OK here's a simple example (although since RF usually means radio frequency, I'll be using Fr)

This being the multi-way forum (aka loudspeakers) radio frequency (RF) should not be a topic for discussion. FR could be mistaken for Full Range

Good example. Add stiffness and you win, and what you lose when you add mass damping doesn't equal what you gain in terms of lowering Q and damping overall panel vibration.

***EDIT: This thread was moved to construction.

Oh well. RF for me and I called it first.

Last edited:

Back up a bit here - I said "add stiffness then add mass".

Increasing stiffness drives the RF up, damping lowers the Q AND shortens the overall decay time for all vibration, not just at the RF.

Thanks Dave for the reference you cited. I would enjoy reading this work. Can you point me in the proper direction? I will do a google search.

Also, Dave I don't exactly follow the terminology you use (I am not very schooled so take it easy). I understand and agree with Johns comments above.

or frequency response.

dave

That was the one the eluded me for some silly reason. Brain cramp mayhaps.

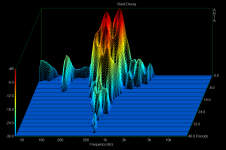

I built an accelerometer:

and I did some basic shmit with Arta to display the burst decay:

This is the broadest unbraced panel (the back) of my curved front 3-ways.

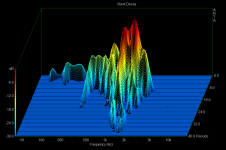

This one is from the smallest unbraced panel (the top):

Quite a difference.

I'm new to the Arta thing so I'll be playing with this for a while.

So much fun, so little time...

Dave - I see he has a couple of books. Which one do you recommend? I will buy it today.

The paper I am reading is "The modification of Timber of Resonances: Perception and Measurement" circa 1988.

I also understand what you were saying about high and low Q resonance and audibility.

True in the BBC paper they started out on the premise that lowering the resonant Q was desired without testing that idea. However, there is still some good information and can be used as a piece of the puzzle. It does explain a few things they found odd like certain spikes were not as audible as others -perhaps Q related.

This is also consistent with audibility of peaks and dips in driver response. The narrower the aberration in bandwidth the less audible.

The paper I am reading is "The modification of Timber of Resonances: Perception and Measurement" circa 1988.

I also understand what you were saying about high and low Q resonance and audibility.

True in the BBC paper they started out on the premise that lowering the resonant Q was desired without testing that idea. However, there is still some good information and can be used as a piece of the puzzle. It does explain a few things they found odd like certain spikes were not as audible as others -perhaps Q related.

This is also consistent with audibility of peaks and dips in driver response. The narrower the aberration in bandwidth the less audible.

Last edited:

Dave - I see he has a couple of books. Which one do you recommend?

I wasn't aware ofmultiple books. His latest "Sound Reproduction" is a summation of his 30-some years of research.

dave

The paper I am reading is "The modification of Timber of Resonances: Perception and Measurement" circa 1988.

Is the paper on-line -- be way easier than wading into my (as yet) unsorted library to dig out the AES journal

dave

Thanx, i got it. On a quick glance, much of it is embedded into the book. One particular phrase i liked, that i don't remember from the book is:

dave

... given the right signal and listening circumstances, it is possible to hear resonances that would be very difficult to detect by any technical measurements.

dave

I thought that was an interesting comment as well. Since it is a pretty general statement it applies to the electronic stream as well. I have heard some pretty darn awful perfectly measuring amplifiers.

Two other things that stand out in this paper are that not all resonance are perceived in a negative way by the listener and resonance issues may take a back seat to the total effect of stereo listening - that is the spatial cues are at least as important.

Two other things that stand out in this paper are that not all resonance are perceived in a negative way by the listener and resonance issues may take a back seat to the total effect of stereo listening - that is the spatial cues are at least as important.

The paper did not answer all my questions however. It certainly does confirm what you are saying however. It does appear that there is more that one way to skin the cat however.

Low Q resonance is more audible according to this research. There does not to be a good reason to damp the panels with this in mind.

In a standard wooden enclosure then you have material choice, thickness as well as bracing and sound absorption within. Still a lot to play with.

From the BBC paper it shows that BB 9mm is a little higher in Q than thicker BB and higher Elastic modulus across the grain but less with the grain.

It also appears that regardless of Q that 1-3k (1-2k the most audible) is a critical region and resonances are more audible in this region. I would think any bracing scheme should keep this in mind. The region around 450Hz can be an issue but is more Q dependent as well as source dependent.

I will use the above to design a box and move resonances, to the extent possible, out of this region. This may be useful as well when evaluating a drive unit. It may be that avoiding low q problems in the 1-3k region is critical for drivers as well.

Low Q resonance is more audible according to this research. There does not to be a good reason to damp the panels with this in mind.

In a standard wooden enclosure then you have material choice, thickness as well as bracing and sound absorption within. Still a lot to play with.

From the BBC paper it shows that BB 9mm is a little higher in Q than thicker BB and higher Elastic modulus across the grain but less with the grain.

It also appears that regardless of Q that 1-3k (1-2k the most audible) is a critical region and resonances are more audible in this region. I would think any bracing scheme should keep this in mind. The region around 450Hz can be an issue but is more Q dependent as well as source dependent.

I will use the above to design a box and move resonances, to the extent possible, out of this region. This may be useful as well when evaluating a drive unit. It may be that avoiding low q problems in the 1-3k region is critical for drivers as well.

Which BBC paper?From the BBC paper

Antique pine...I found it gets used as walkways over mudpits at construction sites !

Tried lotsa various fibers for cabs.

Choose pine because:

Leo did

It's light, I think it looks cool, generally offers a high substrate dimension per bukk.

Plane it down to a good bit thicker than you would hardwood. Once the dirt is off, it's easy on blades, gives greater joint width to work with, sucks up glue and is easy to work into position, use pin-nailer or clamps.

Tried lotsa various fibers for cabs.

Choose pine because:

Leo did

It's light, I think it looks cool, generally offers a high substrate dimension per bukk.

Plane it down to a good bit thicker than you would hardwood. Once the dirt is off, it's easy on blades, gives greater joint width to work with, sucks up glue and is easy to work into position, use pin-nailer or clamps.

Interesting read

If you dont mind I'd like to pose a question...

Because of the shape of the enclosure I will be building, I will almost certainly be using fiberglass to form the back shell. There will be a wood/mdf front baffle curved to meet the back shell something like the picture I sketched up below. Because the shape will be curved (almost bowl like), I anticipate the enclosures will have very good rigidity. In fact, I doubt any internal bracing will be necessary. The one issue I find with fiberglass enclosures is that because of their light weight, their resonant frequency is higher, sometimes making them (depending on size) sound sort of nasally.

I plan on building the midrange/tweeter enclosures as mdf/wood INSIDE of the main fiberglass enclosure to keep the volumes seperate for those drivers. The god thing about this is that the "shell" enclosure volume will be for only the woofers, which will be playing somewhere in the neighborhood of 300hz and down.

Would it be beneficial or just wasteful to (1) add a substance to increase mass to the resin mix (sand perhaps?) and (2) seperate some of the layers of fiberglass resin/matt with a damping product like neoprene or other foam?

.

If you dont mind I'd like to pose a question...

Because of the shape of the enclosure I will be building, I will almost certainly be using fiberglass to form the back shell. There will be a wood/mdf front baffle curved to meet the back shell something like the picture I sketched up below. Because the shape will be curved (almost bowl like), I anticipate the enclosures will have very good rigidity. In fact, I doubt any internal bracing will be necessary. The one issue I find with fiberglass enclosures is that because of their light weight, their resonant frequency is higher, sometimes making them (depending on size) sound sort of nasally.

I plan on building the midrange/tweeter enclosures as mdf/wood INSIDE of the main fiberglass enclosure to keep the volumes seperate for those drivers. The god thing about this is that the "shell" enclosure volume will be for only the woofers, which will be playing somewhere in the neighborhood of 300hz and down.

Would it be beneficial or just wasteful to (1) add a substance to increase mass to the resin mix (sand perhaps?) and (2) seperate some of the layers of fiberglass resin/matt with a damping product like neoprene or other foam?

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

Attachments

Last edited:

Why not put some wood in there ?

Fiberglass it right into or in the fiberglass?

Wood this be a first ?

I was about to think of fiberglass and how it could be used instead of 'expensive' wood joinery, use it for all the easy corners.

Anybody know where to get the 3m cast goodies besides the cast room at the orthopedics center ?

Not that I favor the idea everybody starts using high tech epoxies for everything...I was like...mahn...that's some good stuff ! I could safely make an infinite baffle or whatever out of that in no time with gloves [and goggles if your splashy !

Fiberglass it right into or in the fiberglass?

Wood this be a first ?

I was about to think of fiberglass and how it could be used instead of 'expensive' wood joinery, use it for all the easy corners.

Anybody know where to get the 3m cast goodies besides the cast room at the orthopedics center ?

Not that I favor the idea everybody starts using high tech epoxies for everything...I was like...mahn...that's some good stuff ! I could safely make an infinite baffle or whatever out of that in no time with gloves [and goggles if your splashy !

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Discussion on what materials to build speakers out of