Are the copper traces plated with Silver, Ag?Silvering (max.1%) = FREE

YES! = the plating of Ag or Sn have between 3 - 7um , that depends of a lot of factors. Also, sometimes the plating is not "sticked" perfect to all traces. This is very difficult to be controlled because the "copper structures".

The percent delared " 1%" is the content of Ag in the in the volume of solution.

The percent delared " 1%" is the content of Ag in the in the volume of solution.

Are the copper traces plated with Silver, Ag?

Last edited:

that means the plating is NOT silver.The percent delared " 1%" is the content of Ag in the in the volume of solution.

It is an alloy containing a maximum silver content of 1% and the rest is made up from tin (Sn) and other constituents.

Your description "Silvering (max.1%) = FREE" is wrong.

It should refer to tinning or some other appropriate term relating to solder substantially made from tin (Sn)

My friend,

Do you know what means " PLATING " in general ( is not ONLY by immersion)

By the way, SOLDERING is not also PLATING ?

Please don't try to " disturb" my thread with yours " scientific explaination"

I don't continue to convince you that all I declare are 100 % correct.

It is a matter only of yours understanding.

I really don't want to enter deep in details here about TINNING and SILVERING.

I really can not understand "yours attitude".

I have pleased you to continue discussion to private e-mail.

Here will never ended.

All the best,

Mihai

Do you know what means " PLATING " in general ( is not ONLY by immersion)

By the way, SOLDERING is not also PLATING ?

Please don't try to " disturb" my thread with yours " scientific explaination"

I don't continue to convince you that all I declare are 100 % correct.

It is a matter only of yours understanding.

I really don't want to enter deep in details here about TINNING and SILVERING.

I really can not understand "yours attitude".

I have pleased you to continue discussion to private e-mail.

Here will never ended.

All the best,

Mihai

that means the plating is NOT silver.

It is an alloy containing a maximum silver content of 1% and the rest is made up from tin (Sn) and other constituents.

Your description "Silvering (max.1%) = FREE" is wrong.

It should refer to tinning or some other appropriate term relating to solder substantially made from tin (Sn)

Last edited:

Andrew,

This thread is not about TINNING and SILVERING

I will continue discussion with you ONLY on private e-mail address.

Some things you confuse. ( are used TWO separate solutions, that's are prepared one time / plating ( with trace surface calculation in order to dose the right Sn , Ag quantity........are a lot to descriibe about this)

1. Tinning contain TIN (+ other over 20 chemicals that fix the tin to copper traces and pads)

2. Silvering contain SILVER (+ other over 20 chemicals that fix the silver to copper traces and pads)

You are talking " alloy" .....of what ?

You understood that is MELT the solid TIN and SILVER, and the boards in immersed in the hot bath of those elements.

Here is your wrong understanding.

I explain you for the last time in topic:

Are IMMERSED in solution that looks like a WATER.

I hope you understood now.

My conversation with you was too much for a day.

I have answered you here ONLY to not create a wrong OPINIONS in the mind of others.

Of course, that is your right to think what you want about : what is RIGHT and what is WRONG.

If you have "against things" about my boards you can do it in "diplomatic way" by private message or as I have proposed you to my private e-mail.

A nice weekend I wish you,

Mihai

This thread is not about TINNING and SILVERING

I will continue discussion with you ONLY on private e-mail address.

Some things you confuse. ( are used TWO separate solutions, that's are prepared one time / plating ( with trace surface calculation in order to dose the right Sn , Ag quantity........are a lot to descriibe about this)

1. Tinning contain TIN (+ other over 20 chemicals that fix the tin to copper traces and pads)

2. Silvering contain SILVER (+ other over 20 chemicals that fix the silver to copper traces and pads)

You are talking " alloy" .....of what ?

You understood that is MELT the solid TIN and SILVER, and the boards in immersed in the hot bath of those elements.

Here is your wrong understanding.

I explain you for the last time in topic:

Are IMMERSED in solution that looks like a WATER.

I hope you understood now.

My conversation with you was too much for a day.

I have answered you here ONLY to not create a wrong OPINIONS in the mind of others.

Of course, that is your right to think what you want about : what is RIGHT and what is WRONG.

If you have "against things" about my boards you can do it in "diplomatic way" by private message or as I have proposed you to my private e-mail.

A nice weekend I wish you,

Mihai

easy solution.

Don't refer to your process as "silvering..."

Last edited:

Regarding SHIPPING:

- Only in Europe

- Only through National Post Mail services.

- NOT sent to P.O. Box ( only to home address)

- NOT sent to company ( firm address )

- All packages are sent as " correspondence" ( max.2Kg allowed) , max. A4 format

-All packages are sent with ARRIVAL CONFIRMATION RECEIPT ( signature of receiver at arrival, in order to take the package, than the proof document is returned to sender)

- Only in Europe

- Only through National Post Mail services.

- NOT sent to P.O. Box ( only to home address)

- NOT sent to company ( firm address )

- All packages are sent as " correspondence" ( max.2Kg allowed) , max. A4 format

-All packages are sent with ARRIVAL CONFIRMATION RECEIPT ( signature of receiver at arrival, in order to take the package, than the proof document is returned to sender)

Cheapest_printed_circuit_boards_(PCB's)

An externally hosted image should be here but it was not working when we last tested it.

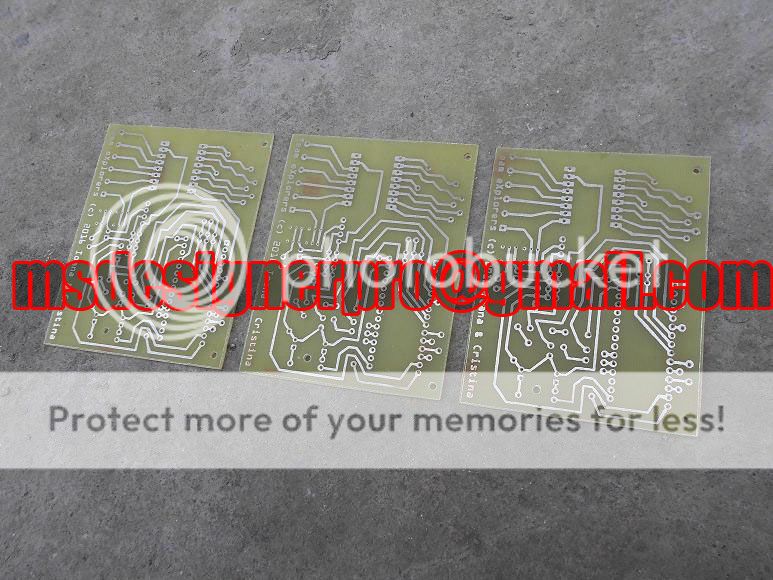

SILVERED test boards with TRACES ( and pad's), NOT only pad's

Copper: 35um or 75um

Single or double side

Maximim size/type: 190x140mm

Maximum quantity: 10 pcs.

Copper: 35um or 75um

Single or double side

Maximim size/type: 190x140mm

Maximum quantity: 10 pcs.

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Vendor's Bazaar

- Cheap printed circuit boards starting with 0,0375 Euro / cm2