Hi Gary,

Thanks for your reply!

Best regards

Peter

Thanks for your reply!

Best regards

Peter

Hi Peter,

No, I simply let the sealed enclosure do its part. I do think a high pass filter would be beneficial if I were using a resistive-vent enclosure as Lynn has suggested.

I really like the way the 416 sounds in a 3 cu ft sealed box, and am inclined to just let it be.

Gary Dahl

You guys know Neo magnets are also conductive, right? It's about 300x less conductive than Alnico and about 60-90x less conductive than aluminum or copper (typical shorting ring materials), but still vastly more conductive than ceramic magnet.

Electrical resistivity:

Alnico: ~50e-8 ohm*cm

Neo: ~150e-6 ohm*cm

Ceramic: ~1e6 ohm*cm

Aluminum: 2.6e-6 ohm*cm

Copper: 1.7e-6 ohm*cm

http://www.intl-magnetics.org/pdfs/0100-00.pdf

Electrical resistivity:

Alnico: ~50e-8 ohm*cm

Neo: ~150e-6 ohm*cm

Ceramic: ~1e6 ohm*cm

Aluminum: 2.6e-6 ohm*cm

Copper: 1.7e-6 ohm*cm

http://www.intl-magnetics.org/pdfs/0100-00.pdf

This combination of drivers, horns and enclosures does what I was hoping for. Eventually I will see what more can be done in fine-tuning and refinement in the crossover, but my plan is to leave them alone for awhile so I can become as familiar with the sound as possible, which will make it a lot easier to evaluate the effect of revisions in the future. At this time I will be turning my attention toward my amps and source components.

One exception: Lynn might send me his 745NEO/aluminum drivers to try, because the comparison would certainly be interesting.

Gary Dahl

Gary if you are able to try the Al would you mind trying it without the RAAL tweeter and commenting on how HF extension fares? Cheers

Alnico more conductive than copper?

No, the figures are for resistivity, not conductivity. Higher numbers are less conductive.

Gary if you are able to try the Al would you mind trying it without the RAAL tweeter and commenting on how HF extension fares? Cheers

Absolutely, I'd love to hear that as well.

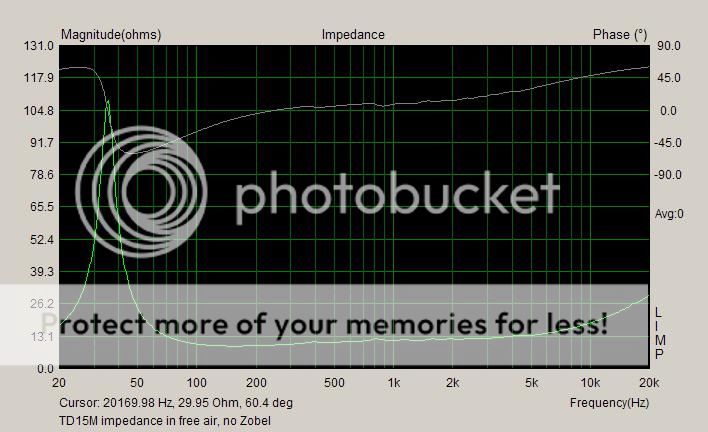

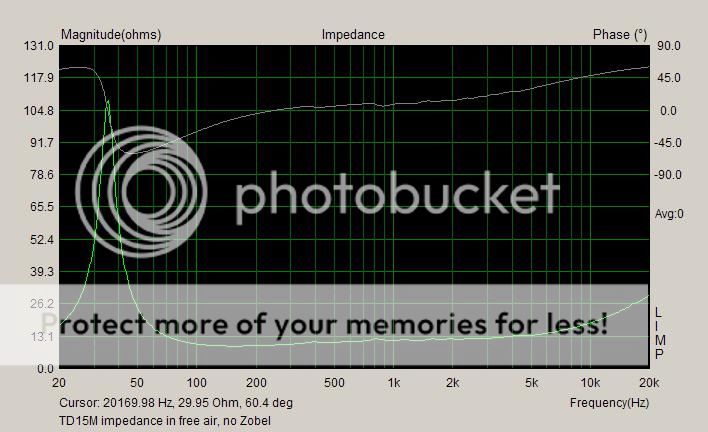

Okay, time for some graphs. First, the TD15M. This was measured in free air with no impedance correction.

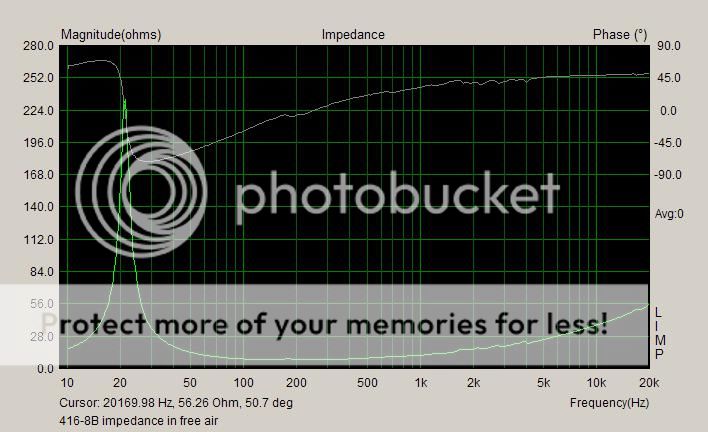

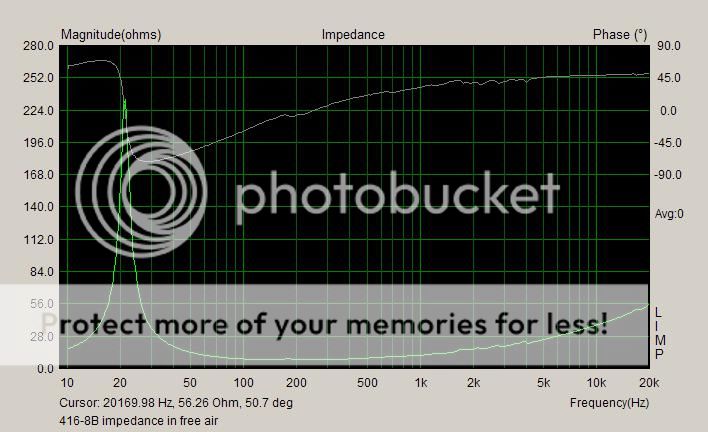

Below is the free-air impedance curve of the 416-8B. Again, no impedance correction. It looks quite a bit like the curve from the TD15M, until you look at the vertical scale and see that the TD15M's HF rise is just half that of the 416-8B.

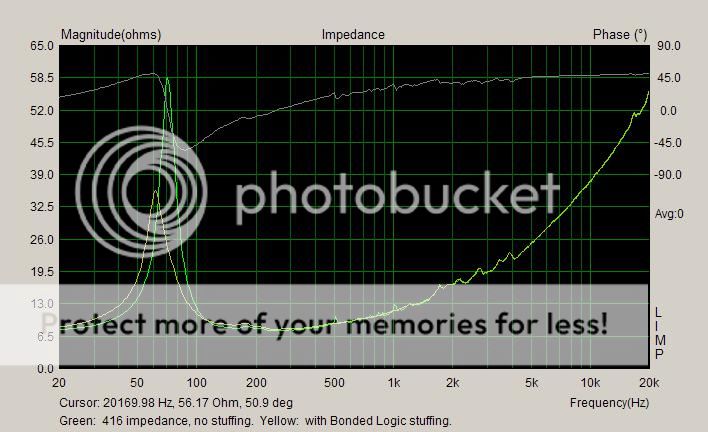

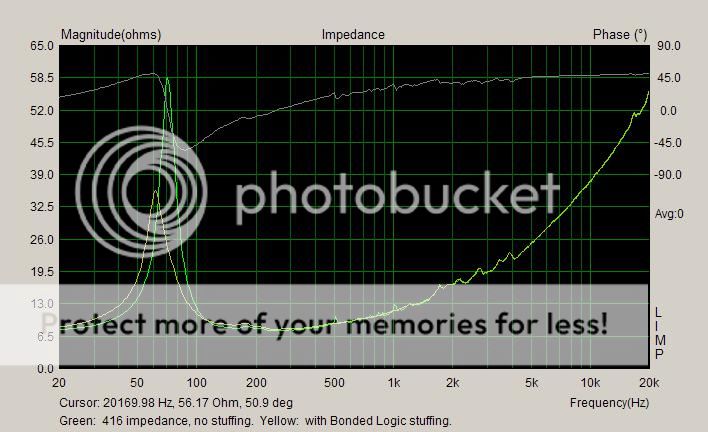

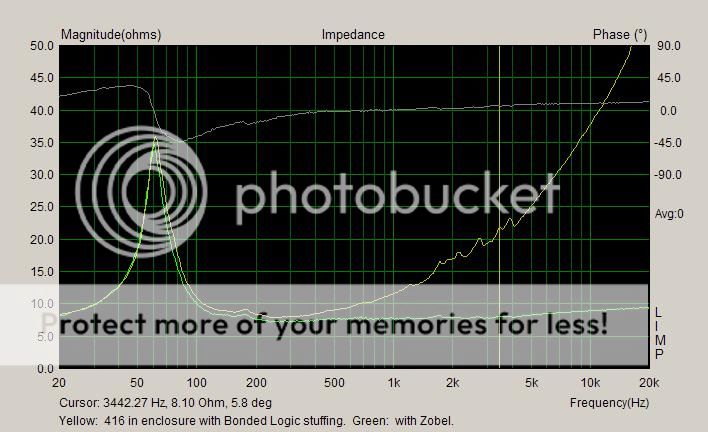

Next, the 416-8B is measured in its enclosure. Green trace was made with no stuffing, yellow trace shows the effect of stuffing (Bonded Logic):

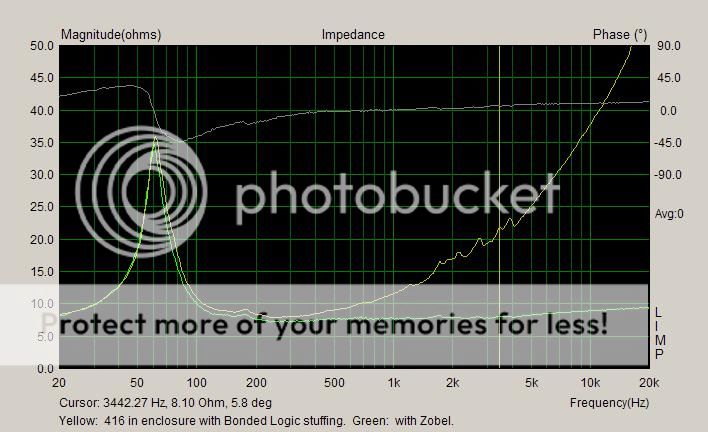

The following graph shows the 416-8B in its enclosure with stuffing, with and without the Zobel network:

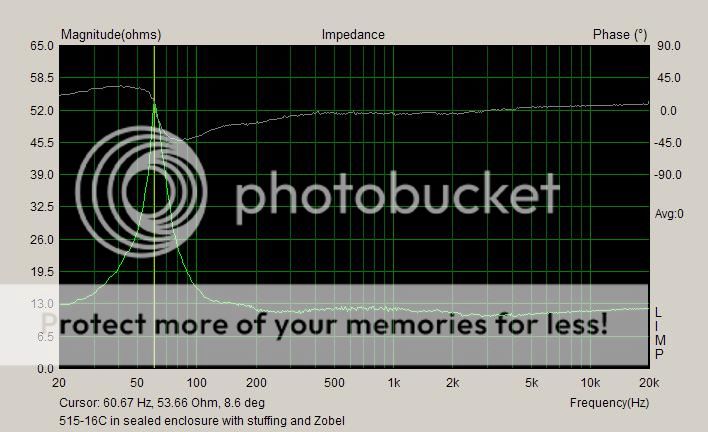

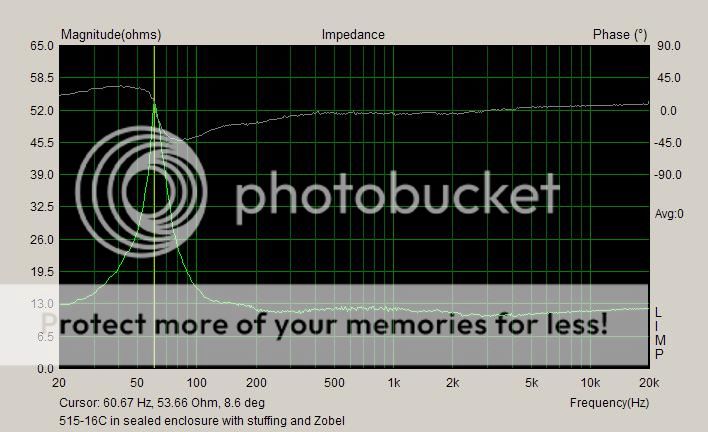

Finally, the 515-16C is shown in its enclosure, with stuffing and Zobel:

Gary Dahl

Below is the free-air impedance curve of the 416-8B. Again, no impedance correction. It looks quite a bit like the curve from the TD15M, until you look at the vertical scale and see that the TD15M's HF rise is just half that of the 416-8B.

Next, the 416-8B is measured in its enclosure. Green trace was made with no stuffing, yellow trace shows the effect of stuffing (Bonded Logic):

The following graph shows the 416-8B in its enclosure with stuffing, with and without the Zobel network:

Finally, the 515-16C is shown in its enclosure, with stuffing and Zobel:

Gary Dahl

It is interesting to compare the TD15M and the GPA 416 side by side.

Both have curvilinear cones, but the TD15M's cone has much more curve and is deeper. The TD15M's voice coil is 2"; the 416's is 3". The TD's cone has a shiny coating on the surface; the 416 is uncoated.

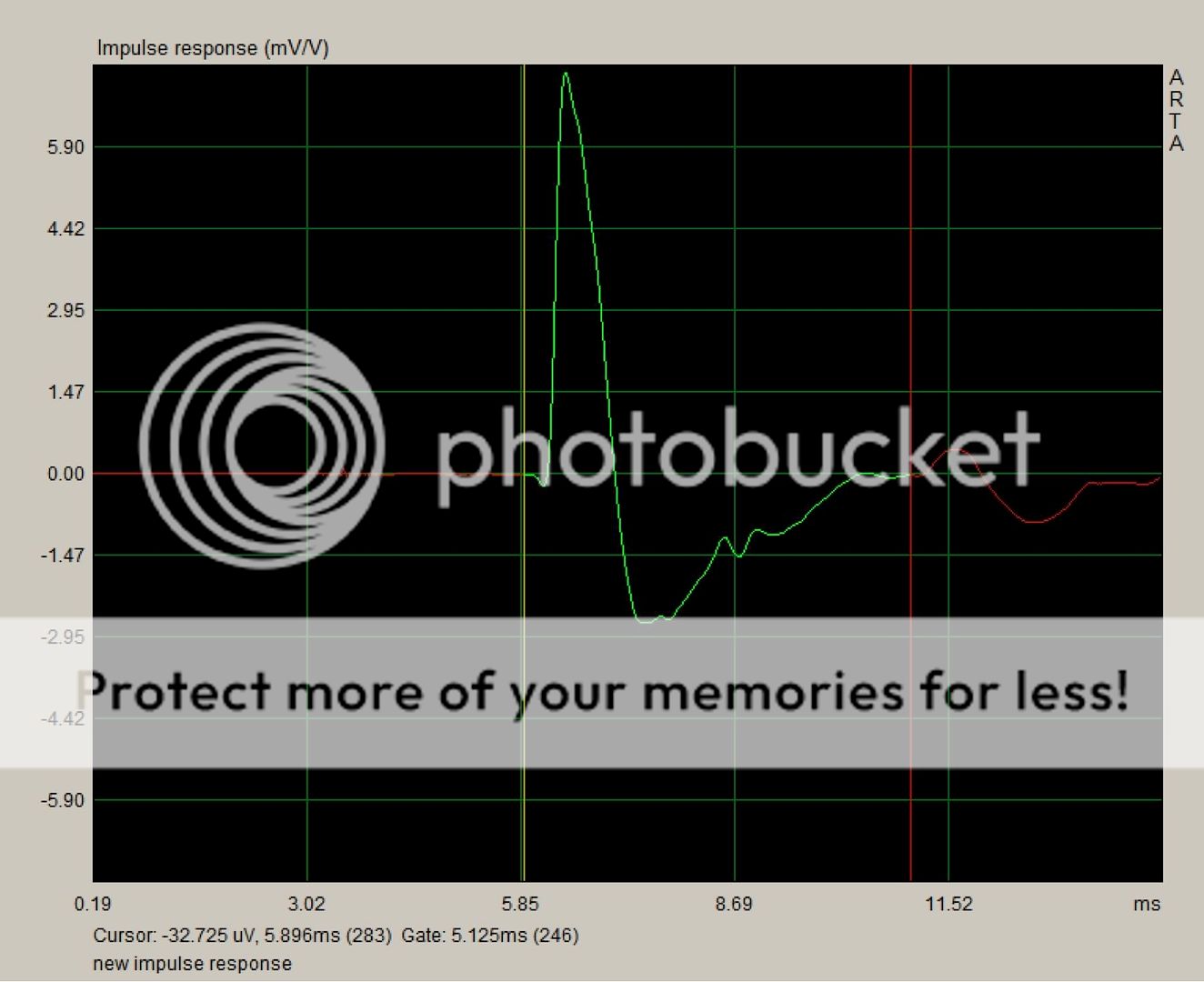

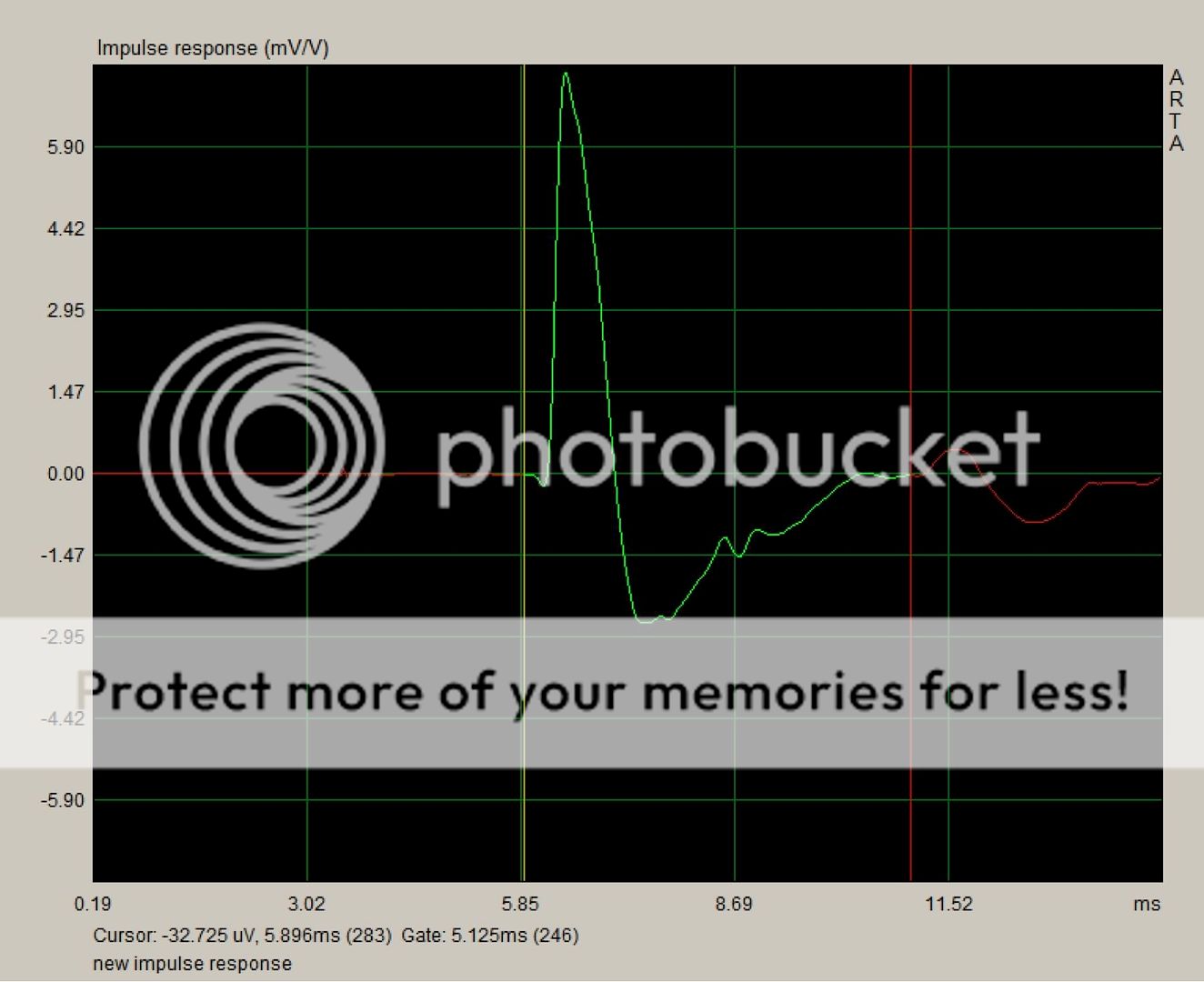

The spiders differ very significantly. The 416's spider is lightweight and soft. With a 5" outer diameter and 3" inner diameter, it provides an inch of material all the way around. The TD15M's spider is thicker and much stiffer. Outer diameter is 6". With just a 2" voice coil, the compliance area is 2" wide all the way around. This provides the necessary support for the high power output levels the TD15M is capable of, but I believe it is responsible for the artifact that I measured in the TD15M's impulse response, shown below. It appears about 2.45 ms, and is visible at around 8.69 ms on the horizontal scale.

Extensive discussion of this artifact took place several hundred pages ago in this thread, and it was also the subject of Dumptruck's thread.

Regardless of the differences between magnet types, I believe that the 416's soft suspension, untreated paper cone and powerful motor combine to make a driver that responds readily to small signals and behaves beautifully at domestic listening levels.

Gary Dahl

Both have curvilinear cones, but the TD15M's cone has much more curve and is deeper. The TD15M's voice coil is 2"; the 416's is 3". The TD's cone has a shiny coating on the surface; the 416 is uncoated.

The spiders differ very significantly. The 416's spider is lightweight and soft. With a 5" outer diameter and 3" inner diameter, it provides an inch of material all the way around. The TD15M's spider is thicker and much stiffer. Outer diameter is 6". With just a 2" voice coil, the compliance area is 2" wide all the way around. This provides the necessary support for the high power output levels the TD15M is capable of, but I believe it is responsible for the artifact that I measured in the TD15M's impulse response, shown below. It appears about 2.45 ms, and is visible at around 8.69 ms on the horizontal scale.

Extensive discussion of this artifact took place several hundred pages ago in this thread, and it was also the subject of Dumptruck's thread.

Regardless of the differences between magnet types, I believe that the 416's soft suspension, untreated paper cone and powerful motor combine to make a driver that responds readily to small signals and behaves beautifully at domestic listening levels.

Gary Dahl

You guys know Neo magnets are also conductive, right? It's about 300x less conductive than Alnico and about 60-90x less conductive than aluminum or copper (typical shorting ring materials), but still vastly more conductive than ceramic magnet.

Electrical resistivity:

Alnico: ~50e-8 ohm*cm

Neo: ~150e-6 ohm*cm

Ceramic: ~1e6 ohm*cm

Aluminum: 2.6e-6 ohm*cm

Copper: 1.7e-6 ohm*cm

http://www.intl-magnetics.org/pdfs/0100-00.pdf

No, the figures are for resistivity, not conductivity. Higher numbers are less conductive.

This is why I am curious. What John Sheerin shows is Alnico being more conductive than aluminum and copper.

e-6 for aluminum and copper, e-8'for Alnico. Or should those be e6 vs e8?

Last edited:

The TD15M seems to have a shorting ring, but the GPA do not. Interesting!

Someone recommended a shorting ring for one of the 3" drivers I use, I think I should investigate it again since it was so many years ago. Did not sound right at the time, but much has changed since.

Someone recommended a shorting ring for one of the 3" drivers I use, I think I should investigate it again since it was so many years ago. Did not sound right at the time, but much has changed since.

Last edited:

You guys know Neo magnets are also conductive, right? It's about 300x less conductive than Alnico and about 60-90x less conductive than aluminum or copper (typical shorting ring materials), but still vastly more conductive than ceramic magnet.

Electrical resistivity:

Alnico: ~50e-8 ohm*cm

Neo: ~150e-6 ohm*cm

Ceramic: ~1e6 ohm*cm

Aluminum: 2.6e-6 ohm*cm

Copper: 1.7e-6 ohm*cm

http://www.intl-magnetics.org/pdfs/0100-00.pdf

Not sure of your source, but every reference I can find places copper elemental @20°C 1.68e−8cm²

and the international metals standard for annealed copper @20°C 1.72e−8cm²

The TD15M seems to have a shorting ring, but the GPA do not. Interesting!

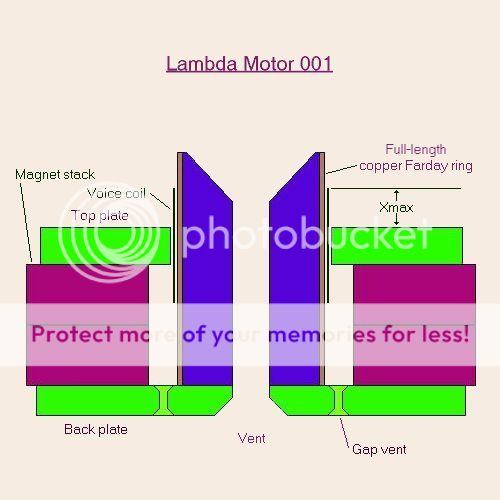

Rather than a shorting ring, the TD15M has a full copper "faraday sleeve" covering the pole piece. A full description of the motor's design features can be found at this link.

From what I understand, alnico drivers don't benefit from shorting rings because the magnet material is already conductive. Does anyone know if the Altec/GPA ceramic-magnet woofers have shorting rings?

Gary Dahl

I think it is about time to investigate deeper into shorting ring aspects. Could be something related with how the change in impedance interacts with the amplifier.

For the GPA416 vs TD15M my first instinct would be cone design differences as the major issue. The TD15M seems really too deep, plus the phase plug design should be creating lots of cross waves that will result in more muffled sound. The GPA should be producing a more coherent wave front.

If Gary is interested in exploring the cone issue, the best place to start is doing measurements starting from as close as you can without the cone hitting the mic, and extend the measurements in about 5cm increments until 1M. MLS driving signal.

For the GPA416 vs TD15M my first instinct would be cone design differences as the major issue. The TD15M seems really too deep, plus the phase plug design should be creating lots of cross waves that will result in more muffled sound. The GPA should be producing a more coherent wave front.

If Gary is interested in exploring the cone issue, the best place to start is doing measurements starting from as close as you can without the cone hitting the mic, and extend the measurements in about 5cm increments until 1M. MLS driving signal.

Last edited:

I would disagree that even an Alnico magnetic motor assembly wouldn't benefit from a

Faraday ring. The eddy currents that you are attempting to minimize are in the steel structure. I will have to look but I do have some printed articles on the application of Faraday rings to loudspeaker motor assemblies if someone is really interested in reading this material.

Faraday ring. The eddy currents that you are attempting to minimize are in the steel structure. I will have to look but I do have some printed articles on the application of Faraday rings to loudspeaker motor assemblies if someone is really interested in reading this material.

soongsc,

I am not sure where I picked up the information anymore but the typical thickness of the Faraday ring or sleeve is 20% of the gap distance to be effective. One of the reasons that many companies use shorting rings instead of a full sleeve within the gap is that it lowers the efficiency of the driver while the shorting rings are not in the gap and do not effect the flux density but are nowhere near as effective. While the shorting rings do cut down on eddy currents they do not flatten the impedance rise as a full Faraday ring in the gap will accomplish.

I am not sure where I picked up the information anymore but the typical thickness of the Faraday ring or sleeve is 20% of the gap distance to be effective. One of the reasons that many companies use shorting rings instead of a full sleeve within the gap is that it lowers the efficiency of the driver while the shorting rings are not in the gap and do not effect the flux density but are nowhere near as effective. While the shorting rings do cut down on eddy currents they do not flatten the impedance rise as a full Faraday ring in the gap will accomplish.

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel