Interesting about Maggies:

http://images.google.com/imgres?img...agnepan+MG1&start=21&gbv=2&ndsp=21&hl=sv&sa=N

(sorry for the conspicuously long url address)

http://images.google.com/imgres?img...agnepan+MG1&start=21&gbv=2&ndsp=21&hl=sv&sa=N

(sorry for the conspicuously long url address)

Samppo said:magnepan uses some sort of restrictors (knobs) to restrict movement of the woofer section..not only good necessary, might explain the less dynamic low end

yeah its because otherwise the membrane would slap into the metal plate in front, i have one set that is doing exactly that at high volumes

Samppo said:magnepan uses some sort of restrictors (knobs) to restrict movement of the woofer section..not only good necessary, might explain the less dynamic low end

That is a possibility, however the more likely explanation is due to the load being presented to the amplifier. Panel speakers are both inefficient & low impedance. This is tough for an amp to drive, especially for transients and percussives in the music.

i heard it once and then tried , with a test generator, sinus of 60 hertz. it ehas flapping unless i pressed on certain point of the frame.

Is it the non linearity of the amp that is doing this ?distortion ? because normaly with my electrostatic speakers this wont occur, is also a 4 ohm load. magnepan SMG1 improved is 5 ohm. should be no problem, but its a hybrid system with a cone for the low notes

Is it the non linearity of the amp that is doing this ?distortion ? because normaly with my electrostatic speakers this wont occur, is also a 4 ohm load. magnepan SMG1 improved is 5 ohm. should be no problem, but its a hybrid system with a cone for the low notes

Resonance

I'm not an expert on magnetic planars, but I've built electrostatic speakers since 1974. In ESL:s its very important to get the right

tension of the membrane, and my experience is that 50-55 Hz

for the first resonance freq is a good value. If you go down to a lower value, the speaker sounds thin and "non-transientic" with added useless "cheap sub woofer" output. If you go higher You will get "bookshelf speaker bass", which is not so funny!

I'm not an expert on magnetic planars, but I've built electrostatic speakers since 1974. In ESL:s its very important to get the right

tension of the membrane, and my experience is that 50-55 Hz

for the first resonance freq is a good value. If you go down to a lower value, the speaker sounds thin and "non-transientic" with added useless "cheap sub woofer" output. If you go higher You will get "bookshelf speaker bass", which is not so funny!

Hmm, anybody know where to find insulated aluminium wire or magnet wire in the netherlands ? because the replacement sets of magnepan are abnormal expensive over here

It must be insulated?

ok well for now , i will make some mid/high panels from a pair of old MG1's going to cut the panel betweet the high part and the mid bass panel make new spacers and place new foil way thinner than the foil used by magnepan, and because my rig to tension the mylar is no longer as 55 cm i will cut the panel in two as well, will stack to of those panels for one speaker. and will use cone driver for the low notes. after all that i still have all the 48 lanes of wider magnet stuff to make some more panels that are a little bit wider than the first one so of axes response will be a bit worse in the hgh frequency department but can still make a nice dipool. or 2

rebuilds

I am in the process of rebuilding my 20 year old full range planar which used ferrites. I have cut the alu foil down to 4.5 mm wide and I am using thinner black plastic bin liners from tescos. The sensitivity is increased significantly by using the lightest membrane you can manage. If it is a success using the thinner plastic, I will rebuild all my planars (10 pairs +). Using the thinner membrane design. You learn as you go along. It keeps my mind active and at my age 72 it's a good thing. HENRY.

My planars go down to about 20 hertz. They also don't require crossovers or transformers or high voltages just 2 or 3 resistors. Depending on the size and impedance of the membrane.

My planars go down to about 20 hertz. They also don't require crossovers or transformers or high voltages just 2 or 3 resistors. Depending on the size and impedance of the membrane.

I am in the process of rebuilding my 20 year old full range planar which used ferrites. I have cut the alu foil down to 4.5 mm wide and I am using thinner black plastic bin liners from tescos. The sensitivity is increased significantly by using the lightest membrane you can manage. If it is a success using the thinner plastic, I will rebuild all my planars (10 pairs +). Using the thinner membrane design. You learn as you go along. It keeps my mind active and at my age 72 it's a good thing. HENRY.

My planars go down to about 20 hertz. They also don't require crossovers or transformers or high voltages just 2 or 3 resistors. Depending on the size and impedance of the membrane.

My planars go down to about 20 hertz. They also don't require crossovers or transformers or high voltages just 2 or 3 resistors. Depending on the size and impedance of the membrane.Re designs,rebuilds.

Here are my pics, hope this helps with ideas etc.

jamesbos's Uploaded Images - Imgur

Here are my pics, hope this helps with ideas etc.

jamesbos's Uploaded Images - Imgur

Interesting thread..

Been playing around with this idea as well for a long time and simulating with Femm. I think I will stick with long neo magnets, not too wide ones to get a small gap and enough turns of the foil (keep impedance up). With short magnets there will be alot of glueing, been there and don't want to do it again..

First maybe try some smaller planars, size of Apogee Stage, and if it works out make another pair and stack them

Cost of magnets is an issue though, but China has alot to offer. Has anyone tried ordering magnets from there, direct from a factory?

yes I have bought a few thousand magnets from china and have been quite happy with their response.The postage is dear but they are still cheaper than anywhere else.I have designed several new designs using the epsilon diaphragm layout, even using ferrites the sensitivity is very much higher than my previous design which only used the interface with the N S layout.My latest design uses 360 50 x 12.7 x 6 mm neos. I had laying around. Using the epsilon diaphragm layout or my modification of it! The sensitivity is far beyond any design I had built before and I have built well over 30 full range planars. Using both neos and ferrites of differing sizes, from 60 x 40 cm to 7' x 2'. After modifying the epsilon layout, I have come to the conclusion I will have to rebuild all my designs as the increase in sensitivity is so spectacular .

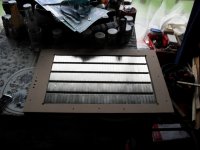

I already have built one with gaps between magnets, but it is not worth the effort of using glue they become very delicate and you have to move them very gingerly or the magnets come adrift .Unless you use a lot of glue!! The large one using ferrites, too dear with neos. The small one uses smaller magnets and it is just as sensitive, with no gaps between magnets so waste of effort using gaps believe me. I speak from experience. You can just see the small one on the right. In the second picture. In the first picture you can see the 60 x 40 cm using the 6 mm neos on the floor.

You can just see the small one on the right. In the second picture. In the first picture you can see the 60 x 40 cm using the 6 mm neos on the floor.

Attachments

Last edited:

Ok!

But you can glue distant-keeper strips of the same perforated material as the magnets are glued on, and aligning the holes. This would, I think spare You a lot of magnets and distortion.

Don't think so, that's even more fiddly cutting the perforated steel, it's hard enough cutting the perforated sheet once with scissors. So cutting it into long strips is almost impossible as it would form a circle as you went along at that width.Getting the holes lined up would be even more of a dilemma!!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- DIY Planar magnetic Hybride

, can't You build a version with some space between the magnets? Maybe a magnets widht between magnets? Please?

, can't You build a version with some space between the magnets? Maybe a magnets widht between magnets? Please?