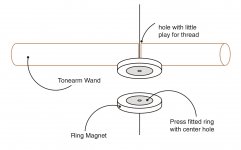

Will this work ? if drilling a center hole in magnet and aligning it is difficult, we can precisely cut a center disc of suitable material. Press fit it in a ring magnet. The center disc would have just enough same diameter hole to the thread one is using. The other end would be tied to base. The same can be applied to opposite side on tone arm. This way the magnet would be self aligned and if the magnetic field in ring is not equal in all area the bottom magnet would rotate in sync with tone arm magnet.

Regards

Regards

Attachments

Hello Hiten,

The above method of fixating the thread will work, everything else won't, particularly not if the proportions in your drawing are realized.

In addition, the bearing will now be MUCH less rigid AND the (desirable)eddy current damping will be lower for the same distance between the magnets.

Lastly, the "exit" hole for the thread(as drawn) gives way too little room for the thread. The thread would touch the rim when tracing even modestly warped records or when a VTA setting different from "horizontal" is required...

Cheerio,

Frank

The above method of fixating the thread will work, everything else won't, particularly not if the proportions in your drawing are realized.

In addition, the bearing will now be MUCH less rigid AND the (desirable)eddy current damping will be lower for the same distance between the magnets.

Lastly, the "exit" hole for the thread(as drawn) gives way too little room for the thread. The thread would touch the rim when tracing even modestly warped records or when a VTA setting different from "horizontal" is required...

Cheerio,

Frank

if drilling a center hole in magnet and aligning it is difficult, we can precisely cut a center disc of suitable material

And why would you do that? Every mechanical work (drilling) destroys magnet.

"Every mechanical work (drilling) destroys magnet."

Well, with the right tools, it doesn't destroy it, but there are far easier ways of connecting/centering the thread to/vs the magnet. All described in this thread....

Seems like a pilgrimage to many, - everyone finds his own way to Rome(or wherever...) in the end.

Cheers,

Frank

Well, with the right tools, it doesn't destroy it, but there are far easier ways of connecting/centering the thread to/vs the magnet. All described in this thread....

Seems like a pilgrimage to many, - everyone finds his own way to Rome(or wherever...) in the end.

Cheers,

Frank

Thank you sir. pardon me for the drawing. It was not in proportion or to the scale. Just a quick drawing of a variation I thought. Exit hole can be made conical. Other variation would be to keep tonearm wand implementation same as your design but the bottom magnet would be free to self align.Hello Hiten,

The above method of fixating the thread will work, everything else won't, particularly not if the proportions in your drawing are realized.

In addition, the bearing will now be MUCH less rigid AND the (desirable)eddy current damping will be lower for the same distance between the magnets.

Lastly, the "exit" hole for the thread(as drawn) gives way too little room for the thread. The thread would touch the rim when tracing even modestly warped records or when a VTA setting different from "horizontal" is required...

Cheerio,

Frank

----

stoN_Cold

There is no mechanical work on magnet. We just have to choose appropriate material to make centre disc which can be easily drilled and press fitted.

Best Regards.

I dont want to step on anyones tails here

I am not interested in building Franks arm ..I have my own design but I would like to offer up my machining skills ..

I could drill the magnets for you guys/gals for a small cost which i would leave up to you guys to decide what would be fair....

I am not currently working so i figured that there maybe a need for this...

if I am out of line I apologize just remove my post..

Cheers

Lawrence

I am not interested in building Franks arm ..I have my own design but I would like to offer up my machining skills ..

I could drill the magnets for you guys/gals for a small cost which i would leave up to you guys to decide what would be fair....

I am not currently working so i figured that there maybe a need for this...

if I am out of line I apologize just remove my post..

Cheers

Lawrence

Arm Setup

Hi All,

Just got my arm initially set up on the turntable and decided to run through the tests on the hifi news test record .I am using a Denon 103 in my arm and calculated the effective mass to be somewhere about 20 grams .Starting with the arm resonance tests all seemed well the resonance started at 11hz still there at 9hz at 7Hz the arm was stable but at 5Hz the arm started a slow resonance .Haven't seen this happen on any of my previous arms which where all unipivots anybody suggest what might be happening.

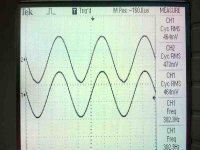

Moving onto the track ability tests I don’t trust my ears so usually attach a scope to look at the waveforms ,the arm tracked through the +12dB ,+14dB and the +15dB tracks with no distortion it was only when I got to the +16dB track I could see a slight distortion on the RH channel starting to creep in .I had initially set the bias so the arm moved slowly in on a blank disc as has been suggested ,turning the bias wheel anti clock wise did remove the distortion but the bias was so much that when trying to cue a record the needle would pull hard to the right and try and jump off the record .Returning the bias to it’s previous setting I increased the tracking force to 2.6 Grams this cleared the distortion but Is obviously getting near to the Denons recommend limit of 2.7 Grams.My previous unipivot flew through all the bias settings only failing on the +18db track with the tracking force set at 2. 5 Grams

Would increasing the effect mass of the arm affect the track ability off the cartridge and remove the very low 5Hz resonance seen or is the resonance present because of insufficient damping with the magnetic bearing .

Mike

Hi All,

Just got my arm initially set up on the turntable and decided to run through the tests on the hifi news test record .I am using a Denon 103 in my arm and calculated the effective mass to be somewhere about 20 grams .Starting with the arm resonance tests all seemed well the resonance started at 11hz still there at 9hz at 7Hz the arm was stable but at 5Hz the arm started a slow resonance .Haven't seen this happen on any of my previous arms which where all unipivots anybody suggest what might be happening.

Moving onto the track ability tests I don’t trust my ears so usually attach a scope to look at the waveforms ,the arm tracked through the +12dB ,+14dB and the +15dB tracks with no distortion it was only when I got to the +16dB track I could see a slight distortion on the RH channel starting to creep in .I had initially set the bias so the arm moved slowly in on a blank disc as has been suggested ,turning the bias wheel anti clock wise did remove the distortion but the bias was so much that when trying to cue a record the needle would pull hard to the right and try and jump off the record .Returning the bias to it’s previous setting I increased the tracking force to 2.6 Grams this cleared the distortion but Is obviously getting near to the Denons recommend limit of 2.7 Grams.My previous unipivot flew through all the bias settings only failing on the +18db track with the tracking force set at 2. 5 Grams

Would increasing the effect mass of the arm affect the track ability off the cartridge and remove the very low 5Hz resonance seen or is the resonance present because of insufficient damping with the magnetic bearing .

Mike

Hello Mike,

Adjusting the bias, aka "antiskating" so the distorsion figures for both channels are equal when the maximum tracking ability is reached does result in overcompensation for "normal" or average modulation level playback. Skating force depends upon the offset angle and the friction occuring when the stylus traces the grooves, - many factors influence the friction: tracking force, stylus profile, quality of stylus contact zone polish, vinyl formulation, MODULATION... so whatever you set your antiskating to, it will always be a compromise as the required force changes between 4 and 18% of the VTF. Go for what you did initially and you ought to experience a more focussed and dynamic presentation due to a lower side thrust on the cantilever.

The 5hz secondary resonance is a result of the low slung counterweights cog being too low. Increasing the eff. mass of the arm will not change that...

How stiff is your tonearm wiring?

Happy holiday weekend to all!

Frank

Adjusting the bias, aka "antiskating" so the distorsion figures for both channels are equal when the maximum tracking ability is reached does result in overcompensation for "normal" or average modulation level playback. Skating force depends upon the offset angle and the friction occuring when the stylus traces the grooves, - many factors influence the friction: tracking force, stylus profile, quality of stylus contact zone polish, vinyl formulation, MODULATION... so whatever you set your antiskating to, it will always be a compromise as the required force changes between 4 and 18% of the VTF. Go for what you did initially and you ought to experience a more focussed and dynamic presentation due to a lower side thrust on the cantilever.

The 5hz secondary resonance is a result of the low slung counterweights cog being too low. Increasing the eff. mass of the arm will not change that...

How stiff is your tonearm wiring?

Happy holiday weekend to all!

Frank

bias setting

Hi Frank,

I am using a very fine hi purity copper single strand cable loosely twisted into two pairs it measures 6 thou diameter and seems to impose little restriction on the arm movement.My weight is just slightly off centre so not greatly low slung.Would the 5Hz resonance cause a issue during normal record playing as it is well out of the audio band .

I reset my VTF TO 2.5g and set the bias to previous setting ,arm slowly moving to the centre on a blank disc.The slight distortion returned to the right channel( I have uploaded a picture from the scope) I tried moving the bias slightly either way but don’t seem to able to get it in both channels just in the right is this the comprise you mentioned .

Mike

Hi Frank,

I am using a very fine hi purity copper single strand cable loosely twisted into two pairs it measures 6 thou diameter and seems to impose little restriction on the arm movement.My weight is just slightly off centre so not greatly low slung.Would the 5Hz resonance cause a issue during normal record playing as it is well out of the audio band .

I reset my VTF TO 2.5g and set the bias to previous setting ,arm slowly moving to the centre on a blank disc.The slight distortion returned to the right channel( I have uploaded a picture from the scope) I tried moving the bias slightly either way but don’t seem to able to get it in both channels just in the right is this the comprise you mentioned .

Mike

Attachments

Hello Mike,

Try the following: track a high quality mono record(i.e. Sonny Rollins : Saxophone Colossus) with your stereo cart, but only the left channel, then the right channel. Rendering of dynamics ought to be identical in both channels, an overcompensation of the skating force will be audible(reduced dynamic shading, truncated maximum peaks).

Trust your ears...

Normal records are not supposed to contain any semi-permanent modulation above 50µ, peaks can hit 80µ. On some Techno 45s and Direct to Disc records peaks can exceed 150µ. Impossible for any cart to track cleanly anyway.

Best,

Frank

Try the following: track a high quality mono record(i.e. Sonny Rollins : Saxophone Colossus) with your stereo cart, but only the left channel, then the right channel. Rendering of dynamics ought to be identical in both channels, an overcompensation of the skating force will be audible(reduced dynamic shading, truncated maximum peaks).

Trust your ears...

Normal records are not supposed to contain any semi-permanent modulation above 50µ, peaks can hit 80µ. On some Techno 45s and Direct to Disc records peaks can exceed 150µ. Impossible for any cart to track cleanly anyway.

Best,

Frank

Hi,

Excellent musical taste too.

Respect,

Try the following: track a high quality mono record(i.e. Sonny Rollins : Saxophone Colossus)

Excellent musical taste too.

Respect,

Is this correct? .....

the bottom magnet should be level with record? and if so, how does one make certain this has been obtained?

the top magnet should be level in all directions with bottom magnet?

I'm having real trouble determining when the bottom magnet is 'level' and also getting the top magnet to match the bottom magnet seems impossible......

has anyone successfully glued a metal or brass washer to a maget? I tried two types of superglue with no success. I don't know if glue and magets go together

the bottom magnet should be level with record? and if so, how does one make certain this has been obtained?

the top magnet should be level in all directions with bottom magnet?

I'm having real trouble determining when the bottom magnet is 'level' and also getting the top magnet to match the bottom magnet seems impossible......

has anyone successfully glued a metal or brass washer to a maget? I tried two types of superglue with no success. I don't know if glue and magets go together

Last edited:

Hi,

"the bottom magnet should be level with record? and if so, how does one make certain this has been obtained?"

Yes, it should be. If its Aluminum housing was turned/bored in one go and the top is cut at a perfect 90° angle, it will be. Many other options to achieve that...

"the top magnet should be level in all directions with bottom magnet?"

How can it be when the armwand moves up and down in use or possibly end s up slightly turned along its axis to achieve perfect Azimuth...?

"I'm having real trouble determining when the bottom magnet is 'level' and also getting the top magnet to match the bottom magnet seems impossible......"

Put the bottom disc housing(with the magnet pressed in) in a high quality chuck, or better, stepped collet, then attach an iron disc(or a bar) to the front(where the magnet ought to be)and turn it. If you see any "wobble" it should be clear what to do next

Cheers,

Frank

"the bottom magnet should be level with record? and if so, how does one make certain this has been obtained?"

Yes, it should be. If its Aluminum housing was turned/bored in one go and the top is cut at a perfect 90° angle, it will be. Many other options to achieve that...

"the top magnet should be level in all directions with bottom magnet?"

How can it be when the armwand moves up and down in use or possibly end s up slightly turned along its axis to achieve perfect Azimuth...?

"I'm having real trouble determining when the bottom magnet is 'level' and also getting the top magnet to match the bottom magnet seems impossible......"

Put the bottom disc housing(with the magnet pressed in) in a high quality chuck, or better, stepped collet, then attach an iron disc(or a bar) to the front(where the magnet ought to be)and turn it. If you see any "wobble" it should be clear what to do next

Cheers,

Frank

started a new build. 1st did not end up working......this one I cannot get the magnet to settle down. it either cants to one side or the other.....

https://www.youtube.com/watch?v=3fxrnhOgs6o&feature=youtu.be

it could be the knot is too large. I already committed to the hole as it is glued in behind magnet. I wanted to avoid glueing but that is what ended my 1st arm's progress. So I had to glue it in there. It's not exactly centered (but real close). So not sure what is wrong here

the other challenge is (and has been) getting the two magnet's to parallel one another. In the end I had to sand a touch (.5mm) the top one seen in pic here to result in parallel. that may also be part the problem as seen in vid?. but i've spent maybe 50 hours (seems like 200) on this project with not a working arm! so I ordered a rega. Compromise and reality always win in the end

https://www.youtube.com/watch?v=3fxrnhOgs6o&feature=youtu.be

it could be the knot is too large. I already committed to the hole as it is glued in behind magnet. I wanted to avoid glueing but that is what ended my 1st arm's progress. So I had to glue it in there. It's not exactly centered (but real close). So not sure what is wrong here

the other challenge is (and has been) getting the two magnet's to parallel one another. In the end I had to sand a touch (.5mm) the top one seen in pic here to result in parallel. that may also be part the problem as seen in vid?. but i've spent maybe 50 hours (seems like 200) on this project with not a working arm! so I ordered a rega. Compromise and reality always win in the end

Attachments

Last edited:

Hi,

Your question has been answered several times in this thread. Might be taking too much time to look it up, so:

When your current arrangement shows unstable behaviour, you could

1: use smaller diameter magnets(height needs to remain the same)

2: attach the thread farther up, relative to the lower magnet. In other words, raise the attachment point of the thread

3: (not recommended) use a counterweight with a lower center of gravity(relative to the bearing level)

Other options do exist, but the above seem to be within your reach.

Don't give up and

good luck!

Frank

Your question has been answered several times in this thread. Might be taking too much time to look it up, so:

When your current arrangement shows unstable behaviour, you could

1: use smaller diameter magnets(height needs to remain the same)

2: attach the thread farther up, relative to the lower magnet. In other words, raise the attachment point of the thread

3: (not recommended) use a counterweight with a lower center of gravity(relative to the bearing level)

Other options do exist, but the above seem to be within your reach.

Don't give up and

good luck!

Frank

So I had to glue it in there.

I glued 2.

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm???