A lower compliance cartridge would be easier to set up. Warrjon

Judging the TAs with the eyes (and a macroscope) is surely easier than with the ears: in criminal trials, eyewitnesses count much more than hearsay.

When seeing the cantilever dancing on eccentricities, I think that the arm is just for garbage. It is clear that with a soft cartridge the effect is more evident, but if it moves less with a hard one, I don't think it is better at all, just less apparent. Probably the effects on the signal are absolutely identical, because a stiffer cartridge simply obtains them from smaller amplitude, but identical, movements

To think that LTs with too much friction may work with low compliance or with very high VTF seems too optimistic, too benevolent for our creatures. Reminds me the rail tilting.

Walter posed the question on cartridge behavior on #3006 - #3026, and I had been looking for an answer on #3027-28, but the theme maybe deserves to be further discussed.

I'm not sure if that summary is for me or another user. hjam

No, for everyone more or less within my same troubles: trying to design another carriage + rail (for a Lil Casey Mk3). With some "small" restrictions: no forward sliding, no pivot shifting, no chattering, almost no resonances. Of course with vert. / hor. friction near 1.0 mN.

Enlarge the details as possible - you'll notice that very few solutions can meet those requirements. While tracking the pivot shift will be minimal for sure, but stylus movements are even smaller.

Forgot to mention, for a radial rail TA: no tilting, and the compound -cartridge+carriage+rail+levers- < 25 gr, balls & screws included. Otherwise, I can remain with my present Mk2 carbon.

carlo

Judging the TAs with the eyes (and a macroscope) is surely easier than with the ears: in criminal trials, eyewitnesses count much more than hearsay.

When seeing the cantilever dancing on eccentricities, I think that the arm is just for garbage. It is clear that with a soft cartridge the effect is more evident, but if it moves less with a hard one, I don't think it is better at all, just less apparent. Probably the effects on the signal are absolutely identical, because a stiffer cartridge simply obtains them from smaller amplitude, but identical, movements

To think that LTs with too much friction may work with low compliance or with very high VTF seems too optimistic, too benevolent for our creatures. Reminds me the rail tilting.

Walter posed the question on cartridge behavior on #3006 - #3026, and I had been looking for an answer on #3027-28, but the theme maybe deserves to be further discussed.

I'm not sure if that summary is for me or another user. hjam

No, for everyone more or less within my same troubles: trying to design another carriage + rail (for a Lil Casey Mk3). With some "small" restrictions: no forward sliding, no pivot shifting, no chattering, almost no resonances. Of course with vert. / hor. friction near 1.0 mN.

Enlarge the details as possible - you'll notice that very few solutions can meet those requirements. While tracking the pivot shift will be minimal for sure, but stylus movements are even smaller.

Forgot to mention, for a radial rail TA: no tilting, and the compound -cartridge+carriage+rail+levers- < 25 gr, balls & screws included. Otherwise, I can remain with my present Mk2 carbon.

carlo

Last edited:

A lower compliance cartridge would be easier to set up. Warrjon

Judging the TAs with the eyes (and a macroscope) is surely easier than with the ears: in criminal trials, eyewitnesses count much more than hearsay.

When seeing the cantilever dancing on eccentricities, I think that the arm is just for garbage.

carlo

I Don't think I explained that very well. The video I posted was BEFORE I made the larger wheels and added the stylus brush. After I did this the cantilever dancing was almost eliminated. Bear in mind this arm is a prototype and cost under $100AUD ($70USD), and sounds better than a very good Technics EPA100 pivoting arm that cost $2000.00. This LT is not garbage it sounds better than any TA I have had - SME, Ittok and EPA100 to name a couple, can it be better, yes it can.

I am gathering parts to make a better arm. Carbide (or O1 silver steel) rods in place of the borosilicate, which are NOT uniform, they are actually elliptical. Better wheels with SS rings on carbon fibre wheels. I will tolerance everything to ensure the horizontal friction does not pull the stylus off centre.

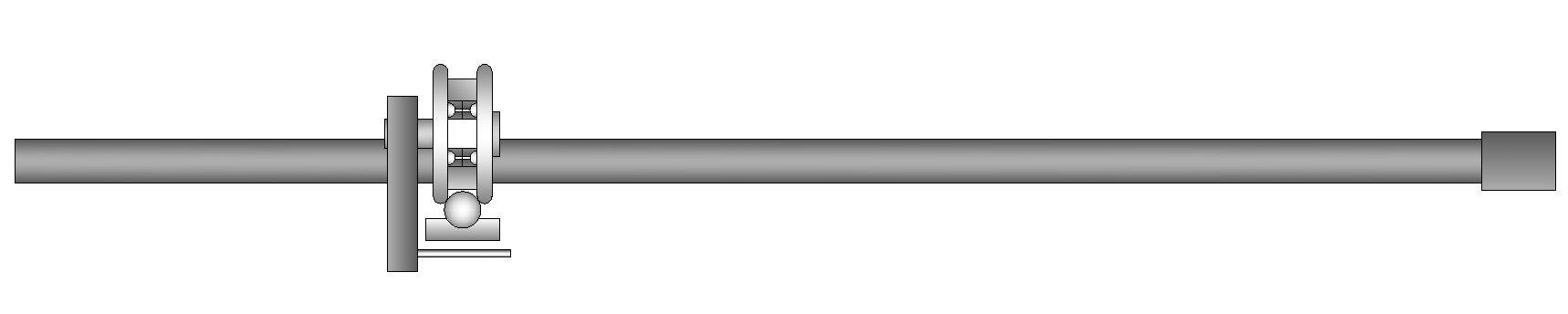

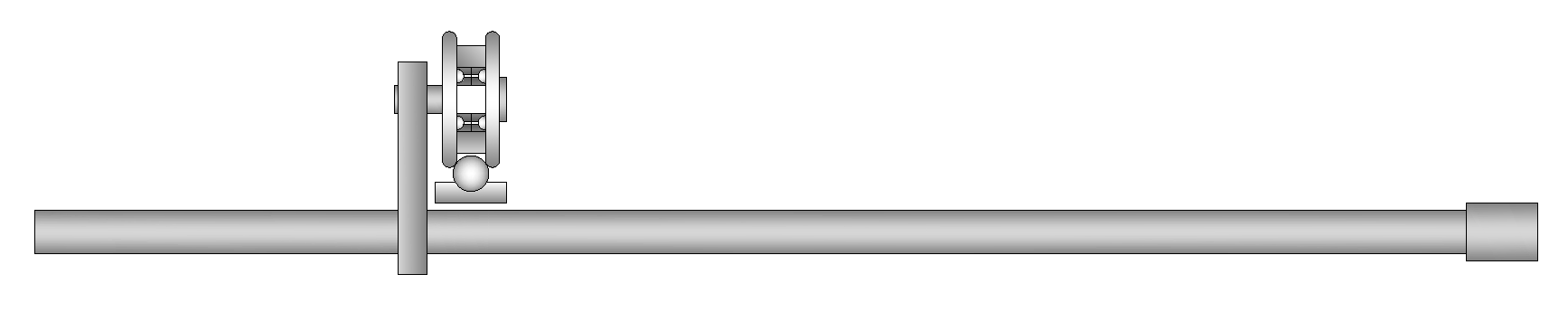

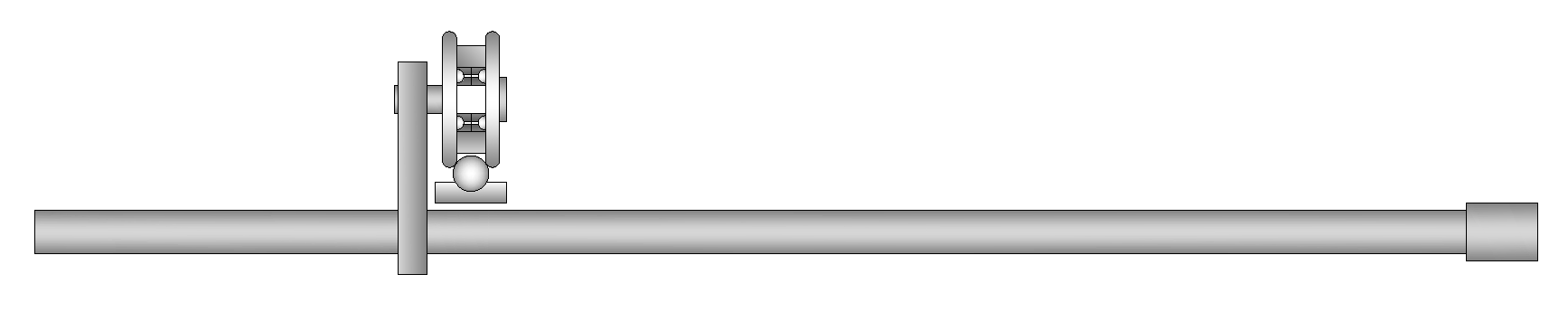

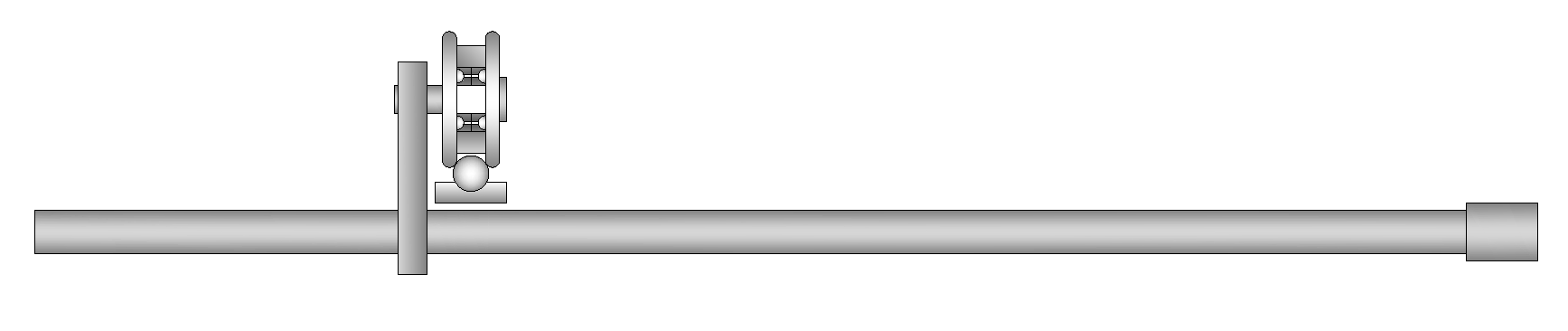

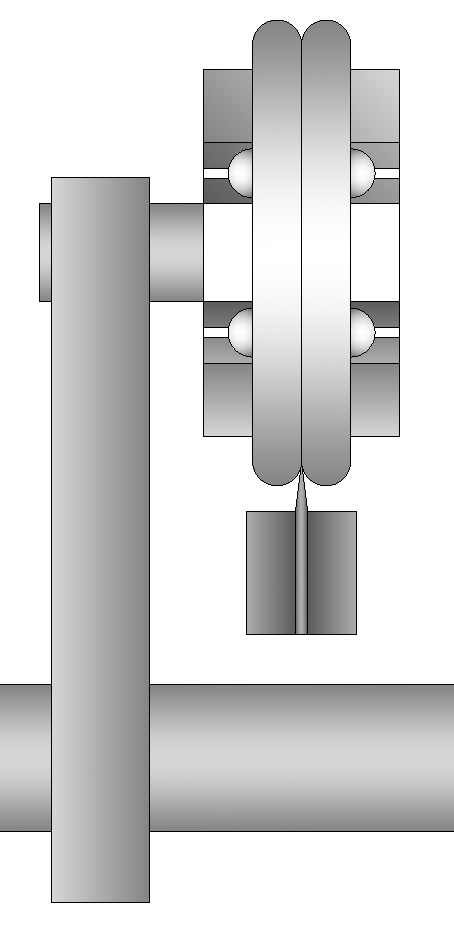

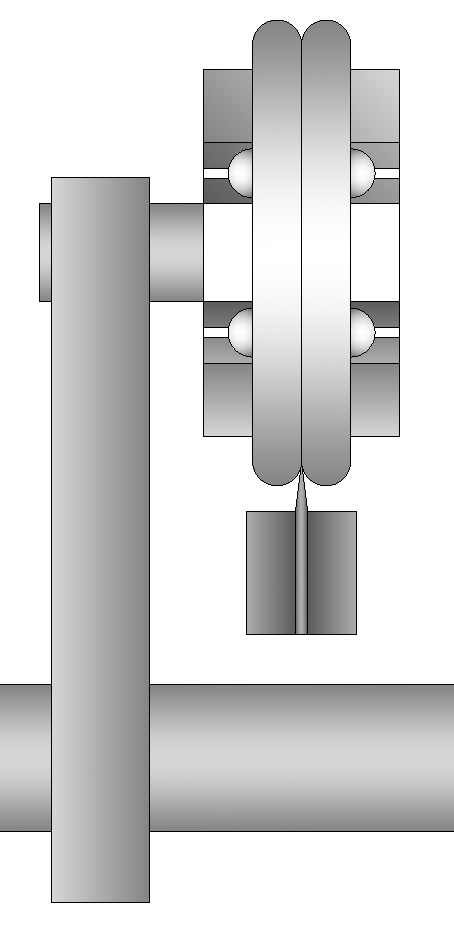

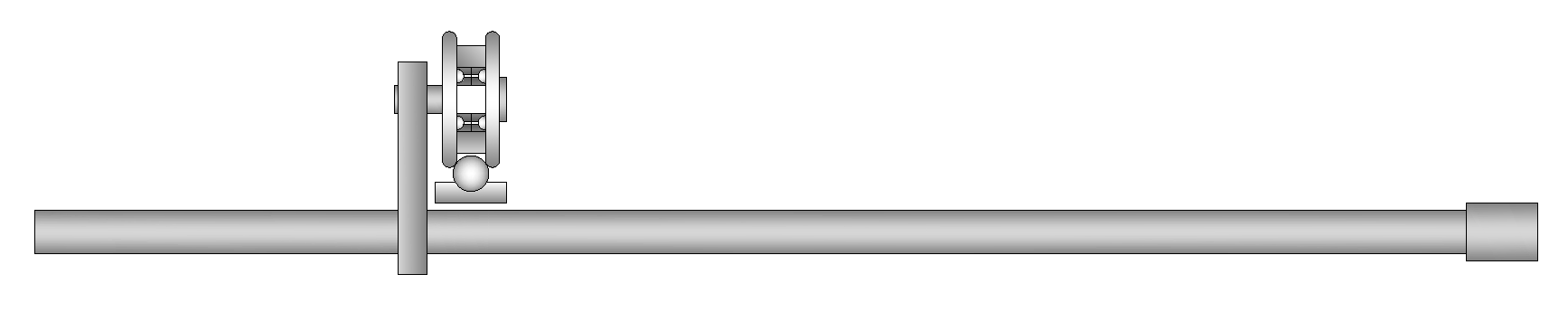

Next drawing. Dual abec-9 bearings pressed to a 9x15x8mmtube and two tungsten rings to form this contraption.

http://www.dahlbergaudiodesign.se/images/linear_5.png

http://www.dahlbergaudiodesign.se/images/linear_5.png

Next drawing. Dual abec-9 bearings pressed to a 9x15x8mmtube and two tungsten rings to form this contraption.

http://www.dahlbergaudiodesign.se/images/linear_5.png

Interesting approach. I look forward to seeing how this develops.

Niffy

Yes very interesting. Have you thought about swapping the arm wand so it's above the rail. This way you can lower the rail and get the COM close to the pivot, this will reduce VTF variation as the arm tracks warps.

The only snag is making some mechanism to move the rail away from the platter for record changes.

The only snag is making some mechanism to move the rail away from the platter for record changes.

Another idea, think slightly dulled down long carpet knife. The armwand is fairly

long so movement due to woobly records schould be quite small. It would make

record changes easier as well. Not sure about arm material but what I have at

hand now is the 200mm titanium rod (13.5gr). I'm thinking that a crossbow

arrow could make a decent arm as well if weight seems to be a problem.

long so movement due to woobly records schould be quite small. It would make

record changes easier as well. Not sure about arm material but what I have at

hand now is the 200mm titanium rod (13.5gr). I'm thinking that a crossbow

arrow could make a decent arm as well if weight seems to be a problem.

Warrjon, evidently i've not explained properly what I meant:

I knew very well that was the video before the cure, and I had very much appreciated that you had posted it (as I did with Lil Casey 1 and 2). Many tell us about subtle changes that induce extraordinary improvements in sound, but there are very few videos around to see the cantilever behavior. Yet they are so simple to make, and to measure too.

What I doubt instead is that an arm in troubles with a high comp. can work well with a low comp: certainly the cantilever moves less, and there can be less skipping because the side force exerted can be bigger, but the damage on the signal maybe is not so different. A smaller bending in a low comp. probably distorts as much as a bigger one in a high comp, because it affects different generators, sized for less or more amplitude of movements.

I posted this as a hypothesis to be discussed, a doubt, not as a revealed truth.

carlo

the compliance to which I refer is only the elastic system of the cartridge. Arm matching here does not interest me

I knew very well that was the video before the cure, and I had very much appreciated that you had posted it (as I did with Lil Casey 1 and 2). Many tell us about subtle changes that induce extraordinary improvements in sound, but there are very few videos around to see the cantilever behavior. Yet they are so simple to make, and to measure too.

What I doubt instead is that an arm in troubles with a high comp. can work well with a low comp: certainly the cantilever moves less, and there can be less skipping because the side force exerted can be bigger, but the damage on the signal maybe is not so different. A smaller bending in a low comp. probably distorts as much as a bigger one in a high comp, because it affects different generators, sized for less or more amplitude of movements.

I posted this as a hypothesis to be discussed, a doubt, not as a revealed truth.

carlo

the compliance to which I refer is only the elastic system of the cartridge. Arm matching here does not interest me

Last edited:

to be even clearer

if one says: my LT has a very high effective vert. and/or hor. mass (it happens on LTs), then I need a low comp. cartridge (for resonance), I agree with him completely.

but if he says: I have a very high friction (it happens on LTs) then I need a low comp. cartridge (for bending), I can't no longer agree.

You simply need to reduce the friction. Exactly what you've done

c

if one says: my LT has a very high effective vert. and/or hor. mass (it happens on LTs), then I need a low comp. cartridge (for resonance), I agree with him completely.

but if he says: I have a very high friction (it happens on LTs) then I need a low comp. cartridge (for bending), I can't no longer agree.

You simply need to reduce the friction. Exactly what you've done

c

Next drawing. Dual abec-9 bearings pressed to a 9x15x8mmtube and two tungsten rings to form this contraption.

http://www.dahlbergaudiodesign.se/images/linear_5.png

That is indeed an interesting design. If you can find a low noise ball bearing, I think it will work very well.

Warrjon, evidently i've not explained properly what I meant:

I knew very well that was the video before the cure, and I had very much appreciated that you had posted it (as I did with Lil Casey 1 and 2). Many tell us about subtle changes that induce extraordinary improvements in sound, but there are very few videos around to see the cantilever behavior. Yet they are so simple to make, and to measure too.

I will make another video today and post it, I might take an old record and make it more off centre to test the arms tracking. The only time the stylus miss tracks now is if the arm wire touches the rail support. This will be fixed in the next iteration with an aluminium tube through the arm (for shielding) and down the rail.

If this arm sounds this good then once I have a better arm with a rail that is more uniform it should improve the sound more. The Borosillicate tubes I used are not very even, I did roll all of the ones I have on my granite surface plate and pick the best, but you could still hear the uneven roll.

I have not done any spectral analysis on this arm as I know it has flaws. I do however plan to measure my next arm. My goal is to move the main arm bending mode to the top of the audio spectrum and to reduce horizontal effective mass so the cartridge tracks without CL deflection. The CL deflection as seen in my video will produce a low frequency signal (1.1Hz) which will be modulated on the audio signal. Vertical effective mass seems to be ok the vertical movement of the arm as it tracks minor undulations is stable, I do not have any badly warped records, I may have to make one for testing.

Last edited:

Really a good result, congratulations Warren - especially considering the previous one, and the compliance of that stylus: time spent for lathing wasn't surely wasted. And thanks for the new video.

Measuring the displacement of the tip with respect to the cartridge into the frames with maximum bending can give you interesting data.

Before doing another arm (but that's our fun) I would try even to drastically decrease the weight of the plexy head shell.

carlo

...it shouldn't be difficult to find rails better than the glass ones

Measuring the displacement of the tip with respect to the cartridge into the frames with maximum bending can give you interesting data.

Before doing another arm (but that's our fun) I would try even to drastically decrease the weight of the plexy head shell.

carlo

...it shouldn't be difficult to find rails better than the glass ones

Last edited:

An addition: it is interesting to observe (already learned with pivoted ones) not only the quantity of the cantilever movement, but also the quality. Maybe the amplitude comes from the friction, while the delay with respect to the carriage, from the hor. eff mass.

If you measure the video frame, it is also interesting to look at how much the carriage moves relative to the length of the eccentricity: it could be less (the stylus was unable to transmit the movement to the carriage) but even more. (the inertia of the carriage drags the stylus beyond the eccentricity)

If you measure the video frame, it is also interesting to look at how much the carriage moves relative to the length of the eccentricity: it could be less (the stylus was unable to transmit the movement to the carriage) but even more. (the inertia of the carriage drags the stylus beyond the eccentricity)

Last edited:

Hi Warrjon,

Definitely an improvement on the previous video.

Judging from the video I would say that the eccentricity of the record is about 0.75mm (resulting in a side to side movement of 1.5mm). If your carriage weighs in at 70g, and a compliance of 30um/mN, then I would expect the deflection at the stylus to be about 0.02mm due to inertia alone. The stylus actually appears to be deflecting by about 0.2mm. It would appear that friction is still the predominant cause of stylus displacement. A 0.2mm deflection is still going to result in almost 2° of lateral tracking error, 1.8° due to friction. Even with this level of LTA error the arm still smoked your 2K reference arm. This confirms that the improvement in sound of a short tube linear arm is due to its resonance characteristics (or lack there of) rather than the reduction in LTA error.

You're definitely moving in the right direction. Good luck with your further developments.

Niffy

Definitely an improvement on the previous video.

Judging from the video I would say that the eccentricity of the record is about 0.75mm (resulting in a side to side movement of 1.5mm). If your carriage weighs in at 70g, and a compliance of 30um/mN, then I would expect the deflection at the stylus to be about 0.02mm due to inertia alone. The stylus actually appears to be deflecting by about 0.2mm. It would appear that friction is still the predominant cause of stylus displacement. A 0.2mm deflection is still going to result in almost 2° of lateral tracking error, 1.8° due to friction. Even with this level of LTA error the arm still smoked your 2K reference arm. This confirms that the improvement in sound of a short tube linear arm is due to its resonance characteristics (or lack there of) rather than the reduction in LTA error.

You're definitely moving in the right direction. Good luck with your further developments.

Niffy

My carriage is 30g including cartridge. The main issue with the arm is the borosilliate tubes not being uniform, there is 1 spot on the rail where there is a change in diameter that before I made the larger wheels always made the arm jump and mistrack. The carbide rods arrived yesterday and out of 4 I ordered 2 are very bent and 2 will be acceptable 0.10mm deflection in the middle. The pics are of the worst one, it's so bad it will not roll easily on the granite surface plate, it rocks back and forth.

I bought a couple of sheets of carbon fibre 3.0 & 0.75mm to make a better carriage, The carbide rings I ordered I only received 1 so I have some 19mm 316SS tube I'll make my own wheels with this and 3.0mm carbon fibre for the hub. I started machining the new arm yesterday when I have it almost finished I'll post some pics.

I bought a couple of sheets of carbon fibre 3.0 & 0.75mm to make a better carriage, The carbide rings I ordered I only received 1 so I have some 19mm 316SS tube I'll make my own wheels with this and 3.0mm carbon fibre for the hub. I started machining the new arm yesterday when I have it almost finished I'll post some pics.

Attachments

Even with this level of LTA error the arm still smoked your 2K reference arm. This confirms that the improvement in sound of a short tube linear arm is due to its resonance characteristics (or lack there of) rather than the reduction in LTA error.

You're definitely moving in the right direction. Good luck with your further developments.

Niffy

Hi Niffy,

The difference is not subtle. The bass dynamics are where the difference is most noticeable. If the current LTA is this good with all of the deficiencies it has I can't wait to hear the new arm where I'll have most of these problems solved.

Hi Warrjon,

If the carriage mass is only 30g then the stylus deflection due to inertia on your torture record would be only about 8um. This would give an LTA error of 0.08° which is going to be completely inaudible. Of course the inertia effects with records with only average eccentricity will be much lower than this again. So don't worry about the inertia of the arm causing any problems.

Sorry to hear about your carbide supply problems. The rods I got from Joe were perfectly straight. They weren't polished to a high finish but an afternoon buffing sorted that. The rings were surprisingly round, varying by only about 10um.

Improving the quality of the bearings made a lot of difference to the sound of my arm. You're in for a real sonic treat.

Niffy

If the carriage mass is only 30g then the stylus deflection due to inertia on your torture record would be only about 8um. This would give an LTA error of 0.08° which is going to be completely inaudible. Of course the inertia effects with records with only average eccentricity will be much lower than this again. So don't worry about the inertia of the arm causing any problems.

Sorry to hear about your carbide supply problems. The rods I got from Joe were perfectly straight. They weren't polished to a high finish but an afternoon buffing sorted that. The rings were surprisingly round, varying by only about 10um.

Improving the quality of the bearings made a lot of difference to the sound of my arm. You're in for a real sonic treat.

Niffy

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm