Metal-glass seals leak. Nothing is perfect. Hence there is a continuing need for getter action, which may be weak when cold. Gas adsorbed onto metal surfaces is an extra problem. Since there is more surface area of non-getter metal than getter, it seems likely to me that gas leaking in will mostly end up on other metals and then released when the valve gets hot. For good gettering action you want the getter to be the hottest part.

Thanks for your suggestion.the actual procedure is really running the tubes with just the heater supply on and no high voltage B+ for 8-12 hrs. tubes don't ionize as bad as crt's do for some reason, but its ionization is most likely caused by improper storage techniques.

After reading the Morgan Jones doc carefully, Iam though baking tubes is suited only to DHT tubes, due a cathode poison possibility on Oxide Cathode tubes.

Iam starting think on cathode induction heating for oxide cathode tubes and even for DHTs.

An externally hosted image should be here but it was not working when we last tested it.

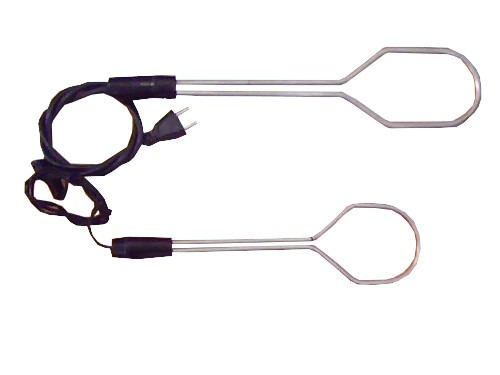

These are very inexpensive heaters intend for water.

ERRATA: I mean say heat the tube getter by induction, not the cathode.If they are intended for water then they might not work too well on small pieces of nickel. Or they might work far too well!

I already test this device in dry conditions and the metal resistor becomes very red instantly.

A better try could be a 220V model linked in a 120 outlet.

I wonder how much time the 6C33/GM70 getter needs to be heated with this device to activate the getter??

Thanks

Really?? I would use it to interfere with the hi SPL boombox from my neighbor's spinster...rs rs rsThe issue with the induction heater is radiated noise. Since it would be used intermittently it might not be an issue, but It would probably cause interference in the HF band.

I will buy a 220V heater and use it in 60V for safe. ThanksImmersion heaters often explode if allowed to run dry. Don't risk that with a mains powered device!

I will buy a 220V heater and use it in 60V for safe. Thanks

I hope you guys are all just jesting around concerning that immersion heater stuff

If there are really people on this forum building amplifiers with B+ in the 100s of volts range and believe that a coiled resistive heater would work as a RF induction heater - then I probably don't want to live on this planet anymore.

Tell me you're just making fun, ok?

Rundmaus

I hope you guys are all just jesting around concerning that immersion heater stuff

If there are really people on this forum building amplifiers with B+ in the 100s of volts range and believe that a coiled resistive heater would work as a RF induction heater - then I probably don't want to live on this planet anymore.

Tell me you're just making fun, ok?

Rundmaus

Not yet April, but it is getting close.

I just think that the whole RF thing, usually in the kHz range, is missing from these water heaters. Which would just make them... Um.... Heaters. Also missing is something about magnetic fields, but oh well, experiments will result in experience.

I'm just sitting back and watching to see what happens.

I like to dip all my tubes in snake oil then let them sit for 3.14159 days before plugging them into a socket.

Hey! Last time you said that your preferred methodology was to take them each to 299 792 457.4 m/s to preserve their characteristics and here I see you changing that this 3.14159 days thing... make up your mind man.

I giveup baking tubes idea after reading the Morgan Jones doc.

I guess you guys prefer expensive Pro heaters from a major fancy brand, if so I would like to see some links suggestions for 6C33/GM70 size tubes (just for comparison purposes).

It must be sized for the getter dimensions, not embrace all the tube to avoid heat the cathode.

The heaters I post sells for so little as 3 to 10 dolars.

Thanks

I guess you guys prefer expensive Pro heaters from a major fancy brand, if so I would like to see some links suggestions for 6C33/GM70 size tubes (just for comparison purposes).

It must be sized for the getter dimensions, not embrace all the tube to avoid heat the cathode.

The heaters I post sells for so little as 3 to 10 dolars.

Thanks

Last edited:

At 3 to 10 dollars it is unlikely to be an inductive heater. There is no point anyway, as a resistive heater is perfectly good for heating water.

I don't understand your remark about 'expensive Pro heaters'. Those on here who bake their valves do them in a domestic oven. Inductive heating is for the initial getter firing which has already been done in the factory.

I don't understand your remark about 'expensive Pro heaters'. Those on here who bake their valves do them in a domestic oven. Inductive heating is for the initial getter firing which has already been done in the factory.

I giveup baking tubes idea after reading the Morgan Jones doc.

I guess you guys prefer expensive Pro heaters from a major fancy brand, if so I would like to see some links suggestions for 6C33/GM70 size tubes (just for comparison purposes).

It must be sized for the getter dimensions, not embrace all the tube to avoid heat the cathode.

The heaters I post sells for so little as 3 to 10 dolars.

Thanks

I am actually beginning to believe that you are serious about this venture.

Well, for that, then this reply is serious.

Those pictures you posted are NOT induction heaters. They are water heaters working at 50 or 60 Hz depending on the country you are in. They are used to heat water. Not much of an inductive field produced even if you step it down to 60 V with a variac or transformer.

Induction heaters produce minimum frequencies in the kHz (kHz = thousands of Hertz) range for their "inductive" heating using a rapidly changing magnetic field. You can read up about this. Even with a suitable coil, capacitors, heavy copper, transformers, components, and a manic departure from all safely concerns, even I won't be dreaming of doing this any time soon.

You mention commercial equipment? The closest I have ever come is my mother in-law's single element induction cooktop for portable table cooking. I wouldn't even do it there (expensive piece of kitchen equipment I would not want to break or replace).

You want to see some links from us? Probably not going to happen. You can do a google search yourself on induction heater and look at the images from other diy people. You can read their successful and unsuccessful stories and their incidents/accidents (like wearing a ring while too close to a heater -- this is near instant heat). I would not recommend any attempt at this because of the crazy high voltage/current/temperature produced. You have been warned.

Nothing with respect to vacuum tubes is perfect (not the perfect envelope, not the perfect material, not the purest of metals) and to spend the time, effort, and money chasing this is a dangerous folly to you and others.

What is so wrong with the tubes that you have in inventory? Be happy with the tubes you have, those are very replaceable.

OK, Iam accepting suggestions on any price heaters, just to see how they are.At 3 to 10 dollars it is unlikely to be an inductive heater. There is no point anyway, as a resistive heater is perfectly good for heating water.

I don't understand your remark about 'expensive Pro heaters'. Those on here who bake their valves do them in a domestic oven. Inductive heating is for the initial getter firing which has already been done in the factory.

Seems my idea was reject for being too inexpensive and dont had a nice looking hardware.

Other idea I would try is a incandecent filament lamp under the tube, it is even more inexpensive than the water boiler, but the heat capability is small.

Thanks for this alert, very useful, I appreciated it.I am actually beginning to believe that you are serious about this venture.

Well, for that, then this reply is serious.

Those pictures you posted are NOT induction heaters. They are water heaters working at 50 or 60 Hz depending on the country you are in. They are used to heat water. Not much of an inductive field produced even if you step it down to 60 V with a variac or transformer.

Induction heaters produce minimum frequencies in the kHz (kHz = thousands of Hertz) range for their "inductive" heating using a rapidly changing magnetic field. You can read up about this. Even with a suitable coil, capacitors, heavy copper, transformers, components, and a manic departure from all safely concerns, even I won't be dreaming of doing this any time soon.

You mention commercial equipment? The closest I have ever come is my mother in-law's single element induction cooktop for portable table cooking. I wouldn't even do it there (expensive piece of kitchen equipment I would not want to break or replace).

You want to see some links from us? Probably not going to happen. You can do a google search yourself on induction heater and look at the images from other diy people. You can read their successful and unsuccessful stories and their incidents/accidents (like wearing a ring while too close to a heater -- this is near instant heat). I would not recommend any attempt at this because of the crazy high voltage/current/temperature produced. You have been warned.

Nothing with respect to vacuum tubes is perfect (not the perfect envelope, not the perfect material, not the purest of metals) and to spend the time, effort, and money chasing this is a dangerous folly to you and others.

What is so wrong with the tubes that you have in inventory? Be happy with the tubes you have, those are very replaceable.

I will avoid these inductive heaters as they seems heat the tube glass too fast.

My tubes are new NOS from 1980s, as never used tubes they need some conditioning or some heat on the getter to clean a possible gass inside.

FullRangeMan, what is used in a tube factory does not put out any HEAT!

It is an RF induction heater, probably in the Kilowatt range. It does usually use a coil, but the coil is big and fat to acommodate the very large RF CURRENT. Not 50/60 Hz. AC mains voltage. Not high voltage AC. Not high voltage DC. Radio Frequency. It's a big big big RF amplifier with a suitable coil to transfer the energy to the load. The load is the metal in the tube.

Think of it as "wireless spot welding". Ok?

_-_-

For indirectly heated tubes, there is nothing you can or should do to them other than run the heaters for say 24 hrs, and bring up the B+ slowly. For DHTs run the heaters for 24 hours and bring up the voltage slowly. Nothing else. Baking the tubes in your oven risks cracking the glass due to stress from temperature differences. Don't do it.

It is an RF induction heater, probably in the Kilowatt range. It does usually use a coil, but the coil is big and fat to acommodate the very large RF CURRENT. Not 50/60 Hz. AC mains voltage. Not high voltage AC. Not high voltage DC. Radio Frequency. It's a big big big RF amplifier with a suitable coil to transfer the energy to the load. The load is the metal in the tube.

Think of it as "wireless spot welding". Ok?

_-_-

For indirectly heated tubes, there is nothing you can or should do to them other than run the heaters for say 24 hrs, and bring up the B+ slowly. For DHTs run the heaters for 24 hours and bring up the voltage slowly. Nothing else. Baking the tubes in your oven risks cracking the glass due to stress from temperature differences. Don't do it.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Baking Tubes Procedure - Help...