Dave - I guess the Fostex enclosure still has some of those significant dips - Overall, I like the Dallas II better, mostly I feel it in the bass, that just seems deeper and more present - but I really don't have the hardware to try to listen to them side by side and pick up the differences. Swapping the drivers between the two enclosures take too long, plus I soldered the leads. My wife is being a good egg about having these monsters in her beautiful living room as it is - she haaaated the Fostex enclosures, and the Dallas is definitely more graceful. I think trying to add another set (I want the Alpair 10ps in a Pensil enclosure bad) would be pushing the issue.

Playing newer rock and roll through them still sounds like it's a bit much for the speakers to handle, There's just not enough separation in the instruments and too much distortion I think just messes the full range up. It does really well with classic rock, acoustic, jazz. Haven't tried classical yet.

Playing newer rock and roll through them still sounds like it's a bit much for the speakers to handle, There's just not enough separation in the instruments and too much distortion I think just messes the full range up. It does really well with classic rock, acoustic, jazz. Haven't tried classical yet.

I think I'll be using some extra tools or my friend's workshop when I build one of these. I have built similar and more complex stuff recently, but had to jigsaw then hand-plane angled edges - maybe this explains why my typical project time is six months to a year !

I notice your room is quite shiny and empty there Kyngfish, I would expect a bit of trouble with upper mids or HF in a room like that, especially with the FE206e, however well it's modified.

I bought an LS1016L Makita double bevel miter for this project and others. For what it can do, I think it's a worthwhile investment, and so far, can be pretty darn precise for almost 1k less than the Festool. I don't know about other builds, but I think its capacity for a flat piece of wood is near 12 inches. For the Dallas build, it was just about perfect for the interior angled pieces.

RE: the room - new house, there will be a rug there in front of the speakers soon, and a couch and some chairs and things, so it will soften up a bit soon enough. I'm not sure what "trouble" means in musical terms. I really wish someone experience from this forum lived in my area to give an objective opinion, but some notes do tend to ring a bit. Overall though, it's leagues ahead of anything I hear around here. My wife thought I was full of it when I explained the difference between an audiophile grade stereo and the trendy B&W or Bose or B&O stuff we hear around here. When she finally heard it she admitted it sounds much better.

Last edited:

Thanks for the tip on the Makita, but I have to manage with an outdoor, covered porch area and a Workmate to do most of my stuff. One day , maybe !

Dave, I pinged Scott an email to see if he could ask Ron if he remembers anything about the chamber mod to go from 206e to 208Ez . It would be nice to get it down on your drawing pack for posterity.

Ah well, that's good news so damping is on the way. 'Trouble' well, you know .. Frank Zappa had Trouble all the time back in '68 ...but no, I'm thinking of the sort that makes you wince when certain guitar notes are played.RE: the room - new house, there will be a rug there in front of the speakers soon, and a couch and some chairs and things, so it will soften up a bit soon enough. I'm not sure what "trouble" means in musical terms. I really wish someone experience from this forum lived in my area to give an objective opinion, but some notes do tend to ring a bit.

Dave, I pinged Scott an email to see if he could ask Ron if he remembers anything about the chamber mod to go from 206e to 208Ez . It would be nice to get it down on your drawing pack for posterity.

Congratulations on your build, they look really nice now that they're ready. Some small things:

For me, they sounded better when angled towards me. Also, these are speakers for a biggish room, will do better with at least 3 meters of separation between them. Experiment with this after you got used to how they sound.

For finishing,I used Osmo Oil mahogany,a very nice German made product. Had almost no smell, and it looks gorgeous.

Try investing in a UMIK microphone, and do some measurements with Rew. Then you can compare them with mine, also posted here. Of course the room will influence the results, but still, it's interesting to see how it works.

They really shine in solo instrumental music. Try some classical solo cello, with a flea watt tube amp, and be shocked . Low quality MP3 will have no chance with this high efficiency system..

. Low quality MP3 will have no chance with this high efficiency system..

For me, they sounded better when angled towards me. Also, these are speakers for a biggish room, will do better with at least 3 meters of separation between them. Experiment with this after you got used to how they sound.

For finishing,I used Osmo Oil mahogany,a very nice German made product. Had almost no smell, and it looks gorgeous.

Try investing in a UMIK microphone, and do some measurements with Rew. Then you can compare them with mine, also posted here. Of course the room will influence the results, but still, it's interesting to see how it works.

They really shine in solo instrumental music. Try some classical solo cello, with a flea watt tube amp, and be shocked

Last edited:

Osmo Oil...

Way ahead of you - I love Osmo - I think I'll stick to just the oil without the color, my wife wants the bright birch color

Just trying to tidy-up the loose end regarding the back-chamber volume for FE208Ez .

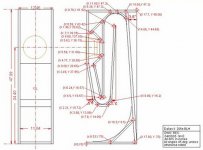

Best I can find at the moment is this low-res picture of the 'Rev.E' version which appears in a few places including DIY Audio.

Can Dave or Scott comment on whether this is one of Ron's drawings ?

I'm interested to see the volume modification is a bit more than I thought - looks like an extra piece of 3/4" in there behind the driver.

Best I can find at the moment is this low-res picture of the 'Rev.E' version which appears in a few places including DIY Audio.

Can Dave or Scott comment on whether this is one of Ron's drawings ?

I'm interested to see the volume modification is a bit more than I thought - looks like an extra piece of 3/4" in there behind the driver.

Attachments

Dave - if you get time can you make your revised 2018 plans ....

http://www.frugal-horn.com/downloads/Dallas2-plans-redraw-120618.pdf

...Link from the 'Ron's horns' page :

Ron Clarke Horns

, as I think those should be the default now, rather than the 2015 redraw ?

http://www.frugal-horn.com/downloads/Dallas2-plans-redraw-120618.pdf

...Link from the 'Ron's horns' page :

Ron Clarke Horns

, as I think those should be the default now, rather than the 2015 redraw ?

Dave - if you get time can you make your revised 2018 plans ...

Should be updated now… i can’t confirm yet, as the cable company has the page cached from when i 1st went and checked.

dave

Hi all,

I'm preparing for a new Dallas II build.

1) I'm interested if you are using dowels or biscuits (or similar) or only glue for joins?

2) If my calculations are right then wood should weight 35kg and there are 22.7 liters of voids to be filled. If filled with sand this is 37kg which is ~58 kg in total. Quite heavy if you need to move them especially on another floor. What is your experience?

Cheers,

V

I'm preparing for a new Dallas II build.

1) I'm interested if you are using dowels or biscuits (or similar) or only glue for joins?

2) If my calculations are right then wood should weight 35kg and there are 22.7 liters of voids to be filled. If filled with sand this is 37kg which is ~58 kg in total. Quite heavy if you need to move them especially on another floor. What is your experience?

Cheers,

V

Thank you Peter. It seems that I will take same approach. Dowels can just make it extra complicated with all these angles.

For the sand I'm still not sure. Will decide once completed.

I can get 0.5 cm thick dense wool fill. Would this be enough for the area behind/around the driver? For the rest as I understand there is no need for any filament?

Vigor

For the sand I'm still not sure. Will decide once completed.

I can get 0.5 cm thick dense wool fill. Would this be enough for the area behind/around the driver? For the rest as I understand there is no need for any filament?

Vigor

Maybe I confused you... I am not going to fill area behind the driver. Just glue some wool felt on the walls. As per my understanding this is required.The rest of the box is just wood.

Filling sand after speakers are build would not be possible as everything will be glued.

Vigor

Filling sand after speakers are build would not be possible as everything will be glued.

Vigor

Dallas 2 build questions.

I have had a good read around, but I am still uncertain about a couple of things.

What (other than the back of the speaker) needs felt covering, and how much (how thick)

Is any electrical correction required? Baffle step correction, or resistor?

Speakers are FS206en (allready well used.)

Build will be 18mm Birch Ply.

I have had a good read around, but I am still uncertain about a couple of things.

What (other than the back of the speaker) needs felt covering, and how much (how thick)

Is any electrical correction required? Baffle step correction, or resistor?

Speakers are FS206en (allready well used.)

Build will be 18mm Birch Ply.

- Home

- Loudspeakers

- Full Range

- Dallas II Build