Hi dtaylo3

I had the same problem as you. Due to microphonics I found myself flying through the room to save the tweeters of my loudspeakers.

Had fixed the nutube with doublesided tape. I was about to throw the project into the dustbin. Then...

1. I remembered an early mail from N. Pass who had fixed the nutube with hotglue to the pcb. UUHHH - not at all audiophile. I had nothing to loose. I could not remove the doublesided tape but I fixed the nutube with hotglue.

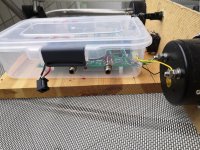

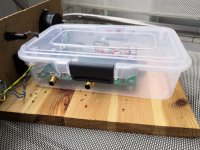

2. In 1-Euro shop I bought a plastic container for food and mounted the nutube inside. No rubber washers, just solid screws into the wooden mounting plate.

The result? I can tab - no I can drum - with my fingers on the plastic container. Nothing happens. No mycrophonics, no tapping sound from the loudspeakers, just music.

And the sound? I have a Khozmo shunt passive attenuator which sounds very clean and precise. With the B1 Nutube the sound transformed into something new and juicy. Never thought this thing would sound that good.

Give it a try!

Hi,

Do you have actual pics of your build (nutube cover)? I'm curious how it looks, as I can't imagine how it looks based on your description alone.

Hi dtaylo3

I had the same problem as you. Due to microphonics I found myself flying through the room to save the tweeters of my loudspeakers.

Had fixed the nutube with doublesided tape. I was about to throw the project into the dustbin. Then...

1. I remembered an early mail from N. Pass who had fixed the nutube with hotglue to the pcb. UUHHH - not at all audiophile. I had nothing to loose. I could not remove the doublesided tape but I fixed the nutube with hotglue.

2. In 1-Euro shop I bought a plastic container for food and mounted the nutube inside. No rubber washers, just solid screws into the wooden mounting plate.

The result? I can tab - no I can drum - with my fingers on the plastic container. Nothing happens. No mycrophonics, no tapping sound from the loudspeakers, just music.

And the sound? I have a Khozmo shunt passive attenuator which sounds very clean and precise. With the B1 Nutube the sound transformed into something new and juicy. Never thought this thing would sound that good.

Give it a try!

How much hotglue did you use on the NuTube? Under it, or did you apply it over and all around? As to the plastic box, can you explain more clearly. The NuTube and PCB is in a plastic box inside the case?

Hi, sorry for the delay.

I applied hotglue just to the long side of the Nutube were there are no connections to the PCB. As I could not remove the double sided tape I just put hot glue at the edge approximately 3 - 5 ml. Just enough to fix the nutube to the PCB.

As some members cited accoustical feedback to the nutube (air gaps in the enclosure were closed etc.) I bought a plastic container for food with a lid. The whole PCB is inside the Box. Made holes for Input/Output and DC. Sealed the holes with hot glue.

The critical measure was to fix the Nutube to the PCB. I can literally drum with my fingers on the container with no feedback at all. No drumming sound from the speakers.

I applied hotglue just to the long side of the Nutube were there are no connections to the PCB. As I could not remove the double sided tape I just put hot glue at the edge approximately 3 - 5 ml. Just enough to fix the nutube to the PCB.

As some members cited accoustical feedback to the nutube (air gaps in the enclosure were closed etc.) I bought a plastic container for food with a lid. The whole PCB is inside the Box. Made holes for Input/Output and DC. Sealed the holes with hot glue.

The critical measure was to fix the Nutube to the PCB. I can literally drum with my fingers on the container with no feedback at all. No drumming sound from the speakers.

My Nutube is dead on one channel. No light any more on this channel. The miniscule wire which runs over the enligthed window (do not know what to call it exactly) is broken. The unit worked for about one to two weeks continuously. I sounded marvellous.

It was not moved. No mechanical shocks. It was just sitting there. For 50 USD a piece it is an expensive experience.

Any help?

It was not moved. No mechanical shocks. It was just sitting there. For 50 USD a piece it is an expensive experience.

Any help?

Hi, sorry for the delay.

I applied hotglue just to the long side of the Nutube were there are no connections to the PCB. As I could not remove the double sided tape I just put hot glue at the edge approximately 3 - 5 ml. Just enough to fix the nutube to the PCB.

As some members cited accoustical feedback to the nutube (air gaps in the enclosure were closed etc.) I bought a plastic container for food with a lid. The whole PCB is inside the Box. Made holes for Input/Output and DC. Sealed the holes with hot glue.

The critical measure was to fix the Nutube to the PCB. I can literally drum with my fingers on the container with no feedback at all. No drumming sound from the speakers.

Thanks for the clarification and photos. Very helpful. I will try the hot glue method first, as it will be easier than de-soldering. My NuTube came with a two very, very thin pads to mount it on, so there is space between the PCB and NuTube on the long, un-soldered side.

My double side tape also has lost its stickiness and after pulling off the eraser I have a thin film of easily removable goop atop the NuTube. So I need to clean the top of the NuTube and try with better doulbe-sided tape.

Hopefully that and the hot glue will help.

Personally, I would not use hot glue on the case of the NuTube. It could possibly be the cause of filament failure (heat stress/expansion on the case causing increased lengthwise strain on the filament). Why add yet another possible failure mode? I suggest using some ordinary adhesive, assuming that the glue does not touch a seam on the szce (again, trying to avoid adding a new failure mechanism.

Yup, those filaments are like hair. Seems that they should be a bit more robust. Common sense. The case is made from glass though, so that is impressive. I don't know what they use for the 'sandwich' though. Another bother are the pins which are also pretty flimsy. I would pay more for an upgraded model from this.

Goes out on Monday.Hi Papa

Can't thank you enough again. Send to Graham Miller. Very nice of you.

Best

Graham

I have used these tubes so many times in various kits. I would say that I have had trouble with less than 1 out of 10. I have made buffer amps, headphone amps and of course the B1K which is my all time favorite. Just sent a custom job using it a few days ago.

Attachments

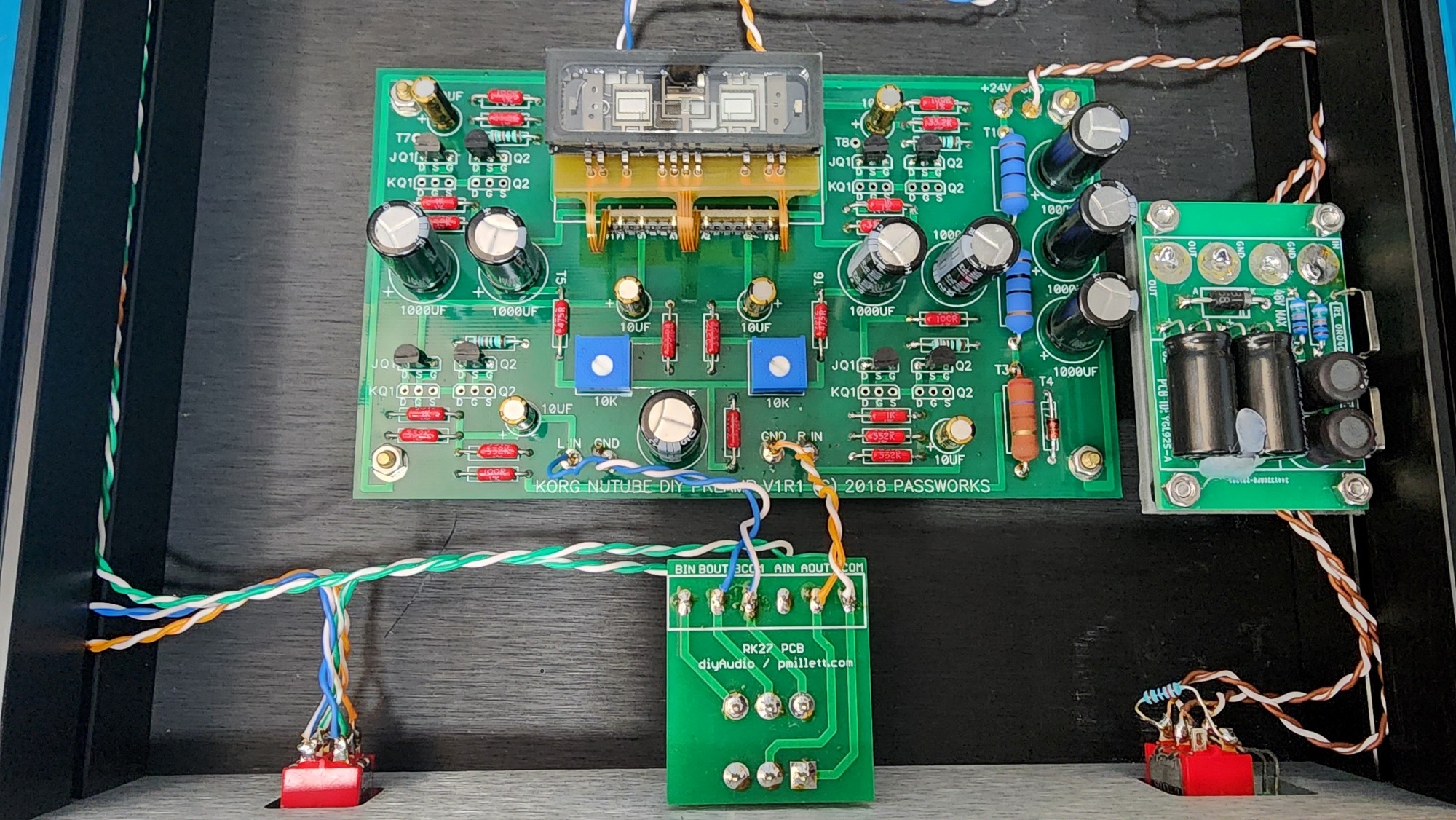

It's been mentioned before I'm sure, and I'll add it again that Pete Millet sells an anti-vibration mount for the Korg. I'm sure you could reach out to him, or use ebay as I did. I've built 3x Korg B1's and as of tonight all three now have the anti-vibration mount and SMPS filter board.

It works well, although you can't use all the foam pieces included in the kit as it will touch the top of the store chassis (learned that one the hard way). I just cut the white foam piece in half to reduce the stacked height and it fits nicely.

I just installed one tonight on my first Krog B1 build (I didn't have the fancy anti-vibration mount on hand for that build), which required me to de-solder (very carefully and patiently) the Nutube from the board, and then reinstall with the anti-vibration kit. I also added the SMPS filter board while the case was open. I 3D printed a beam to hold the SMPS filter board which slides into the rail slot in the side of the Modushop chassis with a little sanding of the beam to ensure a tight fit into the slot (attached as ZIP). I took some photos so I thought I would share what it looks like in a mosaic (see pdf).

(Edited for format/spelling)

It works well, although you can't use all the foam pieces included in the kit as it will touch the top of the store chassis (learned that one the hard way). I just cut the white foam piece in half to reduce the stacked height and it fits nicely.

I just installed one tonight on my first Krog B1 build (I didn't have the fancy anti-vibration mount on hand for that build), which required me to de-solder (very carefully and patiently) the Nutube from the board, and then reinstall with the anti-vibration kit. I also added the SMPS filter board while the case was open. I 3D printed a beam to hold the SMPS filter board which slides into the rail slot in the side of the Modushop chassis with a little sanding of the beam to ensure a tight fit into the slot (attached as ZIP). I took some photos so I thought I would share what it looks like in a mosaic (see pdf).

(Edited for format/spelling)

Attachments

Last edited:

1 out of 10 is a 10% failure rate. Even 1 out of 20 is a 5% failure rate . Assuming 10,000 hour lifetime of the NuTube, this is still, on its face, a not very good performance.

Caution: I am not a statistician or QA/QC expert, but the anecdotal evidence of Ixnay suggests that the NuTube, for whatever reason or set of reasons, does not meet some consumers’ contemporaneous expectations in terms of product life.

Nonetheless, given the sonic performance, one could simply accept that as a necessary cost of achieving that performance.IMO, it would be better if Korg could have adopted a mechanical scheme that would permit the same ease of changeout as a regular audio tube with pins inserted into a socket.

Caution: I am not a statistician or QA/QC expert, but the anecdotal evidence of Ixnay suggests that the NuTube, for whatever reason or set of reasons, does not meet some consumers’ contemporaneous expectations in terms of product life.

Nonetheless, given the sonic performance, one could simply accept that as a necessary cost of achieving that performance.IMO, it would be better if Korg could have adopted a mechanical scheme that would permit the same ease of changeout as a regular audio tube with pins inserted into a socket.

Hi Halauhula

I made a short search about failures of the nutube. I did not check the whole threat but I found at least four reports. Five including mine. In four out of five the heater wire broke on the left side of the Nutube. For the fifths finding the side was not specified. Looking at the high price of 50 USD / piece and the claim of a very long lifetime these results are a shame.

I made a short search about failures of the nutube. I did not check the whole threat but I found at least four reports. Five including mine. In four out of five the heater wire broke on the left side of the Nutube. For the fifths finding the side was not specified. Looking at the high price of 50 USD / piece and the claim of a very long lifetime these results are a shame.

There may be a long life for those NuTube that do not fail. What we may be seeing is that a not-insubstantial proportion of NuTubes have a much shorter lifetime due to filament failure. Why this is manifesting itself is the big Q: is it bad design of the NuTube filament and its internal mounting; bad construction (including poor materials); jostling from shipping or construction; lack of QC testing by Korg; or stress cause by the user/installer, we do not know. This is what professional QA/QC experts are faced with all the time - trying to determine the reason for failure.

Someone could communicate to Korg about this issue, but then again, if Korg gets such information they may get spooked and decide not to offer the NuTube in the future: it can't be a great moneymaker for them. If that happens, people (users) will justifiably get real upset.

Perhaps the way to look at this is to consider the NuTube as an expendable item: like oil or oil filter or brake pads in your car. I just replaced my brake pads and had to have my rotors resurfaced because of malfunctioning (rusted) calipers, for which no fix is available. You just have to consider it as a necessary expense. But, if you get really good longevity out of your (replacement) NuTube, then you can consider that as a lucky thing.

Someone could communicate to Korg about this issue, but then again, if Korg gets such information they may get spooked and decide not to offer the NuTube in the future: it can't be a great moneymaker for them. If that happens, people (users) will justifiably get real upset.

Perhaps the way to look at this is to consider the NuTube as an expendable item: like oil or oil filter or brake pads in your car. I just replaced my brake pads and had to have my rotors resurfaced because of malfunctioning (rusted) calipers, for which no fix is available. You just have to consider it as a necessary expense. But, if you get really good longevity out of your (replacement) NuTube, then you can consider that as a lucky thing.

The Nutube is also used in commercial products. I searched the internet for complaints of broken Nutubes in commercial products but I did not find any. That is not to say that there aren't any. However I think that the diy aspect may be a factor in at least some of the failures reported on this forum.

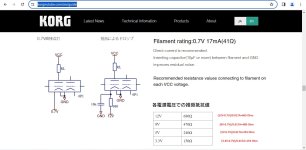

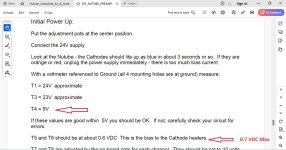

The information published by Korg warned of excess filament voltage, which may destroy the filament. So from a diy construction standpoint it is important to measure the filament voltage. On the B1 Korg, that would be the voltage at T5 and T6. Nelson noted in his DIY Nutube Preamp pdf article that the voltage should be at about 0.6 VDC. Note that Korg specified this to be 0.7V maximum. Anything higher is too high!

Another voltage to be careful of is the voltage at T4. This is set by the 9.1V zener diode in the power supply section. This voltage is the supply for the Nutube filament. Electronic components, including zener diodes, have manufacturing tolerances. With the specified zener diode the tolerance is +/-5%. So the voltage may be somewhere in the range of 8.65V to 9.56V. The high voltage is a concern as that may cause an overvoltage problem at the filament.

So measure T4, T5, and T6. If they measure high, further investigation and changes may be necessary. Potential fixes would be to replace the zener diode if T4 is too high, or change the 475 Ohm filament voltage resistor if T5 and T6 are too high. T4 may be at 9.1V but T5 and T6 may be high if the Nutube draws less than 17mA of current.

Looking at the Korg Nutube website their recommended voltage dropdown resistor for the filament seemed a bit low for 9V. A higher value resistor would be beneficial in keeping the filament voltage within specification. That would be even more critical if the supplied voltage is much higher than 9V and if the Nutube filament draws less than 17mA.

https://www.korgnutube.com/en/guide

The information published by Korg warned of excess filament voltage, which may destroy the filament. So from a diy construction standpoint it is important to measure the filament voltage. On the B1 Korg, that would be the voltage at T5 and T6. Nelson noted in his DIY Nutube Preamp pdf article that the voltage should be at about 0.6 VDC. Note that Korg specified this to be 0.7V maximum. Anything higher is too high!

Another voltage to be careful of is the voltage at T4. This is set by the 9.1V zener diode in the power supply section. This voltage is the supply for the Nutube filament. Electronic components, including zener diodes, have manufacturing tolerances. With the specified zener diode the tolerance is +/-5%. So the voltage may be somewhere in the range of 8.65V to 9.56V. The high voltage is a concern as that may cause an overvoltage problem at the filament.

So measure T4, T5, and T6. If they measure high, further investigation and changes may be necessary. Potential fixes would be to replace the zener diode if T4 is too high, or change the 475 Ohm filament voltage resistor if T5 and T6 are too high. T4 may be at 9.1V but T5 and T6 may be high if the Nutube draws less than 17mA of current.

Looking at the Korg Nutube website their recommended voltage dropdown resistor for the filament seemed a bit low for 9V. A higher value resistor would be beneficial in keeping the filament voltage within specification. That would be even more critical if the supplied voltage is much higher than 9V and if the Nutube filament draws less than 17mA.

https://www.korgnutube.com/en/guide

Attachments

Last edited:

- Home

- Amplifiers

- Pass Labs

- B1 with Korg Triode