Thanks,Sheldon !!

I was thinking of using Kynar because of the extremely high voltages >10kv.

I would be using a rather large toroid core so there wont be much problems using a wire with a thicker insulation.

It is some thing that I may do later this year as it has been in the planning stage for quite a while.

But not to be off subject of the ESL Bass system, I still require a better transformer for my smaller ESL's as well.

I have pushed the bias as far as 10kv and stator voltages past 25kv P-P so far.

As these are the types of voltages that will be required for a large area and D/S bass panel as well.

So for me it is a project of research and also in the making.

We can discuss the trials and tribulations of its feasiblity all day long ,But we will never actually know how well such a system will work until it is tried.

A few have built such large systems through the years and have boasted about there incredible results as they were exactly that,very large systems!

It seems to me that it is possible to create such a system but it is limited to how far one chooses to go with it.

The biggest complaint I have read about ESL's is the bass efficiency and quality.

And the main problem is not the panels them selves, but how and with what they are driven with.

It is very much a project in the working,

As it is not quite yet a reality.

jer

I was thinking of using Kynar because of the extremely high voltages >10kv.

I would be using a rather large toroid core so there wont be much problems using a wire with a thicker insulation.

It is some thing that I may do later this year as it has been in the planning stage for quite a while.

But not to be off subject of the ESL Bass system, I still require a better transformer for my smaller ESL's as well.

I have pushed the bias as far as 10kv and stator voltages past 25kv P-P so far.

As these are the types of voltages that will be required for a large area and D/S bass panel as well.

So for me it is a project of research and also in the making.

We can discuss the trials and tribulations of its feasiblity all day long ,But we will never actually know how well such a system will work until it is tried.

A few have built such large systems through the years and have boasted about there incredible results as they were exactly that,very large systems!

It seems to me that it is possible to create such a system but it is limited to how far one chooses to go with it.

The biggest complaint I have read about ESL's is the bass efficiency and quality.

And the main problem is not the panels them selves, but how and with what they are driven with.

It is very much a project in the working,

As it is not quite yet a reality.

jer

It's generally not the wire types which are pretty much the same except some weird stuff like one for water well pump motors...

BTW if you are so concerned about the VOLTAGE look for such a wire, may be somebody has an overstock but it is not thin by any means

So it's how you wind it for a particular purpose. And, usually layer to layer voltage does not exceed single wire permissible voltage... and if not, you use interlayer isolation. NO probem here

Once again, those few sentences:

use best available core material in terms of hysteresis curve so you can increase core cross section till the magnetizing current value is OK with you.

Lower turn count along with proper winding scheme yeild results you can not achieve with generic electric steel.

Sorry but nothing comes free - $50/lb of good core is for the lowest priced material, but who cares - it's high end is not it?

BTW if you are so concerned about the VOLTAGE look for such a wire, may be somebody has an overstock but it is not thin by any means

So it's how you wind it for a particular purpose. And, usually layer to layer voltage does not exceed single wire permissible voltage... and if not, you use interlayer isolation. NO probem here

Once again, those few sentences:

use best available core material in terms of hysteresis curve so you can increase core cross section till the magnetizing current value is OK with you.

Lower turn count along with proper winding scheme yeild results you can not achieve with generic electric steel.

Sorry but nothing comes free - $50/lb of good core is for the lowest priced material, but who cares - it's high end is not it?

I see that evreyone has lost interest. I, however have not, and continue with my future build.

I have decided to build wire stator panels to replace my current perforated panels. The perfs will be converted to ESL woofers as part of this build.

I have been perusing a number of the Dutch and German ESL sites and have learned of a program called esl_seg_uithat assists in designing wire stator panels. Does anyone know of an English download for this program?

Meanwhile, I still want to build the ESL woofer.

Defining woofer, an ESL panel that will operate from about 130-200 Hz to 50 Hz, then crossed into a dynamic SUB, whose sole function is to pick up that last octave. I never expected to build an ESL SUBwoofer.

So, if you're still intersted, I'd like to hear your input.

J-

I have decided to build wire stator panels to replace my current perforated panels. The perfs will be converted to ESL woofers as part of this build.

I have been perusing a number of the Dutch and German ESL sites and have learned of a program called esl_seg_uithat assists in designing wire stator panels. Does anyone know of an English download for this program?

Meanwhile, I still want to build the ESL woofer.

Defining woofer, an ESL panel that will operate from about 130-200 Hz to 50 Hz, then crossed into a dynamic SUB, whose sole function is to pick up that last octave. I never expected to build an ESL SUBwoofer.

So, if you're still intersted, I'd like to hear your input.

J-

Nope,I haven't lost interest !!!

I have been working on getting my little panels running again.

In doing so I have temporarily fixed a transformer issue that I have been having.

Until, I get the materials,Like two large cores and some wire to do a ground up build and some rewinds and such.

Doing this was essential to get some SPL and frequency measurements of the panels as per driving voltages.

Those I got.

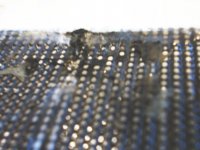

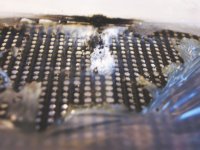

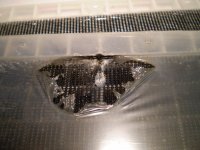

But the panel being tested had a bad spot that needed to be tended to.

On my last test for the day to see how high it would go, it gave out, and I burned it badly shorting the panel.

I think I can repair it to work again and I still have the other one as well.

But it needs to be worked on a little more too, So that it doesn't end up like its brother.

But,In the time I will spend repairing it I can build a new panel designed to take the next step of increased voltages much faster and easier.

I know that these panels can take it but it is pushing there limit of design.

This is not the same panel that failed before but is of the same pair.

It is a bummer as this was in its original form since I made it in 2003 except for some added coats of clear acrylic.

The other one was the one I had used to push to the limits to the point of clipping the diagphram to the stators.

So,after I had gotten all of my baseline measurements I wanted to fix the bad spot and continue on to the extreme limits but the bad spot gave out and I was not quick enough to turn down the power.

The wire mesh worked great for what I had designed them to do.

But the sharp edges of the cut wire and the uneven coating thickness of the very thin powder coated wires have issues that need to be worked out.

Such as corrosion of the aluminium underneath the coating and flexing causing micro cracks that had formed through the years.

I would say that have served me well and can still be used but it is time for a new build anyhow.

They worked perfectly when I first made them they way the were.

I will use this method of construction again sometime soon.

I had just acquired some 10" X 49" perforated metal panels that I may or may not cut in half to do a pair of small bass panels to experiment with before going on to a larger system.

I also have a different type drive method for a Direct-Drive in mind as well than using transformers.

I will embellish those ideas when I get a working model running,So it will be a long process and awhile until I get to that point.

On my next build I will be using my TIG wire method for a little panel slightly larger than the ones that I have been working with, So that I can see how well stator segmentation works.

Now that I have a clear impression of what my little panels sound like and there characteristics with measurements to boot.

Not to mention that I still have one good working identical panel to compare to when needed.

I already have 6 peices of 10" X 36" TIG wire stators made as well that need to be finnished,I just need to make 2 more, or maybe another 10 for a nice sized bass system for 20" X 72" per side.

I was using a 5.5Kv bias and a 1:256 step up ratio.

This panel had withheld up to a maximum 10.5Kv of bias without arcing.

But my supply produces 13.8Kv and so there was a sign of leakage somewhere and now I know where. he,he

I had ran as much as 50V to 60V peak into these before and I was no where's that when it failed!

It just goes to show you that all it takes is one bad weak spot to completely ruin an otherwise perfectly good panel.

Here are some pictures of my now ailing panel.

Gotta Love R&D !!!!

jer

I have been working on getting my little panels running again.

In doing so I have temporarily fixed a transformer issue that I have been having.

Until, I get the materials,Like two large cores and some wire to do a ground up build and some rewinds and such.

Doing this was essential to get some SPL and frequency measurements of the panels as per driving voltages.

Those I got.

But the panel being tested had a bad spot that needed to be tended to.

On my last test for the day to see how high it would go, it gave out, and I burned it badly shorting the panel.

I think I can repair it to work again and I still have the other one as well.

But it needs to be worked on a little more too, So that it doesn't end up like its brother.

But,In the time I will spend repairing it I can build a new panel designed to take the next step of increased voltages much faster and easier.

I know that these panels can take it but it is pushing there limit of design.

This is not the same panel that failed before but is of the same pair.

It is a bummer as this was in its original form since I made it in 2003 except for some added coats of clear acrylic.

The other one was the one I had used to push to the limits to the point of clipping the diagphram to the stators.

So,after I had gotten all of my baseline measurements I wanted to fix the bad spot and continue on to the extreme limits but the bad spot gave out and I was not quick enough to turn down the power.

The wire mesh worked great for what I had designed them to do.

But the sharp edges of the cut wire and the uneven coating thickness of the very thin powder coated wires have issues that need to be worked out.

Such as corrosion of the aluminium underneath the coating and flexing causing micro cracks that had formed through the years.

I would say that have served me well and can still be used but it is time for a new build anyhow.

They worked perfectly when I first made them they way the were.

I will use this method of construction again sometime soon.

I had just acquired some 10" X 49" perforated metal panels that I may or may not cut in half to do a pair of small bass panels to experiment with before going on to a larger system.

I also have a different type drive method for a Direct-Drive in mind as well than using transformers.

I will embellish those ideas when I get a working model running,So it will be a long process and awhile until I get to that point.

On my next build I will be using my TIG wire method for a little panel slightly larger than the ones that I have been working with, So that I can see how well stator segmentation works.

Now that I have a clear impression of what my little panels sound like and there characteristics with measurements to boot.

Not to mention that I still have one good working identical panel to compare to when needed.

I already have 6 peices of 10" X 36" TIG wire stators made as well that need to be finnished,I just need to make 2 more, or maybe another 10 for a nice sized bass system for 20" X 72" per side.

I was using a 5.5Kv bias and a 1:256 step up ratio.

This panel had withheld up to a maximum 10.5Kv of bias without arcing.

But my supply produces 13.8Kv and so there was a sign of leakage somewhere and now I know where. he,he

I had ran as much as 50V to 60V peak into these before and I was no where's that when it failed!

It just goes to show you that all it takes is one bad weak spot to completely ruin an otherwise perfectly good panel.

Here are some pictures of my now ailing panel.

Gotta Love R&D !!!!

jer

Attachments

Hi,

Any stretched membrane without serious dampening methods (like distributed dampening with a mat of damping material) would exhibit a high-Q resonance, which basically every ESL-panel shows (+10...+15dB). Where´s the resonance peak in their measurements? After their own explanation the panel should show an even increased resonance peak. Similar to the functioning of a closed box a ´air-cushion´ would increase the Q considerably.

jauu

Calvin

Speaking of the Sound Lab Panels he uses a distribute resonance described here

Sound Lab Technology: Distributed Resonance - a patented advancement in electrostatic performance

They will still make the subs on request.

Some more basic technical descriptions for those interested.

Sound Lab Technology: Advanced electrostatic technologies in our speakers

The owner R West worked on the KLH 9's and designed the Jantzen ES panel used on the Wilson WAMM speaker.

Hi,

and what does this tell us??

The high-Q resonance is now spread over a couple of panels and a wider frequency range, but each single panel still performs with a high-Q resonance and long decay. Paralleling a couple of panels with different resonances virtually smoothes the overall resonance peak, but spreads the long decay over an increased frequency range. Added, there´s now one single panel, which is the weakest link in the chain. This weak link defines the dynamic range and performance of the complete system. Since it needs considerably reduced diaphragm tension and/or greatly increased free vibrating areas of the diaphragm, the dynamic range of this panel will be small. Drive and bias voltages need to be of high values...as such all disadvantages of high voltages apply. To counter for the deficiencies in dynamic range the panel size needs to be really huge. Compared to this a dynamic dipole woofer builds more compact, is easier to build, requires less driving power and performs way better.

jauu

Calvin

and what does this tell us??

The high-Q resonance is now spread over a couple of panels and a wider frequency range, but each single panel still performs with a high-Q resonance and long decay. Paralleling a couple of panels with different resonances virtually smoothes the overall resonance peak, but spreads the long decay over an increased frequency range. Added, there´s now one single panel, which is the weakest link in the chain. This weak link defines the dynamic range and performance of the complete system. Since it needs considerably reduced diaphragm tension and/or greatly increased free vibrating areas of the diaphragm, the dynamic range of this panel will be small. Drive and bias voltages need to be of high values...as such all disadvantages of high voltages apply. To counter for the deficiencies in dynamic range the panel size needs to be really huge. Compared to this a dynamic dipole woofer builds more compact, is easier to build, requires less driving power and performs way better.

jauu

Calvin

Hi,

and what does this tell us??

The high-Q resonance is now spread over a couple of panels and a wider frequency range, but each single panel still performs with a high-Q resonance and long decay. Paralleling a couple of panels with different resonances virtually smoothes the overall resonance peak, but spreads the long decay over an increased frequency range. Added, there´s now one single panel, which is the weakest link in the chain. This weak link defines the dynamic range and performance of the complete system. Since it needs considerably reduced diaphragm tension and/or greatly increased free vibrating areas of the diaphragm, the dynamic range of this panel will be small. Drive and bias voltages need to be of high values...as such all disadvantages of high voltages apply. To counter for the deficiencies in dynamic range the panel size needs to be really huge. Compared to this a dynamic dipole woofer builds more compact, is easier to build, requires less driving power and performs way better.

jauu

Calvin

Not suited for DIY compared to conventional subwoofers, the technology and voltages involved are definitely not DIY friendly.

As to conventional SW performing "way batter" you have no basis for that assertions since you clearly have never heard the B1 of B2 panels.... I have and they are excellent, better than conventional systems I have heard.

Originally Posted by kevinh

“The owner R West worked on the KLH 9's and designed the Jantzen ES panel used on the Wilson WAMM speaker.”

Sorry that is not correct; it was Arthur Janszen who designed and was granted U.S. Patent 2631196 back in 1953 and founded Janszen Laboratory in 1954; for trademark purposes the letter Z was always capitalized to distinguish between the esl tweeter the JansZen and the name Janszen. He licensed the design to the Neshaminy Electronic Corp. in 1959, which manufactured the tweeter up until the mid 70s. Arthur Janszen became a vice president of KLH; which was of course, Henry Kloss, Malcolm S. Low, and J. Anton Hoffman. It was Arthur Janszen who was involved with the design of the famous KLH 9 electrostatic loudspeaker. After the 9s came his Acoustech X speaker the”x” standing for 10 of course. In the mid 1970s Mr. Janszen developed a hybrid esl speker for Electrostatic Research Corporation; unfortunately that venture was not successful. Mr. Janszen eventually left the audio industry to pursue other interests.

When Neshaminy Electronic Corp., ceased manufacturing in 1975 the corporation's assets were acquired by Electronics Industries and it is here where Dr. Roger West enters the picture as Dr. West was employed by EI to design a replacement tweeter to the original Janszen esl panel. However, Dr. West left Electronics Industries and in 1978 founded his own company SoundLab, so his involvement was less than assumed. Furthermore, he never collaborated with Arthur Janszen on esl panel redesign.

What confuses many is that Dr. West used an esl panel with the visual appearance of a JansZen type tweeter for his SoundLAB Marquee center channel speaker but that panel is not a Janszen or RtR but is Dr. West's own design. Furthermore, Dr. West's SoundLAB Marquee speaker came out far after the Wilson Audio WAMM had come and gone. The SoundLAB Marquee after all is a center channel speaker introduced during the 5.1 home theater and surround sound era of the home audio market.

By 1980, the tooling and rights to the JansZen tweeter design were acquired by Don Kliewer of Winslow Industries. It was Mr. Kliewer's Winslow Industries that supplied as an OEM all the tweeter panels for Wilson Audio's use in the WAMM aka Wilson Audio Modular Monitor, during its production in the 1980s. When Mr. Kliewer passed away the tooling for the tweeters languished for a few years. A fact which certainly contributed to the discontinuation of the Wamm design. The loss of a source for the esl tweeters and the difficulty Wilson Audio had in stocking replacement KEF B139 mid-woofers certainly mandated the decision to retire the design. Wilson Audio needed to maintain their existing stock of drivers for the service and repair of Wamm systems already out in the field.

By the way, Mr. Kliewer had also acquired the tooling for the RtR tweeters, which was JansZen's main competitor back in the 1970s and thus confusing the issue as to which tweeter one is referring to, a JansZen or RtR or possibly best just to call them a Kliewer tweeter at that point in their history. Visually the JansZen tweeters were either black or grey pvc stator frames, later production light grey, early units were black. This is in contrast to the RtR stators which were often blue or green pvc; you will see the green type in the Crown ES series, a 1970s hybrid speaker. The RtR tweeter arrays were also used in the famous Fulton J Modular speaker which may have helped to inspire the Wilson WAMM system. It was the RtR tweeter that was used in the early Infinity Servo Static esl speakers. The midrange was Infinity's own design and was the source of much failure in the Servo Static 1 and 1A models.

To confuse the issue more by the late 1980s Mr. Kliewer interchanged the pvc he used, probably due to what raw pvc he could obtain, the economics of small volume production at play here, as a result some of his tweeters do not follow that color identifier. When Mr. Kliewer passed away there were only around 150 pairs of tweeters left as unsold stock which the estate liquidated. I assume most of these were acquired by Wilson Audio for repair parts but maybe not, who knows.

Arthur Janszen's son David who resurrected the JansZen company name in 2005 was able, I believe, to reacquire the original tooling sometime around 2006 but Mr. Janszen could clarify that matter. Also, as David Janszen will tell you the coating on the JansZen tweeter's mylar diaphragm was always more complex than simply graphite a point which has sometimes been mistakenly made.

I hope this bit of audio history was informative for some but probably very boring for most here.

Yep, those are the series 2 JansZen tweeters in addition to the gray pvc stator frame the insulated stator wire is wound around each frame and then the two are bonded together with the mylar diaphragm sandwiched between them. In the older series one JansZen panels the stator wire was cut and bonded to the inside only of each black pvc frame. This main design difference was done for the ease of manufacture. A higher speed winding machine could be used and there were less rejected parts due to misplaced or out of alignment stator wires.

In regards to the history of Wilson Audio and the WAMM, of course John Curl could supply far more information as it was he who extensively rebuilt and modified all of the Crown EQ-2 equalizers that were used as part of the WAMM system; in addition, I believe, to the active 2 way crossover that separated the signal to the subwoofer units and the mid / high frequency tower amplifiers. The system had to be bi-amped. If anyone cares; the 18” subwoofer driver was a custom OEM unit supplied by the German company Magnat probably best known for their plasma tweeters they manufactured in the 1980s.

In regards to the history of Wilson Audio and the WAMM, of course John Curl could supply far more information as it was he who extensively rebuilt and modified all of the Crown EQ-2 equalizers that were used as part of the WAMM system; in addition, I believe, to the active 2 way crossover that separated the signal to the subwoofer units and the mid / high frequency tower amplifiers. The system had to be bi-amped. If anyone cares; the 18” subwoofer driver was a custom OEM unit supplied by the German company Magnat probably best known for their plasma tweeters they manufactured in the 1980s.

Sorry that is not correct; it was Arthur Janszen who designed and was granted U.S. Patent 2631196 back in 1953 and founded Janszen Laboratory in 1954; for trademark purposes the letter Z was always capitalized to distinguish between the esl tweeter the JansZen and the name Janszen. He licensed the design to the Neshaminy Electronic Corp. in 1959, which manufactured the tweeter up until the mid 70s. Arthur Janszen became a vice president of KLH; which was of course, Henry Kloss, Malcolm S. Low, and J. Anton Hoffman. It was Arthur Janszen who was involved with the design of the famous KLH 9 electrostatic loudspeaker. After the 9s came his Acoustech X speaker the”x” standing for 10 of course. In the mid 1970s Mr. Janszen developed a hybrid esl speker for Electrostatic Research Corporation; unfortunately that venture was not successful. Mr. Janszen eventually left the audio industry to pursue other interests.

When Neshaminy Electronic Corp., ceased manufacturing in 1975 the corporation's assets were acquired by Electronics Industries and it is here where Dr. Roger West enters the picture as Dr. West was employed by EI to design a replacement tweeter to the original Janszen esl panel. However, Dr. West left Electronics Industries and in 1978 founded his own company SoundLab, so his involvement was less than assumed. Furthermore, he never collaborated with Arthur Janszen on esl panel redesign.

What confuses many is that Dr. West used an esl panel with the visual appearance of a JansZen type tweeter for his SoundLAB Marquee center channel speaker but that panel is not a Janszen or RtR but is Dr. West's own design. Furthermore, Dr. West's SoundLAB Marquee speaker came out far after the Wilson Audio WAMM had come and gone. The SoundLAB Marquee after all is a center channel speaker introduced during the 5.1 home theater and surround sound era of the home audio market.

By 1980, the tooling and rights to the JansZen tweeter design were acquired by Don Kliewer of Winslow Industries. It was Mr. Kliewer's Winslow Industries that supplied as an OEM all the tweeter panels for Wilson Audio's use in the WAMM aka Wilson Audio Modular Monitor, during its production in the 1980s. When Mr. Kliewer passed away the tooling for the tweeters languished for a few years. A fact which certainly contributed to the discontinuation of the Wamm design. The loss of a source for the esl tweeters and the difficulty Wilson Audio had in stocking replacement KEF B139 mid-woofers certainly mandated the decision to retire the design. Wilson Audio needed to maintain their existing stock of drivers for the service and repair of Wamm systems already out in the field.

By the way, Mr. Kliewer had also acquired the tooling for the RtR tweeters, which was JansZen's main competitor back in the 1970s and thus confusing the issue as to which tweeter one is referring to, a JansZen or RtR or possibly best just to call them a Kliewer tweeter at that point in their history. Visually the JansZen tweeters were either black or grey pvc stator frames, later production light grey, early units were black. This is in contrast to the RtR stators which were often blue or green pvc; you will see the green type in the Crown ES series, a 1970s hybrid speaker. The RtR tweeter arrays were also used in the famous Fulton J Modular speaker which may have helped to inspire the Wilson WAMM system. It was the RtR tweeter that was used in the early Infinity Servo Static esl speakers. The midrange was Infinity's own design and was the source of much failure in the Servo Static 1 and 1A models.

To confuse the issue more by the late 1980s Mr. Kliewer interchanged the pvc he used, probably due to what raw pvc he could obtain, the economics of small volume production at play here, as a result some of his tweeters do not follow that color identifier. When Mr. Kliewer passed away there were only around 150 pairs of tweeters left as unsold stock which the estate liquidated. I assume most of these were acquired by Wilson Audio for repair parts but maybe not, who knows.

Arthur Janszen's son David who resurrected the JansZen company name in 2005 was able, I believe, to reacquire the original tooling sometime around 2006 but Mr. Janszen could clarify that matter. Also, as David Janszen will tell you the coating on the JansZen tweeter's mylar diaphragm was always more complex than simply graphite a point which has sometimes been mistakenly made.

I hope this bit of audio history was informative for some but probably very boring for most here.

When Roger was in Salt Lake City in the late 70's I bought a pair of Z50's from him, before he built the R1's under the Sound Lab name. The way he has taken the A1 panels and refined them over a 30yr+ period is truly remarkable.

You know more of the details than I do.

straying a little

Over the past several evenings I have beem perusing the Elektrosaten ESL club website. The Dutch and Germans seem to be heavily in to ESL DIY construction.

One program listed as "esl_seg_ui" keeps getting mentioned. As I understand it, the program assists in predicting wire stator panel response under various parameters. Has anyone used this program, and can it be found in an English version?

Now, back to woofers.

Thanks to those who are contributing the history. RtR cells were also used by ESS (then Electrostatic Sound Systems) in thier "Super Quad" and "Transtatic" models. They played around with JanZens, but as I remember there were some reliability issues. When the Heil device was introduced, they changed their name to "ESS" and dropped the 'statics altogether. I also remember the Servo Statik- I had a freind who owned about half a pair of them. He owned the tweeters and the sub and Infinity owned the mid panels because that's where they spent most of their time.

Neat subwoofer, though- as close as anyone in our crowd got to hearing the Servo Statiks was that sub and Stax headphones together.

J

Over the past several evenings I have beem perusing the Elektrosaten ESL club website. The Dutch and Germans seem to be heavily in to ESL DIY construction.

One program listed as "esl_seg_ui" keeps getting mentioned. As I understand it, the program assists in predicting wire stator panel response under various parameters. Has anyone used this program, and can it be found in an English version?

Now, back to woofers.

Thanks to those who are contributing the history. RtR cells were also used by ESS (then Electrostatic Sound Systems) in thier "Super Quad" and "Transtatic" models. They played around with JanZens, but as I remember there were some reliability issues. When the Heil device was introduced, they changed their name to "ESS" and dropped the 'statics altogether. I also remember the Servo Statik- I had a freind who owned about half a pair of them. He owned the tweeters and the sub and Infinity owned the mid panels because that's where they spent most of their time.

Neat subwoofer, though- as close as anyone in our crowd got to hearing the Servo Statiks was that sub and Stax headphones together.

J

He,he,he,he, I am very glad to see that I have raised such an enthusiasm as that is my very intent indeed.

I must say that it has been along time passion to be finally seeing these projects a reality.

But, I must also give credit to those In these threads whom have help me out tremendously as well.

The list is too long to name each one individually.

Just two years ago the only thing I can say that I really new about transformers was how the transformation ratio worked and the rest was a mystery.

Knowing also, this was the key to and stopping me from finishing my system.

I had to embark on what makes them tick and this is were the DIYaudio community really kicked in to help me understand this mysterious beast.

Ever since I could hold a pencil I replaced it with a soldering iron and In the mid 70's was when High end audio started to come about.

Occasionally I would see the schematic of some high power amplifier and I would say to my self "They want $1000 for that thing!" and I would tally up the price of the components and in most cases it would have cost me much much less than $200 for one or two of them, not to mention quantity's of 10 prices.

Being transformers and heatsinks the most costly of component,just as it is today.

Although $200 was a gracious amount of money in those days and I did with what I had at the time as well keeping up with the latest technologies through the years.

It was when I saw a write up in Popular Mechanics Magazine on the Quad and Magnepan planar speakers that really got me going and again saying to my self "Is That All There is to Those Things?", that's what got my guff and my journey began.

Not to mention a really old HI-Fi book that mentioned the mysterious ESL and Plasma speaker technologies that I found in the school library and stuff on tesla coils.

At this point H.V. became my newest quest as all of these things are exactly that, H.V devices.

Back in those days we didn't have vast limitless tank of information called the internet.

It wasn't until I had found Roger Sander articles of DIY ESL's reprinted in a book called The Audio Amateur published in 1980.

Copies of his articles can be found on his website.

I Can't even start to explain the joy and nearly started sobbing when I had discovered the chapters in that book fully describing several systems.

It was the moment of a brand new meaning to the word "WoW, I can not believe what I am looking at !!".

Remember this was nearly 20 years before the existence of this very forum.

And, It took me that long, almost to the year, Of the discovery of that one book when I finally built my first working pair of panels.

The very first time I had actually heard commercial set of ML's was just a few weeks before I had finished mine in 2003.

I had already been accustomed to the Apogee's for some time so I knew what to expect. But, I wasn't expecting to be blown away by the multifold in clarity.

This drove my passion for these things X squared.

Finding the proper materials was very difficult through the years as I didn't find the .25mil mylar until about 1992 from an ad in PM for company that supplied materials to build ultra lite aircraft and they were having a going out of business sale.

It was around 1998 the internet was starting to come around and I had started to discovered all of the websites oversea's featuring ESL's.

I printed off every thing I could find and I still have them stored in a box.

Complete projects from the TAC website when the were still displayed.

And because of the net, Info on materials and resources suddenly became very easy to obtain.

At that time I lived in Naples Florida and things were quite setback from the rest of the world back then.

So, when I tried to explain to someone what I was trying to do,Welllets just say that it was hard for them to understand or willing to go out of their way to get the info that I requested and told me good luck.

This was very hard coming from the very same area I now live in,But I pushed on anyway.

I like to use the words "simple" and "easy", Calvin cringes every time those words are mentioned.

Truthfully I can't blame him as it has been a bit of a long road to learn all of the how's and why's and what don't work.

But structurally it is no different to building a model airplane kit as it they do have a lot in common with lots of challenges to overcome to have a decent and reliable product ( I do mean ESL's).

Just like an Ole' Boy used to tell me back in the days of being a chef,

" It is easy when you know how Fry it's easy when you know how"! he,he,he

I will never forget that !!!

Keep on DIYin' !!!!

jer

I must say that it has been along time passion to be finally seeing these projects a reality.

But, I must also give credit to those In these threads whom have help me out tremendously as well.

The list is too long to name each one individually.

Just two years ago the only thing I can say that I really new about transformers was how the transformation ratio worked and the rest was a mystery.

Knowing also, this was the key to and stopping me from finishing my system.

I had to embark on what makes them tick and this is were the DIYaudio community really kicked in to help me understand this mysterious beast.

Ever since I could hold a pencil I replaced it with a soldering iron and In the mid 70's was when High end audio started to come about.

Occasionally I would see the schematic of some high power amplifier and I would say to my self "They want $1000 for that thing!" and I would tally up the price of the components and in most cases it would have cost me much much less than $200 for one or two of them, not to mention quantity's of 10 prices.

Being transformers and heatsinks the most costly of component,just as it is today.

Although $200 was a gracious amount of money in those days and I did with what I had at the time as well keeping up with the latest technologies through the years.

It was when I saw a write up in Popular Mechanics Magazine on the Quad and Magnepan planar speakers that really got me going and again saying to my self "Is That All There is to Those Things?", that's what got my guff and my journey began.

Not to mention a really old HI-Fi book that mentioned the mysterious ESL and Plasma speaker technologies that I found in the school library and stuff on tesla coils.

At this point H.V. became my newest quest as all of these things are exactly that, H.V devices.

Back in those days we didn't have vast limitless tank of information called the internet.

It wasn't until I had found Roger Sander articles of DIY ESL's reprinted in a book called The Audio Amateur published in 1980.

Copies of his articles can be found on his website.

I Can't even start to explain the joy and nearly started sobbing when I had discovered the chapters in that book fully describing several systems.

It was the moment of a brand new meaning to the word "WoW, I can not believe what I am looking at !!".

Remember this was nearly 20 years before the existence of this very forum.

And, It took me that long, almost to the year, Of the discovery of that one book when I finally built my first working pair of panels.

The very first time I had actually heard commercial set of ML's was just a few weeks before I had finished mine in 2003.

I had already been accustomed to the Apogee's for some time so I knew what to expect. But, I wasn't expecting to be blown away by the multifold in clarity.

This drove my passion for these things X squared.

Finding the proper materials was very difficult through the years as I didn't find the .25mil mylar until about 1992 from an ad in PM for company that supplied materials to build ultra lite aircraft and they were having a going out of business sale.

It was around 1998 the internet was starting to come around and I had started to discovered all of the websites oversea's featuring ESL's.

I printed off every thing I could find and I still have them stored in a box.

Complete projects from the TAC website when the were still displayed.

And because of the net, Info on materials and resources suddenly became very easy to obtain.

At that time I lived in Naples Florida and things were quite setback from the rest of the world back then.

So, when I tried to explain to someone what I was trying to do,Welllets just say that it was hard for them to understand or willing to go out of their way to get the info that I requested and told me good luck.

This was very hard coming from the very same area I now live in,But I pushed on anyway.

I like to use the words "simple" and "easy", Calvin cringes every time those words are mentioned.

Truthfully I can't blame him as it has been a bit of a long road to learn all of the how's and why's and what don't work.

But structurally it is no different to building a model airplane kit as it they do have a lot in common with lots of challenges to overcome to have a decent and reliable product ( I do mean ESL's).

Just like an Ole' Boy used to tell me back in the days of being a chef,

" It is easy when you know how Fry it's easy when you know how"! he,he,he

I will never forget that !!!

Keep on DIYin' !!!!

jer

Last edited:

Hi,

Did I say anything about conventional SWs? No, talk was about dipolar woofers! Its the dipolar feature that gives the drum-like ESL membrane an acceptable bass in room at all. If a classical (monopolar) woofer would perform with a comparably high Q as nearly all ESLs do, nobody would grant them good performance. Instead they´d be dismissed as lowquality right away.

On the other hand does a dynamic dipole profit from the superiority of dynamic drivers in the bass region AND the dipole character. A dynamic dipole woofer knocks out ESL bass with regard to precision, dynamics, linearity, compactness, drive demands (ohh, I remember repeating myself here )

)

I also think it somehow funny that a person unknown to me, explains the world what I have listened to or not have listened to and how well my listening sense works.

jauu

Calvin

Sorry, but whats Your basis or expertise then? Is there a theoretical backup You might want to share with us?kevinh: As to conventional SW performing "way batter" you have no basis for that assertions since you clearly have never heard the B1 of B2 panels...

Did I say anything about conventional SWs? No, talk was about dipolar woofers! Its the dipolar feature that gives the drum-like ESL membrane an acceptable bass in room at all. If a classical (monopolar) woofer would perform with a comparably high Q as nearly all ESLs do, nobody would grant them good performance. Instead they´d be dismissed as lowquality right away.

On the other hand does a dynamic dipole profit from the superiority of dynamic drivers in the bass region AND the dipole character. A dynamic dipole woofer knocks out ESL bass with regard to precision, dynamics, linearity, compactness, drive demands (ohh, I remember repeating myself here

I also think it somehow funny that a person unknown to me, explains the world what I have listened to or not have listened to and how well my listening sense works.

jauu

Calvin

Speaking of the Sound Lab Panels he uses a distribute resonance described here

Sound Lab Technology: Distributed Resonance - a patented advancement in electrostatic performance

It was recently pointed out to me(thanks mike beck) that all 8 claims in the Sound Lab patent were cancelled in 1994 when the patent was rexamined.

See the last page of the attached patent US5054081.

Perhaps it was discovered that Magnepan's 1972 patent (US3674946) already taught the technique of distributed resonance for planar ribbons. See Figure 12 & 13 for details of diaphragm sectioning and resulting distributed resonances. Applying the concept to ESLs, perhaps, was not deemed novel enough to warrant a patent.

Attachments

geraldfryjr's post was wonderful reading and many happy DIY ESL memories flooded back.

I built a Sanders-like amp to drive Dayton-Wright elements and later, whole D-W intact speakers. There is a big difference between cones and ESLs and there is maybe a comparable difference between driving with a Sanders amp versus step-up transformers. No kidding.

Pity those kinds of amps are so potentially lethal. But given the sweat devoted to some minor tweaks in sound creation, sure funny that people aiming for the best sound don't insist on direct-drive high-voltage (2400 V B-plus) amps.

The new book by Nobel laureate Kahneman discusses in much detail the illusions of expertise as well as how faulty our judgments can be. I am sure the voluminous (and Nobel-winning) research he recounts will be entirely wasted on those who judge their own creations with their own ears (esp. persons of an engineering cast of mind... I won't pick on any specific nationalities or language groups because that kind of obtuseness is widespread) but thought I mention it anyway for others.

Ben

I built a Sanders-like amp to drive Dayton-Wright elements and later, whole D-W intact speakers. There is a big difference between cones and ESLs and there is maybe a comparable difference between driving with a Sanders amp versus step-up transformers. No kidding.

Pity those kinds of amps are so potentially lethal. But given the sweat devoted to some minor tweaks in sound creation, sure funny that people aiming for the best sound don't insist on direct-drive high-voltage (2400 V B-plus) amps.

The new book by Nobel laureate Kahneman discusses in much detail the illusions of expertise as well as how faulty our judgments can be. I am sure the voluminous (and Nobel-winning) research he recounts will be entirely wasted on those who judge their own creations with their own ears (esp. persons of an engineering cast of mind... I won't pick on any specific nationalities or language groups because that kind of obtuseness is widespread) but thought I mention it anyway for others.

Ben

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- ESL woofer- anybody game?

![1274561826[1].jpg](/community/data/attachments/247/247217-c1c8e76d2ba48d0dd3dbf10a05979208.jpg)

![1293468283[1].jpg](/community/data/attachments/247/247224-15ed0458b824d0f659dd1a5391e3d50b.jpg)