Yeah. Just use auralex foam.The test cell that I outlined is intended to test the sound absorption of a material.

There are many materials that do not transmit sound well, that's because the sound reflects off them, sound absorbent materials do transmit sound, but they absorb some of it as they do, and this is the property we need for box stuffing.

The type of foam Rod mentioned in the article, (used by a speaker designer aquaintance of his), does not transmit sound well because it reflects a lot of it. Thinking that this is what is needed for box lining the speaker "designer" in question assumed this was what was needed, and was absolutely convinced of it despite the speaker system in question having very obvious resonances coming through the cone.

rcw.

Auralex foam is specifically designed to absorb bass. No problems at all.I'm surprised it seemed no one mentioned about the midrange.

In a commonly seen 2-way, midbass driver covers a very broad range, maybe as broad as 40-3kHz. And since the cone is largely sound-transparent (or at least in some frenquency range), whatever trapped in the box would probably escape through the cone (if in a sealed box).

In my own (limited) experiences, the mid to midbass range (say, centered around 200Hz) is the most troublsome. The absorbability drops, the cone can't effectively separate it, and the strong standing wave frenqucies are nearby.... How can this be dealt with stuffing? I'd prefer box with non-parallel walls for this reason, if OB is not an option, but this is beyond this topic.

From here, I'm also curious about the midrange performance of those 'pipe-style' speakers, i.e., TL, MLTL, MLQWT, BIB... etc. Classic TL for example, all frequencies above tuning point should be 'transmitted' down the pipe and the mid to mid-high should be absorbed along the way.... But in reality, the back of the driver is probably facing a very near rear wall. Doesn't the reflection penetrate the cone right away? How effective the stuffing is working here?

And yet, people seem highly sensitised to it, which seems to be the case with many low-level artifacts.

Yep. Measurements can't do away with what you hear.

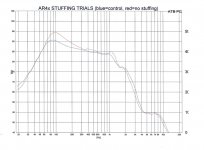

Hi, Tony, what do those different colors stand for?

Hi CLS I may have posted the wrong colours as I am colour blind

What I think is light blue is the nearfield response of an MW144 woofer in a sealed enclosure of approx 5L volume with no stuffing or damping materials.

What I think is the yellow line (could be lime green) is exactly the same setup but with "egg crate" foam on the rear wall.

What I think is the dark blue line is exactly the same setup but with the "SORBERFLEX® ALR" on the rear wall. I chose to buy it because it seemed similar in construction to "Black Hole 5" which I had read quite a bit about, but had considered to be out of reach price wise.

In all cases there was no stuffing and only the rear of the enclosure was covered.

I guess it also shows that some speakers DO have significant reflections come through the cones

Tony.

Auralex foam is specifically designed to absorb bass. No problems at all.

How effective is it? Is there any 3rd party testing?

If an effective bass absorbing material do exit, then we may build a small sealed box which behave like an IB (WOW!), or a PERFECT labyrinth. That'd be fascinating!

Is it THAT effective?

Well I fired up speaker-workshop, man did I do a lot of measurements.... Unfortunately I don't have measurements done at the same time for with filling, and with the pyrotek damping. They are in separate speaker-workshop files so I can't put them on the same graph (not that it would necessarily be a valid comparison anyway.

It looks like the filling did damp the reflections quite well, but as I said before I didn't care for the resulting sound. Anyway for completeness here is the graph of the box with filling. The most interesting thing to me is the complete change of behaviour at 2K... I'm going to have to do some more tests now! I did note also that I had done some tests with the soundsorber on the top and bottom which also had an effect around the 2K mark...

I also changed mic's a few times so whether this result is directly comparable to the first graph I posted is questionable.

I will do some more tests over the coming weeks and post the results. I'll be careful to make certain all drive levels are the same and mic positioning is as close to the same as possible

Tony.

edit: the second graph is the one that I am mentioning the complete change at 2K... note both these graphs I had noted as being with filling..... go figure...

It looks like the filling did damp the reflections quite well, but as I said before I didn't care for the resulting sound. Anyway for completeness here is the graph of the box with filling. The most interesting thing to me is the complete change of behaviour at 2K... I'm going to have to do some more tests now! I did note also that I had done some tests with the soundsorber on the top and bottom which also had an effect around the 2K mark...

I also changed mic's a few times so whether this result is directly comparable to the first graph I posted is questionable.

I will do some more tests over the coming weeks and post the results. I'll be careful to make certain all drive levels are the same and mic positioning is as close to the same as possible

Tony.

edit: the second graph is the one that I am mentioning the complete change at 2K... note both these graphs I had noted as being with filling..... go figure...

Attachments

Last edited:

100% wrong. Thanks for spreading disinformation. Increased volume and lowered fs is a side effect and not the point of stuffing. You should have left the foam in place.

We're both right. In a closed box, system stuffing does both functions (e.g. damp standing waves and increase the effective box volume by increasing the compliance). Thirdly, the system Q can be controlled by the amount of stuffing. In a given closed box system, system Q's in the range of <0.5 to >>1.0 are possible with varying amounts of stuffing. The 'tightness' or 'looseness' of the bass sound is a function of system Q. Tightness is associated with lower Q. Looseness or more 'boom box' sound can be had with Q's well over 1 - All with the same volume box and driver. Attached is a NF response test of an Acoustic Research model 4x acoustic suspension speaker done as part of a larger stuffing study I conducted. The blue line is with the original rock wool stuffing. The red line is with the stuffing removed. The benefit of the stuffing is clearly evident in the flatter hump at system resonance (lowered Q as well) with is lowered appaox. 10 hz and, also the attenuation of the just over 1 khz hump in the response. This speaker certainly wouldn't be considered 'critically damped', I suspect, by design to yeild a warm, overall tone many AR enthusiasts love.

Granted, stuffing mitigates stanting waves, particularly at the upper range of a woofers response curve. However, most woofer's response are normally attenuated in the upper range with series inductors designed to mesh the response of the woofer's smooth pass band with either a tweeter or midrange element. OTOH, if you are designing a speaker with a woofer having no series wired coil, then certainly it would be judicious to address the higher frequency standing waves that could indeed be audibly noticeable.

BTW, the 4x used in the study did have a series coil with the woofer in the crossover.

Attachments

And yet, people seem highly sensitised to it, which seems to be the case with many low-level artifacts.

That or they are highly motivated to believe it, real or not.

What percentage of box volume would you dedicate to foam in a cost no object sealed speaker?

Probably close to 100% as long as the foam is not compressed. Ideal would be custom cut blocks that exactly fit the enclosure. This is not practical however. But I generate a lot of sacraps and these work nicely.

Auralex foam is specifically designed to absorb bass. No problems at all.

Foam is foam and none of it works very well at LF. Basically the material is secondary to the situation (volume and location) especially at LFs.

Thats why the automotive guys have been using it for years, even decades. They didn't bleach it and it was all kinds of colors.

Similar stuff, different application: Natural Cotton Fiber Insulation, Natural Cellulose Insulation

dave

That thing linked here appear to be around 20 to 25kg/m3

I have found similar material with density ranging from 18kg/m3 to 75kg/m3

(18, 25, 50, 75)

What do you think is the best density in a closed box?

http://www.diyaudio.com/forums/multi-way/31208-enclosure-stuffing.html

More posts on stuffing from a few years back.

More posts on stuffing from a few years back.

Foam is foam and none of it works very well at LF. Basically the material is secondary to the situation (volume and location) especially at LFs.

Oh please. You specifically require a particular type of foam for your waveguide plugs.

Different foams have different properties, though we're largely agreed, it's not very effective at LF- few things are, until you go very thick.

Oh please. You specifically require a particular type of foam for your waveguide plugs.

Waveguides are not low frequencies and there are substantial differences at high frequencies.

Badman: said:And yet, people seem highly sensitised to it, which seems to be the case with many low-level artifacts.

That or they are highly motivated to believe it, real or not.

Id have thought that +- 6db around the 750 Hz mark (as shown in post #31) would be well and truly audible... Admittedly I only measured it bare and then again with various materials damping it. I did not sit down and extensively listen to see if I could hear the difference between bare and damped. Also that measurement is nearfiled, but even so it clearly shows a large difference between damoed and undamped. I was not able to get decent measurements at 1M due to too many reflections so I can't offer any evidence as to what the difference would be at a more normal distance.

The one time I did notice a difference (audibly) was with the stuffing, but this was over three years ago, so my memory might be failing me, and it is quite probable that I over stuffed in order to get the stuffing to be as effective as the foam. I do seem to recall adding more and more until I got measurements with the peaks damped significantly.

edit: the cabinet depth is 211mm which is approx 1/2 wavelenght at 810Hz... Note that looking at the graph again the peak is close to 800Hz.

Tony.

Last edited:

Waveguides are not low frequencies and there are substantial differences at high frequencies.

Of course. But that's in direct conflict with "foam is foam". If you mean "At low frequencies", then I'm more inclined to agree, but even then, the different foams will behave very differently. The very open structure of the foam you use in the waveguides would provide dramatically less attenuation than a "normal" open celled foam, and a closed cell would only take up box volume.

"Most open-celled foams used for acoustic purposes are largely the same at low frequencies" is probably what you meant, but that's a lot of qualification to have to add to a statement like "foam is foam".

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Enclosure Stuffing