You got pics?

it looks like a box in the back of a van,

this box,

Reed Exodus Anarchy 25hz Tapped Horn - AVS Forum

scaled up about 20% for this sub

http://www.amazon.com/gp/product/B002GHBUFY/ref=ox_sc_act_title_1?ie=UTF8&m=ANZ5B8ZZ261JD

Last edited:

Don't want to think how many hours it took to cut 120 holes in 3/4" with the Roto-Slow though...

http://www.amazon.com/dp/B00004T7P2...e=asn&creative=395129&creativeASIN=B00004T7P2

??

Any way this could be recalibrated to standard measurements? Im in need of a new sub, and this looks like a perfect project for me, I'm just worried that going with the closest conversion in material thickness could end badly.. If someone could Americanize these measurements, I'll have the subs on order as soon as possible-Thanks in advance for any help!

Oh snap!

Nice,

My son has that subwoofer in his car--if the dual version in a tapped horn works great, he better watch out.

My tapped horn project involves a single 10" I have laying around but the dual JBL 12 will be next. It is great to know that Spuddy will be building one so I can get an idea of the chaos when dealing with huge tapped horns. Good luck!

Oh yeah, if you want to covert the drawings from metric to inches, just divide the numbers by 25.4 since 25.4mm = 1 inch.

I was, but Petter PM'd me and let me know that just using the closest thickness of American plywood (in my case, 3/4") wouldn't hurt the sound quality. Knowing that, I'm gonna hold the same measurements, just with slightly different wall thicknesses.Hi Spuddy,

Are you looking for inch measurements for the drawings from Post #1, e.g.: see attached?

Regards,

Cheers!

Thanks for the support, hopefully this beast can live up to its potentialNice,

My son has that subwoofer in his car--if the dual version in a tapped horn works great, he better watch out.

My tapped horn project involves a single 10" I have laying around but the dual JBL 12 will be next. It is great to know that Spuddy will be building one so I can get an idea of the chaos when dealing with huge tapped horns. Good luck!

Oh yeah, if you want to covert the drawings from metric to inches, just divide the numbers by 25.4 since 25.4mm = 1 inch.

My biggest concern with metrics was that I can't get metric plywood here, but since that isn't a problem according to Petter, I'm gonna take the easy road and use the first measurement conversion site that comes up on a google search. I'll be buying wood tomorrow (ok its 2am, so later today really

I suppose it's time for a small update

I got 3 sheets of some gorgeous 3/4" void-free birch plywood at the local lumber yard (90 bucks a sheet, but at least it looks like it should cost that much.. small consolation haha) I have about half the cuts done now, and after converting to inches, the total cabinet size turned out to be about 3/8" thinner than the 22mm ply version while retaining the same internal volume. If its any help to future builders, I'm writing down every dimension being cut, so no one else has to worry about converting everything and adjusting for wood thickness after this.

Meanwhile, I've had my new woofers hooked up to the Reggae music channel for the last several days, so they should be plenty broken in when it's go time

Also, I've got a question- Do the woofers have to be hooked up in parallel, or is series fine as well? I got a hold of my first childhood amp from the buddy I sold it to in highschool to run this thing (a Peavey CS-800) and it has plenty of juice to run series at 8 ohms, but to my knowledge it isn't 2 ohm stable, which is where it'd be with parallel.

Pictures and stuff come when it's done!

I got 3 sheets of some gorgeous 3/4" void-free birch plywood at the local lumber yard (90 bucks a sheet, but at least it looks like it should cost that much.. small consolation haha) I have about half the cuts done now, and after converting to inches, the total cabinet size turned out to be about 3/8" thinner than the 22mm ply version while retaining the same internal volume. If its any help to future builders, I'm writing down every dimension being cut, so no one else has to worry about converting everything and adjusting for wood thickness after this.

Meanwhile, I've had my new woofers hooked up to the Reggae music channel for the last several days, so they should be plenty broken in when it's go time

Also, I've got a question- Do the woofers have to be hooked up in parallel, or is series fine as well? I got a hold of my first childhood amp from the buddy I sold it to in highschool to run this thing (a Peavey CS-800) and it has plenty of juice to run series at 8 ohms, but to my knowledge it isn't 2 ohm stable, which is where it'd be with parallel.

Pictures and stuff come when it's done!

Ahhh, the CS800

I had a 1993 model year CS1000 with the DDT compression limiter and really liked the amp--until I picked it up.

Run the subs in series since the CS will tend to BBQ itself at 2 ohms--I run my

dual 4 ohm 15" isobaric sub in series for 8 ohms and have no issues. Heck, my 2.5 way center channel runs the woofers in series strings (4 of them) and that is how they are done.

I can't remember but maybe you can bridge the CS800? Running 800 watts into the dual JBL sub with the anti-clipping DDT engaged would be an added layer of protection.

Glad that you are going full monty on the 2x12 TH, that will be my next build after I finish off my single 10 practice TH. Good luck and may everything work correctly when you're done.

I had a 1993 model year CS1000 with the DDT compression limiter and really liked the amp--until I picked it up.

Run the subs in series since the CS will tend to BBQ itself at 2 ohms--I run my

dual 4 ohm 15" isobaric sub in series for 8 ohms and have no issues. Heck, my 2.5 way center channel runs the woofers in series strings (4 of them) and that is how they are done.

I can't remember but maybe you can bridge the CS800? Running 800 watts into the dual JBL sub with the anti-clipping DDT engaged would be an added layer of protection.

Glad that you are going full monty on the 2x12 TH, that will be my next build after I finish off my single 10 practice TH. Good luck and may everything work correctly when you're done.

HOLY...

Petter, you are freaking brilliant! Using the 45 watt preamp alone, this thing was already making my Velodyne SPL1200 something of an oversized paperweight; Now with my Peavey CS-800 amp hooked up, it produces far and away the most impressive bass I have ever heard in a theater environment. I have no idea what its actual SPL ceiling is because my dog started crying before I could get that far, and frankly, I won't be finding out tonight either because screw the world, I'm watching me some loud movies first (gotta have priorities haha.) I just wanted to pass the good news on before getting back to the theater for anyone following the build.

At some point tomorrow I'll have pictures, recalibrated plans for any fellow Americans using 3/4" plywood and inches for measuring, and whatever sort of specs I can provide with a basic SPL meter and YouTube subwoofer tests (sorry everyone, but for a hardcore sound guy I pretty much have no means of measuring audio specs.) In the meantime, rest assured that this design is a heck of a thing, I'm as giddy as a school boy, and it's totally possible for a >$500 homemade sub to make IMAX look stupid (as long as you're ok with your sub doubling as a false wall )

)

Back to the theater I go, peace out!

Petter, you are freaking brilliant! Using the 45 watt preamp alone, this thing was already making my Velodyne SPL1200 something of an oversized paperweight; Now with my Peavey CS-800 amp hooked up, it produces far and away the most impressive bass I have ever heard in a theater environment. I have no idea what its actual SPL ceiling is because my dog started crying before I could get that far, and frankly, I won't be finding out tonight either because screw the world, I'm watching me some loud movies first (gotta have priorities haha.) I just wanted to pass the good news on before getting back to the theater for anyone following the build.

At some point tomorrow I'll have pictures, recalibrated plans for any fellow Americans using 3/4" plywood and inches for measuring, and whatever sort of specs I can provide with a basic SPL meter and YouTube subwoofer tests (sorry everyone, but for a hardcore sound guy I pretty much have no means of measuring audio specs.) In the meantime, rest assured that this design is a heck of a thing, I'm as giddy as a school boy, and it's totally possible for a >$500 homemade sub to make IMAX look stupid (as long as you're ok with your sub doubling as a false wall

Back to the theater I go, peace out!

Thanks for the good word 18hurts

I've put several movies through this beast now (I think I'm gonna name it "Kraken" after seeing what it does for the finale of "Clash of the Titans" ) and I'm left scratching my head over the quality of my Velodyne. It's understandable that the Kraken should be louder and deeper due to its size, but the I'm very surprised at how much cleaner it sounds as well- It's about as transparent as I could ever hope for, and my $1,300 servo-driven sub isn't even in the same league in that regard. Something about the way it produces sound just meshes with my Klipsches flawlessly, playing in a way that basically makes it disappear at the same time it slowly destroys the foundation of my house; Maybe it's because the rumble comes in so well under 20 hertz that the standard theatrical rolling boom sounds come across more naturally, like wind or distant thunder? I'm every bit as blown away by the quality as I am from its power at any rate! It's like adding a whole new dimension to cinema once you can comfortably hit frequencies in the teens, definitely worth the effort

) and I'm left scratching my head over the quality of my Velodyne. It's understandable that the Kraken should be louder and deeper due to its size, but the I'm very surprised at how much cleaner it sounds as well- It's about as transparent as I could ever hope for, and my $1,300 servo-driven sub isn't even in the same league in that regard. Something about the way it produces sound just meshes with my Klipsches flawlessly, playing in a way that basically makes it disappear at the same time it slowly destroys the foundation of my house; Maybe it's because the rumble comes in so well under 20 hertz that the standard theatrical rolling boom sounds come across more naturally, like wind or distant thunder? I'm every bit as blown away by the quality as I am from its power at any rate! It's like adding a whole new dimension to cinema once you can comfortably hit frequencies in the teens, definitely worth the effort

Back to construction.. Rather than trying to find or make some sort of spacer for the innermost woofer, I did something I DO NOT RECOMMEND (gotta have a disclaimer..) which was simply peeling the rubber face mount thing off the top of the woofer, and using it on the bottom as the spacer. It worked like a charm, but I'm sure JBL won't honor any warranty from a partially dismantled sub like that, so again, I don't recommend it

Here it is actually mounted with the rubber on the bottom side

If there's anything negative to say about the design, it's that (at least with 4x8' plywood sheets) you can only get 3 full width panels out of the 4' available, leaving a frustrating 11 inch wide, 8 foot long piece of firewood when you're done. After all my cuts, I was short one mid-size panel, so rather than buy a whole new $90 sheet, I just dado jointed two pieces together and went with that. I thought I had a pre-glue photo as well, but I guess I forgot to save it on my phone (whoops!) Here it is after being glued and cut to size anyway

Oh so close! My bracing is definitely not as hardcore as the design was showing, but I didn't really plan ahead too well, and even if I cut full-length braces like originally intended, I would have no way of getting them secured in place due to my drill not fitting in such a tight area between the walls. If you want mega-bracing in one of these, be sure to have a way to install everything before diving right in, because you really can't go backwards.

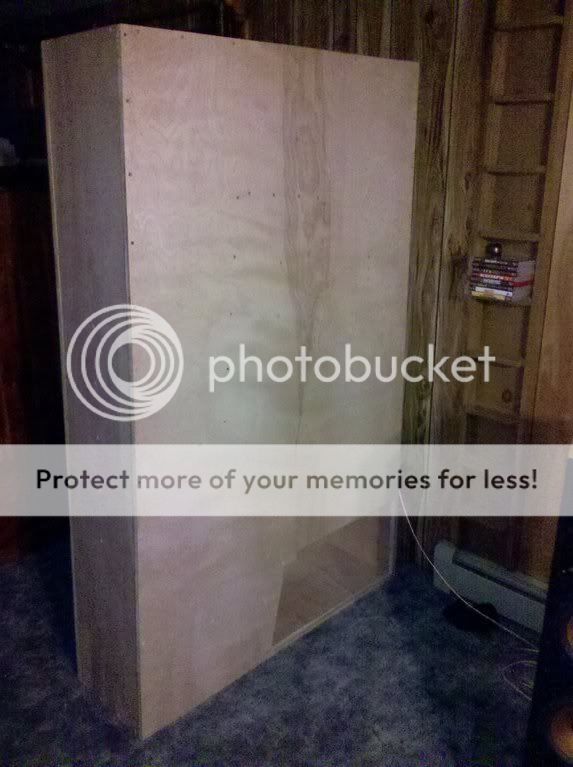

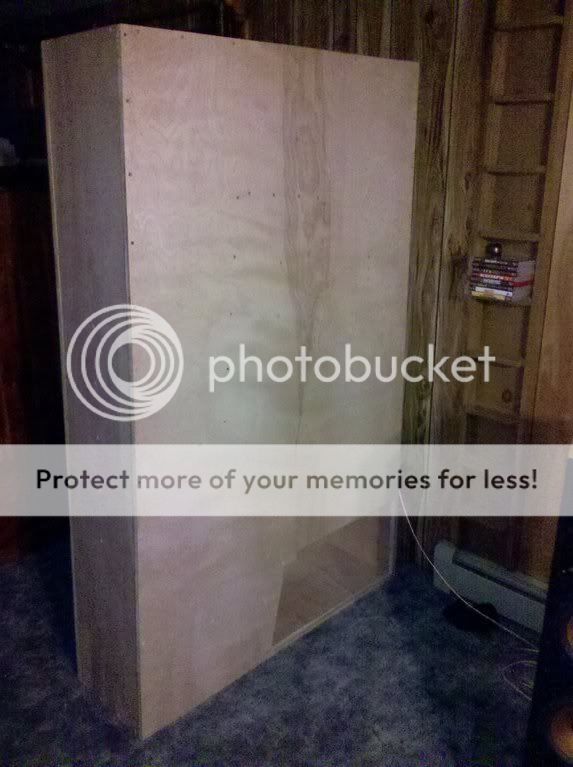

Here she is, totally assembled, but unfinished as of yet (that'll have to wait til spring, I'm a busy guy in the winter) It's actually smaller at the top than bottom, guess my camera fish-eyed the shot a bit ha

I still have plenty more info and things to share, but some friends are gonna be here for movie night, so I gotta go now!

I've put several movies through this beast now (I think I'm gonna name it "Kraken" after seeing what it does for the finale of "Clash of the Titans"

Back to construction.. Rather than trying to find or make some sort of spacer for the innermost woofer, I did something I DO NOT RECOMMEND (gotta have a disclaimer..) which was simply peeling the rubber face mount thing off the top of the woofer, and using it on the bottom as the spacer. It worked like a charm, but I'm sure JBL won't honor any warranty from a partially dismantled sub like that, so again, I don't recommend it

Here it is actually mounted with the rubber on the bottom side

If there's anything negative to say about the design, it's that (at least with 4x8' plywood sheets) you can only get 3 full width panels out of the 4' available, leaving a frustrating 11 inch wide, 8 foot long piece of firewood when you're done. After all my cuts, I was short one mid-size panel, so rather than buy a whole new $90 sheet, I just dado jointed two pieces together and went with that. I thought I had a pre-glue photo as well, but I guess I forgot to save it on my phone (whoops!) Here it is after being glued and cut to size anyway

Oh so close! My bracing is definitely not as hardcore as the design was showing, but I didn't really plan ahead too well, and even if I cut full-length braces like originally intended, I would have no way of getting them secured in place due to my drill not fitting in such a tight area between the walls. If you want mega-bracing in one of these, be sure to have a way to install everything before diving right in, because you really can't go backwards.

Here she is, totally assembled, but unfinished as of yet (that'll have to wait til spring, I'm a busy guy in the winter) It's actually smaller at the top than bottom, guess my camera fish-eyed the shot a bit ha

I still have plenty more info and things to share, but some friends are gonna be here for movie night, so I gotta go now!

Spuddy,

You are my hero! I built a pair of 6 foot tall vertical line arrays in my garage, the 5" woofers and tweeters are L O U D ! ! ! They sound decent for a metal garage and are driven by a 45 watt per channel receiver. The bass is augmented by a single Acoustic Research ported 12" subwoofer in the corner. It sounds decent at around 10 watts per channel but the sub is running out of breath close to max output.

My plan was use my 10" subwoofer I had laying around for a tapped horn but a good point was brought up by a friend of mine: 12 foot arrayed guitar monitor. Calculated max output with the single 10" outside in an open field and it won't have the output. Running my 600 watt X 2 power amp into 12 ohms nominal in an arrayed mono stack and the other channel into the Kraken would mesh very well.

Soooo---thanks to Spuddy, my 10" TH project is on the back burner... the dual 12" TH will be my first tapped horn. Figure if I'm going to build one, go all the way first shot out and get what I wanted in the first place.

18 Hz.... hurts the dog so I don't think I'll suffer from a lack of bass from the Kracken. So I need three sheets of 3/4" ply, two JBL 12" subs and a ton of glue, screws and an available amp. If I'm going to go through the hassle of building a pair of 6 foot tall arrays (12 woofers/48 tweeters each speaker) figure I might as well build the 2x12 TH JBL sub to match their output.

Thanks again for going into the unknown with this project and proving Petter to be a genius--many more foundations will crack with this valuable information.

You are my hero! I built a pair of 6 foot tall vertical line arrays in my garage, the 5" woofers and tweeters are L O U D ! ! ! They sound decent for a metal garage and are driven by a 45 watt per channel receiver. The bass is augmented by a single Acoustic Research ported 12" subwoofer in the corner. It sounds decent at around 10 watts per channel but the sub is running out of breath close to max output.

My plan was use my 10" subwoofer I had laying around for a tapped horn but a good point was brought up by a friend of mine: 12 foot arrayed guitar monitor. Calculated max output with the single 10" outside in an open field and it won't have the output. Running my 600 watt X 2 power amp into 12 ohms nominal in an arrayed mono stack and the other channel into the Kraken would mesh very well.

Soooo---thanks to Spuddy, my 10" TH project is on the back burner... the dual 12" TH will be my first tapped horn. Figure if I'm going to build one, go all the way first shot out and get what I wanted in the first place.

18 Hz.... hurts the dog so I don't think I'll suffer from a lack of bass from the Kracken. So I need three sheets of 3/4" ply, two JBL 12" subs and a ton of glue, screws and an available amp. If I'm going to go through the hassle of building a pair of 6 foot tall arrays (12 woofers/48 tweeters each speaker) figure I might as well build the 2x12 TH JBL sub to match their output.

Thanks again for going into the unknown with this project and proving Petter to be a genius--many more foundations will crack with this valuable information.

Spuddy, I am really glad  that you built this subwoofer. Ever since I

that you built this subwoofer. Ever since I

designed it I wanted someone that could make it real. The design was

optimized according to:

1) Low freq. extintention

2) About 1200 mm wide

3) As thin as possible to fit behind a movie screen or to be hidden some how. (that´s why it did not fit on x no. of sheets)

4) Easy built with not too much foldings.

5) Cheap long throw drivers.

The name Kracken will be its name from here and so on. Great choise, sounds terrifying

Thanks for your initial comments, it looks like you are happy so far and that makes me proud

Looking forward to your furure comments!

that you built this subwoofer. Ever since I

that you built this subwoofer. Ever since Idesigned it I wanted someone that could make it real. The design was

optimized according to:

1) Low freq. extintention

2) About 1200 mm wide

3) As thin as possible to fit behind a movie screen or to be hidden some how. (that´s why it did not fit on x no. of sheets)

4) Easy built with not too much foldings.

5) Cheap long throw drivers.

The name Kracken will be its name from here and so on. Great choise, sounds terrifying

Thanks for your initial comments, it looks like you are happy so far and that makes me proud

Looking forward to your furure comments!

Spuddy - if you have one of the old black - weighs a freakin ton - CS-800's

then it can do 2 ohm 24/7 no problem. Actually it will handle any resistance thrown at it.

Look for the old video of Peavey demoing it. If I recall they ran it full tilt and shorted it - no problems at all.

Very nice build and congrats.

Ive got a pair of 15" DVC Daytons that might work well in such a setup. Time to play with HR.

then it can do 2 ohm 24/7 no problem. Actually it will handle any resistance thrown at it.

Look for the old video of Peavey demoing it. If I recall they ran it full tilt and shorted it - no problems at all.

Very nice build and congrats.

Ive got a pair of 15" DVC Daytons that might work well in such a setup. Time to play with HR.

Sounds like you're making a heck of a thing there- Is that all set up for some heavy jam sessions? Neighbors must love you haha. While I can't give you any measured SPL specs, I can say the Kraken shouldn't have any issues keeping up with your soundstage- In my theater at least, it can actually outplay my entire set up, and I'm sending 100+ watts per channel to 2 Klipsch RF-5 towers, 2 Klipsch RF-3 towers and a Klipsch RF-3II Center. Full blast, you can understand dialogue from 50 feet outside of my house with the windows shut but the Kraken takes it in strideSpuddy,

You are my hero! I built a pair of 6 foot tall vertical line arrays in my garage, the 5" woofers and tweeters are L O U D ! ! ! They sound decent for a metal garage and are driven by a 45 watt per channel receiver. The bass is augmented by a single Acoustic Research ported 12" subwoofer in the corner. It sounds decent at around 10 watts per channel but the sub is running out of breath close to max output.

My plan was use my 10" subwoofer I had laying around for a tapped horn but a good point was brought up by a friend of mine: 12 foot arrayed guitar monitor. Calculated max output with the single 10" outside in an open field and it won't have the output. Running my 600 watt X 2 power amp into 12 ohms nominal in an arrayed mono stack and the other channel into the Kraken would mesh very well.

Soooo---thanks to Spuddy, my 10" TH project is on the back burner... the dual 12" TH will be my first tapped horn. Figure if I'm going to build one, go all the way first shot out and get what I wanted in the first place.

18 Hz.... hurts the dog so I don't think I'll suffer from a lack of bass from the Kracken. So I need three sheets of 3/4" ply, two JBL 12" subs and a ton of glue, screws and an available amp. If I'm going to go through the hassle of building a pair of 6 foot tall arrays (12 woofers/48 tweeters each speaker) figure I might as well build the 2x12 TH JBL sub to match their output.

Thanks again for going into the unknown with this project and proving Petter to be a genius--many more foundations will crack with this valuable information.

I'm doing my best to get the metric-standard conversion into MS paint for you; Bear with me, as I'm a very slow MS painter (tough being a perfectionist and using a very rough-cut program), but it should be ready for the weekend if nothing unexpected pops up. For now though, you'll need:

-2 JBL GT0 1214 subs (get em on eBay for $84 each with free shipping from seller billselectronicgear2000)

-3 sheets of 3/4" void-free plywood or MDF

-Couple pounds of coarse 1 5/8" drywall screws (and some separate screws/bolts for mounting the woofers if you wish to go that route- personally, I just used the drywall screws, but it's a bit hairy because there's not much room for error if the wood happens to have a soft spot right where the screw needs to be

-Big bottle of wood glue

-Counter sinking bit (if you don't already have one. You definitely need to counter sink the holes if you want the screws to hold tightly while the glue dries though. This is important!)

-Some pegs/proper size drill bit/clamps for dado jointing one of the panels (If you want to keep it down to 3 sheets)

-Heavy wiring, and putty to fill the hole you'll make to wire the two speakers together

ANNNDDDD before I forget, make the port opening before gluing and screwing anything and you'll save a lot of hassle. Also have a way to get your bracing in place from the start, because a standard drill won't fit where it needs to be once you have walls up. You probably already know half of what I said, but I figure it's worth posting the problems I had at any rate

Aww shucks, I been e-hugged by PetterSpuddy, I am really gladthat you built this subwoofer. Ever since I

designed it I wanted someone that could make it real. The design was

optimized according to:

1) Low freq. extintention

2) About 1200 mm wide

3) As thin as possible to fit behind a movie screen or to be hidden some how. (that´s why it did not fit on x no. of sheets)

4) Easy built with not too much foldings.

5) Cheap long throw drivers.

The name Kracken will be its name from here and so on. Great choise, sounds terrifying

Thanks for your initial comments, it looks like you are happy so far and that makes me proud

Looking forward to your furure comments!

Looks like you hit your goals pretty well!

1) That's a home run. This sub has let me know that my house's resonant frequency is 16hz. Seriously, 16hz is downright VIOLENT full-bore, and it still goes deeper that that

2) Sounds about right

3) Couldn't be much thinner than it is and still use 12's! It's also juuuust thin enough to work as a false wall in my case haha

4) Seemed like a lot to me, but I've never made a horn. At any rate, only a few cuts needed to be angled because most were close enough to 90* to not worry about, and that definitely saved some time.

5) There's our winner! Hard to top the Kraken at a mere $480 total cost!

That's my amp all right! Nothing but 65 pounds of steel, aluminum, and 2 monster capacitersSpuddy - if you have one of the old black - weighs a freakin ton - CS-800's

then it can do 2 ohm 24/7 no problem. Actually it will handle any resistance thrown at it.

Look for the old video of Peavey demoing it. If I recall they ran it full tilt and shorted it - no problems at all.

Very nice build and congrats.

Ive got a pair of 15" DVC Daytons that might work well in such a setup. Time to play with HR.

15" drivers in this thing sounds scary, keep us posted if you end up doing that!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Build your own 2x12" TH (The Kraken 212 TH)