Very interesting!

Did you measure their response curves and T/S?

I measured TS parameters and impedance curves using LIMP and the ARTA MeasuringBox. Results were remarkably consistent across multiple trials, using both added-mass and closed-box methods. Accuracy seemed to be limited mainly by my cheap multimeter. GPA doesn't provide a Re spec for the 16-ohm version of the 515, and my meter doesn't give stable resistance readings in this range. Slight changes in the value entered for Re produce significant variations in the TS parameters, so I would like to solve that issue before posting the data. The woofers performed as predicted in the 3 cu ft sealed enclosure, so I got what I needed.

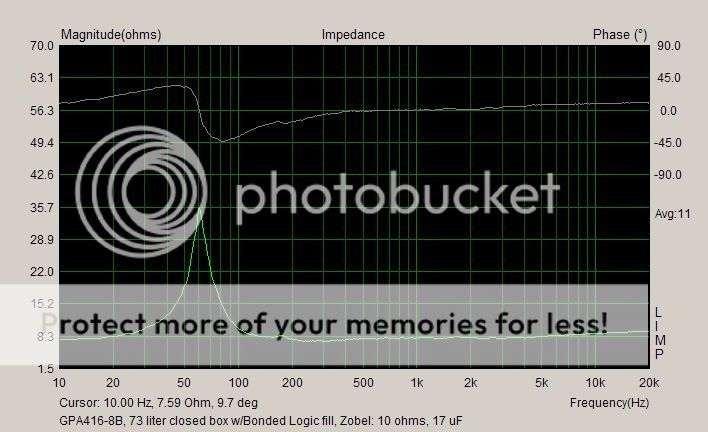

For fun, here's the impedance curve of the 416 in its enclosure, measured with a Zobel network:

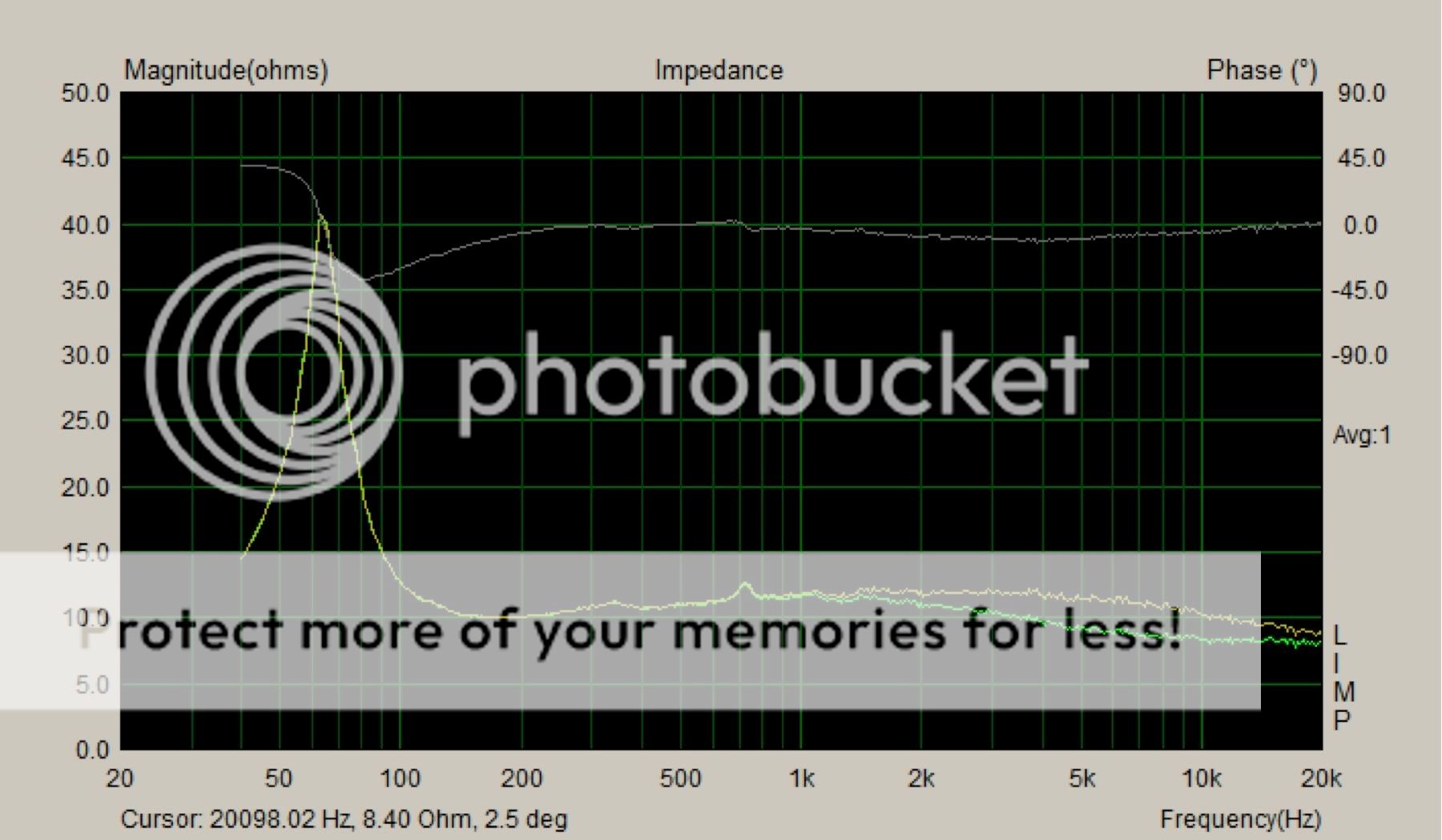

In comparison, here is the TD15M in the same enclosure with its Zobel network. The curves were made with different cap values, 2 uF (yellow) and 3 uF.

Gary Dahl

$360 each, plus freight. The 515C is $550 each.

Gary Dahl

Thanks. That would be around 260€. For an AlNiCo it may not be too bad.

Question for Europeans: If anyone have ordered these drivers, how much was the shipping costs for a driver or two ?

.

Now all we have to do it get you to try some Altec or GPA alnico 1.4" drivers on the horns.

Actually, I started with that. Three years ago, I began with GPA 288-8H drivers (Classic Series alnico) and really wanted to like them. I just couldn't get past the diaphragm breakup issues, which got in the way of realistic reproduction of woodwinds and upper strings. The Radian 745 aluminum/ceramic measured and sounded much better, and you know where I went from there.

What I would really love to see: beryllium diaphragms for the GPA 288…but my wallet is relieved that they don't exist.

Gary Dahl

From the GPA product sheet:

Even though it hasn’t been proven, some have theorized that although the flux density of a ferrite magnet motor is the same as the flux density of an equally charged AlNiCo magnet motor when both motors are at rest, once their voice-coils are charged with voltages from amplifiers, the flux density of the AlNiCo motor is more dynamic than that of the ferrite motor. Compared to the relatively firm flux density of a ferrite magnet or neodymium magnet, the flux density of an equally charged AlNiCo magnet may be decreased just enough by the peak voltages in a voice- coil to cause subtle decreases in the excitation of this voice-coil, which is physically attached to the membrane that produces the audible sound.

Has anyone any technical parameters to explain the phenomena? It sounds like the current in the coil is changing the molecule pattern in the material.

Even though it hasn’t been proven, some have theorized that although the flux density of a ferrite magnet motor is the same as the flux density of an equally charged AlNiCo magnet motor when both motors are at rest, once their voice-coils are charged with voltages from amplifiers, the flux density of the AlNiCo motor is more dynamic than that of the ferrite motor. Compared to the relatively firm flux density of a ferrite magnet or neodymium magnet, the flux density of an equally charged AlNiCo magnet may be decreased just enough by the peak voltages in a voice- coil to cause subtle decreases in the excitation of this voice-coil, which is physically attached to the membrane that produces the audible sound.

Has anyone any technical parameters to explain the phenomena? It sounds like the current in the coil is changing the molecule pattern in the material.

Gary can you tell us how did you change (enlarge) the openings in the face plate of your enclosure? I use the JBL 2235 under a JMLC 350 horn with GPA 388 driver and want to try the 416 woofer.

Chris

I scratched my head for quite awhile on this one. On the plus side, the inside hole was already the right size, so I only needed to enlarge the outer recess for the woofer's flange. The original front panel was made by stacking two layers, the inside panel having a hole for the inner part of the frame, and the outside panel having a hole just big enough for the woofer's flange. The resulting build left the flange almost flush with the outer panel. This whole assembly was in a rectangular recess 1/4" deep, allowing space for the 1/8" grill panel and the velcro to hold it in place.

The process involves filling the original hole with scrap material, and cutting a new circle. If you cut the filler piece to fit precisely in the outer hole, its guide hole can be used when cutting the new recess.

Here's what I did:

1. Cut three pieces of 1" x 4" to fit vertically behind the front panel. I made them a bit shorter than the inside height. One piece was placed at the center, the other two along the left and right sides of the woofer hole. Additional pieces of scrap were made to wedge them in place, spanning the distance between the back wall and the three pieces. These provide support for the next layer.

2. Cut a circular piece to fill the smaller opening (in my case, 14.125". Nail it to the three support pieces with wire brads. The size of this piece isn't critical.

3. Cut another circular piece to fit inside the outer circle. Nail it to the inner circle. This piece must fit precisely, because it provides the center hole for the circle cutting jig.

I built the stack of supporting material thick enough to be even with the area that surrounds the grill recess, so the router would have a flat, stable surface to travel over.

4. Cut the outside diameter of the new circle with a router. The GPA/Altec frames are 16", so I set my jig for 16.125". I made multiple passes, adding 1/4" to the depth each time. Once I had reached the required depth, I set the circle jig to a smaller diameter. The final depth is critical, because it must be the same every time; otherwise the woofer frame won't have a flat mounting surface.

5. Work your way inward until the inside circle is reached. Remove the filling materials carefully, so as not to damage the new mounting surface.

It is important to support the stack of fill material from behind! Cutting the first hole took 5 hours because of all the head scratching. The second one took less than an hour. Hope this helps.

Gary Dahl

Do you use damping materials in that sealed box? And if yes, what kind of materials? Just curious...

Yes, I use Bonded Logic insulation material. It is made from recycled cotton.

Gary Dahl

Found a French distributor of GPA drivers

Great Plains Audio - 4U music

For GPA 416-8B AlNiCo they are charging:

Price: € 466.44 inc VAT (€ 390.00 excluding VAT)

(that's about 630$)

(that's about 630$)

.

Great Plains Audio - 4U music

For GPA 416-8B AlNiCo they are charging:

Price: € 466.44 inc VAT (€ 390.00 excluding VAT)

(that's about 630$)

(that's about 630$).

Elias,

Might want to try ebay; Altec Lansing GPA 416 416 8B Alnico New | eBay

Looks to me directly from Great Plains Audio, ships worldwide.

Might want to try ebay; Altec Lansing GPA 416 416 8B Alnico New | eBay

Looks to me directly from Great Plains Audio, ships worldwide.

…

The new system has what I call tonal weight and density, which makes for superb reproduction of piano. This was a weak area for the Ariel, and a goal I very much agreed with.

These speakers are in the same room with my treasured German-made Wilhelm Steinberg piano. I don't think it's realistic to expect that the two will ever sound exactly the same; their radiation patterns are profoundly different.

But the reproduction of piano is now a strength instead of a weakness. The 416 has made the biggest contribution to this.

…

That's great and promising news, to my view (and sound preferences).

This combination of drivers, horns and enclosures does what I was hoping for. Eventually I will see what more can be done in fine-tuning and refinement in the crossover, but my plan is to leave them alone for awhile so I can become as familiar with the sound as possible, which will make it a lot easier to evaluate the effect of revisions in the future. At this time I will be turning my attention toward my amps and source components.

One exception: Lynn might send me his 745NEO/aluminum drivers to try, because the comparison would certainly be interesting.

Gary Dahl

That's even greater and more promising news. Now I have hope…

From the GPA product sheet:

Even though it hasn’t been proven, some have theorized that although the flux density of a ferrite magnet motor is the same as the flux density of an equally charged AlNiCo magnet motor when both motors are at rest, once their voice-coils are charged with voltages from amplifiers, the flux density of the AlNiCo motor is more dynamic than that of the ferrite motor. Compared to the relatively firm flux density of a ferrite magnet or neodymium magnet, the flux density of an equally charged AlNiCo magnet may be decreased just enough by the peak voltages in a voice- coil to cause subtle decreases in the excitation of this voice-coil, which is physically attached to the membrane that produces the audible sound.

Has anyone any technical parameters to explain the phenomena? It sounds like the current in the coil is changing the molecule pattern in the material.

That is a well known phenomena and has to do with the hysteresis effects in the magnet material. The voice coil creates a magnet field of its own which can add or subtract from the static field. Where the load line is WRT to the magnetic properties curve will determine to what extent this modulation occurs. In alnico there is a third order effect which results from the magnet being conductive (unlike neo and ferrite). Current loops can get setup in the magnet which reduces the flux modulation (like a shorting ring). The amount of these effects for any specific structure can be quite complex. The extent to which any of this is audible is quite an open area.

Thus the question is where this intended area of use exactly is. It's interesting that there such a difference of opinion here. If you ask Geddes he will say using the compression driver BE250 from 800 or 1Khz to 17kHz isn't a problem. Most DIY'ers seems to however to have a different opinion. They also use a supertweeter on top of a 2" TAD, something you don't see with studio/PA speakers using that driver. Are the DIYers pushing the boundaries of perfection, or is there another reason why they prefer an extra driver and cross over?I have over time come to pay less attention to harmonic distortion figures when it comes to loudspeakers. As long as I don't try to use a drive unit outside it's intended area of use, most of them usually have low enough distortion at the levels I use them.

Regarding speaker distortion. A lot of people experience electrostatics as non fatiguing speakers. If it's not related to distortion, what is it? Less reflections due to beaming? But we have that with other speakers too. Or is it lack of diffraction? Or could it be that distortion is actually more important then we think when listening for a longer period of time?

It is the most important thing of all. Once one gets over the buzz of having something technically "more correct", then you have to live with it - unless you immediately dive into the next project, trying to make it "even more correct" ...Regarding speaker distortion. A lot of people experience electrostatics as non fatiguing speakers. If it's not related to distortion, what is it? Less reflections due to beaming? But we have that with other speakers too. Or is it lack of diffraction? Or could it be that distortion is actually more important then we think when listening for a longer period of time?

Distortion is not just speaker, it's the speaker plus amp combination that determines that, at the first level of 'cause' ... unsettling audible artifacts are the difference between an audio system working - and convincing sound reproduction ...

Last edited:

Regarding speaker distortion. A lot of people experience electrostatics as non fatiguing speakers. If it's not related to distortion, what is it? Less reflections due to beaming? But we have that with other speakers too. Or is it lack of diffraction? Or could it be that distortion is actually more important then we think when listening for a longer period of time?

My take is to move as much air as possible with a low mass cone/diaphragm. That's what electostats do but no where near as efficiently as real fully horn loaded high energy conversion, low mass/lots of air movement horn system.

A few things I am wondering about:That is a well known phenomena and has to do with the hysteresis effects in the magnet material. The voice coil creates a magnet field of its own which can add or subtract from the static field. Where the load line is WRT to the magnetic properties curve will determine to what extent this modulation occurs. In alnico there is a third order effect which results from the magnet being conductive (unlike neo and ferrite). Current loops can get setup in the magnet which reduces the flux modulation (like a shorting ring). The amount of these effects for any specific structure can be quite complex. The extent to which any of this is audible is quite an open area.

If this phenomena is due to eddy currents, then wouldn't a shorting ring in a normal magnet produce the same effect? Surely it would show up in Qe, would it not? A quick search did show that Alnico is more conductive than other magnet material by some 3 times.

Is the hysteresis of Alnico larger or smaller than neodymium?

May it also be that the hysteresis effect of force just having a proper match with hoe the cone flexes, which would have a much greater effect in audibility? Certainly it may effect damping.

I am curious that GPA did not publish measurement curves, rather, just some calculation from the TS parameters as shown in the product sheet. Certainly would like to have a look at the impedance curve without the Zobel.

Last edited:

From the GPA product sheet:

Even though it hasn’t been proven, some have theorized that although the flux density of a ferrite magnet motor is the same as the flux density of an equally charged AlNiCo magnet motor when both motors are at rest, once their voice-coils are charged with voltages from amplifiers, the flux density of the AlNiCo motor is more dynamic than that of the ferrite motor. Compared to the relatively firm flux density of a ferrite magnet or neodymium magnet, the flux density of an equally charged AlNiCo magnet may be decreased just enough by the peak voltages in a voice- coil to cause subtle decreases in the excitation of this voice-coil, which is physically attached to the membrane that produces the audible sound.

Has anyone any technical parameters to explain the phenomena? It sounds like the current in the coil is changing the molecule pattern in the material.

Flux modulation of the magnet by the voice coil is a well known form of motor distortion and has been discussed on the forum a number of times before. Look for posts from speaker dave on the topic in other threads.

You actually have it backwards - ferrite (without shorting rings) is by far the worst of all the commonly used speaker magnet materials for flux modulation, and is certainly much worse than Alnico, which is considered to be pretty good. (Sorry I don't have figures in front of me but I have seen them before)

You're confusing permanent loss of flux with temporary flux modulation with the AC signal. Ferrite has little or no permanent loss of flux when overdriven, while Alnico is prone to being demagnetised from being over driven, however this loss of flux is permanent and doesn't come and go in an AC cycle. Eventually an Alnico magnet - if abused, can loose a significant amount of flux such that BL drops considerably from what it was when new.

On the other hand the dynamic flux modulation during an AC cycle is worst with ferrite due to the hysteresis properties of the magnetic material - ferrite does not have a "firm flux density" as you suggest, the set point "bends" quite a lot with the applied AC signal and because of the hysteresis loop it does so in a non linear fashion, thus a linear current waveform is distorted into a non-linear motor drive force to the cone - the distortion differences between a plain (no shorting ring) ferrite motor and an Alnico or neodymium motor are large and easy to measure. (Whether its audible or not is uncertain)

Inherent distortion products on a plain ferrite motor can be as little as 30-35dB down, while the same motor with an Alnico or neodymium magnet could be as much as 45-50dB down, largely due to reduction in flux modulation.

I hadn't realised Alnico was conductive until Earl pointed it out, so I'm not sure how much of the superiority of Alnico for flux modulation is inherent in the magnetic properties of the material, and how much is due to it effectively having a built in shorting ring - but at the end of the day it doesn't really matter.

Neodymium as well as being very strong for the size doesn't suffer from either the flux modulation problems of ferrite, (its one of the best for low flux modulation) nor the permanent loss of flux from overdrive of Alnico (it has no permanent loss for any reasonable working conditions) so if price is no object neodymium is the clear winner.

Flux shorting rings added to ferrite reduce the flux modulation problems considerably for little effort or cost, so most good quality ferrite motors these days should have them. Still not as good as neodymium with its inherently superior magnetic properties, but a worthwhile improvement.

Last edited:

As usual Simon gives a full, clear and precise explanation. I wish that I had as much patience in writing long explanations as he does.

I recently switched magnets in my speakers to Neo for many of the reasons stated, but mass was a big reason as well. I just do not understand the ALNICO craze as Neo is clearly the better choice.

I recently switched magnets in my speakers to Neo for many of the reasons stated, but mass was a big reason as well. I just do not understand the ALNICO craze as Neo is clearly the better choice.

POS,

The only advantage that ceramic magnets have over alnico or neo magnets is price. Why anyone would still insist on alnico is beyond me, I see no special qualities that would make it a choice over neo magnets. I think that most of the alnico desire is just attached to the love of some vintage equipment such as compression drivers but see no reason that these design could not use neo as a substitute in a reproduction of those drivers with improved quality. One advantage of alnico in specific designs may be the grade of neo selected and the curie point of the specific material being to low for the neo and the possibility of demagnetization due to temperature rise. At the same time if I remember correctly alnico is not only subject to flux loss due to the magnetic energy in the voivecoil but also to impact if I remember correctly. Hit an alnico magnet and if I remember correctly they will lose charge. This is one of the reason that very old commercially used alnico compression drivers would need to be re-magnetized to bring them back into original condition.

The only advantage that ceramic magnets have over alnico or neo magnets is price. Why anyone would still insist on alnico is beyond me, I see no special qualities that would make it a choice over neo magnets. I think that most of the alnico desire is just attached to the love of some vintage equipment such as compression drivers but see no reason that these design could not use neo as a substitute in a reproduction of those drivers with improved quality. One advantage of alnico in specific designs may be the grade of neo selected and the curie point of the specific material being to low for the neo and the possibility of demagnetization due to temperature rise. At the same time if I remember correctly alnico is not only subject to flux loss due to the magnetic energy in the voivecoil but also to impact if I remember correctly. Hit an alnico magnet and if I remember correctly they will lose charge. This is one of the reason that very old commercially used alnico compression drivers would need to be re-magnetized to bring them back into original condition.

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel