Hi Few,

My suggestion would be to check eBay from time to time if you want to build an air bearing arm. You may find some used but working air bearings at much lower prices than new ones. Air bushing may still be the best choice you can have.

3/4" air bushing may be your best choice because it can be used with wide range of cartridges. 1" air bushing has better sounding than 3/4" but it is too heavy and it has to be used with low compliance cartridges.

Jim

My suggestion would be to check eBay from time to time if you want to build an air bearing arm. You may find some used but working air bearings at much lower prices than new ones. Air bushing may still be the best choice you can have.

3/4" air bushing may be your best choice because it can be used with wide range of cartridges. 1" air bushing has better sounding than 3/4" but it is too heavy and it has to be used with low compliance cartridges.

Jim

Hi Terry,

Tell the truth. I don't know. This is the site I bought my material from

Aluminum Bar | Standard and Custom Cuts | Online Metals

Jim

Tell the truth. I don't know. This is the site I bought my material from

Aluminum Bar | Standard and Custom Cuts | Online Metals

Jim

You mean just push the hose over the barb of the connector fitting? That seems pretty fragile to me.I don’t think you need a clamp for the air hose. Just make sure that the air hose is rate at 60 psi.

Congratulations! You have done an excellent job. I especially like the bridge.

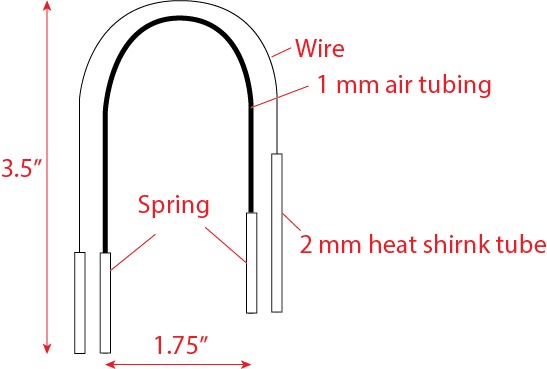

However, I can see there is one very important and critical implementation that needs to be improved, i.e., the arrangement of the air tubing and the wire. I have done many experiments. My arrangement of the wire and air tubing improves the movements of the air bearing greatly.

Here is an image to illustrate how I arranged the wire and air tubing. I think it is the best possible arrangement as I know. One option is to add two springs. These springs are from retractable ball pens. I don't use springs now.

First, it seems to me that you aren't using the air tubing I recommended in this thread. Personally, I can't find anything which is better than the one I recommended. I think it is a must to use the air tubing that I recommended to ensure high performance. If you live in the States, you may pm me your mailing address so I can send you a foot of said air tubing to you for free.

I used wire from my Sennheiser 600 headphone. If you don't have a similar wire, I would recommend using 34 g enamel magnet wire, 3 strands for each signal. I also saw the Litz wire on ebay. I haven't had any experience with this particular Litz wire, but it looks like it will work just fine.

https://www.ebay.com/itm/154427464738?_trkparms=amclksrc=ITM&aid=111001&algo=REC.SEED&ao=1&asc=20160908105057&meid=5f2c3430fcee4341ac03238bc0f9d543&pid=100675&rk=2&rkt=15&sd=374099452652&itm=154427464738&pmt=1&noa=1&pg=2380057&brand=Unbranded&_trksid=p2380057.c100675.m4236&_trkparms=pageci:4ff26ec0-df92-11ec-9ea3-2ef122f642f0|parentrq:119e6c461810a9bf870ee63efffa1312|iid:14

BTW, how heavy is your arm with the air bearing?

However, I can see there is one very important and critical implementation that needs to be improved, i.e., the arrangement of the air tubing and the wire. I have done many experiments. My arrangement of the wire and air tubing improves the movements of the air bearing greatly.

Here is an image to illustrate how I arranged the wire and air tubing. I think it is the best possible arrangement as I know. One option is to add two springs. These springs are from retractable ball pens. I don't use springs now.

First, it seems to me that you aren't using the air tubing I recommended in this thread. Personally, I can't find anything which is better than the one I recommended. I think it is a must to use the air tubing that I recommended to ensure high performance. If you live in the States, you may pm me your mailing address so I can send you a foot of said air tubing to you for free.

I used wire from my Sennheiser 600 headphone. If you don't have a similar wire, I would recommend using 34 g enamel magnet wire, 3 strands for each signal. I also saw the Litz wire on ebay. I haven't had any experience with this particular Litz wire, but it looks like it will work just fine.

https://www.ebay.com/itm/154427464738?_trkparms=amclksrc=ITM&aid=111001&algo=REC.SEED&ao=1&asc=20160908105057&meid=5f2c3430fcee4341ac03238bc0f9d543&pid=100675&rk=2&rkt=15&sd=374099452652&itm=154427464738&pmt=1&noa=1&pg=2380057&brand=Unbranded&_trksid=p2380057.c100675.m4236&_trkparms=pageci:4ff26ec0-df92-11ec-9ea3-2ef122f642f0|parentrq:119e6c461810a9bf870ee63efffa1312|iid:14

BTW, how heavy is your arm with the air bearing?

Last edited:

Thank you Jim! Would never have got here without you and your thread. Will have to read your note carefully a few times and try to implement your suggestions.

A couple of preliminary thoughts, though. I'm using Tygon 1 mm tubing instead of 1/32", which is about 1/3 more massive. The reason is that there was insufficient air pressure using 1/32", which I also tried. Must have been using too long a piece - I'll try again. No need to send me any more, but thank you for the kind thought!

I'm using fine silver tonearm wire from another air bearing, the Trans-Fi Terminator. It's gossamer thin, at least by my standards. The geometry you suggest is interesting. I'll see if the tonearm wire is stiff enough to sustain that shape.

The whole arm with base is about 7kg, which is pretty heavy. I can get away with that because I designed the turntable to accept a large cantilevered mass. The platter is about 45kg, the TT air bearing is the big thrust bushing from New Way.

The wand is very heavy at 230g including counterweight and air bushing - but the sound of the Koetsu is just simply excellent. More refined, more detailed than ever before. Resonances are small and well controlled by the Panzerholz wand, which is fabricated so there are some 300 boundaries (hardwood / phenolic glue) between cartridge and air bearing. Also, Niffy's reflex clamp works beautifully to flatten records. Vertical resonance is about 11Hz, Horizontal about 7Hz.

I know you will not like the 230g - my next attempt will be lower. But if the sound never does improve from here, I'll still be well pleased. Everything is extremely solid and finely adjustable, and adjustable on-the-fly. My last azimuth correction was 2 minutes of arc. And I'm still learning how to get the best from this!

Thanks again for your help and the help of all the other contributors.

A couple of preliminary thoughts, though. I'm using Tygon 1 mm tubing instead of 1/32", which is about 1/3 more massive. The reason is that there was insufficient air pressure using 1/32", which I also tried. Must have been using too long a piece - I'll try again. No need to send me any more, but thank you for the kind thought!

I'm using fine silver tonearm wire from another air bearing, the Trans-Fi Terminator. It's gossamer thin, at least by my standards. The geometry you suggest is interesting. I'll see if the tonearm wire is stiff enough to sustain that shape.

The whole arm with base is about 7kg, which is pretty heavy. I can get away with that because I designed the turntable to accept a large cantilevered mass. The platter is about 45kg, the TT air bearing is the big thrust bushing from New Way.

The wand is very heavy at 230g including counterweight and air bushing - but the sound of the Koetsu is just simply excellent. More refined, more detailed than ever before. Resonances are small and well controlled by the Panzerholz wand, which is fabricated so there are some 300 boundaries (hardwood / phenolic glue) between cartridge and air bearing. Also, Niffy's reflex clamp works beautifully to flatten records. Vertical resonance is about 11Hz, Horizontal about 7Hz.

I know you will not like the 230g - my next attempt will be lower. But if the sound never does improve from here, I'll still be well pleased. Everything is extremely solid and finely adjustable, and adjustable on-the-fly. My last azimuth correction was 2 minutes of arc. And I'm still learning how to get the best from this!

Thanks again for your help and the help of all the other contributors.

Hi esls,My implementation, which owes much to many. The only real innovation is precision tangentiality, which is easily adjusted to 5 microns or so. On the fly, not that this matters much.

View attachment 1059171

Very nice job.

Are the two vertical extrusions from a company called 80-20?

Are the two orange/black units right angle drives?

Sincerely,

Ralf

Hi esls,My implementation, which owes much to many. The only real innovation is precision tangentiality, which is easily adjusted to 5 microns or so. On the fly, not that this matters much.

View attachment 1059171

Very nice job.

Are the two vertical extrusions from a company called 80-20?

Are the two orange/black units right angle drives?

Sincerely,

Ralf

esls,

230 grams is on the heavy side. If possible, it would be nice to control it under 200 grams. However, if the vertical resonance is 11 Hz and the horizontal is 7 Hz, it should be fine, especially with Koetsu cartridge. I use epoxy to glue the arm directly on the air bearing in order to save some mass. Your arm wand seems like a solid wood one. If you can make it hollow, the mass may be reduced.

My air tubing is 5/16" all the way from the compressor to the arm, and only the last 5.5" is 1/32" tubing. I have no problem with the pressure. I know the airflow will be limited. But for an air-bearing arm, it is an advange. Air bearing requires high pressure and low flow. 1 mm tubing may be a little heavier than 1/32" tubing. I believe it makes no difference if you make the same arrangement as mine. In your current arrangement, even a 1/32" tubing may drag the bearing sideway because the tubing may be too heavy on one side.

A Koetsu cartridge with an air-bearing arm, if you can stand the maintenance of an air compressor, you will never go back to conventional arms.

Jim

230 grams is on the heavy side. If possible, it would be nice to control it under 200 grams. However, if the vertical resonance is 11 Hz and the horizontal is 7 Hz, it should be fine, especially with Koetsu cartridge. I use epoxy to glue the arm directly on the air bearing in order to save some mass. Your arm wand seems like a solid wood one. If you can make it hollow, the mass may be reduced.

My air tubing is 5/16" all the way from the compressor to the arm, and only the last 5.5" is 1/32" tubing. I have no problem with the pressure. I know the airflow will be limited. But for an air-bearing arm, it is an advange. Air bearing requires high pressure and low flow. 1 mm tubing may be a little heavier than 1/32" tubing. I believe it makes no difference if you make the same arrangement as mine. In your current arrangement, even a 1/32" tubing may drag the bearing sideway because the tubing may be too heavy on one side.

A Koetsu cartridge with an air-bearing arm, if you can stand the maintenance of an air compressor, you will never go back to conventional arms.

Jim

Ralf, I use Igus dry (plastic) bearings for 3 linear actuators, each of which is a carriage moved by a screw, with end blocks. These also have counters (nearest 100 microns, but move finely enough to read to about 10) and brakes - which are the orange/black units at the top, and one at the back for tangentiality. In addition, there are two good size linear slides with brakes. These latter units are under the left and right sides of the frame. The result is high precision positioning with rock solid movement and rock solid locking. Igus are pricey but they really get the job done.

Jim, thanks for your further thoughts. I want to change cartridges and make fine but solid azimuth adjustments, so I used an elastomeric glue from Chemlink, M1, to glue an aluminum plate of 2024 alloy to the bearing. A platform on the wand then screws to this, and shims are placed between the bearing plate and the platform. Since the base of the triangle formed by the shim, the bearing plate, and the wand platform is 45mm, and combinations of shims allow 0.0005" increments, adjustments on the order of 1 minute of arc are possible. The connection is more solid than the connection of cartridge to wand. Adjustments of the vertical sleds with the knobs at the top are capable of +/- 1 degree without overly compromising horizontal balance, so this provides an easy way to translate readings on the vertical sled counters to shim size, which allows for progressively fine azimuth. Long answer as to why a simple gluing job won't quite work for me.

Wand is in fact hollow. Next one will have a bigger void for reduced mass, exactly as you suggest. I'm not experiencing obvious air tube drag, but that doesn't mean there's no room for improvement. I will shorten the 1/'32" tubing in such an attempt.

Next two wands are going to be a lighter Panzerholz, as discussed, and a sapphire tube with suitable plate and platform. 2024 Al? 7075 Al Temper 0? Must think some more.

Also have a lighter wand, about 170g, which I used to test and to investigate the tonearm. I put a cheap Grado on this one, and vertical resonance was a bit high in frequency, suggesting that the Grado with compliance 20 needed more mass! Even so, it didn't sound half bad - wonder what one of their big cartridges might do?

As for standing the compressor maintenance, I must do that in any case for the air bearing turntable, so it's not an issue. Thank you for all your help in getting me to the place I've been coveting for 20 years.

Jim, thanks for your further thoughts. I want to change cartridges and make fine but solid azimuth adjustments, so I used an elastomeric glue from Chemlink, M1, to glue an aluminum plate of 2024 alloy to the bearing. A platform on the wand then screws to this, and shims are placed between the bearing plate and the platform. Since the base of the triangle formed by the shim, the bearing plate, and the wand platform is 45mm, and combinations of shims allow 0.0005" increments, adjustments on the order of 1 minute of arc are possible. The connection is more solid than the connection of cartridge to wand. Adjustments of the vertical sleds with the knobs at the top are capable of +/- 1 degree without overly compromising horizontal balance, so this provides an easy way to translate readings on the vertical sled counters to shim size, which allows for progressively fine azimuth. Long answer as to why a simple gluing job won't quite work for me.

Wand is in fact hollow. Next one will have a bigger void for reduced mass, exactly as you suggest. I'm not experiencing obvious air tube drag, but that doesn't mean there's no room for improvement. I will shorten the 1/'32" tubing in such an attempt.

Next two wands are going to be a lighter Panzerholz, as discussed, and a sapphire tube with suitable plate and platform. 2024 Al? 7075 Al Temper 0? Must think some more.

Also have a lighter wand, about 170g, which I used to test and to investigate the tonearm. I put a cheap Grado on this one, and vertical resonance was a bit high in frequency, suggesting that the Grado with compliance 20 needed more mass! Even so, it didn't sound half bad - wonder what one of their big cartridges might do?

As for standing the compressor maintenance, I must do that in any case for the air bearing turntable, so it's not an issue. Thank you for all your help in getting me to the place I've been coveting for 20 years.

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY Air Bearing Linear Arm