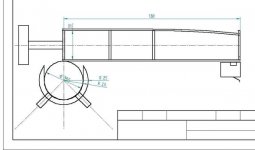

I found this acrylic tube (50mm outer dia, 40mm inner diameter) in RS components catalog, item 282-2262, and acrylic rod (40mm diameter) item 824-468. (Do a search using item numbers at their website, www.rs-components.com).

So I'm thinking of doing an airarm where the acrylic rod slides inside the acrylic tube instead of using aluminum angles. The top of the tube will be cut off so the rod has vertical freedom and be able to float. The acrylic is easy to machine and tapping threads into for fastening screws and such. The airhose can be connected to several nipples that are screwed into the acrylic tube. The acrylic tube I'm looking at has 10mm thick walls, so shouldn't pose too much a problem.

Any thoughts?

So I'm thinking of doing an airarm where the acrylic rod slides inside the acrylic tube instead of using aluminum angles. The top of the tube will be cut off so the rod has vertical freedom and be able to float. The acrylic is easy to machine and tapping threads into for fastening screws and such. The airhose can be connected to several nipples that are screwed into the acrylic tube. The acrylic tube I'm looking at has 10mm thick walls, so shouldn't pose too much a problem.

Any thoughts?

Attachments

Any thoughts?

I think it looks pretty interesting! You would get a bigger surface area that way. But the inner rod would be somewhat heavy - can you do it with a tube inside, cut some of the weight?

SemperFi,

looks neat!

but be prepared for the acrylic tube getting warped after you milled off the upper half.

Acrylic tubes are extrusion profiles and have the iiner tensions of such.

Dtopic, coincident creativity!

looking at your tonearm wand i found myself calmly using indecent language as i had a very similar idea today: the tonearm wand being a framework of matches, yes, of wooden matches.

I bet it would sound gorgeous, provided the framework is properly done.

Jeremy,

how do you think it would look to have a mechanical linear tracker with such a tonearm wand and having a Koetsu Urushi mounted into it for demonstration ...i will leave the red heads on the matches

ROTFLMAO

looks neat!

but be prepared for the acrylic tube getting warped after you milled off the upper half.

Acrylic tubes are extrusion profiles and have the iiner tensions of such.

Dtopic, coincident creativity!

looking at your tonearm wand i found myself calmly using indecent language as i had a very similar idea today: the tonearm wand being a framework of matches, yes, of wooden matches.

I bet it would sound gorgeous, provided the framework is properly done.

Jeremy,

how do you think it would look to have a mechanical linear tracker with such a tonearm wand and having a Koetsu Urushi mounted into it for demonstration ...i will leave the red heads on the matches

ROTFLMAO

DIY Turntable Arm

Coming in here a bit late, but Kal Rubinson mentioned capillary (sp?) tubing on the Teres list last year as being a VERY limp tubing, that even when pressurized with air remains limp. This was in context of having the air tube go to the slider as opposed to the base V channel. I'm still interested in this, I think you would need a smaller pump as there would be no wasted air bleeding through uncovered air holes. With the capillary tubing there would be no resistance to the air bearing as long as it was supported somehow so that it doesn't drag on the turntable.

RonS

Coming in here a bit late, but Kal Rubinson mentioned capillary (sp?) tubing on the Teres list last year as being a VERY limp tubing, that even when pressurized with air remains limp. This was in context of having the air tube go to the slider as opposed to the base V channel. I'm still interested in this, I think you would need a smaller pump as there would be no wasted air bleeding through uncovered air holes. With the capillary tubing there would be no resistance to the air bearing as long as it was supported somehow so that it doesn't drag on the turntable.

RonS

as long as it was supported somehow so that it doesn't drag on the t

You have to do that with the tonearm wires anyway so you could maybe combine the two supports into one part. Interesting. I guess this tubing is a medical supply? We'll have to try and get ol' Kal in here for comment.

Yes, it's a medical supply item. I'll take a look around town.

Depending on the gauge of the tonearm wire, you might have to support that as well, in which case the same support could be used for the air tube. I have a good length of Van den hul silver tonearm wire which I had planned on using to wire up my arm. I had envisioned it coming out of the armtube somewhere around the counterweight and forming a large loop up, and then back down to a termination block. This way there would be slack for freedom of slider movement, but I wouldn't need a support for it. Something like the Rockport I think.

RonS

Depending on the gauge of the tonearm wire, you might have to support that as well, in which case the same support could be used for the air tube. I have a good length of Van den hul silver tonearm wire which I had planned on using to wire up my arm. I had envisioned it coming out of the armtube somewhere around the counterweight and forming a large loop up, and then back down to a termination block. This way there would be slack for freedom of slider movement, but I wouldn't need a support for it. Something like the Rockport I think.

RonS

Kal's reply, posted with his permission:

Well, we tried 2 ways to do the tubing connection to the rider. One was

very small-bore polyethylene capillary tubing but we had problems with

the stiffness impeding movement. More successful was extremely supple

synthetic rubber tubing. While 2-3x the diameter of the PE, it is very

limp when not under any pressure. The advantageshere was that, with its

larger bore, one needed less pressure to get adequate flow to pressurize

the bearing. We stopped experimenting while working on a way to run the

signal leads through that tubing.

Kal

More successful was extremely supple synthetic rubber tubing.

Can we get more info about this product, where was it obtained? Can we get any more? Can Kal supply it? What happened to his experiment of placing the signal wiring inside the tube?

RonS

Regarding the tapered tube controvery: the old Mauser 98 bolt-action rifle had a stepped, not a tapered barrel. People assumed that Paul designed it that way to make machining cheaper for a military battle rifle. Not so. He found that the stepped machining had less vibration than a tapered tube. He found that each step acted as a mechanial low pass filter.

Interesting thread, with a lot of theory and good explanations, but where are all the examples? (... hope I don't offend anyone ).

Here are two examples on how it could be done - first my own which started out as a copy of the Versa Dynamic (.. too short):

The bearing rod is solid and the VTA can be adjusted during playing. Please not that the arm is not connected on the above pictures. During playing the thin silicone rubber hose as well as the thin silver wires stand in an arch behind the arm.

Here is something quite different made by my friend Søren Bertram. No air and no hoses - but wheels:

More pictures and a little more explanation on my site http://www.soundimage.dk

Here are two examples on how it could be done - first my own which started out as a copy of the Versa Dynamic (.. too short):

The bearing rod is solid and the VTA can be adjusted during playing. Please not that the arm is not connected on the above pictures. During playing the thin silicone rubber hose as well as the thin silver wires stand in an arch behind the arm.

Here is something quite different made by my friend Søren Bertram. No air and no hoses - but wheels:

More pictures and a little more explanation on my site http://www.soundimage.dk

janils said:Here is something quite different made by my friend Søren Bertram. No air and no hoses - but wheels:

Jan,

how does the mechanical linear tracker perform ? I see there is a Benz LP cartridge, so the owner might be well convinced that it deserves an expensive cartridge.

best regards,

Hartmut from Munich

Hello Hartmut,

Oh yes, Søren Bertram is very much into high-end. When I visited him it was top of the line Accuphase all the way through. Normally he uses Rowland equipment. He makes his own silver cables which he distribute here in Scandinavia - http://www.audiokabel.dk/ (only in Danish).

We first listened to SACD and CD played on an Accuphase DP-77. Later we switched to LP's and allthough Søren wants to upgrade his MC/RIAA stage this was very convincing. As I have heard it many times before it very much depends on the software. Sometimes the SACD/CD is better and sometimes the LP. He played a Leonard Cohen record and listening to the CD in direct comparison was a big dissapointment.

Anyway the arm is not the weakest link here. Just this week he has upgraded to a Platine Verdier, but still uses the DIY arm.

A few more pictures (with Danish text) here: http://www.soundimage.dk/Friends/bertram2.htm

BTW - are you the Hartmut I met at the Triode Festivals in Denmark?

Oh yes, Søren Bertram is very much into high-end. When I visited him it was top of the line Accuphase all the way through. Normally he uses Rowland equipment. He makes his own silver cables which he distribute here in Scandinavia - http://www.audiokabel.dk/ (only in Danish).

We first listened to SACD and CD played on an Accuphase DP-77. Later we switched to LP's and allthough Søren wants to upgrade his MC/RIAA stage this was very convincing. As I have heard it many times before it very much depends on the software. Sometimes the SACD/CD is better and sometimes the LP. He played a Leonard Cohen record and listening to the CD in direct comparison was a big dissapointment.

Anyway the arm is not the weakest link here. Just this week he has upgraded to a Platine Verdier, but still uses the DIY arm.

A few more pictures (with Danish text) here: http://www.soundimage.dk/Friends/bertram2.htm

BTW - are you the Hartmut I met at the Triode Festivals in Denmark?

another simple unipivot

I thought I would throw my unipivot design out there. Seems to work fairly well, but I can't see living with it permanently.

http://boozhoundlabs.com/arm1/

jsn

An externally hosted image should be here but it was not working when we last tested it.

I thought I would throw my unipivot design out there. Seems to work fairly well, but I can't see living with it permanently.

http://boozhoundlabs.com/arm1/

jsn

I sure didn't notice any hum pickup. The leads are twisted in left/right pairs so that should help.

In the photo you can see my cheezy record clamp made out of a stainless steel flange from a hig vacuum system. It is more for holding warped records down than anything. It is disgusting how many brand new records arrive warped!

You can also see my cork-and-dynamat turntable mat.

jsn

In the photo you can see my cheezy record clamp made out of a stainless steel flange from a hig vacuum system. It is more for holding warped records down than anything. It is disgusting how many brand new records arrive warped!

You can also see my cork-and-dynamat turntable mat.

jsn

Don't be ashamed of the cork and Dynamat thing. I must have about 2 SQ FT of the dynamat inside my Thorens TD-125. I think the Technics in the background kinda ruins the picture though. I never thought of using the high vac plate for a record clamp. I had to settle for the diode platform from the ring laser gyro in a MK48 Torpedo. I put a bubble level in top so I could check that the earth hasn't tilted on it's axis overnight. We were interested in the quantity of fluid in each of three damping pillars, the Miller's Pillars that is.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY TurnTable arm