Hello one and all, a few years back I bought a pair of Mark Audio CHN-50 drivers. They've sat for nearly 3 years and I thought it was high time to do something with them.

Having a search on here brought up the uMar-KenSET as a really interesting design. I contacted Dave, bought the blue prints and started to model them in FreeCad. Nothing too ambitious just yet, stick with the tried and tested.

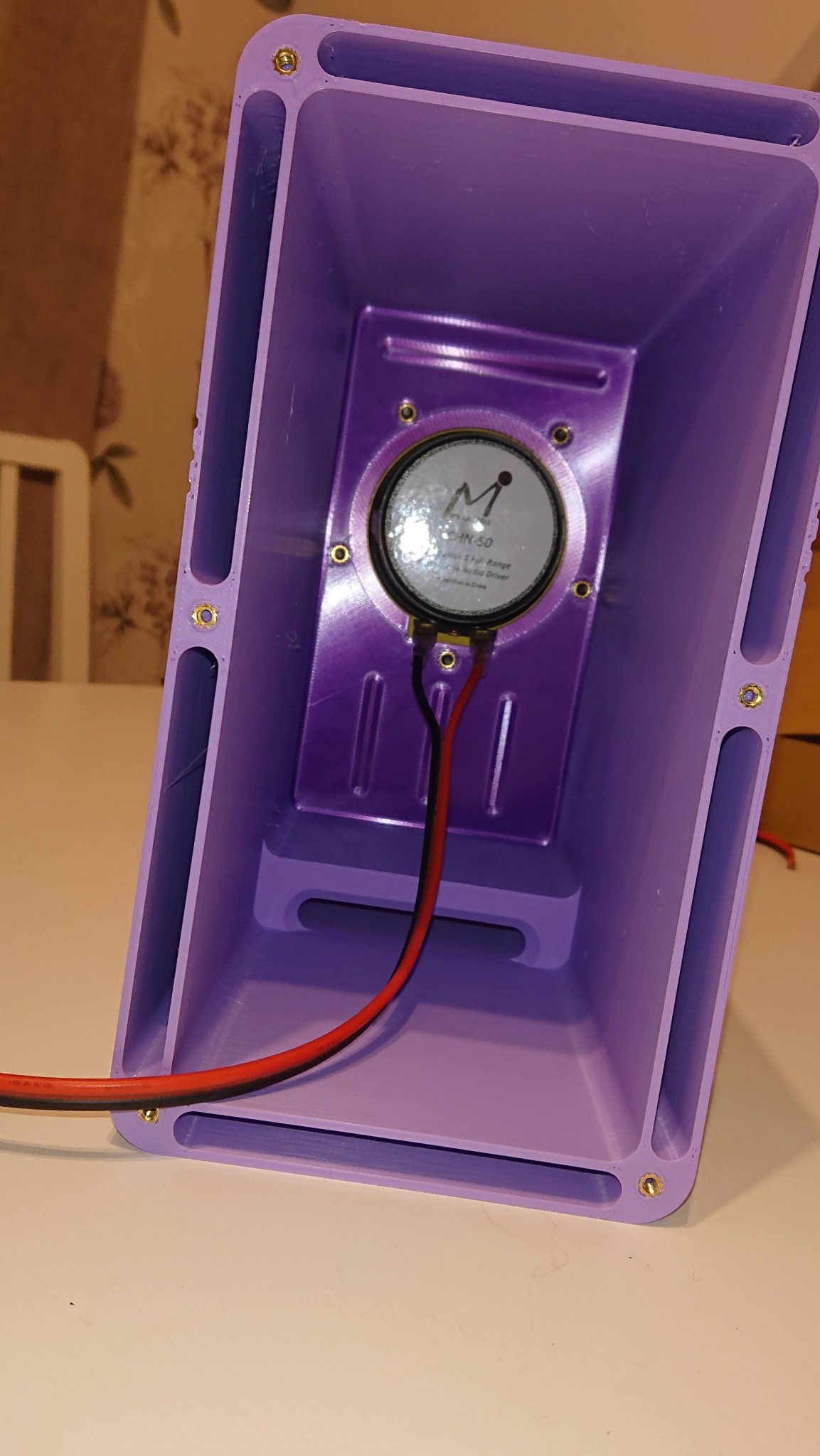

I broke the drivers in over the course of a week, run from a Fossi digital amp. So, we all love pictures right?

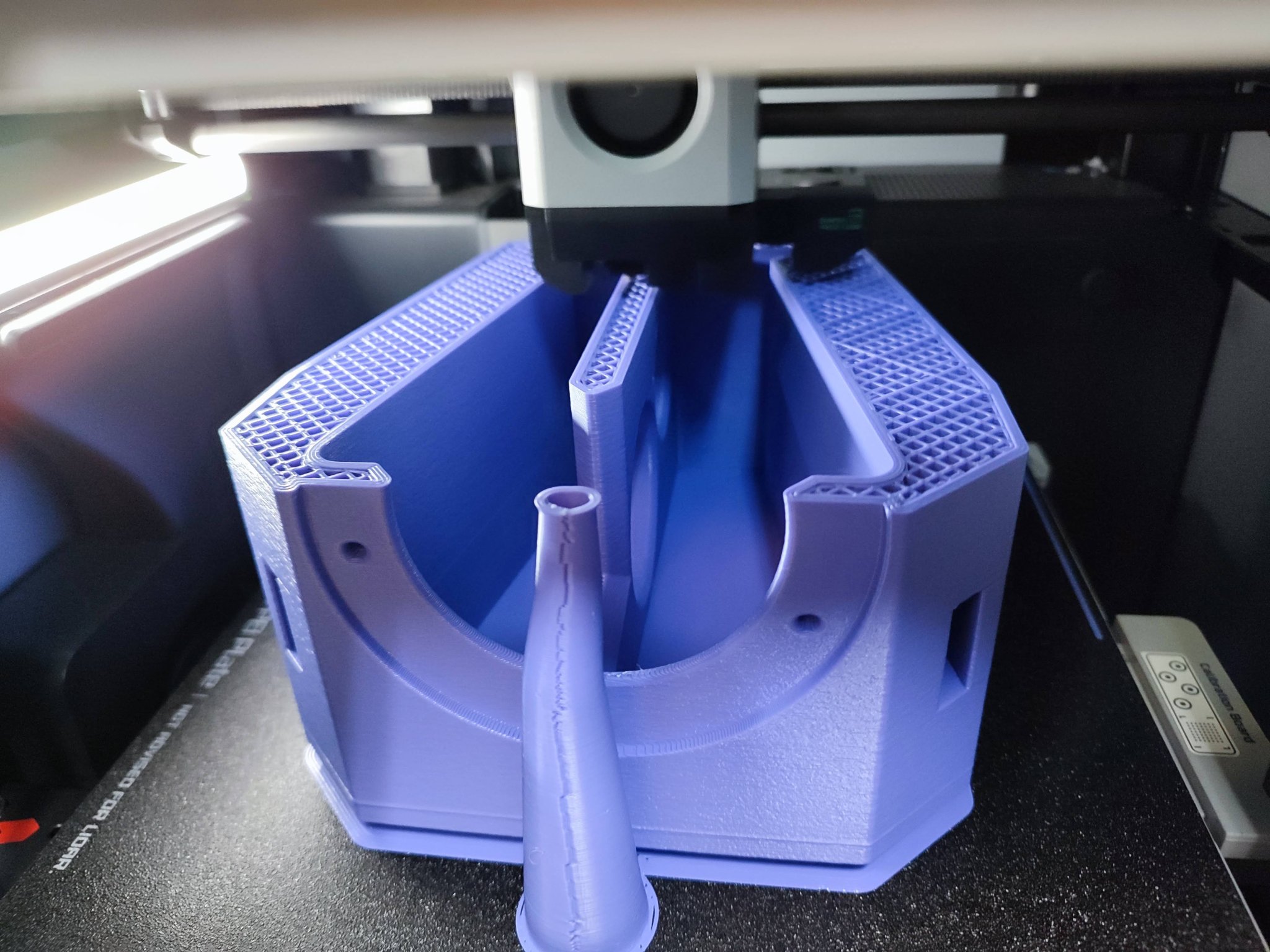

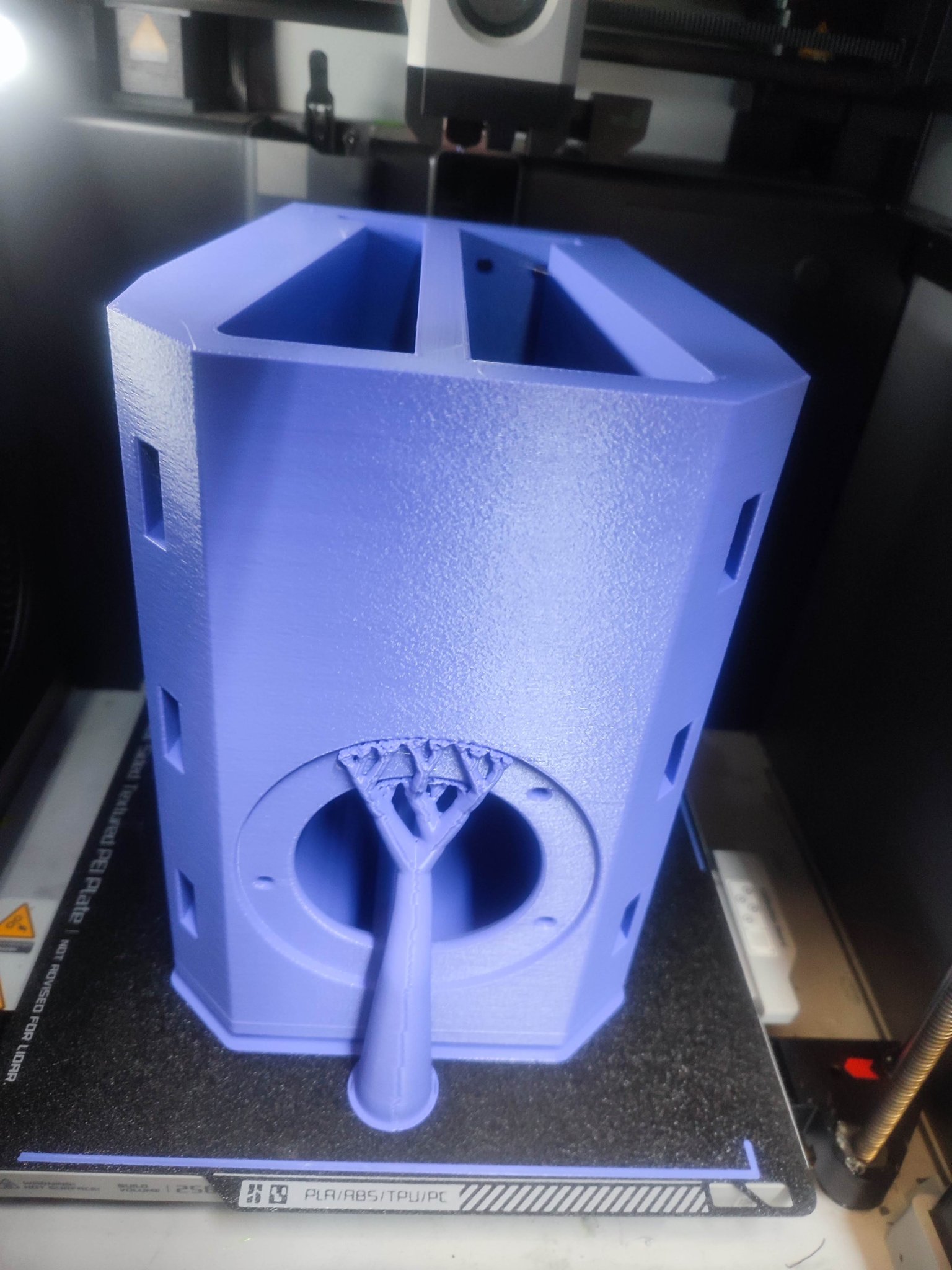

3.5 walls with a 0.8mm nozzle, 40% infill. Very Peri colour to compliment the decor.

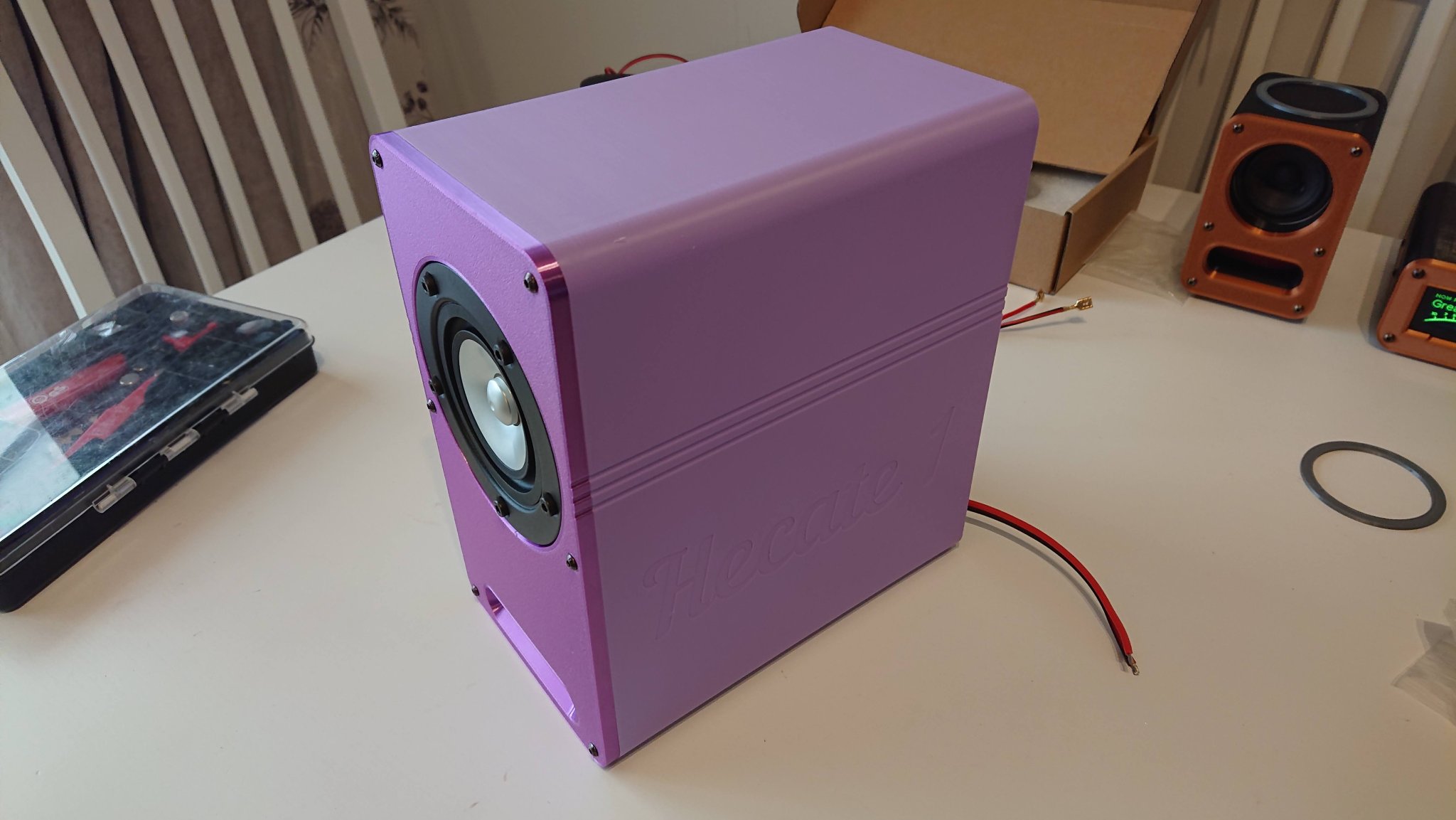

I'm very impressed with the sound they produce, even over blue tooth connection they're a lovely listen. Well the one that's kind of complete is! Around 42 hours of print time, and 2 kg / 4.4 lb of filament so far in the single enclosure. I still need to print a base once the wool felt has arrived. The other is in a cardboard box - needs must!

Maybe, most importantly, the good lady of the house loves the look. Hopefully by next weekend the pair will be ready for full enjoyment.

It's been a very long time since I've posted anything on here and it's great to see some familiar names and the friendly help and advice. Thank you & keep up the good work,

Steve

Having a search on here brought up the uMar-KenSET as a really interesting design. I contacted Dave, bought the blue prints and started to model them in FreeCad. Nothing too ambitious just yet, stick with the tried and tested.

I broke the drivers in over the course of a week, run from a Fossi digital amp. So, we all love pictures right?

3.5 walls with a 0.8mm nozzle, 40% infill. Very Peri colour to compliment the decor.

I'm very impressed with the sound they produce, even over blue tooth connection they're a lovely listen. Well the one that's kind of complete is! Around 42 hours of print time, and 2 kg / 4.4 lb of filament so far in the single enclosure. I still need to print a base once the wool felt has arrived. The other is in a cardboard box - needs must!

Maybe, most importantly, the good lady of the house loves the look. Hopefully by next weekend the pair will be ready for full enjoyment.

It's been a very long time since I've posted anything on here and it's great to see some familiar names and the friendly help and advice. Thank you & keep up the good work,

Steve

Lovely!!!

I posted the pic over here: https://www.diyaudio.com/community/...ken-gallery-pictures-only.214897/post-7651624

dave

I posted the pic over here: https://www.diyaudio.com/community/...ken-gallery-pictures-only.214897/post-7651624

dave

Last edited:

Member

Joined 2009

Paid Member

I don’t know squat about 3d printing - what’s the purple cauliflower thing for on the driver cut out ? I’m guessing it’s because you can’t 3d print over a hole, it needs a surface to support the layers above right ?

I guess there are endless design variations that you could incorporate that Dave would not have included because of construction difficulties that for you, with 3d printing would have no issue with at all. This opens up all sorts of possibilities, such as curved side walls and goodness knows what else!

I guess there are endless design variations that you could incorporate that Dave would not have included because of construction difficulties that for you, with 3d printing would have no issue with at all. This opens up all sorts of possibilities, such as curved side walls and goodness knows what else!

endless design variations that you could incorporate that Dave would not have included

:^)

Many.

dave

Thanks for the interest. The 2nd cabinet has been printed. All assembled and listening showed a little over stuffed with the wool felt. I added a little on the brace towards the rear and it was just too much. Removed that single piece to experience a much more enjoyable sound. I've listened to more music through these than I have listened to for a long time. They make me want to experience all my favourites and ventures into genres I don't usually dabble. It makes me wonder what the superior drivers in the Mark Audio range are capable of.

I've got them against the wall on top of my existing 5.1 left and right boxes. I'm simply enjoying them and even my better half has listened to them extensively and she rarely shows any interest in my audio endeavours!

I've got them against the wall on top of my existing 5.1 left and right boxes. I'm simply enjoying them and even my better half has listened to them extensively and she rarely shows any interest in my audio endeavours!

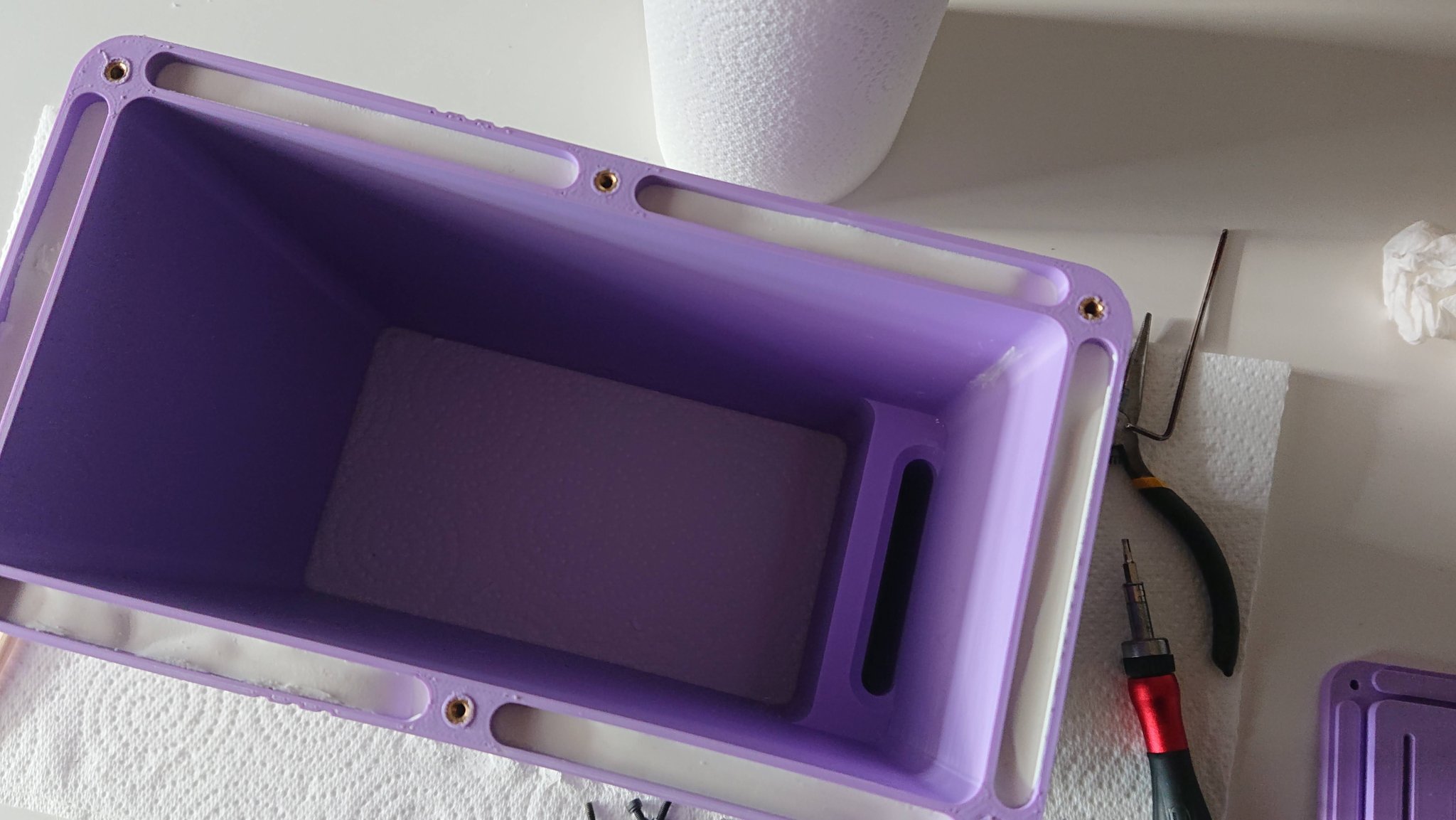

Showing the added wool near the ports. Elimination of this single piece improved the sound for my ears.

And finished with a set of black shoes. I tried a silver to match the cone but swmbo nor I were keen on the colours. All in all, I'm very happy. Even amazed given their diminutive size!

This is eSun PLA in the colour of Very Peri. It's a little more lilac than the pictures show. I'm happy with it being pla as the section should hold and the speakers won't be in direct sunlight. Smaller components in warmer environments may lead me to use other filament/plastics but here I'm confident I'll be fine.That enclosure looks very nice. What kind of filament did you use?

3.5 walls with a 0.8mm nozzle with 40% infill with the cabinet sides being 31mm thick overall means it's quite a solid cabinet. With the base the 3d printer enclosure weighs around 2.1 kg or 4.6lbs

The cauliflower thing is a tree support, you've got it spot on, to help support the layers above.I don’t know squat about 3d printing - what’s the purple cauliflower thing for on the driver cut out ? I’m guessing it’s because you can’t 3d print over a hole, it needs a surface to support the layers above right ?

I guess there are endless design variations that you could incorporate that Dave would not have included because of construction difficulties that for you, with 3d printing would have no issue with at all. This opens up all sorts of possibilities, such as curved side walls and goodness knows what else!

As for other construction options, when you've got a hammer everything looks like a nail! Yes I've seen some nice looking organic shaped cabinets. I just need to let the creative juices flow 😁

Thank you Dave, some amazing company there. Last pictures of these, honest!Lovely!!!

I posted the pic over here: https://www.diyaudio.com/community/...ken-gallery-pictures-only.214897/post-7651624

dave

I had to add a filter to get them to look like they do in real life.

Dave, do you have a picture or cad of the logo you've used on other builds please? I'd love to 3d print a version for these.

Last edited:

Buy the planet and i can provide th efiles that Steve sent me. The design is proprietary. eMail me if interested.

dave

Plan set, I presume?

Yes, thanx CHris, i did fix teh typo.

https://www.diyaudio.com/community/threads/planet10-hifi-minionken-plan-set-subscriptions.186350/

dave

https://www.diyaudio.com/community/threads/planet10-hifi-minionken-plan-set-subscriptions.186350/

dave

Thank you for the kind words. As Dave mentioned, the original work is a paid design that helps keep the lights on here. For this reason I won't be releasing the .stl files as the rights belong to Dave.Beautifull compact speaker you made. Is there any possibility to get my hands on the stl files to print them as well? Keep sharing your work on these babies.

If you do purchase the plan set, I can provide Dave with the step file so you can alter the cut out for the alpair 5.x driver.

Good luck with your endeavour, I'd say a good "full" range design is a great start.

I designed my own a few months ago but rather than waste filament I printed hollow walls and filled them with Plaster of Paris mixed with PVA glue. It was my first attempt at a serious design and my ADHD led to the serious oversight in compensating for the driver and port volumes. I've been using them to mostly listen to electronic music (Tangerine Dream, Johannes Schmoelling etc.) and they sound amazing, but rock and metal sound a little hollow, which I think is down to the volume being lower than it should be.

I'm about to start my second iteration with the proper considerations and if I'm happy with them I'll post them on Printables along with my other Hi-Fi stuff (there's more waiting to go on).

I tried lagging the interior with wool felt but it had a very detrimental effect so I ripped it all out and replaced it with some microfibre cloth. I may try some glass fibre insulation to see if the 'effective' volume increase has any benefit.

The PoP expansion led to a very slight bulge in the middle of the edges so there are a few things to consider with the next version. I'm considering a modular approach so that the port length can be tuned, and I think the chamfer on both ends was a mistake as well! I really was jumping in at the deep end with both feet and some heavy boots on, but it was probably the most rewarding thing I've ever attempted.

I'm about to start my second iteration with the proper considerations and if I'm happy with them I'll post them on Printables along with my other Hi-Fi stuff (there's more waiting to go on).

I tried lagging the interior with wool felt but it had a very detrimental effect so I ripped it all out and replaced it with some microfibre cloth. I may try some glass fibre insulation to see if the 'effective' volume increase has any benefit.

The PoP expansion led to a very slight bulge in the middle of the edges so there are a few things to consider with the next version. I'm considering a modular approach so that the port length can be tuned, and I think the chamfer on both ends was a mistake as well! I really was jumping in at the deep end with both feet and some heavy boots on, but it was probably the most rewarding thing I've ever attempted.

The slot in the front is a reflex port - you can see how far it travels into the cavity in the picture showing the back of the driver. The slots in the sides are cavities, before I filled them. The second image along shows them filled just below the surface to mate with the tenon type fittings. The grooves in the front and back plates are to break up the deformation modes.

- Home

- Loudspeakers

- Full Range

- CHN-50 starring in uMar-KenSET - 3D Printed version