While waiting for the parts we could read this NwAvGuy: Op Amp Measurements

When done reading the previous then start at this one http://www.sg-acoustics.ch/analogue_audio/ic_opamps/pdf/opamp_distortion.pdf

Copied from the MPP-thread (it needs to go here (I think))

You could glue the smd (using double sided sticking tape) to the middle of a dip socket/header and use some thin (silver?) wire to connect the smd to the pins, while working under a loupe.

Got all the bits for it box and all will have to do that when listening to FiFi is not possible (tely on neighbours in).

TT is already wired for balanced as I had INA LT1028 X5 X2 split passive RIAA

before.

Give me couple of weeks and it shuld be done.

Only scary bit is SMD to DIL part but I duble up on spares and have couple of presents from Analog devices to exercise on.

You could glue the smd (using double sided sticking tape) to the middle of a dip socket/header and use some thin (silver?) wire to connect the smd to the pins, while working under a loupe.

I would like to see yout wire bender Frans

Nice work bksabath

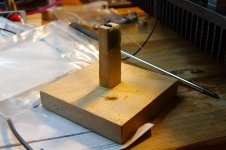

Here it is, the (c) FdW 'Wire bender'

Attachments

Last edited:

Super cool... I will build one ASAP... I am actually working in a "Menuiserie" so I can have easy access to all sorts of wood and corresponding machines.... (I am also considering building a pair of speaker enclosures)

I'm sure that the speakers will be the easy part

Can't see anything wrong

BTW you need a resistor wire bender, I will post a picture of mine later today.

There is one thing wrong, IMO you should first have done the full build of the raw, then the pre- and then the clean power supply, this to be enable you to test each step before connecting the next step. By building the input stage very early you risk (there is not much risk

Yes I know never got around to get one

Still I am pretty made up with the smd welding

Now that I got around to it is pretty easy

Just a bit of solder paste on track and hold chip with crocodile clip

Just touching with wet solder tip does the trick

About SMD. I do like non-SMD, old school through-hole, constructions, and I like them spacy

Quite right

Just bit and pieces out of stock or Postman waiting for house to be empty

I can not wait to see/get a listening report from you

I can not wait to see/get a listening report from you

Right no presssure then

Today I have been making those

Shuld take care of same vibration when mounting PCB

Attachments

Right no presssure then

Today I have been making those

Shuld take care of same vibration when mounting PCB

Nice, I did mount my boards on nylon struts and bolts in the boxes, then the boxes are mounted on separate nylon struts and bolts to a 'floating' sub-frame, floating (not truly) by being flexible. Due to the high mass of the 2mm thick copper box the whole system is mass-dampened.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Balanced input all DC coupled RIAA preamp