or really lucky = Love Room

Edit: Here's a write up on using one as an air pressure pump for paint spray: http://www.volksrods.com/id36.htm

Edit: Here's a write up on using one as an air pressure pump for paint spray: http://www.volksrods.com/id36.htm

I am using 2 aquarium pumps in parallel, each one rated at 1.75psi and 800l/h.

The air requirement here is more about volume than pressure - as the pressure rises the noise from the manifold rises too. Lots of flow at lower pressure is the way to go. That kinda eliminates using a tank I think (have I got that right?).

On pump noise. This is really worth finding a good solution for. I tried a fair amount of things to quieten the pumps I am using. I damped their enclosures. I added an expansion chamber. I tried turning them down and up. No matter what cupboard I put them in they were still audible (annoyingly so). Eventually I put them into one of those alu tool boxes (you know the ones that photographers use for equipment). Its foam lined and I have that in an adjoining room and run a pipe to the arm from there. Not an ideal solution maybe, but it works.

I think for anyone about to build one of these things, the aquarium pump route is a very realistic way to go, but you will need to site it in another room.

Other than that one point, this arm is a great performer and will be a keeper for me. I need to go back and refit one or 2 parts to optimise it a bit more, but at least I now know its well worth it.

Fran

The air requirement here is more about volume than pressure - as the pressure rises the noise from the manifold rises too. Lots of flow at lower pressure is the way to go. That kinda eliminates using a tank I think (have I got that right?).

On pump noise. This is really worth finding a good solution for. I tried a fair amount of things to quieten the pumps I am using. I damped their enclosures. I added an expansion chamber. I tried turning them down and up. No matter what cupboard I put them in they were still audible (annoyingly so). Eventually I put them into one of those alu tool boxes (you know the ones that photographers use for equipment). Its foam lined and I have that in an adjoining room and run a pipe to the arm from there. Not an ideal solution maybe, but it works.

I think for anyone about to build one of these things, the aquarium pump route is a very realistic way to go, but you will need to site it in another room.

Other than that one point, this arm is a great performer and will be a keeper for me. I need to go back and refit one or 2 parts to optimise it a bit more, but at least I now know its well worth it.

Fran

moving mass... in a good way...

really, is there any other way?

bear, if the freedom exists to build something, to me, it just makes sense to reduce any moving mass as much as possible. Then make sure you have enough counterweight to offset the cartridge mass.

I guess I assume some common sense and some idea of Inertia is known so that folks can participate in, what really is in effect, a physics problem.(and bear this is not a dig at you, as I am confident that you understand, but perhaps some others may not... and that is not a dig at any, just trying to clarify as much as possible for all.)

Kinda like racing cars---reducing the unsprung weight has a profound effect on how the complete suspension acts and responds to road conditions. Reduce the sprung weight and those effects will be greater...

ah..cars n' tonearms...2 great hobbies. (Ok and motorbikes too)

stew

really, is there any other way?

bear, if the freedom exists to build something, to me, it just makes sense to reduce any moving mass as much as possible. Then make sure you have enough counterweight to offset the cartridge mass.

I guess I assume some common sense and some idea of Inertia is known so that folks can participate in, what really is in effect, a physics problem.(and bear this is not a dig at you, as I am confident that you understand, but perhaps some others may not... and that is not a dig at any, just trying to clarify as much as possible for all.)

Kinda like racing cars---reducing the unsprung weight has a profound effect on how the complete suspension acts and responds to road conditions. Reduce the sprung weight and those effects will be greater...

ah..cars n' tonearms...2 great hobbies. (Ok and motorbikes too)

stew

pump noise....

a buddy of mine was working for a time spraying a very nasty two part epoxy paint which required a full fatial mask with air. The vibration of the air pump was driving him crazy. So he tried to add in line foam filters to smooth things out. In the end he built a muffler iside of a length of plastic pipe. The muffler had staggered baffles with foam also filling the cavity. The muffler was what smoothed things out as far as him feeling vibration on his face. So if you can feel it you can hear it and it will impact your tonearm as well. Hope that this is helpful in making things work a little better.

a buddy of mine was working for a time spraying a very nasty two part epoxy paint which required a full fatial mask with air. The vibration of the air pump was driving him crazy. So he tried to add in line foam filters to smooth things out. In the end he built a muffler iside of a length of plastic pipe. The muffler had staggered baffles with foam also filling the cavity. The muffler was what smoothed things out as far as him feeling vibration on his face. So if you can feel it you can hear it and it will impact your tonearm as well. Hope that this is helpful in making things work a little better.

OK, TransFi - the "official" Terminator arm site mentions two suitable air pumps:

- Sera 550 pump: max 550 L/Hr @ 150 mbar (2 psi),

adjustable flow control Note: no noise rating

- Rena 400 air: Max 133*2 L/Hr @ 4.5 psi (310 mbar)

adjustable flow control Note: <30db noise

Frans (2 parallel) pump is rated at 800*2 L/hr @ 1.7 psi (117 mbar). I presume this wouldn't run reliably on 1 pump & yet this would give an airflow of 400 L/Hr - I guess the pressure that this is delivered at is important also

Quote from Sera manual:

- Sera 550 pump: max 550 L/Hr @ 150 mbar (2 psi),

adjustable flow control Note: no noise rating

- Rena 400 air: Max 133*2 L/Hr @ 4.5 psi (310 mbar)

adjustable flow control Note: <30db noise

Frans (2 parallel) pump is rated at 800*2 L/hr @ 1.7 psi (117 mbar). I presume this wouldn't run reliably on 1 pump & yet this would give an airflow of 400 L/Hr - I guess the pressure that this is delivered at is important also

Quote from Sera manual:

Every diaphragm pump produces an audible vibration & hum noise. This can be minimised by providing a counter pressure. A hose clamp or regulator valve that reduces airflow also considerably reduces the noise.

What cartridge can i use?

Is the any difference in the calculations from the Compliance?

I m planing to use the Sumiko Blue Point Special Evo III in a terminator style tone arm.

Is there some kind of rule that i can use to find out what is the right cartridge for this arm.

Regards George

Is the any difference in the calculations from the Compliance?

I m planing to use the Sumiko Blue Point Special Evo III in a terminator style tone arm.

Is there some kind of rule that i can use to find out what is the right cartridge for this arm.

Regards George

Another take on this...

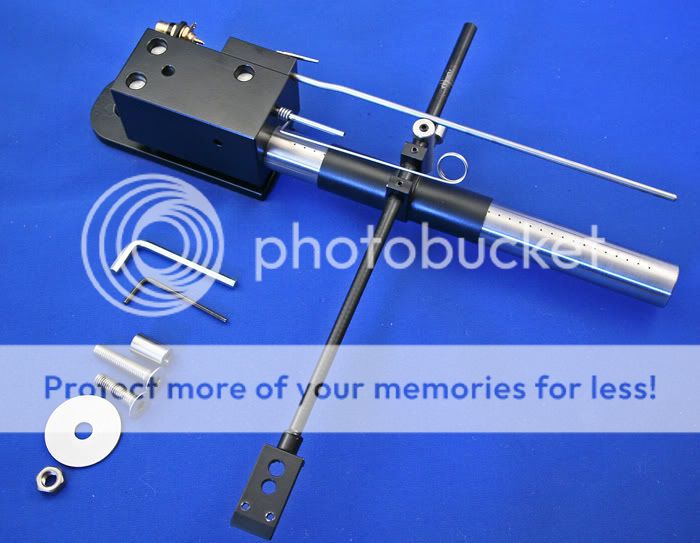

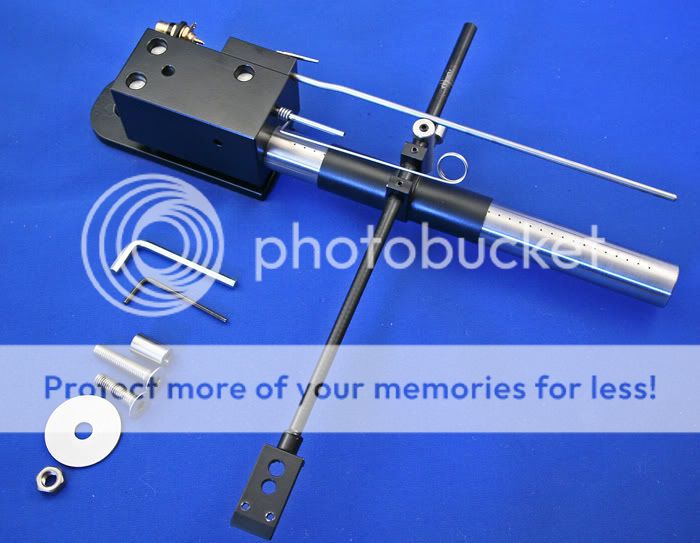

I read through this thread and found a lot of interesting information. I studied the Terminator air-bearing linear-tracking tonearm and have been tinkering with the idea of building one myself. Then I stumbled across this inexpensive air-bearing linear-tracking tonearm and recalled the above quoted post.

This got me thinking in another direction. Using aluminum pipe and tube and epoxy adhesives I came up with this (very) rough sketch. Carbon fiber is another idea.

The arm would slide along the length and pivot around the axis of the tube. The second larger sleeve would be drilled to allow the arm to be bonded to the "slider". Obviously this design would put the tube fairly close to the record surface so the arm itself would probably need to be long enoug to clear the radius of an LP.

Any problems inherent in this design stand out? Comments?

Martin

Nanook said:couldn't something like this be done to underhang a "tube" style air bearing?

I read through this thread and found a lot of interesting information. I studied the Terminator air-bearing linear-tracking tonearm and have been tinkering with the idea of building one myself. Then I stumbled across this inexpensive air-bearing linear-tracking tonearm and recalled the above quoted post.

This got me thinking in another direction. Using aluminum pipe and tube and epoxy adhesives I came up with this (very) rough sketch. Carbon fiber is another idea.

An externally hosted image should be here but it was not working when we last tested it.

The arm would slide along the length and pivot around the axis of the tube. The second larger sleeve would be drilled to allow the arm to be bonded to the "slider". Obviously this design would put the tube fairly close to the record surface so the arm itself would probably need to be long enoug to clear the radius of an LP.

Any problems inherent in this design stand out? Comments?

Martin

DIY FOREVER!

Here's DIY air-bearing tonearrm in a post from HiFiForum, including many great pictures:

http://www.hififorum.nu/forum/topic.asp?TOPIC_ID=61202 In Swedish, original post

http://www.hififorum.nu/forum/topic.asp?TOPIC_ID=61202 In English, Google Translate

.

Mounted on the underrated classic, JVC QL-7 direct-drive turntable.

.

Here's DIY air-bearing tonearrm in a post from HiFiForum, including many great pictures:

http://www.hififorum.nu/forum/topic.asp?TOPIC_ID=61202 In Swedish, original post

http://www.hififorum.nu/forum/topic.asp?TOPIC_ID=61202 In English, Google Translate

.

Mounted on the underrated classic, JVC QL-7 direct-drive turntable.

.

Just curious, how do one drill 0.3mm holes in the tube?

Easy, with a 0.3mm drill bit

You can use a PCB drilling machine or a drill Proxxon unit

An externally hosted image should be here but it was not working when we last tested it.

I managed to drill seven holes with a drill so bring plenty of drills.

Regards George

Just curious, how do one drill 0.3mm holes in the tube?

Depends on material

Brass would make it easier to drill

But just about anything today is cut by using lazer or water

But such arm has a small flaw

And thats all the holes outside the arm console

And that dammed noisy air pump

But it sure is a fine arm to use, and simply magical to the music

.

Hard to believe this is a DIY project!

air bearing tonearm from China with specs

00. http://www.records33.com/Gimg/20102114429349.jpg

01. http://www.records33.com/Gimg/201021144213898.jpg

02. http://www.records33.com/Gimg/20091117114423343.jpg

03. http://www.records33.com/Gimg/2009111711314150.jpg

04. http://www.records33.com/Gimg/200911171135736.jpg

05. http://www.records33.com/Gimg/2009111792628247.jpg

06. http://www.records33.com/Gimg/2009111792632735.jpg

07. http://www.records33.com/Gimg/2009111710352184.jpg

08. http://www.records33.com/Gimg/2009111792637397.jpg

09. http://www.records33.com/Gimg/200911171236995.jp9

10. http://www.records33.com/Gimg/2009111701826283.jpg

11. http://www.records33.com/Gimg/20091117142335639.jpg

12. http://www.records33.com/Gimg/20091117112512625.jpg

13. http://www.records33.com/Gimg/20091117153135250.jpg

14. http://www.records33.com/Gimg/200911162314776.jpg

15. http://www.records33.com/Gimg/2009111623127252.jpg

16. http://www.records33.com/Gimg/20091117101834364.jpg

17. http://www.records33.com/Gimg/20091117101834364.jpg

18. http://www.records33.com/Gimg/20091116234017512.jpg

19. http://www.records33.com/Gimg/20091116223130969.jpg

20. http://www.records33.com/Gimg/20091117161736891.jpg

21. http://www.records33.com/Gimg/200911170621587.jpg

22. http://www.records33.com/Gimg/20091117151940648.jpg

23. http://www.records33.com/Gimg/2009111622451535.jpg

24. http://www.records33.com/Gimg/20091116222211144.jpg

25. http://www.records33.com/Gimg/20091116231852953.jpg

26. http://www.records33.com/Gimg/20091117112528451.jpg

27. http://www.records33.com/Gimg/20091117112539962.jpg

28. http://www.records33.com/Gimg/20091117112951428.jpg

29. http://www.records33.com/Gimg/2009115135429857.jpg

30. http://www.records33.com/Gimg/2009122161216582.jpg

31. http://www.records33.com/Gimg/20091130114210950.jpg

32. http://www.records33.com/Gimg/20091130105043573.jpg

33. http://www.records33.com/Gimg/201011322817108.gif

.

Hard to believe this is a DIY project!

air bearing tonearm from China with specs

An externally hosted image should be here but it was not working when we last tested it.

00. http://www.records33.com/Gimg/20102114429349.jpg

01. http://www.records33.com/Gimg/201021144213898.jpg

02. http://www.records33.com/Gimg/20091117114423343.jpg

03. http://www.records33.com/Gimg/2009111711314150.jpg

04. http://www.records33.com/Gimg/200911171135736.jpg

05. http://www.records33.com/Gimg/2009111792628247.jpg

06. http://www.records33.com/Gimg/2009111792632735.jpg

07. http://www.records33.com/Gimg/2009111710352184.jpg

08. http://www.records33.com/Gimg/2009111792637397.jpg

09. http://www.records33.com/Gimg/200911171236995.jp9

10. http://www.records33.com/Gimg/2009111701826283.jpg

11. http://www.records33.com/Gimg/20091117142335639.jpg

12. http://www.records33.com/Gimg/20091117112512625.jpg

13. http://www.records33.com/Gimg/20091117153135250.jpg

14. http://www.records33.com/Gimg/200911162314776.jpg

15. http://www.records33.com/Gimg/2009111623127252.jpg

16. http://www.records33.com/Gimg/20091117101834364.jpg

17. http://www.records33.com/Gimg/20091117101834364.jpg

18. http://www.records33.com/Gimg/20091116234017512.jpg

19. http://www.records33.com/Gimg/20091116223130969.jpg

20. http://www.records33.com/Gimg/20091117161736891.jpg

21. http://www.records33.com/Gimg/200911170621587.jpg

22. http://www.records33.com/Gimg/20091117151940648.jpg

23. http://www.records33.com/Gimg/2009111622451535.jpg

24. http://www.records33.com/Gimg/20091116222211144.jpg

25. http://www.records33.com/Gimg/20091116231852953.jpg

26. http://www.records33.com/Gimg/20091117112528451.jpg

27. http://www.records33.com/Gimg/20091117112539962.jpg

28. http://www.records33.com/Gimg/20091117112951428.jpg

29. http://www.records33.com/Gimg/2009115135429857.jpg

30. http://www.records33.com/Gimg/2009122161216582.jpg

31. http://www.records33.com/Gimg/20091130114210950.jpg

32. http://www.records33.com/Gimg/20091130105043573.jpg

33. http://www.records33.com/Gimg/201011322817108.gif

.

Well,

to put it mildly, that's impressive!

poking around his web site, I found some more pictures of this arm.

Here is a link to some sort of user manual

to put it mildly, that's impressive!

poking around his web site, I found some more pictures of this arm.

Here is a link to some sort of user manual

Last edited:

Easy, with a 0.3mm drill bit

You can use a PCB drilling machine or a drill Proxxon unit

An externally hosted image should be here but it was not working when we last tested it.

I managed to drill seven holes with a drill so bring plenty of drills.

Regards George

Any recommendation on drilling speed for different materials: brass, steel, aluminum?

Thanks

With these small drills, it does not really matter how fast your machine turnsAny recommendation on drilling speed for different materials: brass, steel, aluminum?

Thanks

Approximately 20,000 RPM is enough to drill well in all materials

Use a cooling / lubricating fluid otherwise the drill break too fast.

Greetings George

Here is Trutium air tonarm TT on e-bay. From the pictures it does look that holes are bigger than 0.3mm:

TRITIUM AIR BEARING BRASS PHONO TURNTABLE RECORD PLAYER - eBay (item 150273127372 end time Jun-09-10 11:57:22 PDT)

YouTube - TRITIUM AIR BEARING ULTIMATE TONE ARM TONEARM TRIPHAZER TURNTABLE DEMO

It does look very much DIY-like.

TRITIUM AIR BEARING BRASS PHONO TURNTABLE RECORD PLAYER - eBay (item 150273127372 end time Jun-09-10 11:57:22 PDT)

YouTube - TRITIUM AIR BEARING ULTIMATE TONE ARM TONEARM TRIPHAZER TURNTABLE DEMO

It does look very much DIY-like.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Air bearing tangent tone arm