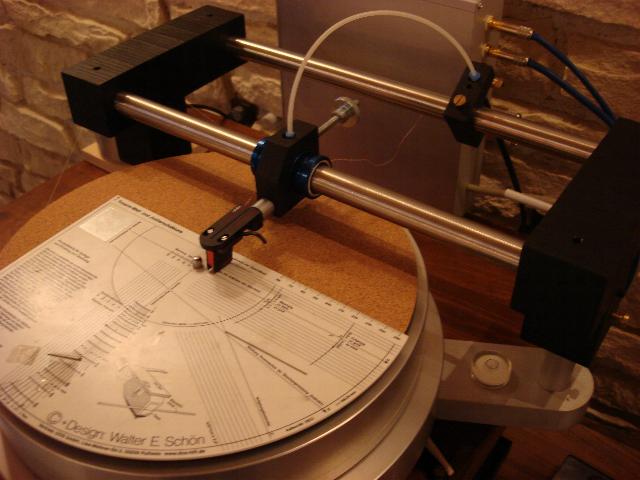

Here's my first lash up - proved it worked

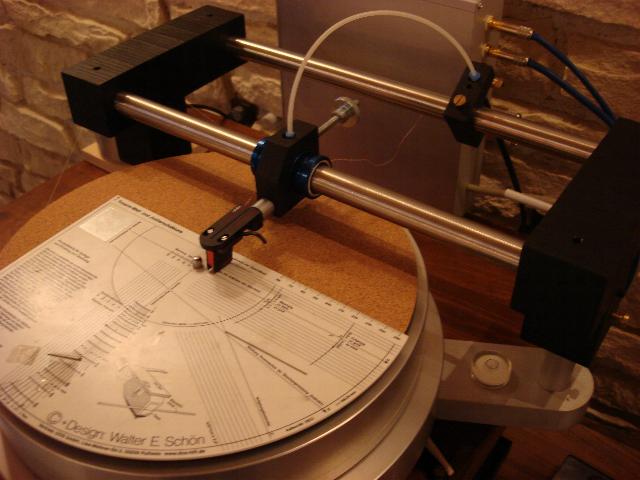

Here is my Terminator copy.

Worked very well with a 33 PGT but I would guess not with the low compliance fair I am now using.

shutting the air pump up needed a sealed MDF carpet damped box with 6 5mm air holes.

I also had it on a SL-1210 for a while.

Air pump box

Fun projects.

An externally hosted image should be here but it was not working when we last tested it.

Here is my Terminator copy.

Worked very well with a 33 PGT but I would guess not with the low compliance fair I am now using.

shutting the air pump up needed a sealed MDF carpet damped box with 6 5mm air holes.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I also had it on a SL-1210 for a while.

An externally hosted image should be here but it was not working when we last tested it.

Air pump box

An externally hosted image should be here but it was not working when we last tested it.

Fun projects.

I wonder....

I made my armtube holder in lignum vitae - think hard dense wood. But I've seen a few made here now in brass or alu. Do anyone know which might be better?

I went for the wood because I thought it would be lighter and therefore make the whole carriage lighter. But maybe I'm missing out?

Comments?

Fran

I made my armtube holder in lignum vitae - think hard dense wood. But I've seen a few made here now in brass or alu. Do anyone know which might be better?

I went for the wood because I thought it would be lighter and therefore make the whole carriage lighter. But maybe I'm missing out?

Comments?

Fran

I wonder....

I made my armtube holder in lignum vitae - think hard dense wood. But I've seen a few made here now in brass or alu. Do anyone know which might be better?

I went for the wood because I thought it would be lighter and therefore make the whole carriage lighter. But maybe I'm missing out?

Comments?

Fran

I think that will depend on the compliance of the cart you are using.

You can see on one of the shots above I have extra angle aluminium on top that improved the sound. Can also play with massing the vertical too. Of course the air lift has to be able to carry it - Ultimately I think that is probably why they are not suitable for SPU's

mmm. I might just make up a crosspiece in alu and see does it make a difference. The problem is the table is sounding great at the moment, so I'm vey reluctant to touch anything!

FWIW, I've done a fair bit of messing with air supplies, and I think they make a large difference. Best so far has been 2 x aquarium pumps run in parallel. Gives the required airflow and at a low enough pressure.

Fran

FWIW, I've done a fair bit of messing with air supplies, and I think they make a large difference. Best so far has been 2 x aquarium pumps run in parallel. Gives the required airflow and at a low enough pressure.

Fran

Der AeroStatement

Just found another DIY arm from a German website that uses the New Way air-bearing bushing. Very cool! I think the name "AeroStatement" came from a pun on the Clearaudio Statement turntable that its linear mechanical arm uses an unusually wide mounting bridge.

http://methe-family.de/der_aerostatement.htm (German site translated via Google Translate)

.

.

Just found another DIY arm from a German website that uses the New Way air-bearing bushing. Very cool! I think the name "AeroStatement" came from a pun on the Clearaudio Statement turntable that its linear mechanical arm uses an unusually wide mounting bridge.

http://methe-family.de/der_aerostatement.htm (German site translated via Google Translate)

.

.

New Way air bearing bushing

According to member Paul Eber in this post who has successfully build an arm out of the bushing and here's his quote:

I think many already knew that the Kuzma Airline tonearm also uses the 20mm New Way bushing.

www.newwaydistributor.com/featuredapp.html - "Audiophiles Use Air Bearings for Sound Improvement"

.

.

woodturner-fran: "That new way bearing looks like a great option. How much are they?"

According to member Paul Eber in this post who has successfully build an arm out of the bushing and here's his quote:

Paul Ebert: "The air bushing is from New Way Bearings (New Way Air Bearings). It is part #S301201 and the pillow block for it is part #S8012P01. They aren't cheap. The pair is about $240. It will operate between 40 and 80 psi, with 60 being recommended (high pressure for a tone arm). I managed to find a relatively quiet oil-less air compressor. It is a Thomas 607FA22 compressor. Even that is too loud (57 dB). It resides in the basement."

I think many already knew that the Kuzma Airline tonearm also uses the 20mm New Way bushing.

www.newwaydistributor.com/featuredapp.html - "Audiophiles Use Air Bearings for Sound Improvement"

.

.

Hello Guys

My Name is Michael Methe from Germany (www.methe-family.de)

Is there anybody who hast interest to a "New Way Air Bushing plus some parts for building an own airbearing tonearm?

If so, please have a look here and scroll a little bit down:

Zu Verkaufen

You can contact me via email.

Regards and always happy listening,

yours Michael

My Name is Michael Methe from Germany (www.methe-family.de)

Is there anybody who hast interest to a "New Way Air Bushing plus some parts for building an own airbearing tonearm?

If so, please have a look here and scroll a little bit down:

Zu Verkaufen

You can contact me via email.

Regards and always happy listening,

yours Michael

Does the new way come with the shaft? If it doesn,t then you will find it difficult to machine a tolerance where just enough and too much will result in air rush escaping the shaft will make its own sound signature. You want the least possible air noise existing the perimeter shaft.

To make it work right will require a centerless grinder to get the perfect balance of low tolerance and the right air pressure to keep it quiet as it moves. You will need very even and tight dimensions to make the best of the new way if it doesn,t come with the shaft. A centerless grinder is the only way to make it sing properly.

Regards

David

To make it work right will require a centerless grinder to get the perfect balance of low tolerance and the right air pressure to keep it quiet as it moves. You will need very even and tight dimensions to make the best of the new way if it doesn,t come with the shaft. A centerless grinder is the only way to make it sing properly.

Regards

David

Last edited:

Hey guys, sorry to resurrect an old thread but I have a question. I have put together one of these arms based on the terminator model and it functions well (and has fabulous detail retrieval and absolutely black background!) but has very weak bass compared to my pivoted arms. Would there be some typical problem or mistake that one could make when making one of these tonearms that would cause this that I am just unaware of? I have heard a lot of discussion on the internet about hoe air bearing arms just have weak bass... is this true? I used to own an ET-2 and I don't recall bass being a problem in general. Off the top of your heads, could you think of anything I could look at as a potential source of the problem? It tracks well, runs on two aquarium pumps in parallel and has a hard-walled surge tank made out of a 4 foot long piece of 6 inch pvc. All connections are secure and there is no air leakage. The movement of the sled is smooth and without hiccups. However I am having some problem adjusting vta due to some problems with my mount design - could this do it? Thanks.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Air bearing tangent tone arm