.2 (good but less than the two above !)

Speed of Sound (Km/s) through the material (greater loss if the material is not homogenous like : honeycomb or multiply wood, sandwich, mixed material...)

- lead : 2.6 km/s

- Mdf : 1.8 (better)

- birch ply : 2.2 (near lead but better, certainly due to the glue and multiple difraction of the sound; Mdf seems better but internal loss measurement proves it's not, so speed of air is not a sufisant proof for internal loss : how is made the material stays important : the more internal diffraction due to the structure the better : again honeycomb, obstacles which change the directivity into the material, sandwich : different density : mass-spring effect))

- Silicone rubber/caoutchouc : 0.04 ( a dream, like a snail in marmelade : very slow !)

- Elastomer : 0.15 (much much better than classic material but no better than caoutchouc/rubber

- - Cork (dense panel): 0.35

We can see but for make it easy than multiple sandwich materials is a good thing for a bafle ! natural caoutchouc rubber should be sourced : but we can bet high density foam/Eva can be near (rubber is heavy !)

We can also bet than if too dense, we can loose the internal damping, so a trade off must be found (density of the EVA)

We can also see than woven materials are good : kevlar, aramid, carbon, due to their stifness and high internal diffraction (and as it's light we see it for cones !)

Speed of air through the material is certainly a good indication for the lowest frequencies as the density (both to make obstacle to the high sound pressure and avoid the bafle to have vibration and have a once more driver

Just 2 cents from a rapid reading without any scientific knowledge and to give some numbers !

Last edited:

Usefull picture from the box amps ! Hey you're Lucky : you can buy with a cheap price the excellent Oyaide interconnect at Yodobashi Camera ! ( I use the across 750 iirc ) !

PS : http://www.ikea.com/fr/fr/catalog/products/30081467/ : here for europeans : cheap & 4 size to mold a 2Pi sphere (make two glue it and you have your 0.5 dB nearly flat difraction !

As I saw EVA is very used for role game armor, I fail on some book about how to mold for mask, shape, restauration of antics, etc ! A wilde domain than cabinet construction !

Make it cheap and good is the funny way of all of this !

PS : http://www.ikea.com/fr/fr/catalog/products/30081467/ : here for europeans : cheap & 4 size to mold a 2Pi sphere (make two glue it and you have your 0.5 dB nearly flat difraction !

As I saw EVA is very used for role game armor, I fail on some book about how to mold for mask, shape, restauration of antics, etc ! A wilde domain than cabinet construction !

Make it cheap and good is the funny way of all of this !

Last edited:

Stiffness measured with Young module : E MPa

- lead : 17 000

- Mdf : 8 000 (so worst)

- birch ply : 15 000 (near from lead)

- Silicone rubber/caoutchouc: 100

- Elastomer : 500 to 1000

Internal loss : (vibration damping)

- lead : 0.1 (good)

- Mdf : 0.05 (worst)

- birch ply : 0.1 (same as lead but as density is lower than lead, birch ply is good if you don't need thin bafle !)

- Paris plaster : 0.005 (bad ! I'm surprised here but I bet with fiber in it it can be improved !

- Silicone rubber/caoutchouc : 0.4 ( a dream)

- Elastomer : 0.4 (bigger dream)

- Cork (dense panel) : 0.2 (good but less than the two above !)

Speed of Sound (Km/s) through the material (greater loss if the material is not homogenous like : honeycomb or multiply wood, sandwich, mixed material...)

- lead : 2.6 km/s

- Mdf : 1.8 (better)

- birch ply : 2.2 (near lead but better, certainly due to the glue and multiple difraction of the sound; Mdf seems better but internal loss measurement proves it's not, so speed of air is not a sufisant proof for internal loss : how is made the material stays important : the more internal diffraction due to the structure the better : again honeycomb, obstacles which change the directivity into the material, sandwich : different density : mass-spring effect))

- Silicone rubber/caoutchouc : 0.04 ( a dream, like a snail in marmelade : very slow !)

- Elastomer : 0.15 (much much better than classic material but no better than caoutchouc/rubber

- - Cork (dense panel): 0.35

These numbers are really helpful! thanks Eldam. It also shows what every material scientist knows, there is no perfect material. Every material has strengths and weaknesses and needs to be matched to the application.

Was reading up on elastomer https://en.wikipedia.org/wiki/Elastomer and EVA is classified as an elastomer! But elastomer is a broad range of materials. Hot glue sticks are actually EVA but in its non-foam form.

This has got me thinking about trying an EVA-elastomer-EVA sandwich. Maybe a 1mm rubber sheet, or using silicon rubber caulking as glue. Next time I am at TokyuHands I will have a look at some of their rubber sheets and rolls.

Also neoprene is an elastomer. http://www.dupont.com/products-and-services/plastics-polymers-resins/elastomers.html

Last edited:

Yes, we have to mix to have the best of all the three parameters : stiffness, weight, surface damping, internal loss (internal damping which has also to see with the weight according the frequency to tame) !

I believe the foam/EVA is just fantastic : simple and better than wood for mids and above : allow people like me to want to jump more in the box construction !

!

I also look for rubber sheet or liquid one : the liquid one are all made with mix of bitume and you can't find dats about what it allows : more made for proofing from water ! Rubber sheet for cars (1 mm to 4 mm) seem good !

But I think all those are the icing on the cake ! Foam/EVA is enough ! We just need to play more with it to try to find the best density trade offs ! Also with a second material to make it even better is certainly more than enough !

!

Good job and sharing you made Jeshi ! Thanks for all of that (also with X ) .

Did you see what Avant Guard made with its little white speaker : I listened to it : sound is bad (mainly in the bass and mid bass and it's a directive speaker in the shop I listened to it !) : a sort of white hard rubber enclosure with wave guides in a all in one white enclosure : look is fantastic ! when you touch it it seems like hard rubber which flex a little when you put a finger on it !

! when you touch it it seems like hard rubber which flex a little when you put a finger on it !

I believe the foam/EVA is just fantastic : simple and better than wood for mids and above : allow people like me to want to jump more in the box construction

I also look for rubber sheet or liquid one : the liquid one are all made with mix of bitume and you can't find dats about what it allows : more made for proofing from water ! Rubber sheet for cars (1 mm to 4 mm) seem good !

But I think all those are the icing on the cake ! Foam/EVA is enough ! We just need to play more with it to try to find the best density trade offs ! Also with a second material to make it even better is certainly more than enough

Good job and sharing you made Jeshi ! Thanks for all of that (also with X ) .

Did you see what Avant Guard made with its little white speaker : I listened to it : sound is bad (mainly in the bass and mid bass and it's a directive speaker in the shop I listened to it !) : a sort of white hard rubber enclosure with wave guides in a all in one white enclosure : look is fantastic

Last edited:

I believe the foam/EVA is just fantastic : simple and better than wood for mids and above : allow people like me to want to jump more in the box construction!

But I think all those are the icing on the cake ! Foam/EVA is enough ! We just need to play more with it to try to find the best density trade offs ! Also with a second material to make it even better is certainly more than enough!

Good job and sharing you made Jeshi ! Thanks for all of that (also with X ) .

Thanks Eldam, but we really have to give XRK the credit here. XRK started the foam-core idea several years ago, built dozens of speakers, then started working with XPS foam and built more speakers and got several people on board with the foam idea and keeps building speakers

I just started exploring EVA foam as a material which might actually be a better material for speaker enclosures than wood and trying to study/test how to prove this hypothesis through building speakers with EVA and trying to come up with test methods.

That is really cool that Avant Guard is using a hard rubber material in some of their speakers. Hopefully other speaker makers will also start to explore alternative materials since I think there is still a lot of room for exploration here.

this one : ZERO 1 by Avantgarde Acoustic

I just don't understand it had so much good review ! Just the look is good !

!

I just don't understand it had so much good review ! Just the look is good

this one : ZERO 1 by Avantgarde Acoustic

I just don't understand it had so much good review ! Just the look is good!

That's a nice looking design to be sure. A point source synergy style horn will sound better though. Won't be as shallow though but being shallow only gives so much horn loading and directivity is not constant.

what adhesive are y'all using? i was searching for an alternate material so i could start a project w/out extensive woodworking knowledge and tools, and this seems like a perfect fit. the internet tells me 3M Fastack 77 -or- hot glue work the best...which is it?

For foam core I use hot melt. I also use white PVA and recently low VOC Liquid Nails for large jobs or areas. Hot melt is great for tacking and serving as a clamp for slower drying glues.

Fastack 77 is good for bonding large sheets together like facing foam with thin plywood.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- EVA foam for performance speaker enclosures