Full digital crossover is set. Hybrid was a early thought but I wont do it.

Should be no problem with just one fitting notch. At least I just use one in the passive crossover with M74A.I ordered some cheaper parts for notchfilter to test. I just found one example on diyaudio with twin notchfilter for the M74B. But at least in VituixCad I could achieve similar results with just one notch filter. I will test it. What are your thoughts on one or two notch filters?

I didn't get the 2nd pic - looks good.Im settled on closer spacing, also makes the speaker smaller, lighter and easier to build. I posted a picture out of sketchup earlier this thread or what do you mean?

I cross passive a little over 2kHz. These tweeters have so low THD, they can take more as most people think.What do you recommend as a crossoverpoint for the tweeter? To me it was recommended not to go lower than 2,5khz with the T25B.

I always buy in 10kg bags for construction ... these last for a few projects.The sheepwool you mention just arrived todayAlso used some sheepwool in my last speaker and will do it here also.

I did absorption on the front with my latest reference design - but it needed 25mm for a good effect. So I would not reckon with significant influence.The baffleedges will be a little bit more rounded as I will sand by hand. But not much. The front will also be covered with 4mm sheep felt (German: Filz). As Rockport or Wilson Audio have done it before (the darker part at the front if you look at the pictures). I think this will also help a little with diffrection? But to tell the truth: I mostly do it as I like the look.

I would still suggest some minimal experiments like adding resistance in series with the midrange and tweeter (e.g. 10 or 22 ohm), or a 1mH air cored inductor for the woofer, and then adjust the active filters to make the response flat. Unless you are using "special" drivers like AMT, planar, or electrostatic, where the different operating principle avoids the usual problems (stray inductance in the voice coil leading to IMD and hysteresis distortion), it could sound quite a bit better than active filters on their own.Full digital crossover is set. Hybrid was a early thought but I wont do it.

Hallo,

bad news The PTT10 should arrive 19.01.24 at my distributor. After I didnt get any updates, I asked them about it and now they told me, that Purifi told them, that the PTT10 will arrive at early to mid March... I dont know if Purifi is delaying, after they gave my distributor a set date for delivery just one week earlier or more likely: my distributor just sold more than they have... So maybe 1-2 more months till they arrive. (hopefully)

The PTT10 should arrive 19.01.24 at my distributor. After I didnt get any updates, I asked them about it and now they told me, that Purifi told them, that the PTT10 will arrive at early to mid March... I dont know if Purifi is delaying, after they gave my distributor a set date for delivery just one week earlier or more likely: my distributor just sold more than they have... So maybe 1-2 more months till they arrive. (hopefully)

Last weekend I just finished more parts for the cabinets (pictures attached). I did some internal waves on the "Ripps" of the cabinet, like I saw in a other build. Maybe it will help with resonances, maybe not. But it looks cool (sorry) and wasnt more work. The walls now alter between 19mm-31mm. I will also do some braces that connects top to bottom with 30-40% overlay between the braces and Weicon Flex 310 M as glue.

Soon my new Hypex connection cables will arrive and then I will start with some real measurements of the T25B/M74B in the baffle. I just build a turning table for it.

I was not able to get some realistic results with the diffraction tool of VituixCad... until I noticed the problem. After updating from Windows 10 to 11 I wasnt the Admin of my own Pc! So VituixCad could not write in .txt documents... No fix I found helped, so I installed my Pc new... But finally I was able to use the diffraction tool and did some simulations with my baffle.

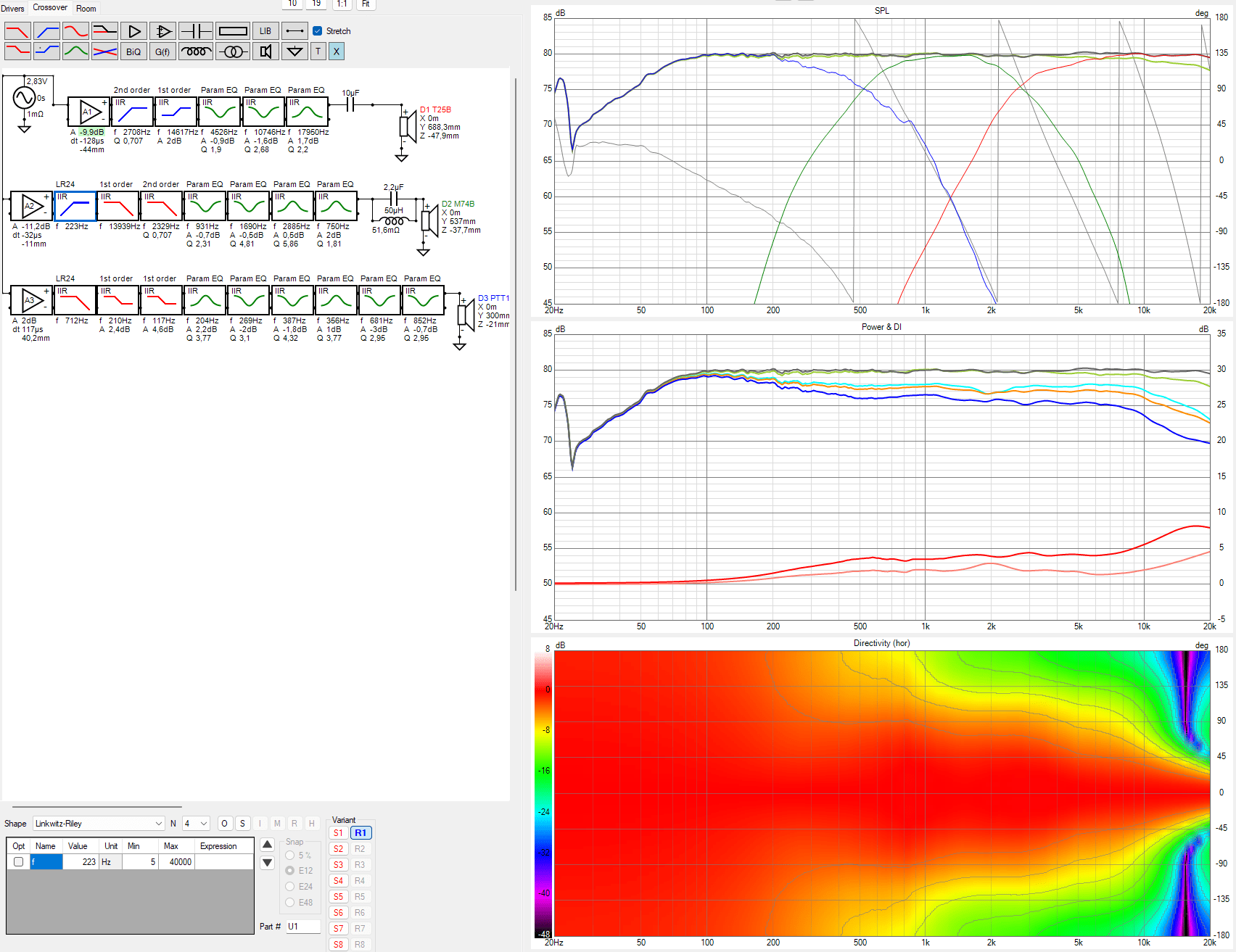

I tried some different things but the best results I could get, was with 1.2 c-t-c spacing for tweeter-midrange and a closer spacing with midrange-woofer. So in Hifijim/Kimmo I trust. Maybe the crossover is total ********? Here is the current state. (SPL adjusted to 80 db as a reference point)

There is a Dip in ER Total at 2k. The rest looks not to bad in my noobish opinion. (Just noticed the 1st order LP on the M74B is still in, its out now)

bad news

Last weekend I just finished more parts for the cabinets (pictures attached). I did some internal waves on the "Ripps" of the cabinet, like I saw in a other build. Maybe it will help with resonances, maybe not. But it looks cool (sorry) and wasnt more work. The walls now alter between 19mm-31mm. I will also do some braces that connects top to bottom with 30-40% overlay between the braces and Weicon Flex 310 M as glue.

Soon my new Hypex connection cables will arrive and then I will start with some real measurements of the T25B/M74B in the baffle. I just build a turning table for it.

I was not able to get some realistic results with the diffraction tool of VituixCad... until I noticed the problem. After updating from Windows 10 to 11 I wasnt the Admin of my own Pc! So VituixCad could not write in .txt documents... No fix I found helped, so I installed my Pc new... But finally I was able to use the diffraction tool and did some simulations with my baffle.

I tried some different things but the best results I could get, was with 1.2 c-t-c spacing for tweeter-midrange and a closer spacing with midrange-woofer. So in Hifijim/Kimmo I trust. Maybe the crossover is total ********? Here is the current state. (SPL adjusted to 80 db as a reference point)

There is a Dip in ER Total at 2k. The rest looks not to bad in my noobish opinion. (Just noticed the 1st order LP on the M74B is still in, its out now)

Attachments

Last edited:

Hallo,

was a little bit ill so couldn't work. I now just progressed on the baffle. Unfortunatly the PTT10 should ship this week, but still no sign of delivery. Soundimport shows now 12.04.24 so finger crossed. Until then I cant finish the baffle. Some parts ar now glued with wood glue, but most of the parts are not fixed jet. The braces and so on will then glued with Weicon Flex.

Somebody wrote me per PM that I should rethink my 0 Point for the Y-axis in VituixCad. Correct would be between Tweeter and Midrange. So I changed that. Tweeter now at 74,5mm, M74B -74,5mm and PTT10 -315,5mm. But without real measurements I dont see a point in posting the new crossover here. But its simpler now, less peq.

I want to add some top to bottom bracing for the bass cabinet. But not to much. I have some massiv beech wood sticks as leftovers I want to use. I think about putting them parallel to each other or in a criss-cross pattern. I hope you can see what I mean in the two pictures. Do you guys have a advice what would work out better?

Thank you

was a little bit ill so couldn't work. I now just progressed on the baffle. Unfortunatly the PTT10 should ship this week, but still no sign of delivery. Soundimport shows now 12.04.24 so finger crossed. Until then I cant finish the baffle. Some parts ar now glued with wood glue, but most of the parts are not fixed jet. The braces and so on will then glued with Weicon Flex.

Somebody wrote me per PM that I should rethink my 0 Point for the Y-axis in VituixCad. Correct would be between Tweeter and Midrange. So I changed that. Tweeter now at 74,5mm, M74B -74,5mm and PTT10 -315,5mm. But without real measurements I dont see a point in posting the new crossover here. But its simpler now, less peq.

I want to add some top to bottom bracing for the bass cabinet. But not to much. I have some massiv beech wood sticks as leftovers I want to use. I think about putting them parallel to each other or in a criss-cross pattern. I hope you can see what I mean in the two pictures. Do you guys have a advice what would work out better?

Thank you

Attachments

Hi, I dont know if i fully understand what you meen with "perturbing"? The Insert was the way to make the baffle around tweeter and mid as small as possible and still fit the 10 inch woofer. The corners will also be rounded but only after the driver arrives and the spartula work is finished.

Do you have a opinion on the bracing I showed?

Do you have a opinion on the bracing I showed?

Very impressive build, lukerhunter!what would work out better

With your stiff and heavy construction I can only think that you don't really need additional bracing ...

Parallel! You want it to be stiff and not "bending" over the bracing.I want to add some top to bottom bracing for the bass cabinet. But not to much. I have some massiv beech wood sticks as leftovers I want to use. I think about putting them parallel to each other or in a criss-cross pattern. I hope you can see what I mean in the two pictures. Do you guys have a advice what would work out better?

Why did you do the "waves" at the inside of the woofer cabinet? I mean it looks pretty cool - but at the wavelength the woofer is playing ...

So you would use top to bottom bracing in General? I also tend to go parallel.

The waves come from two speakers here from diy Audio. One was a high linearray. Dont know the exact Threads. One hoped with shifting thickness of the wall, to spread the cabinet resonance of the wall to a wider Range of frequencies and so lower them in there possible audibility. But he also Said, he dont know if its worked.

I know PBN Montana Sammy speaker also use multiple layers with grooves in it, to help with standing Waves. (I dont belive this works)

Gauder Acoustics also use multiple layers with waves in there higher end speakers. (But Mr Gauder also Talks some questionable Stuff on YouTube)

As I want to cut the inside of the layers with the jigsaw, to Safe a lot of time and just made a Template to draw the lines on the MDF, it was Like 1% more effort to made Waves instead of a straight line.

Will it help with resonances, standigwaves or reflections? I dont know. But I think there is a much higher Chance it helps than it hurts. Most likely I will Never know, as I wont do the Same endloser again without them.

The waves come from two speakers here from diy Audio. One was a high linearray. Dont know the exact Threads. One hoped with shifting thickness of the wall, to spread the cabinet resonance of the wall to a wider Range of frequencies and so lower them in there possible audibility. But he also Said, he dont know if its worked.

I know PBN Montana Sammy speaker also use multiple layers with grooves in it, to help with standing Waves. (I dont belive this works)

Gauder Acoustics also use multiple layers with waves in there higher end speakers. (But Mr Gauder also Talks some questionable Stuff on YouTube)

As I want to cut the inside of the layers with the jigsaw, to Safe a lot of time and just made a Template to draw the lines on the MDF, it was Like 1% more effort to made Waves instead of a straight line.

Will it help with resonances, standigwaves or reflections? I dont know. But I think there is a much higher Chance it helps than it hurts. Most likely I will Never know, as I wont do the Same endloser again without them.

Yes!So you would use top to bottom bracing in General? I also tend to go parallel.

The form of your speaker will already help to get stiffer. Just stay with 40-50mm wod thickness if you want great behaviour.

Normally resonance behaviour evens out and builds an average and you still get a weaker area (coincidence frequency), especially when you glue stuff together.

I also had good results with 1-2mm iron sheets glued on the inside with a thick layer of flexible floor glue. Brings weight and dampens resonances.

What would you suggest as better than minidsp? I’ve had power ice plate amps from minidsp on 2 active systems and they’re reliability is poor. I’ve moved to Hypex and they have been excellent. In my experience the DSP Module is what fails on the minidsp plates.Very interesting project!

I'd suggest to look for alternatives for the miniDSP though. I used a miniDSP during development of the OSMC, but the sound quality was never right. I prefer passive/analogue filters where possible. It it has to be digital, look for something better than miniDSP.

Last edited:

I'm also not very happy with their plate amps but I never had one fail. But I had failed Hypex boards, but not on plate amps.What would you suggest as better than minidsp? I’ve had power ice plate amps from minidsp on 2 active systems and they’re reliability is poor. I’ve moved to Hypex and they have been excellent. In my experience the DSP Module is what fails on the minidsp plates.

The cheap MiniDSP like the ones mbrennwa used are really just beginners toys to get a foot into DSP.

The new Flex HTx seem to be a really good unit and I always liked their software. Let's wait for some measurements from ASR.

- Home

- Loudspeakers

- Multi-Way

- DIY 3 Way-Loudspeaker with (maybe) Hybrid Crossover - BlieSMa+Purifi+miniDSP