Here's the new Antek grid view: http://www.antekinc.com/grids/

I'm surprised no one on this site has bothered to make an ESL specific toroidal transformer and find some (PET) polyethylene terathylate diaphragm material with a plasma-deposited conductive coating already applied.

I'm surprised no one on this site has bothered to make an ESL specific toroidal transformer and find some (PET) polyethylene terathylate diaphragm material with a plasma-deposited conductive coating already applied.

No, that would give 1:80 but it will also increase the overall transformer capacitance greatly.

I said put the winding's in parallel not series.

You could try it though, I have used such a configuration before to get to 1:256 with my cores but the impedance gets really really low at that point.

jer

I said put the winding's in parallel not series.

You could try it though, I have used such a configuration before to get to 1:256 with my cores but the impedance gets really really low at that point.

jer

Last edited:

No, that would give 1:80 but it will also increase the overall transformer capacitance greatly.

I said put the winding's in parallel not series.

You could try it though, I have used such a configuration before to get to 1:256 with my cores but the impedance gets really really low at that point.

jer

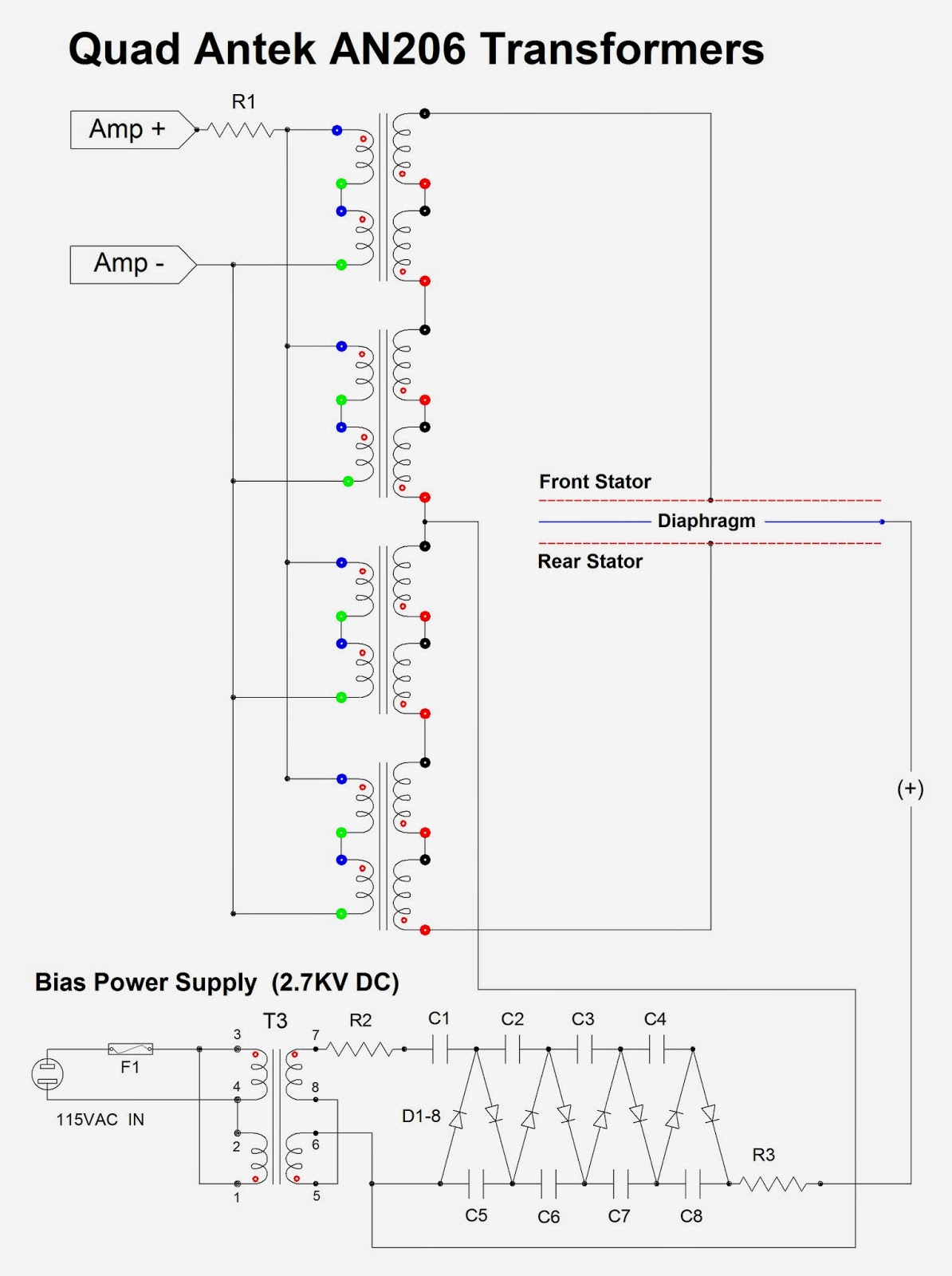

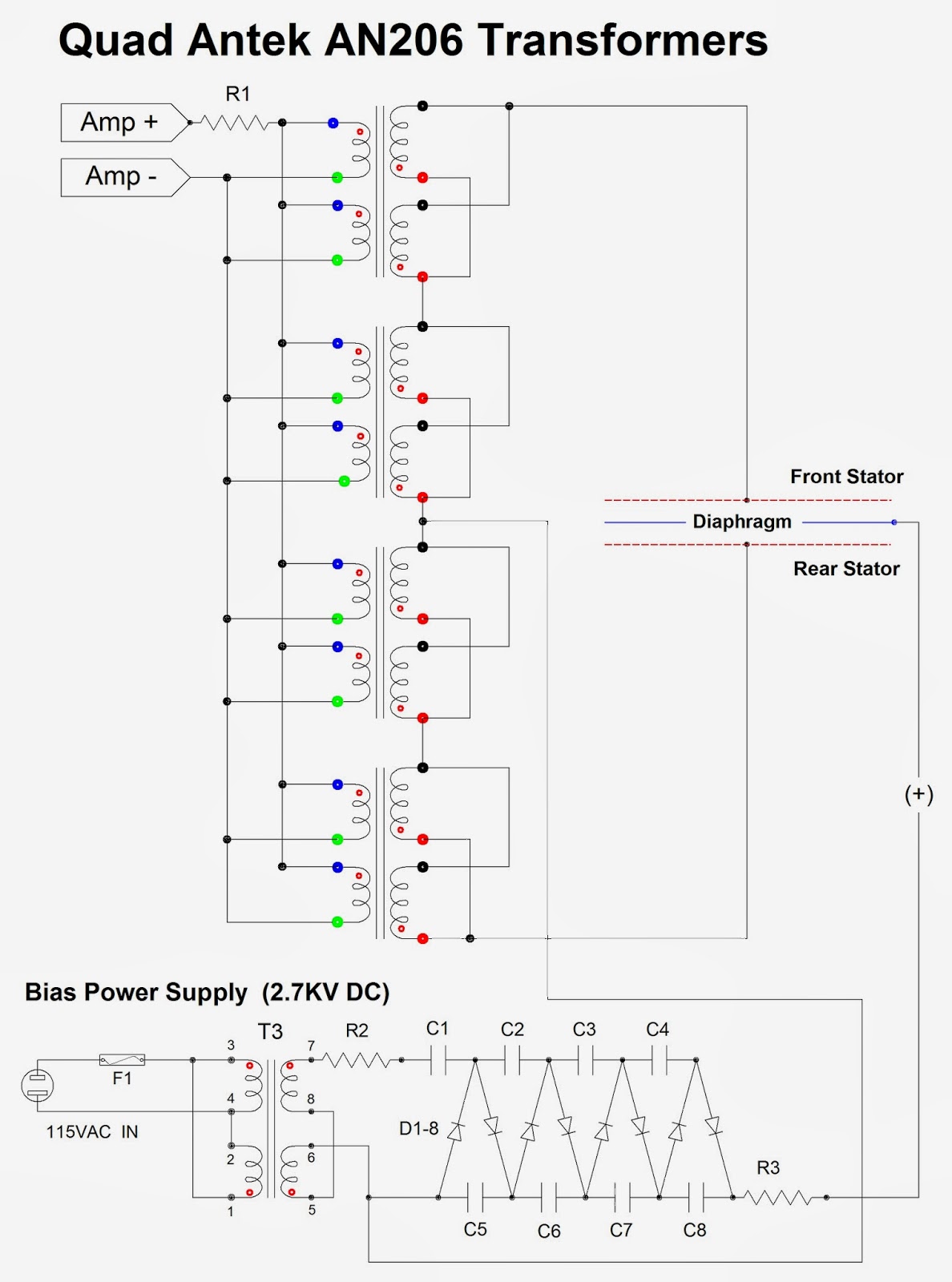

You should get decent performance out of them using 4 per panel with each ones individual pair of 6v winding's and 120v winding's in parallel.

Using 4 cores wired for 1:80.

At $11 a piece this is cost effective vs Performance.

Keep us posted on your finding's.

jer

P.S. They really did a terrible job of hacking up their website!!!!

OK, I think I've got it.... will post another sketch in a few.

Last edited:

Each transformer wired as 6V/120V and in a final configuration as 6V/480V.

jer

Is this what you had in mind?

Hi,

X83 You're happily invited to volunteer ;-)

M.v.d.Veen has made really good toroids, sold also under the Plitron brand.

since You need maybe 2-4 different models, I doubt that it would be worthwhile.

ITO sputtered film is a standard product for TFT Display manufacturing.

But as we know from ML, its not stable, which ML tries to circumvent in painting the film with what they call 'Slurry'.

Afaik the lowest film thickness that can be sputtered is 12um.

Due to thermal power input thinner films wrinkle and destroy.

It seems that only sputtering with Ge would allow for lower thicknesses.

Still though expect to pay 1500eu just for first samples. Also expect dozens if not hundreds of meters of wasted film at the beginning until the process uniforms and you get a decent output.

Also expect to buy several km of film.

But don't feel upset. Just go ahead. The crowd will follow You soon in safe distance

jauu

Calvin

X83 You're happily invited to volunteer ;-)

M.v.d.Veen has made really good toroids, sold also under the Plitron brand.

since You need maybe 2-4 different models, I doubt that it would be worthwhile.

ITO sputtered film is a standard product for TFT Display manufacturing.

But as we know from ML, its not stable, which ML tries to circumvent in painting the film with what they call 'Slurry'.

Afaik the lowest film thickness that can be sputtered is 12um.

Due to thermal power input thinner films wrinkle and destroy.

It seems that only sputtering with Ge would allow for lower thicknesses.

Still though expect to pay 1500eu just for first samples. Also expect dozens if not hundreds of meters of wasted film at the beginning until the process uniforms and you get a decent output.

Also expect to buy several km of film.

But don't feel upset. Just go ahead. The crowd will follow You soon in safe distance

jauu

Calvin

Or you can just use Licron Crystal.

I have fancied the idea of building a custom Toroid Transformer for ESl's for quite some time.

However it has taken my about 3 years to fully understand all that is involved in such a design.

Now all I need is to do is get the materials.

Start with the largest core you can afford,

Silicon Steel Toroidal Cores - In Stock

Then add a rather thick insulation coating to the core as this will help keep the self capacitance down.

Start with at least a thickness of .050" to .100"

Calculate your primary's number of turns (inductance) for your lowest frequency of operation at an impedance no lower than 4 or 8 ohms at the lowest frequency.

This is the one drawback about using the power toroid method that we are using now.

The impedance at 300hz to 360hz is quite low as well.

Typically in the 2 ohm range or lower.

It is also the the point of saturation when using a large amplifier that can produce at least 40Vrms.

Try to go for a higher impedance in to the 16 to 64 ohm range if the core is large enough.

Although, This will certainly increase the amount of total turns.....A lot!

For as low as 200Hz to 300hz this is quite feasible.

But, For a full range down to 20hz or 40hz your talking about some very big iron or take a hit in high frequency performance due to the very large self capacitance of the transformer.

Expect a very large secondary of about 10,000 turns or more using a smaller core like the very expensive Plitron's.

Then start winding your secondary First, as this will give you the smoothest surface area to start with and help you to keep each individual turn straight and non-overlapping to the next adjacent turn.

It may take about 3 or 4 layers to meet the requirements as per some of my preliminary calculations.

I have come up with a few with only 2 or 3 layers as wire gauge plays a big part of this.

30 ga. is great as far as durability of being able to handle the current should a short or arc over occur in the panels.

32ga is about the absolute smallest I would go as this greatly increases the amount of turns you can put in a given space.

It is also hard to work with and easy to break but not as bad as using the thinner stuff like 40ga. or 42ga. as these would fuse in a second should an overload situation come up and all of that work would be rendered useless.

Again you want a very thick layer of insulation in between the each next layer of turns.

Not for insulating purposes but again to keep the secondary's self (inter winding) capacitance at a minimum.

Keep in mind that you are still talking about 2000 to 5000 turns just for the secondary using a core as large as Alpha cores PN#140 2683VA core as it is moderately priced at $36.72!!!

You would need to probably want to split the secondary into two or more sections and keep them exactly identical.

This too will keep the inter winding capacitance lower and prevent any flashover between the layers on the winding sections to the other half as about 10Kv is produced across the secondary as a whole.

Alternating the connections of the layers as well, as is done in typical high grade OPT's.

Again to help keep the inter winding capacitance at a minimum.

Once a good working model as been made then it is possible to submit the design to a winding firm and have a lot of them made up.

It would take an extreme amount of patients to do, and some may not be up to this.

I have spent many hours through the years winding small Tesla coils perfectly by hand my whole life.

The larger the core you can start with the easier it may be to work on, as well as lessen the overall amount of total turns.

Not to mention that the inside diameter starts to get increasingly smaller per every layer of winding's and insulation in between them.

This limits how many winding's you can put on each successive layer without any of the turns overlapping.

C-cores are better when looking at these aspects, although they do cost a bit more as well.

FWIW

jer

I have fancied the idea of building a custom Toroid Transformer for ESl's for quite some time.

However it has taken my about 3 years to fully understand all that is involved in such a design.

Now all I need is to do is get the materials.

Start with the largest core you can afford,

Silicon Steel Toroidal Cores - In Stock

Then add a rather thick insulation coating to the core as this will help keep the self capacitance down.

Start with at least a thickness of .050" to .100"

Calculate your primary's number of turns (inductance) for your lowest frequency of operation at an impedance no lower than 4 or 8 ohms at the lowest frequency.

This is the one drawback about using the power toroid method that we are using now.

The impedance at 300hz to 360hz is quite low as well.

Typically in the 2 ohm range or lower.

It is also the the point of saturation when using a large amplifier that can produce at least 40Vrms.

Try to go for a higher impedance in to the 16 to 64 ohm range if the core is large enough.

Although, This will certainly increase the amount of total turns.....A lot!

For as low as 200Hz to 300hz this is quite feasible.

But, For a full range down to 20hz or 40hz your talking about some very big iron or take a hit in high frequency performance due to the very large self capacitance of the transformer.

Expect a very large secondary of about 10,000 turns or more using a smaller core like the very expensive Plitron's.

Then start winding your secondary First, as this will give you the smoothest surface area to start with and help you to keep each individual turn straight and non-overlapping to the next adjacent turn.

It may take about 3 or 4 layers to meet the requirements as per some of my preliminary calculations.

I have come up with a few with only 2 or 3 layers as wire gauge plays a big part of this.

30 ga. is great as far as durability of being able to handle the current should a short or arc over occur in the panels.

32ga is about the absolute smallest I would go as this greatly increases the amount of turns you can put in a given space.

It is also hard to work with and easy to break but not as bad as using the thinner stuff like 40ga. or 42ga. as these would fuse in a second should an overload situation come up and all of that work would be rendered useless.

Again you want a very thick layer of insulation in between the each next layer of turns.

Not for insulating purposes but again to keep the secondary's self (inter winding) capacitance at a minimum.

Keep in mind that you are still talking about 2000 to 5000 turns just for the secondary using a core as large as Alpha cores PN#140 2683VA core as it is moderately priced at $36.72!!!

You would need to probably want to split the secondary into two or more sections and keep them exactly identical.

This too will keep the inter winding capacitance lower and prevent any flashover between the layers on the winding sections to the other half as about 10Kv is produced across the secondary as a whole.

Alternating the connections of the layers as well, as is done in typical high grade OPT's.

Again to help keep the inter winding capacitance at a minimum.

Once a good working model as been made then it is possible to submit the design to a winding firm and have a lot of them made up.

It would take an extreme amount of patients to do, and some may not be up to this.

I have spent many hours through the years winding small Tesla coils perfectly by hand my whole life.

The larger the core you can start with the easier it may be to work on, as well as lessen the overall amount of total turns.

Not to mention that the inside diameter starts to get increasingly smaller per every layer of winding's and insulation in between them.

This limits how many winding's you can put on each successive layer without any of the turns overlapping.

C-cores are better when looking at these aspects, although they do cost a bit more as well.

FWIW

jer

For that number of ESL-winding patients, I'd try a mental hospital.*snip

It would take an extreme amount of patients to do, and some may not be up to this.

snip

jer

Given the geometrical challenge of winding toroids, I found it very interesting to learn of the machines used (often in India) to wind them. Frankly, now that I see how a machine does it, I am befuddled about how a human would do the winding.

Yup, ticnpop is a good guy.

Ben

*kidding aside, many thanks for one more very informative post

I'm surprised no one on this site has bothered to make an ESL specific toroidal transformer and find some (PET) polyethylene terathylate diaphragm material with a plasma-deposited conductive coating already applied.

http://przyrbwn.icm.edu.pl/APP/PDF/116/a116zs33.pdf

Vacuum Coating | LinkedIn

http://gaia.lbl.gov/btech/papers/28826.pdf

One of links describes graphite/diamond vacuum deposition on surfaces. I have always wondered if graphite coatings are reliable due to possible reaction with oxygen under conditions of corona, as graphite should react with ozone contributing to greenhouse gas emissions.

How about Quad & Co.? Was not the coating carbon based?

Hi,

If the conductive component of Quad ESL >=63 is really carbon(this could be suspected from color?) I guess it's suspended in a kind of polymer which would protect it from contacting atmosphere.

According to some sources carbon should react with ozone :

Ozone reaction with carbon nan... [J Nanosci Nanotechnol. 2007 Apr-May] - PubMed - NCBI

Now the question is if an ESL would produce this substance under normal conditions; I suspect that high drive voltages are required when air starts to ionize.

Just thoughts, anyone has real experience?

Regards,

Lukas.

Two comments

I have used graphite coatings for years without any trouble.

The Quads use a nylon based coating

hope this helps

The Quad ESL - Original Quad Coating

I have used graphite coatings for years without any trouble.

The Quads use a nylon based coating

hope this helps

The Quad ESL - Original Quad Coating

** 50VA 230V/2x6V

** 6V6 transformers

** Each transformer wired as 6V/120V and in a final configuration as 6V/480V

** 230v 2x6 transformer

** 240v/6v X 2 power toroids

If you could help me understand all the jargon & nomenclature, I think it would help me come much closer to feeling oriented in the world of ESL step up transformers. I read the NEETS modules on transformers and a few others so I'm not completely in the blind but all the above bullet points are examples of things I don't understand how to read.

I know that a ratio of 1:50 means the secondary coil has 50 times the number of wingdings as the primary. But how do i read all the above nomenclature.

thanks for your help

Eddie

** 6V6 transformers

** Each transformer wired as 6V/120V and in a final configuration as 6V/480V

** 230v 2x6 transformer

** 240v/6v X 2 power toroids

If you could help me understand all the jargon & nomenclature, I think it would help me come much closer to feeling oriented in the world of ESL step up transformers. I read the NEETS modules on transformers and a few others so I'm not completely in the blind but all the above bullet points are examples of things I don't understand how to read.

I know that a ratio of 1:50 means the secondary coil has 50 times the number of wingdings as the primary. But how do i read all the above nomenclature.

thanks for your help

Eddie

** 50VA 230V/2x6V

** 6V6 transformers

** Each transformer wired as 6V/120V and in a final configuration as 6V/480V

** 230v 2x6 transformer

** 240v/6v X 2 power toroids

If you could help me understand all the jargon & nomenclature, I think it would help me come much closer to feeling oriented in the world of ESL step up transformers. I read the NEETS modules on transformers and a few others so I'm not completely in the blind but all the above bullet points are examples of things I don't understand how to read.

I know that a ratio of 1:50 means the secondary coil has 50 times the number of wingdings as the primary. But how do i read all the above nomenclature.

thanks for your help

Eddie

Hi Eddie, I'll take a stab at this:

"50VA 230V/2x6V":

Dsignates a transformer having a 50 volt-amp power rating, a single 230 volt primary winding and two 6-volt secondary windings. If wired in series the secondaries would add: (6+6)=12 volts. If in wired in parallel ((6+6)/2) the secondaries' voltage remains 6 volts.

"240V/6V x 2 power toroids":

Since dual 6v secondaries would correctly be expressed as "2x6V", I'm gonna guess this refers to two transformers, each having a single 240 volt primary winding and a single 6 volt secondary winding.

Unlike the US which used 115 to 120 house voltage, many countries use 230 volt or 240 volts in homes. The transformers you referenced are typically "step-down" transformers designed to step down 230 or 240 house voltage to 6 volts (secondaries in parallel) or 12 volts (secondaries in series). When used to power ESL speakers, we typically use two transformers and turn them around, with the 6 volt windings wired in parallel and connecting to the amplifier, and the 230 volt windings in series (230 + 230) and connecting to the stators. And most arrangements would connect (center tap) the negative lead from the bias supply at the series connection between the two transformers' 230v windings.

The term "6v/240v configuration" could refer to a transformer with single primary and secondary windings or may refer to a 2x120V/2x6V transformer (turned around) with the 6 volt windings wired parallel giving 6 volts, and the 120 volt windings in series, giving 240 volts--- hence; "6v/240v"

As for the winding ratio: For 6v/230v, the ratio would be 230/6= 38.33 for 1:38 for a single transformer. And if you couple two transformers in tandem the ratio is doubled to 1:76

Last edited:

good job CharlieM. that definitely cleared up a lot of things.

So if I see 230V/6V, can I assume that the primary has 230 turns around core and the secondary has six turns around the core? To put my question another way, does one turn around the core result in one volt of capacity? in other words, that 230v/6v is rated to handle a max of up to 230v being applied to the primary (but less than 230 volts applied to the primary would be fine just not more than 230V) ?

So if I see 230V/6V, can I assume that the primary has 230 turns around core and the secondary has six turns around the core? To put my question another way, does one turn around the core result in one volt of capacity? in other words, that 230v/6v is rated to handle a max of up to 230v being applied to the primary (but less than 230 volts applied to the primary would be fine just not more than 230V) ?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- ESL transformer question